Essential Guide to Komatsu Forklift Repair Manual

Understanding the intricacies of machinery upkeep is vital for ensuring optimal performance and longevity. This section delves into the fundamental aspects of servicing and troubleshooting various industrial lifting devices. With a focus on practical knowledge, it aims to equip operators and technicians with the necessary tools to address common issues and enhance operational efficiency.

Effective maintenance practices not only extend the life of equipment but also promote safety in the workplace. By following systematic procedures, users can identify potential problems before they escalate, reducing downtime and repair costs. This comprehensive resource offers insights into standard practices, essential tools, and troubleshooting techniques tailored for a range of lifting machinery.

Through careful attention to detail and adherence to guidelines, operators can foster a proactive approach to maintenance. This not only benefits individual users but also contributes to the overall productivity of the work environment. Emphasizing the importance of routine checks and systematic approaches, this guide serves as a valuable asset for anyone involved in the operation and care of heavy lifting apparatus.

Understanding Komatsu Forklift Basics

This section delves into the fundamental aspects of industrial lifting equipment, essential for efficient warehouse operations. Recognizing the key components and functions of this machinery is crucial for enhancing productivity and ensuring safety in the workplace.

Types of Equipment: Various models exist, each tailored for specific tasks. Familiarizing oneself with these options aids in selecting the right machine for the job, whether it involves heavy lifting or navigating tight spaces.

Core Components: Understanding the primary elements, such as the power source, mast, and load handling attachments, is vital. Each part plays a significant role in the overall functionality, impacting performance and reliability.

Operational Principles: Mastering the basic operating principles is necessary for effective use. Knowledge of how to control the equipment safely and efficiently can significantly reduce the risk of accidents and damage to goods.

Maintenance Insights: Regular upkeep is imperative for longevity. Being aware of common maintenance tasks can help operators keep the machinery in optimal condition, ensuring it operates smoothly and reduces downtime.

Overall, grasping the essentials of this type of industrial equipment not only boosts operational efficiency but also fosters a safer working environment.

Common Issues with Komatsu Forklifts

In the realm of industrial machinery, certain challenges frequently arise that can hinder performance and productivity. Understanding these common complications is essential for ensuring efficient operation and longevity of equipment. This section delves into typical problems encountered with these robust machines, highlighting their impact and potential solutions.

Hydraulic System Failures: One prevalent issue involves the hydraulic components, which can suffer from leaks or decreased pressure. This may result in reduced lifting capacity or sluggish movements. Regular inspections and timely fluid replacement can mitigate these risks.

Electrical System Malfunctions: Electrical components can often present challenges, such as blown fuses or faulty wiring. These problems can lead to unexpected shutdowns or erratic behavior. Ensuring proper connections and routine electrical checks can help maintain reliability.

Engine Performance Issues: Engine-related complications, such as overheating or stalling, can significantly affect operational efficiency. Regular maintenance, including oil changes and filter replacements, is crucial to prevent these issues from arising.

Tire Wear and Damage: Tires endure substantial stress and can wear down over time, leading to poor traction and stability. Regularly inspecting tire condition and maintaining proper inflation can enhance safety and performance.

Transmission Problems: Transmission failures can cause difficulties in gear shifting, impacting maneuverability. Regular servicing and adherence to manufacturer guidelines can help identify early signs of trouble.

By proactively addressing these typical concerns, operators can enhance the overall performance and lifespan of their equipment, ensuring smooth and efficient operations in demanding environments.

