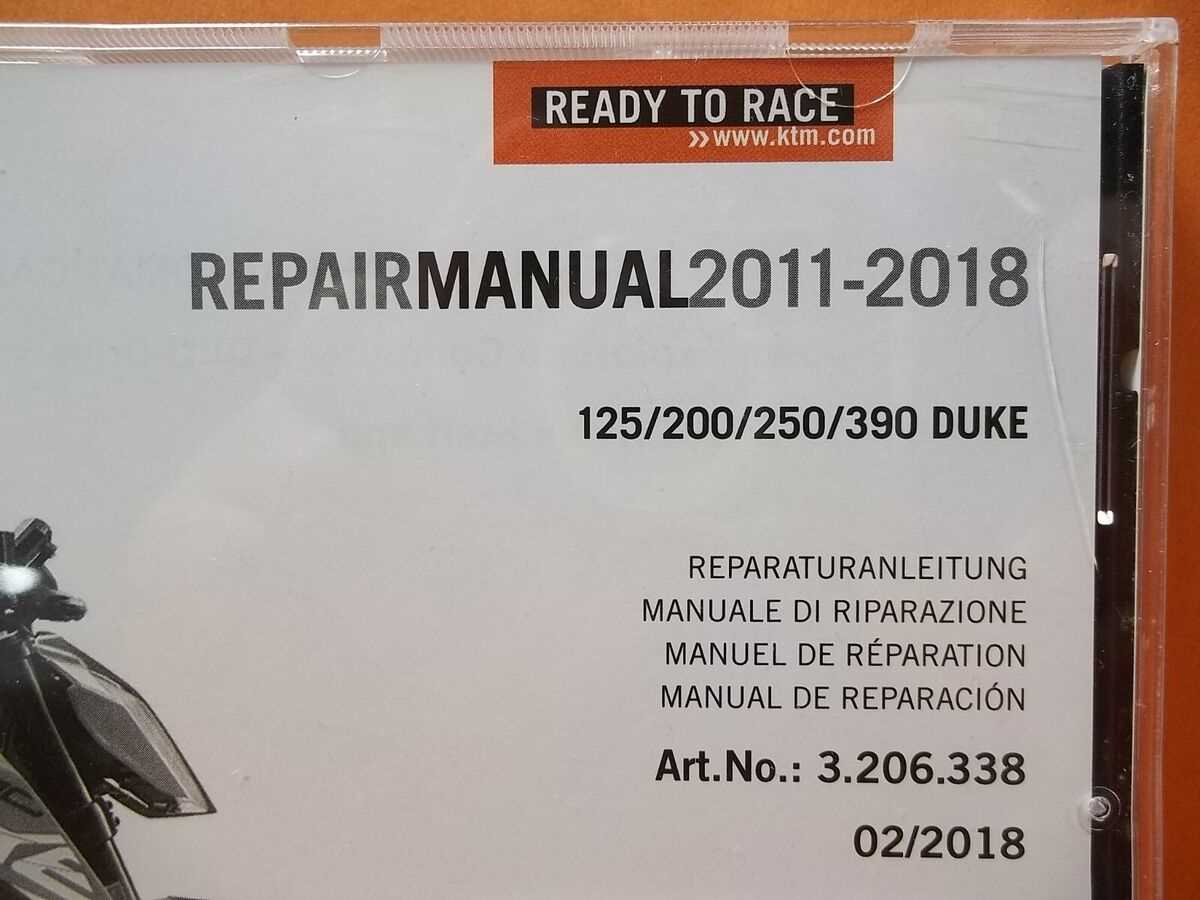

KTM Duke Repair Guide

Ensuring the longevity and optimal performance of a two-wheeled vehicle requires comprehensive understanding and consistent upkeep. This section focuses on essential aspects that every owner should be familiar with, highlighting the importance of regular checks and preventative measures.

From engine performance to electrical systems, each component plays a vital role in the overall functionality. Understanding how to diagnose issues, perform routine maintenance, and execute repairs will empower riders to keep their machine in peak condition.

Equipping yourself with knowledge about various procedures and techniques can save time and enhance safety. With the right approach, maintaining your vehicle can transform into an enjoyable and fulfilling experience.

