Guide to Repairing Klaxon Horns

In the realm of automotive maintenance, ensuring the proper functionality of sound signaling devices is essential for both safety and communication on the road. These essential components serve as crucial tools for alerting others and enhancing visibility during travel. Understanding their workings and potential issues can lead to more effective management and longevity of these devices.

Throughout this section, we will explore various techniques and approaches to revitalizing these auditory signaling systems. From diagnosing common problems to implementing effective solutions, this guide aims to equip you with the knowledge necessary to tackle any challenges that may arise.

By gaining insight into the inner workings and troubleshooting methods, you will be empowered to take on the task of restoring these important elements of your vehicle. Whether you are a seasoned enthusiast or a newcomer to automotive care, this resource will provide valuable guidance for maintaining optimal performance.

Understanding Klaxon Horn Functionality

This section explores the operational principles and characteristics of sound-emitting devices commonly found in vehicles. These units serve as critical components in alerting others to the presence of the vehicle, enhancing safety and communication on the road.

Mechanism of Sound Production

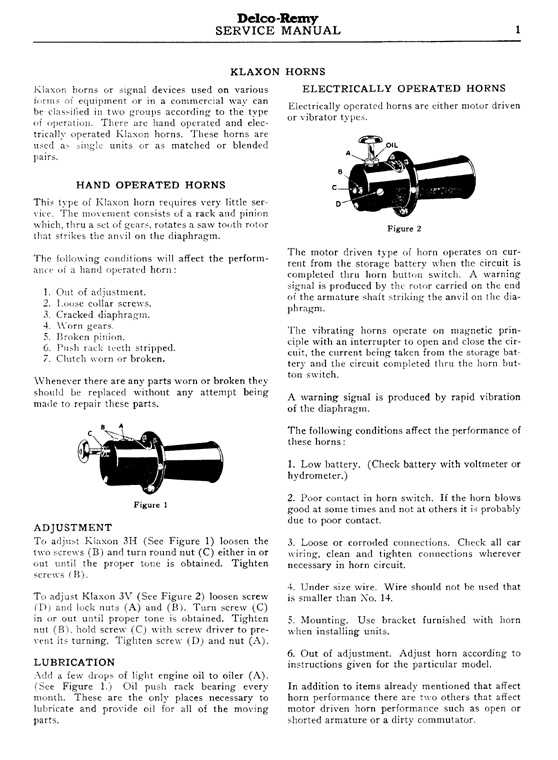

The core function of these devices relies on an electromagnet that creates a magnetic field, enabling a diaphragm to vibrate. This vibration generates sound waves that produce the characteristic tone. The intensity and frequency of the sound can be influenced by the design of the diaphragm and the power supplied to the unit.

Importance in Vehicle Safety

Common Issues with Klaxon Horns

When dealing with sound-emitting devices, users often encounter a range of problems that can affect performance and functionality. Understanding these common challenges can aid in diagnosing issues and implementing effective solutions.

Electrical Problems

One prevalent issue stems from electrical connections. Corroded terminals, loose wires, or faulty relays can disrupt the flow of electricity, resulting in inadequate sound production or complete silence. Regular inspection and maintenance of connections are essential to ensure optimal operation.

Mechanical Failures

Another area of concern involves mechanical components. Wear and tear over time can lead to malfunctions in the internal mechanisms responsible for generating sound. Factors such as exposure to moisture, dirt accumulation, or physical damage may contribute to these failures. Addressing these mechanical aspects promptly can restore functionality.

Tools Needed for Repairs

To effectively restore and maintain your device, a variety of instruments will be essential. These tools facilitate both disassembly and reassembly, ensuring that every component is addressed properly. Gathering the right equipment before starting your project will streamline the process and enhance the quality of your work.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For removing screws from the casing and components. |

| Multimeter | To check electrical connections and troubleshoot issues. |

| Wrench Set | For loosening or tightening bolts and nuts. |

| Wire Cutters | To trim or strip wires as needed during the process. |

| Heat Gun | For softening adhesives or heat-shrink tubing. |

| Safety Goggles | To protect your eyes while working with tools and components. |

Step-by-Step Repair Process

This section outlines a systematic approach to restoring a sound-emitting device that may not be functioning properly. Following these steps can help identify issues and ensure effective solutions are applied to bring the device back to operational status.

Preparation and Inspection

Begin by gathering necessary tools such as a multimeter, screwdrivers, and cleaning materials. Carefully examine the unit for any visible signs of damage, corrosion, or loose connections. This initial assessment will help pinpoint the source of the malfunction.

Disassembly and Cleaning

Once the device has been inspected, proceed to disassemble it by removing screws and carefully separating components. Take note of how parts are arranged for easier reassembly later. Clean all parts with appropriate solutions to remove dirt or corrosion that may interfere with performance.

Testing Your Klaxon Horn

Ensuring the functionality of your signaling device is essential for safety and effective communication. Regular assessments can help identify any issues that may affect performance, enabling timely interventions.

