Comprehensive Guide to Kioti DK45 Repair Manual

When it comes to ensuring the longevity and optimal performance of your agricultural machinery, understanding the intricacies of upkeep is essential. This section delves into the vital aspects of maintaining and troubleshooting your equipment, enabling you to address common issues effectively. With proper knowledge, you can enhance productivity and minimize downtime in your operations.

Regular maintenance is not merely a suggestion; it is a necessity for any operator looking to sustain their vehicle’s efficiency. By familiarizing yourself with the operational mechanics and components, you can swiftly identify potential problems before they escalate into significant malfunctions. This proactive approach not only saves time but also reduces repair costs in the long run.

Furthermore, having access to detailed instructions on handling various aspects of your machinery can empower you to take charge of its care. From simple adjustments to more complex repairs, understanding the processes involved can significantly boost your confidence and skill level. Emphasizing hands-on experience alongside theoretical knowledge will prepare you to tackle any challenges that arise during your equipment’s lifecycle.

Overview of Kioti DK45 Tractor

This section provides an in-depth look at a versatile agricultural machine designed for various farming tasks. It highlights key features, specifications, and overall performance, helping users understand its capabilities and applications in different environments.

| Feature | Specification |

|---|---|

| Engine Type | 4-Cylinder Diesel |

| Horsepower | 45 HP |

| Transmission | Synchro Shuttle |

| Weight | 3,200 lbs |

| Lift Capacity | 2,200 lbs |

| Fuel Tank Capacity | 6.5 gallons |

This powerful tractor is equipped to handle a variety of implements, making it an ideal choice for both small farms and larger agricultural operations. Its robust design ensures durability, while user-friendly controls enhance overall operation efficiency.

Common Issues Faced by Owners

Many operators encounter a variety of challenges with their agricultural machinery. Understanding these common problems can aid in effective maintenance and ensure optimal performance.

Mechanical Concerns

One of the primary categories of issues relates to mechanical components. These can include:

- Engine starting difficulties

- Transmission malfunctions

- Hydraulic system leaks

- Wear and tear on belts and hoses

Electrical Problems

Another frequent area of concern involves the electrical systems of the equipment. Owners often report:

- Faulty battery connections

- Defective lighting systems

- Issues with electrical wiring and fuses

- Problems with the ignition system

Addressing these issues promptly can prevent further complications and prolong the lifespan of the machinery.

Essential Tools for Repairs

When tackling maintenance tasks on your machinery, having the right set of instruments is crucial for efficiency and effectiveness. Proper tools not only facilitate the process but also ensure safety and precision in every operation. This section highlights the fundamental equipment every operator should consider for successful upkeep.

Wrenches are among the most important items in any toolkit. They come in various sizes and types, allowing for the loosening and tightening of bolts and nuts with ease. A good set of both open-end and socket wrenches can significantly expedite the process.

Screwdrivers are equally vital, with different styles such as flathead and Phillips available for various screws. Having a range of sizes will help tackle multiple tasks without unnecessary delays.

Another key component is a multimeter, which is essential for diagnosing electrical issues. This tool allows you to measure voltage, current, and resistance, helping you to pinpoint problems effectively.

Finally, investing in a quality toolbox to keep everything organized is important. A well-arranged workspace enhances productivity and reduces the risk of losing essential tools.

Equipping yourself with these fundamental instruments will ensure that you are prepared for any challenges that may arise during maintenance activities.

Step-by-Step Maintenance Procedures

Regular upkeep of your machinery is essential to ensure optimal performance and longevity. This section outlines essential procedures that should be performed periodically to maintain functionality and prevent potential issues.

-

Fluid Checks:

- Inspect engine oil levels; top up if necessary.

- Check coolant levels and refill to recommended levels.

- Examine hydraulic fluid for clarity and proper level.

-

Filter Replacement:

- Replace air filters to maintain airflow efficiency.

- Change fuel filters to ensure clean fuel delivery.

- Check and replace hydraulic filters if dirty.

-

Greasing Points:

- Identify and lubricate all grease fittings.

- Ensure moving parts are adequately lubricated to reduce wear.

-

Inspection of Belts and Hoses:

- Examine belts for signs of wear or cracking.

- Check hoses for leaks, fraying, or bulging.