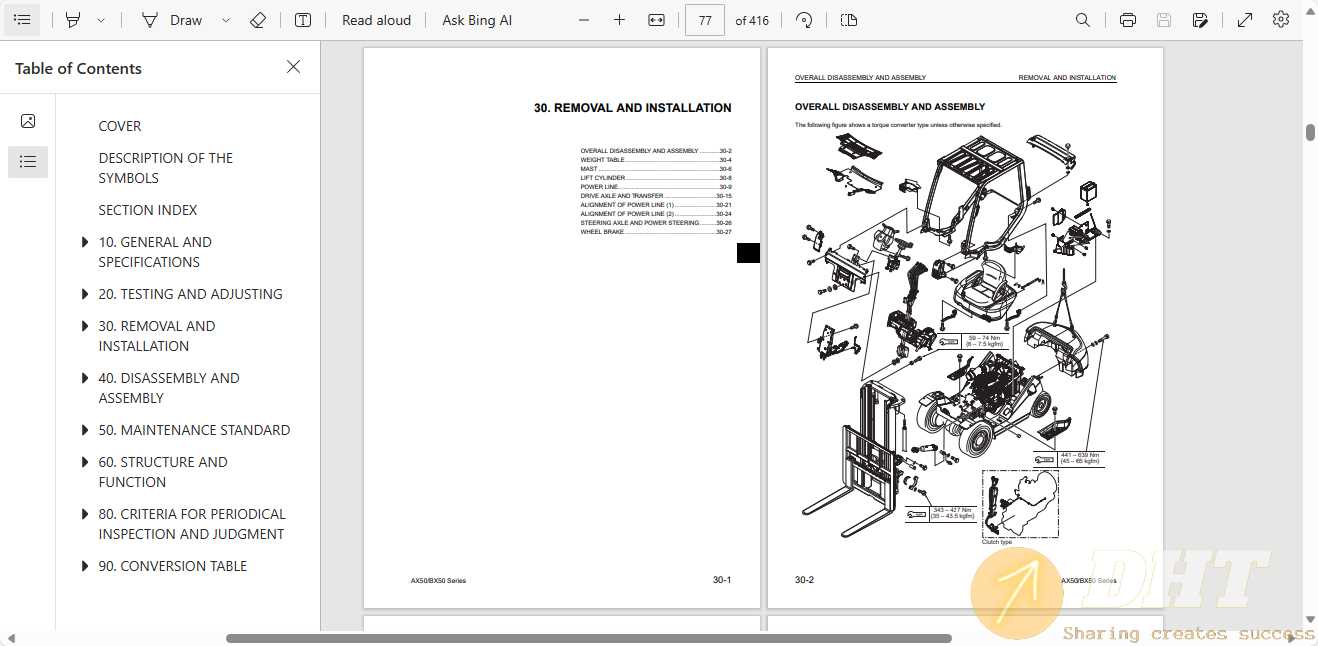

Step-by-Step Repair Procedures

This section provides a comprehensive guide to executing maintenance tasks efficiently and effectively. Following systematic methods ensures that each procedure is completed accurately, minimizing downtime and enhancing operational reliability.

Below is a structured approach to tackling common maintenance activities. Each step is outlined to facilitate understanding and implementation.

| Step | Description |

|---|---|

| 1 | Gather necessary tools and equipment. Ensure everything is in good condition and easily accessible. |

| 2 | Disconnect power sources to ensure safety during the process. |

| 3 | Inspect the component for signs of wear or damage. Document any issues found. |

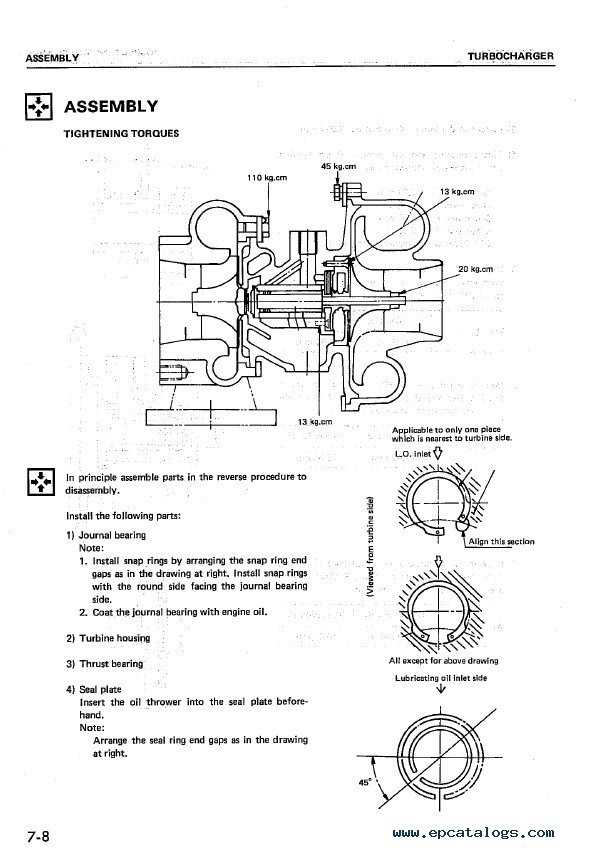

| 4 | Remove the faulty component following proper disassembly procedures. |

| 5 | Install the new or refurbished part, ensuring all connections are secure and aligned. |

