Comprehensive Guide to Kioti Tractor Repair Manual

In the world of farming and heavy-duty machinery, ensuring optimal performance is crucial for productivity and longevity. Knowledge about maintaining and troubleshooting equipment is essential for operators and owners alike. This section delves into the intricacies of upkeep and offers guidance for effectively managing your equipment.

Having a comprehensive resource at hand can make a significant difference in addressing common issues and performing routine assessments. A thorough understanding of components and systems not only aids in preventing breakdowns but also enhances overall efficiency. This guide will serve as an invaluable reference for those looking to extend the life of their machinery.

Whether you’re dealing with minor adjustments or more complex challenges, familiarizing yourself with the operational aspects is key. By following systematic procedures and recommendations, you can ensure your machinery remains in peak condition, ready to tackle the demands of your tasks.

Understanding Kioti Tractors

This section aims to provide insights into the machinery renowned for their efficiency and versatility in various agricultural and landscaping tasks. With a focus on reliability and user-friendly features, these machines are designed to meet the needs of both professionals and hobbyists alike.

Features and Benefits

The equipment is equipped with advanced technology that enhances performance and ease of use. From powerful engines to ergonomic controls, each component is engineered to improve productivity. Moreover, the range of attachments available allows users to adapt the machinery for a wide array of applications, making it a valuable asset in any outdoor project.

Maintenance and Care

Common Issues with Kioti Tractors

Owners of agricultural machinery often encounter various challenges that can affect performance and efficiency. Understanding these frequent problems is essential for maintaining optimal functionality and ensuring longevity. Below are some typical concerns that may arise with these machines.

1. Hydraulic System Failures: A common issue involves the hydraulic components, which may experience leaks or reduced pressure. These malfunctions can lead to diminished lifting capabilities, impacting overall productivity.

2. Engine Troubles: Users may notice irregularities in engine performance, such as stalling or difficulty starting. These symptoms could be attributed to fuel delivery problems, air filter blockages, or electrical issues that require careful diagnosis.

3. Transmission Problems: Gear shifting difficulties often occur, resulting in a lack of responsiveness. This can stem from low fluid levels, worn-out components, or improper adjustments that need to be addressed promptly.

4. Electrical System Issues: Electrical failures can manifest as blown fuses, malfunctioning lights, or non-responsive controls. Regular checks of the wiring and connections can help prevent these issues from escalating.

5. Tire and Wheel Concerns: Tire wear and improper alignment are also prevalent issues. Regular inspection and maintenance of the wheels can help ensure stability and safety during operation.

Addressing these common challenges through routine maintenance and timely interventions can significantly enhance the performance and reliability of the equipment.

Essential Tools for Tractor Repair

Maintaining and servicing machinery requires a well-equipped toolkit. Having the right instruments not only enhances efficiency but also ensures that tasks are completed safely and effectively. Whether addressing minor adjustments or conducting major overhauls, a comprehensive set of tools is indispensable for any mechanic.

Basic Hand Tools

Starting with the fundamentals, a selection of hand tools is crucial. Wrenches and sockets in various sizes allow for the tightening and loosening of bolts and nuts. Screwdrivers of different types–flathead and Phillips–are necessary for accessing components. Additionally, pliers are invaluable for gripping and manipulating small parts, while a hammer can assist in driving or removing fasteners.

Specialized Equipment

In addition to basic tools, having specialized equipment can significantly streamline work processes. A hydraulic jack is essential for lifting heavy parts safely. A diagnostic scanner helps in identifying issues by reading error codes from the machine’s computer system. Lastly, a good-quality torque wrench ensures that all fastenings are applied to the correct specifications, preventing damage and enhancing performance.

Step-by-Step Repair Guide

This section offers a comprehensive approach to addressing common issues in agricultural machinery. By following a systematic process, you can ensure efficient troubleshooting and effective solutions, prolonging the life of your equipment.

Preparation

- Gather all necessary tools and materials.

- Ensure the workspace is clean and organized.

- Review the safety protocols to avoid accidents.

Identification of Issues

- Perform a visual inspection of the machine.

- Listen for unusual sounds during operation.

- Check fluid levels and look for leaks.

- Utilize diagnostic tools if available to pinpoint the problem.

By adhering to these steps, you will be better equipped to handle maintenance tasks and enhance the performance of your machinery.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires regular care and attention. Implementing a consistent maintenance routine not only enhances performance but also minimizes costly repairs down the line. Here are some essential tips to keep your machinery running smoothly.

- Regular Inspections: Conduct frequent checks on key components such as belts, hoses, and filters to identify wear and tear early.

- Fluid Checks: Maintain optimal fluid levels by regularly checking oil, coolant, and hydraulic fluids. Replace them as recommended by the manufacturer.

- Cleanliness: Keep the exterior and engine compartment clean to prevent debris buildup, which can lead to overheating and other issues.