-

Battery Maintenance:

- Inspect battery terminals for corrosion and clean as needed.

- Check battery charge levels and connections.

Following these procedures systematically will help ensure your equipment runs smoothly and efficiently for years to come.

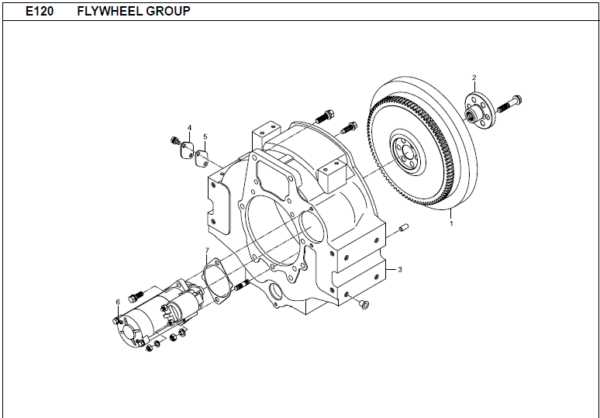

Understanding the Engine Components

Engines are intricate systems composed of various parts that work harmoniously to convert fuel into mechanical energy. Each component plays a critical role in ensuring optimal performance, efficiency, and longevity. A comprehensive grasp of these elements not only aids in troubleshooting but also enhances overall maintenance practices.

Main Components of an Engine

Familiarity with the primary parts of an engine can significantly improve one’s ability to address common issues and carry out effective maintenance. Below is a brief overview of essential engine components:

| Component | Function |

|---|---|

| Block | Houses cylinders and other components; serves as the foundation of the engine. |

| Pistons | Move up and down within cylinders to compress fuel-air mixture and generate power. |

| Cylinder Head | Seals the top of the cylinders; contains valves and spark plugs. |

| Crankshaft | Converts linear motion of pistons into rotational motion to drive the vehicle. |

| Camshaft | Controls the opening and closing of valves for air and fuel intake and exhaust. |

Additional Components

Understanding auxiliary parts is equally important as they contribute to the overall efficiency and functionality of the engine. Here are a few notable components:

| Component | Function |

|---|---|

| Fuel Injector | Delivers precise amounts of fuel into the combustion chamber. |

| Oil Pump | Circulates oil to lubricate moving parts and reduce friction. |

| Thermostat | Regulates engine temperature by controlling coolant flow. |

| Exhaust System | Expels combustion gases from the engine, reducing emissions and noise. |

| Ignition System | Ignites the air-fuel mixture in the combustion chamber for efficient power generation. |

Hydraulic System Troubleshooting Guide

Understanding the complexities of a hydraulic system is essential for maintaining optimal performance and efficiency. This guide aims to assist users in identifying common issues that may arise within hydraulic mechanisms, ensuring that users can effectively diagnose problems and implement suitable solutions. A systematic approach can prevent further complications and prolong the lifespan of the equipment.

One of the first signs of trouble can be inconsistent or reduced hydraulic pressure. If you notice a lack of power in the hydraulic functions, inspect the fluid levels and quality. Low or contaminated fluid can severely affect system performance. Ensure that the reservoir is filled to the appropriate level and that the fluid is free from debris and discoloration.

Another critical area to examine is the presence of leaks. Visible fluid accumulation around hoses, fittings, or cylinders can indicate a breach in the system. Tightening connections or replacing worn-out seals may resolve the issue. Regularly checking for signs of wear and tear will help maintain system integrity.

Furthermore, unusual noises during operation, such as grinding or whining, often suggest mechanical problems. These sounds can stem from worn components or air trapped in the hydraulic lines. Bleeding the system may alleviate this issue, but it’s crucial to assess and replace any damaged parts to prevent future failures.

Finally, ensure that all control valves function smoothly. Sticking or unresponsive valves can disrupt the flow and create inefficiencies. Cleaning or adjusting the valves may restore proper operation. Regular maintenance checks will enhance system reliability and performance, making troubleshooting simpler when issues arise.