| 6 | Reconnect power sources and perform initial tests to confirm functionality. |

| 7 | Conduct a final inspection and ensure that all tools are removed from the work area. |

Adhering to these steps can help in achieving successful maintenance, extending the life of the equipment, and ensuring safety in operation.

Essential Tools for Forklift Maintenance

Proper upkeep of heavy lifting equipment requires a selection of specific instruments that ensure optimal performance and safety. Having the right tools on hand not only streamlines the process of maintenance but also helps in identifying potential issues before they escalate. This section outlines the must-have tools that are essential for effective servicing.

1. Wrenches and Sockets

These tools are fundamental for tightening and loosening various bolts and nuts. A comprehensive set should include both metric and imperial sizes to accommodate different components.

2. Screwdrivers

Both flathead and Phillips head screwdrivers are vital for accessing electronic panels and securing covers. A magnetic screwdriver can also be beneficial for retrieving dropped fasteners.

3. Multimeter

This device is crucial for diagnosing electrical issues. It allows the technician to measure voltage, current, and resistance, providing insight into the health of electrical systems.

4. Hydraulic Jack

For lifting heavy parts, a hydraulic jack is indispensable. It enables easy access to the undercarriage and other hard-to-reach areas, facilitating thorough inspections.

5. Torque Wrench

To ensure that bolts are tightened to the manufacturer’s specifications, a torque wrench is essential. This tool helps prevent over-tightening, which can lead to component failure.

6. Cleaning Supplies

Regular cleaning of components is important for maintaining efficiency. A good set of brushes, rags, and degreasers should be included in any maintenance kit.

7. Safety Gear

Personal protective equipment, including gloves, goggles, and steel-toed boots, is crucial for the safety of the technician during maintenance tasks.

Equipping a service area with these essential tools not only enhances the efficiency of maintenance tasks but also promotes a safer working environment. Regular inspections and timely servicing can prolong the lifespan of the machinery and ensure that it operates smoothly.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance work is crucial to preventing accidents and injuries. Proper measures and guidelines must be adhered to in order to protect both personnel and equipment. This section highlights essential safety practices to follow during any maintenance activities.

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear such as gloves, safety glasses, and hard hats to safeguard against potential hazards. |

| Work Area Organization | Maintain a clean and organized workspace to reduce the risk of slips, trips, and falls. |

| Proper Tool Usage | Utilize the correct tools for specific tasks and ensure they are in good condition to avoid accidents. |

| Electrical Safety | Disconnect power sources before beginning work to prevent electrical shocks and short circuits. |

| Fire Safety | Keep flammable materials away from the work area and have fire extinguishers readily accessible. |

| Training and Procedures | Ensure all personnel are trained in safety protocols and understand emergency procedures. |

By implementing these safety measures, individuals can significantly reduce the risk of accidents and create a safer working atmosphere during maintenance tasks.

Maintaining Optimal Forklift Performance

Ensuring peak efficiency and longevity of industrial lifting equipment requires regular attention and care. By adhering to a structured maintenance routine, operators can significantly enhance performance, reduce downtime, and extend the lifespan of their machinery. Understanding the fundamental aspects of upkeep is essential for achieving reliable operation in various work environments.

Regular Inspections: Conducting frequent evaluations of the equipment is crucial. This includes checking for signs of wear, ensuring that all components are functioning correctly, and identifying potential issues before they escalate. A proactive approach helps maintain safety standards and operational reliability.