Additionally, attention to the following areas can further enhance longevity:

- Proper Storage: When not in use, store equipment in a sheltered area to protect it from harsh weather conditions.

- Scheduled Servicing: Adhere to a servicing schedule that includes thorough inspections and necessary replacements to ensure all systems function correctly.

- Usage Practices: Operate machinery according to the guidelines, avoiding excessive loads and abrupt maneuvers that can cause damage.

By integrating these practices into your routine, you can significantly extend the lifespan of your equipment and enhance its overall performance.

When to Seek Professional Help

Understanding the limits of your knowledge and experience is crucial when dealing with complex machinery. While some issues can be resolved with basic troubleshooting and maintenance, others may require the expertise of a trained technician. Recognizing when to consult a professional can save time, money, and prevent further damage.

Signs Indicating Professional Assistance is Needed

Look for symptoms such as persistent performance issues, unusual noises, or error messages that do not resolve with standard procedures. If the equipment shows signs of overheating or leaks, it’s best to seek help. Ignoring these warning signs can lead to more significant problems down the line.

Benefits of Professional Intervention

Hiring an expert not only ensures that the job is done correctly but also brings peace of mind. Professionals have the necessary tools and experience to diagnose issues accurately and can often identify underlying problems that an untrained eye might miss. Investing in professional services can ultimately extend the lifespan of your equipment and enhance its performance.

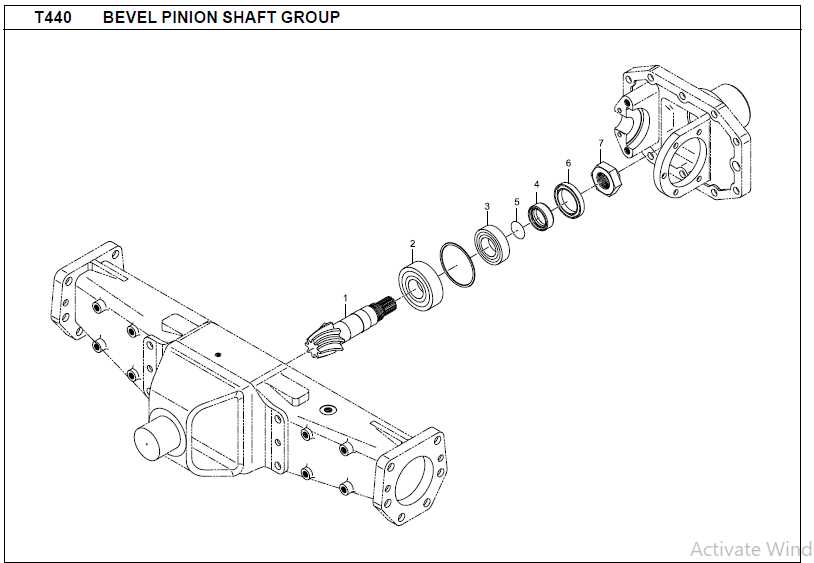

Parts Replacement Process Explained

The procedure for substituting components is essential for maintaining optimal performance and longevity of machinery. Understanding the steps involved can significantly enhance the efficiency of the task and minimize downtime. This section outlines the key phases in the replacement journey, emphasizing the importance of preparation and precision.

Initially, it is crucial to identify the specific component that requires substitution. Conducting a thorough assessment ensures that the right part is selected, preventing unnecessary delays or complications. Once the part is identified, gathering the necessary tools and safety equipment is the next step. Proper preparation sets the foundation for a smooth replacement process.

Next, removing the faulty component involves carefully following the prescribed sequence to avoid damaging surrounding parts. Documenting each step can be beneficial, especially for those new to this process. Once the old part is removed, the new component should be inspected for any defects before installation. This ensures that the replacement is reliable and meets the required standards.

Finally, the new component must be installed with precision, ensuring that all connections are secure and properly aligned. After installation, conducting a thorough check to confirm that everything functions as intended is essential. This comprehensive approach not only facilitates successful component substitution but also enhances the overall reliability of the equipment.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, it is crucial to prioritize safety to prevent accidents and ensure a secure working environment. Proper precautions can significantly reduce the risk of injury and equipment damage, allowing for a more efficient and effective service process.

Essential Safety Measures

Before starting any maintenance work, make sure to implement the following essential safety measures:

| Safety Measure | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate PPE such as gloves, safety goggles, and steel-toed boots to protect against hazards. |

| Workspace Organization | Keep the work area tidy and free from clutter to prevent tripping and ensure easy access to tools and equipment. |

| Proper Tool Usage | Utilize the right tools for the job and ensure they are in good condition to avoid accidents and ineffective work. |

| Machine Stabilization | Ensure that the machinery is properly stabilized and secured before starting any work to prevent unintended movement. |

| Emergency Preparedness | Be aware of emergency procedures and have a first aid kit readily available in case of accidents. |

Awareness and Training

Continuous education and training are vital for anyone involved in equipment maintenance. Staying informed about potential risks and the proper handling of tools can further enhance safety during any service activity.