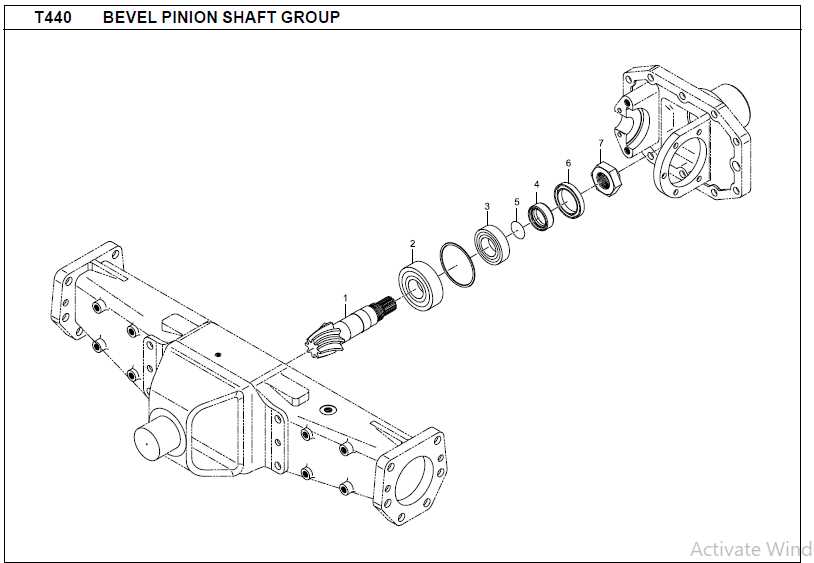

Transmission System Insights

The transmission system serves as a vital component in the machinery, playing a crucial role in the transfer of power from the engine to the wheels. Understanding its mechanics and functionality is essential for optimal performance and longevity of the equipment. This section delves into the intricacies of the transmission, providing valuable insights for users and technicians alike.

Different types of transmission systems operate under varying principles, impacting their efficiency and application. Key elements include the gearbox, clutches, and various control mechanisms that ensure smooth operation under different load conditions.

| Component | Function |

|---|---|

| Gearbox | Adjusts torque and speed, allowing for versatile performance. |

| Clutch | Engages and disengages power flow, enabling smooth shifting. |

| Control System | Monitors and regulates transmission performance and efficiency. |

Regular maintenance and prompt attention to any signs of wear can significantly enhance the durability of the transmission system. Understanding its components and their interactions is key to troubleshooting and ensuring efficient operation.

Electrical System Diagnostics Explained

Diagnosing electrical systems in machinery is crucial for ensuring optimal performance and longevity. This process involves systematically identifying faults and malfunctions within the electrical components. By understanding the various elements of the electrical system, operators can efficiently troubleshoot issues and maintain functionality.

Key Components of Electrical Diagnostics

The main elements involved in diagnosing electrical systems include the battery, wiring harness, switches, and connectors. Each of these components plays a vital role in the overall operation. A thorough examination of the battery’s condition, for example, can reveal underlying problems that may affect the entire electrical network. Additionally, inspecting wiring for wear or damage can prevent larger issues down the line.

Diagnostic Tools and Techniques

Utilizing the right tools is essential for effective diagnosis. Multimeters, for instance, are invaluable for measuring voltage, current, and resistance. Oscilloscopes can provide a visual representation of electrical signals, helping to identify irregularities. Techniques such as visual inspections, continuity tests, and load testing are also important steps in the diagnostic process, allowing for a comprehensive evaluation of the system’s integrity.

Replacing Key Filters and Fluids

Maintaining the performance of your machinery is crucial for its longevity and efficiency. One essential aspect of upkeep involves the regular replacement of filters and fluids. This process not only ensures that the equipment runs smoothly but also prevents potential damage caused by contaminants and degraded substances.

Importance of Regular Maintenance

Routine maintenance helps to:

- Enhance engine performance

- Reduce wear and tear on components

- Improve fuel efficiency

- Extend the lifespan of the equipment

Steps for Replacing Filters and Fluids

- Gather necessary tools and materials:

- New filters

- Appropriate fluids

- Wrenches and screwdrivers

- Container for old fluids

- Consult the equipment’s specifications for exact locations.

- Ensure the equipment is cool before starting.

- Use a container to catch any draining fluids.

- Carefully unscrew old filters and dispose of them properly.

- Install new filters, ensuring a tight seal.

- Follow manufacturer recommendations for fluid types and quantities.

- Run the equipment briefly and inspect for any signs of leakage.