Fluid Levels: Keeping an eye on hydraulic and engine fluids is vital. Regularly inspecting and topping off these fluids can prevent overheating and ensure smooth operation. Contaminated fluids should be replaced promptly to maintain optimal functionality.

Tire Maintenance: Tires play a significant role in stability and performance. Regularly inspecting for proper inflation and tread wear can enhance traction and reduce the risk of accidents. Replacing worn tires in a timely manner contributes to overall safety and efficiency.

Battery Care: For electric models, battery health is paramount. Regular charging and maintenance of battery terminals help ensure reliable power supply. Cleaning the terminals and checking fluid levels can prevent performance issues and extend battery life.

Training and Safety: Providing comprehensive training for operators enhances the effective use of the equipment. Knowledge of safe operating practices not only improves performance but also minimizes the risk of accidents, ensuring a safer workplace.

By prioritizing these maintenance practices, operators can ensure their lifting equipment remains in optimal condition, ultimately contributing to a more productive and safe working environment.

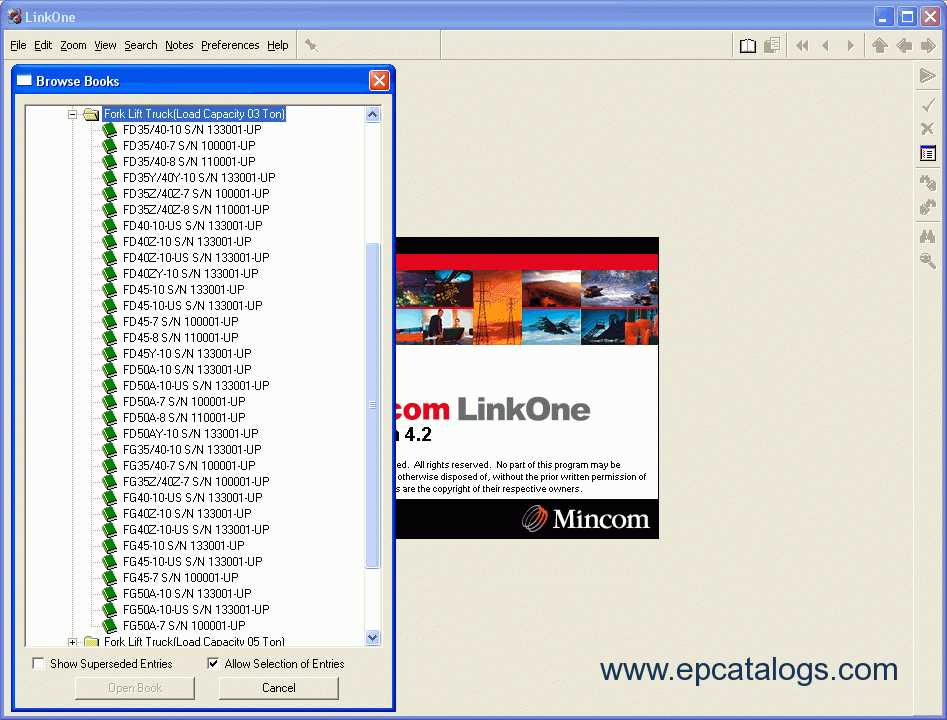

Identifying Forklift Model Specifications

Understanding the specifications of various handling machines is essential for efficient operation and maintenance. Accurate identification of these details allows operators and technicians to ensure compatibility with attachments, optimal performance, and adherence to safety standards. This section will guide you through the key aspects of model specifications, facilitating informed decision-making.

Key Specifications to Consider

When evaluating the characteristics of a handling machine, several critical parameters should be assessed:

| Specification | Description |

|---|---|

| Model Number | A unique identifier that signifies the specific design and features of the unit. |

| Load Capacity | The maximum weight that the machine can safely lift and transport. |

| Lift Height | The maximum vertical distance the load can be raised. |

| Power Source | The type of energy used to operate the machine, such as electric, diesel, or LPG. |

| Dimensions | Overall size, including width, length, and height, which impacts maneuverability. |

Locating Model Information

To accurately identify the specifications, check the machine’s nameplate, typically located on the chassis or the operator’s compartment. This plate contains essential information, including the model number and additional details that are crucial for maintenance and part replacement.