Resources for Kioti Owners

Owning a piece of heavy machinery comes with its own set of challenges and responsibilities. Access to the right tools and information can significantly enhance the ownership experience, ensuring optimal performance and longevity. Various resources are available to help operators maintain their equipment effectively and efficiently.

Online Communities and Forums

Engaging with fellow enthusiasts through online platforms can provide invaluable insights and support. Many websites host forums where owners can share experiences, troubleshoot issues, and exchange tips. Participating in these communities fosters a sense of camaraderie and offers practical advice from those with similar interests.

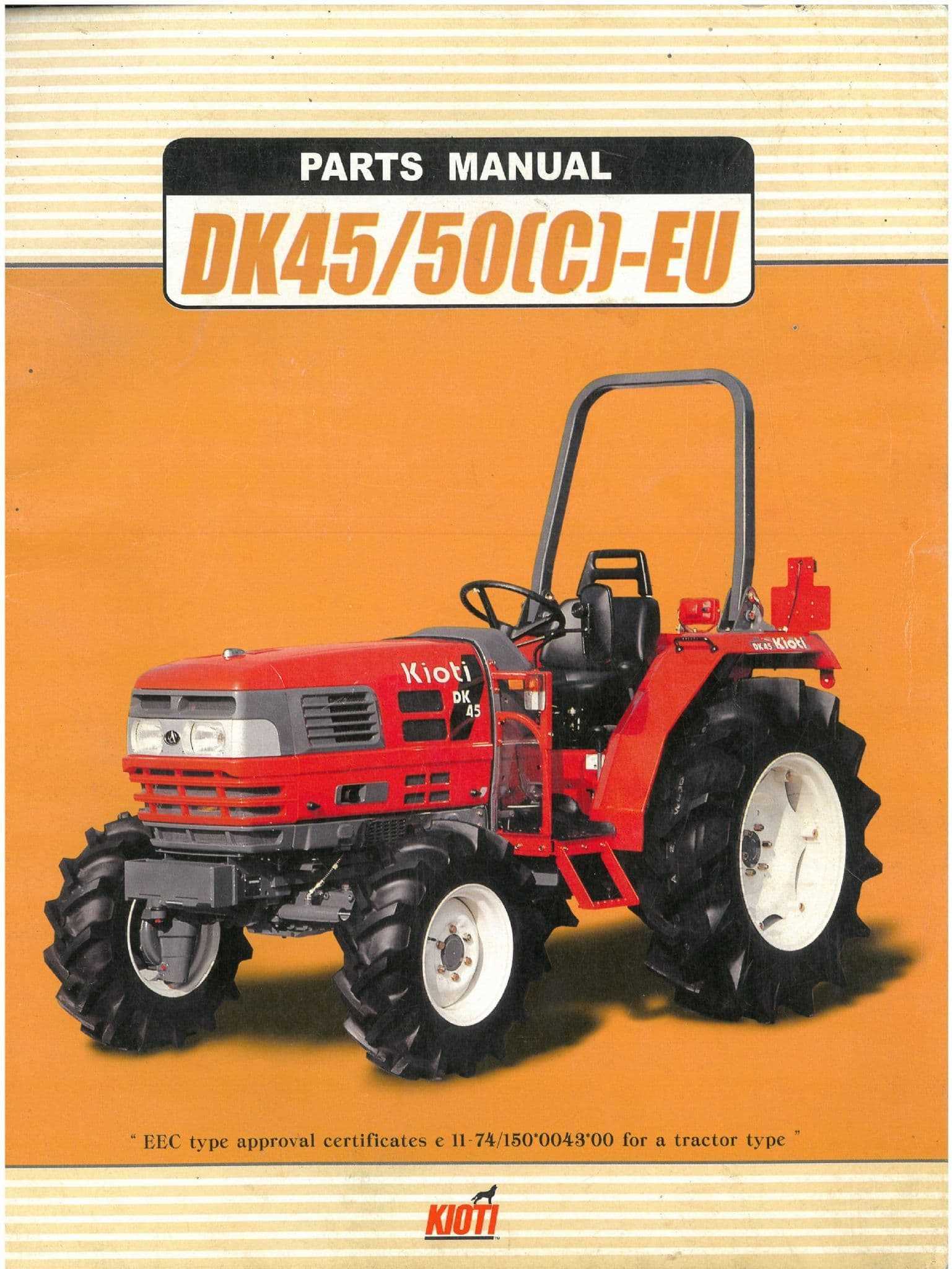

Official Support and Documentation

Manufacturers often provide a wealth of information through official channels. This may include technical documents, maintenance guides, and customer service contacts. Utilizing these resources ensures that owners have access to reliable and accurate information tailored to their specific equipment, enhancing overall operational knowledge.