Regularly replacing filters and fluids is a vital part of equipment management. By following these steps, you can help maintain optimal performance and prevent costly repairs in the future.

Safety Tips During Repairs

When undertaking maintenance tasks on machinery, prioritizing safety is crucial. Adhering to proper guidelines ensures not only your well-being but also the longevity of the equipment. Awareness and preparation can prevent accidents and injuries in the workspace.

Here are some essential safety precautions to consider:

| Tip | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and other appropriate personal protective equipment to shield yourself from potential hazards. |

| Ensure Proper Ventilation | Work in well-ventilated areas to avoid inhaling harmful fumes and ensure a safe environment. |

| Disconnect Power Sources | Before beginning any task, ensure that all power sources are turned off and disconnected to prevent accidental activation. |

| Organize Your Workspace | Keep your tools and materials organized to minimize the risk of accidents and enhance efficiency during the process. |

| Read Instructions Thoroughly | Familiarize yourself with guidelines and procedures related to the equipment to ensure you understand all necessary steps. |

By implementing these strategies, you can create a safer working environment and effectively manage maintenance tasks. Stay vigilant and proactive to minimize risks during your activities.

Upgrading Parts for Improved Performance

Enhancing the functionality of machinery can significantly boost its efficiency and longevity. By upgrading certain components, operators can achieve better power output, improved fuel efficiency, and overall enhanced operational capabilities. This section explores various options for part upgrades that can lead to superior performance.

When considering enhancements, it is crucial to focus on key areas:

- Engine Modifications: Upgrading the engine components can lead to increased horsepower and torque. Options include performance air filters, exhaust systems, and fuel injectors.

- Transmission Enhancements: Improving transmission efficiency can provide smoother shifts and better torque delivery. Consider upgrading to a high-performance clutch or transmission cooler.

- Suspension Upgrades: Enhanced suspension systems improve handling and stability. Options like heavy-duty shock absorbers and reinforced springs can make a significant difference.

- Tire and Wheel Improvements: Selecting high-performance tires and lightweight wheels can enhance traction and reduce rolling resistance.

In addition to these areas, it is essential to assess the compatibility of new parts with existing systems to ensure seamless integration and avoid potential issues.

- Research available upgrades thoroughly to understand their benefits and limitations.

- Consult with professionals or experienced operators for insights on the best options.

- Prioritize quality components from reputable manufacturers to ensure durability and reliability.

- Plan the upgrades strategically to minimize downtime and maximize performance gains.

By investing in these enhancements, operators can not only improve performance but also extend the lifespan of their equipment, ultimately leading to a more productive and efficient operation.

Where to Find Replacement Parts

Finding the right components for your agricultural machinery is essential for maintaining optimal performance and longevity. Whether you are in need of a specific part for repair or upgrade, several reliable sources can help you locate what you need.

Authorized Dealers

One of the most reliable sources for components is authorized dealerships. They offer:

- Genuine parts with manufacturer warranties.

- Expert advice on compatibility and installation.

- Access to the latest product releases and updates.

Online Retailers

The internet is a valuable resource for sourcing various parts. Consider these options:

- Specialized agricultural equipment websites.

- Major e-commerce platforms that host multiple sellers.

- Online auction sites for used or hard-to-find components.

Always ensure you check the reviews and ratings of sellers when purchasing online to guarantee quality and reliability.

Resources for Further Assistance

When it comes to maintaining and troubleshooting your machinery, having access to reliable resources can make all the difference. Whether you’re a seasoned operator or a newcomer, finding the right support can enhance your understanding and help you tackle challenges effectively.

One valuable option is to connect with online forums and communities where enthusiasts and experts share their experiences and insights. These platforms often provide practical tips, solutions to common issues, and a space to ask questions. Additionally, video tutorials on popular streaming platforms can visually guide you through complex procedures, making it easier to follow along.

For those seeking official guidance, consider reaching out to authorized dealers or service centers. They often have the latest information and can offer professional advice tailored to your specific equipment. Furthermore, subscription-based services may provide comprehensive databases of troubleshooting techniques and parts availability, ensuring you have all the information at your fingertips.

Lastly, don’t overlook the value of local workshops and training sessions. Participating in these events can deepen your knowledge and give you hands-on experience under the guidance of qualified instructors, ultimately empowering you to handle repairs with confidence.