Follow the steps below to evaluate the effectiveness of your signaling device:

| Step | Action | Notes |

|---|---|---|

| 1 | Inspect connections | Ensure all wires are securely attached and free from corrosion. |

| 2 | Test power supply | Use a multimeter to verify voltage at the terminals. |

| 3 | Activate the device | Engage the switch to check for sound output. |

| 4 | Listen for clarity | Ensure the sound is loud and distinct without distortion. |

| 5 | Check for unusual noises | Listen for any rattling or buzzing that may indicate issues. |

By following these steps, you can maintain optimal performance and address any potential problems promptly.

Electrical Connections Explained

Understanding the intricacies of electrical links is essential for effective troubleshooting and maintenance. This section delves into the fundamental aspects of wiring systems, highlighting key components and their roles in ensuring optimal functionality.

Proper connectivity is vital for reliable operation. Various types of connections can impact performance, and recognizing their specific characteristics can aid in diagnosing issues. Below is a summary of common connection types and their respective functions:

| Connection Type | Description |

|---|---|

| Soldered | A permanent and strong bond created by melting solder to join wires, ensuring low resistance. |

| Crimped | A method that involves deforming a connector to create a secure attachment, ideal for quick assembly. |

| Twisted Pair | Two insulated wires twisted together, often used to reduce electromagnetic interference. |

| Plug-and-Socket | A detachable connection allowing for easy assembly and disassembly, commonly used in modular setups. |

Familiarity with these connections enhances one’s ability to address electrical concerns efficiently. Proper handling and maintenance of these links contribut

Preventive Maintenance Tips

Regular upkeep is essential for ensuring optimal performance and longevity of your sound-emitting device. By following a few simple practices, you can help prevent issues and extend the lifespan of your equipment.

Routine Inspections

Conducting periodic checks can help identify potential problems before they escalate. Look for signs of wear and tear, such as frayed wires or loose connections. Keeping components clean and free from debris also contributes to efficient operation.

Storage and Environmental Considerations

Proper storage is crucial in maintaining functionality. Ensure that the device is kept in a dry and cool environment, away from extreme temperatures and humidity. Additionally, protect it from exposure to harsh chemicals and contaminants.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Monthly | Check for physical damage and wear. |

| Clean Connections | Every 3 months | Ensure contacts are free from corrosion. |

| Test Functionality | Every 6 months | Confirm all functions operate as expected. |

| Inspect Cables | Annually | Replace any damaged or frayed cables. |

Choosing Replacement Parts Wisely

Selecting the right components for your device is crucial for ensuring optimal performance and longevity. It is essential to consider various factors when sourcing alternatives to guarantee compatibility and efficiency.

Quality and specifications should always be at the forefront of your decision-making process. Understanding the requirements of your system will help you make informed choices that enhance functionality.

| Factor | Considerations |

|---|---|

| Material Quality | Opt for high-grade materials to ensure durability and reliability. |

| Compatibility | Verify that the parts fit seamlessly within your existing framework. |

| Performance Ratings | Choose components with proven performance to maximize efficiency. |

| Manufacturer Reputation | Research suppliers to ensure they are well-regarded in the industry. |

By carefully evaluating these elements, you can significantly enhance the effectiveness and lifespan of your equipment. Making informed choices will lead to better results and reduce the likelihood of future issues.

Safety Precautions During Repair

Ensuring a secure environment while addressing mechanical issues is paramount. Adopting specific guidelines helps prevent accidents and promotes efficiency. Understanding potential hazards and implementing protective measures can significantly enhance safety for all involved in the process.

General Guidelines

Before beginning any maintenance tasks, it is crucial to evaluate the workspace. Keep the area clean and organized to minimize risks. Use appropriate tools and equipment designed for the specific job. Additionally, wear suitable protective gear, such as gloves and goggles, to shield against injuries.

Electrical Safety

When handling devices involving electrical components, taking precautions is vital. Disconnect the power source before starting any work. Verify that all tools are insulated to prevent electrical shocks. If unfamiliar with electrical systems, seek assistance from a knowledgeable individual.

| Safety Measure | Description |

|---|---|

| Clean Workspace | Keep the area tidy to avoid tripping and other hazards. |

| Protective Gear | Use gloves and goggles to prevent injuries. |

| Power Disconnection | Always unplug devices before beginning work. |

| Tool Inspection | Check that tools are in good condition and suitable for the task. |

Resources for Further Learning

Expanding your knowledge on maintenance and restoration can greatly enhance your skills and understanding. Numerous resources are available to guide enthusiasts and professionals alike in their journey to mastering these techniques.

- Books: Look for titles focused on automotive systems, sound devices, and electronic components. These texts often provide in-depth insights and troubleshooting methods.

- Online Forums: Join communities dedicated to enthusiasts where you can share experiences, ask questions, and receive valuable tips from seasoned practitioners.

- Video Tutorials: Platforms like YouTube offer a plethora of instructional videos demonstrating various techniques and common issues encountered during maintenance.

- Workshops and Courses: Consider enrolling in local classes or online courses that cover relevant topics, allowing for hands-on experience and expert guidance.

- Technical Manuals: Seek out detailed guides that focus on electronic components and devices, as they often contain schematics and repair procedures.

Utilizing these resources can significantly enhance your abilities and confidence in handling similar devices effectively.