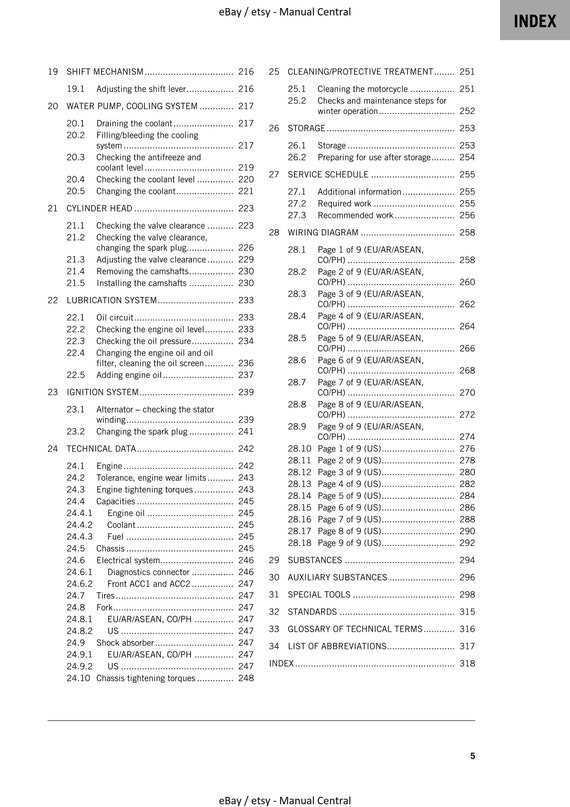

KTM Duke Repair Guide Overview

This section provides a comprehensive look at essential resources for maintaining and troubleshooting your motorcycle. Understanding the key elements of these documents can greatly enhance your ability to address common issues and perform routine maintenance effectively.

Key Components include detailed instructions for various systems, ensuring you can tackle tasks ranging from simple adjustments to more complex repairs. Having access to structured information can save time and improve the quality of your work.

Importance of Maintenance cannot be overstated. Regular checks and timely interventions can prolong the life of your vehicle, ensuring safety and optimal performance. Utilizing well-organized guidance can empower you to keep your motorcycle in excellent condition.

Essential Maintenance Tips for KTM Duke

Proper upkeep of your motorcycle is crucial for ensuring optimal performance and longevity. Regular checks and basic maintenance can prevent common issues and enhance your riding experience. Here are some vital practices to keep your bike in top shape.

Fluid Checks

Regularly inspect all essential fluids, including engine oil, coolant, and brake fluid. Maintaining the correct levels and replacing fluids as needed will help avoid overheating and ensure smooth operation.

Tire Maintenance

Check tire pressure and tread depth frequently. Properly inflated tires improve handling and fuel efficiency, while adequate tread depth ensures better grip on various surfaces.

Brake System Inspection

Regularly examine the brake pads and discs for wear. Effective braking is vital for safety, so replacing worn components promptly is essential.

Chain Care

Keep the drive chain clean and properly lubricated. A well-maintained chain reduces wear on the sprockets and improves overall drivetrain efficiency.

Electrical System Checks

Inspect the battery and electrical connections for corrosion and tightness. Ensuring a reliable electrical system is key to avoiding starting issues and maintaining performance.

Periodic Tune-Ups

Schedule regular tune-ups to check engine performance, adjust settings, and replace filters. This proactive approach will enhance efficiency and prolong the life of your motorcycle.

Common Issues and Solutions for Duke

This section addresses frequent challenges faced by riders and provides practical solutions to enhance the overall experience. By understanding typical problems and their remedies, enthusiasts can ensure a smoother journey and prolonged functionality.

- Engine Performance Problems

- Check fuel quality; using premium fuel can resolve hesitation and poor acceleration.

- Inspect air filter for clogs; a clean filter promotes better airflow and efficiency.

- Regularly change spark plugs to maintain optimal ignition performance.

- Electrical System Failures

- Test battery condition; replacing an old battery can restore functionality.

- Examine wiring for damage; frayed wires can lead to intermittent issues.

- Ensure all connections are tight; loose connections can cause various electrical problems.

- Braking System Concerns

- Inspect brake pads for wear; replacing worn pads enhances safety.

- Check brake fluid levels; low fluid can affect braking performance.

- Bleed brakes periodically to remove air bubbles, ensuring responsive braking.

- Suspension Issues

- Examine shock absorbers for leaks; replacing them improves ride quality.

- Adjust suspension settings based on rider weight for optimal comfort and control.

- Regularly check for wear on suspension components to prevent handling problems.