Troubleshooting Electrical Problems

Identifying and resolving electrical issues is crucial for maintaining optimal performance of heavy machinery. Electrical systems can exhibit a variety of symptoms that may hinder functionality, from simple malfunctions to more complex failures. Understanding the common signs and employing a systematic approach can significantly streamline the diagnostic process.

Common Symptoms: Users may encounter a range of indicators such as flickering lights, unresponsive controls, or complete power loss. Each of these symptoms may point to underlying electrical failures, including faulty connections, damaged components, or drained batteries. It is essential to observe these signs carefully to guide troubleshooting efforts.

Initial Steps: Begin the diagnostic process by inspecting the battery and connections. Ensure that terminals are clean and tightly secured. Next, examine fuses for any signs of damage, as a blown fuse can disrupt the entire electrical circuit. If everything appears intact, proceed to check wiring harnesses for wear or disconnections.

Using a Multimeter: A multimeter is an invaluable tool for diagnosing electrical issues. By measuring voltage and continuity, one can pinpoint problematic areas within the circuit. Start by testing the voltage at the battery and work your way through various components to identify any discrepancies that could indicate a fault.

Component Inspection: If initial checks do not reveal the issue, focus on individual components such as relays, switches, and solenoids. Inspect these parts for physical damage and ensure they operate correctly when activated. Sometimes, even a minor issue within a single component can disrupt the entire system.

Consulting Documentation: When faced with persistent problems, referring to technical resources can provide valuable insights. Schematics and wiring diagrams can help visualize connections and identify potential failure points, facilitating a more effective troubleshooting process.

In conclusion, a methodical approach to identifying electrical faults can greatly enhance the longevity and reliability of machinery. By recognizing symptoms, employing diagnostic tools, and thoroughly inspecting components, operators can effectively address and resolve electrical challenges.

Replacing Key Components Efficiently

When it comes to maintaining heavy machinery, ensuring the timely replacement of critical parts is essential for optimal performance. This section will guide you through the process of efficiently swapping out vital elements, minimizing downtime and enhancing productivity.

To achieve effective replacements, follow these steps:

- Preparation: Gather all necessary tools and parts before starting the process.

- Safety First: Ensure the machine is turned off and secured to prevent accidental movement.

- Documentation: Review relevant guidelines and specifications to understand the procedure for each component.

- Sequential Approach: Tackle one component at a time to maintain focus and avoid confusion.

- Inspection: Check surrounding parts for wear or damage while accessing the main component.

Following these best practices can significantly streamline the replacement process and ensure that each key part functions optimally.

Consider the following tips to enhance your efficiency:

- Use Quality Parts: Opt for high-quality replacements to extend the lifespan of your machinery.

- Track Maintenance: Keep a log of replacements and maintenance activities to identify patterns and predict future needs.

- Training: Ensure that personnel are well-trained in handling specific components to minimize errors.

- Regular Checkups: Schedule routine inspections to catch potential issues before they require extensive replacements.

By adopting these strategies, you can ensure that the replacement of essential components is carried out efficiently and effectively, leading to improved machinery reliability.

Accessing Manufacturer Resources Online

In today’s digital age, manufacturers provide a wealth of resources to assist users in maintaining and troubleshooting their equipment. Online platforms enable quick access to essential information, ensuring that operators can effectively manage their machines without unnecessary delays.

Finding Official Websites

One of the first steps in accessing manufacturer resources is locating the official website. Here are some tips for finding the right site:

- Use search engines with the manufacturer’s name followed by keywords such as “support” or “resources.”

- Look for URLs that end with the manufacturer’s domain, which usually indicates authenticity.

- Check for sections dedicated to customer support or product information.

Utilizing Online Tools and Downloads

Once you’ve found the official site, take advantage of the various tools and downloadable content available:

- Access technical documentation, including guides and specifications.

- Download software updates that enhance performance and safety.

- Explore troubleshooting tools that can help identify and resolve issues efficiently.

By leveraging these online resources, users can enhance their understanding and management of their machinery, leading to improved performance and longevity.