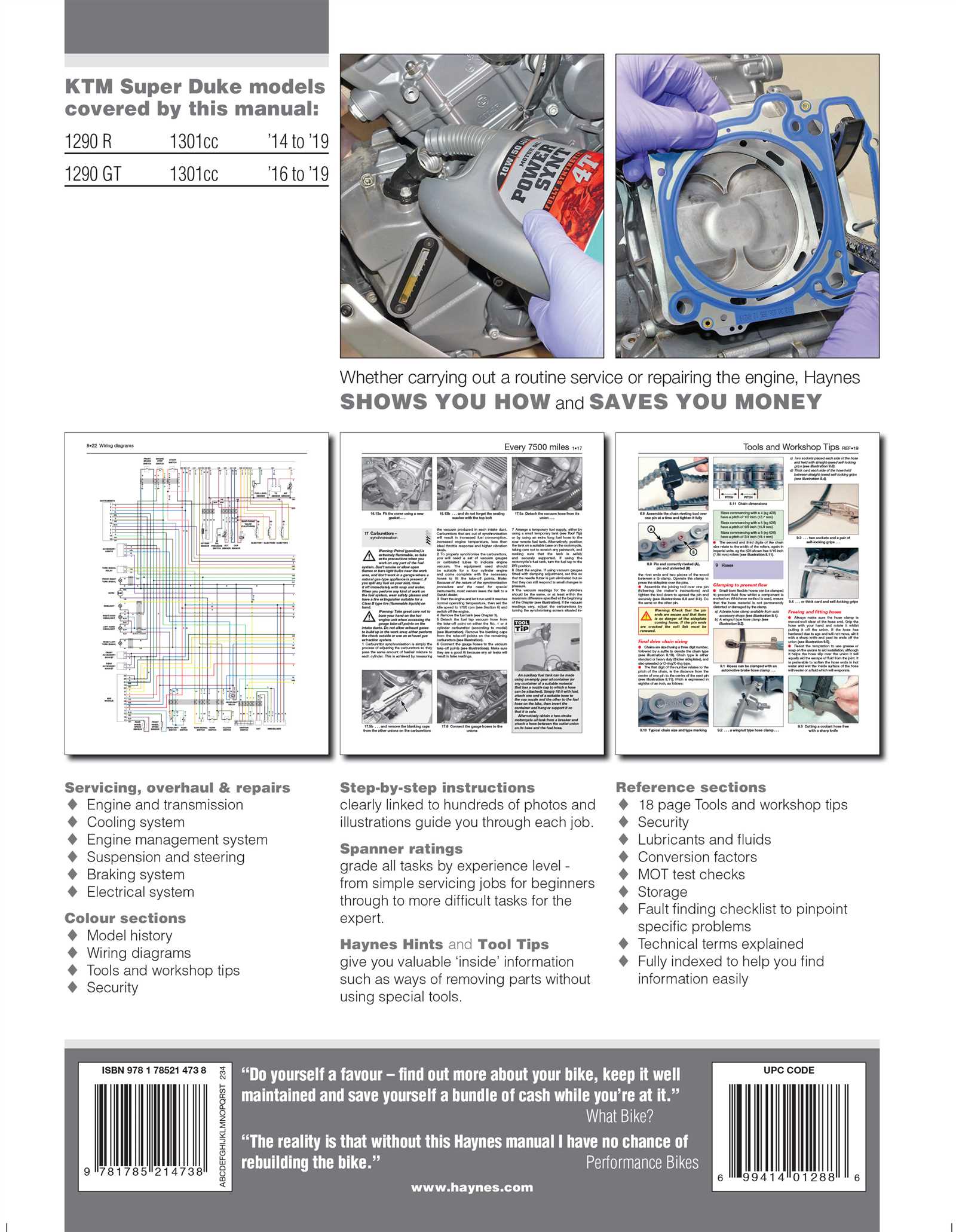

Tools Needed for KTM Duke Repairs

When maintaining and servicing a motorcycle, having the right equipment is essential for ensuring efficiency and precision. Proper tools not only simplify the task at hand but also contribute to the longevity of the vehicle.

Start with a basic set of hand tools, including wrenches, sockets, and screwdrivers. These items are crucial for loosening and tightening various components. Additionally, a torque wrench is important to apply the correct amount of force, preventing damage from over-tightening.

A quality set of pliers and wire cutters will be beneficial for dealing with cables and electrical connections. Specialty tools may also be required, such as a chain breaker or a tire lever, depending on the maintenance tasks you plan to undertake.

For more advanced procedures, consider investing in a service manual or guide specific to your model, which can provide insights into unique requirements and specifications. Lastly, a good workbench and adequate lighting will enhance your workspace, allowing for a more organized and efficient repair process.

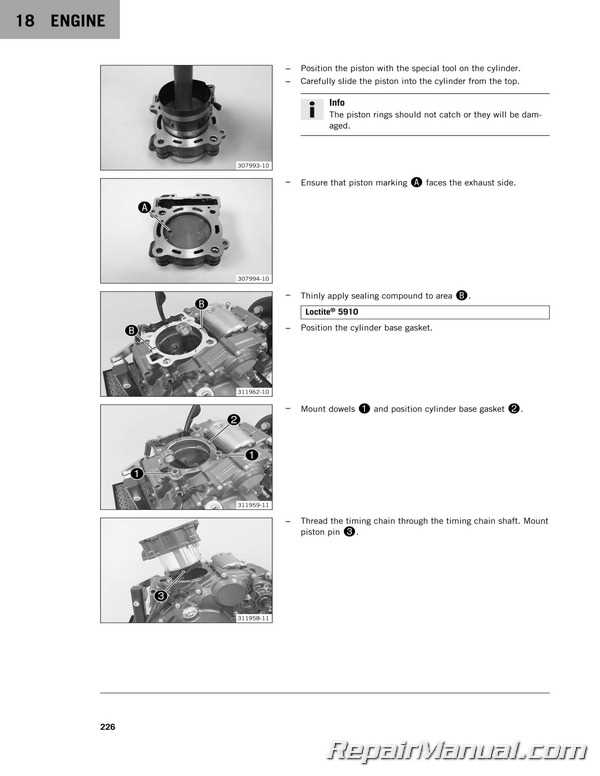

Step-by-Step Engine Troubleshooting

This section provides a systematic approach to diagnosing engine issues. By following these steps, you can effectively identify and address common problems that may arise during operation. Proper troubleshooting can save time and prevent further complications.

Initial Checks

Before delving into complex diagnostics, conduct a series of preliminary checks. Ensure the following components are in optimal condition:

| Component | Check Method | Notes |

|---|---|---|

| Fuel System | Inspect fuel level and quality | Use fresh fuel for best performance |

| Electrical Connections | Examine wiring and terminals | Look for corrosion or loose connections |

| Air Filter | Check for cleanliness | Replace if dirty to ensure proper airflow |

Advanced Diagnostics

If initial checks do not resolve the issue, proceed to more advanced diagnostics. Use the following methods to pinpoint engine faults:

- Compression Test: Measure cylinder pressure to assess internal wear.

- Leak-Down Test: Identify air leaks in the combustion chamber.

- Diagnostic Scanner: Utilize electronic tools to retrieve error codes.

Transmission Maintenance and Adjustments

Proper care and fine-tuning of the transmission system are essential for ensuring optimal performance and longevity of your vehicle. Regular inspections and adjustments can help maintain smooth operation and prevent potential issues that may arise from neglect.

To begin with, it’s important to routinely check the fluid levels and quality. Low or contaminated fluid can lead to shifting problems and increased wear on components. Replace the fluid as per the manufacturer’s guidelines to keep the system functioning efficiently.

Additionally, the alignment and tension of the drive components should be monitored. Proper alignment prevents undue strain on the parts, while correct tension allows for smooth power transfer. Adjustments can be made to achieve the manufacturer-recommended specifications, which can significantly enhance overall reliability.

Finally, inspect the clutch system for signs of wear or improper adjustment. A well-maintained clutch ensures responsive gear changes and can help avoid premature wear on both the clutch and transmission. Regular maintenance checks will keep the system in excellent condition, ensuring a seamless riding experience.

Brake System Inspection and Repair

Ensuring optimal performance of the braking system is crucial for safety and efficiency. Regular checks and timely interventions can prevent potential issues and enhance the longevity of components.

Start by assessing the following key areas:

- Brake Pads: Examine for wear and tear. Pads should be replaced if they are thinner than the recommended thickness.

- Brake Discs: Look for signs of warping or scoring. Smooth surfaces are essential for effective braking.

- Fluid Levels: Ensure brake fluid is at the appropriate level and free of contaminants. Low fluid can indicate a leak.

- Hoses and Lines: Inspect for cracks, leaks, or fraying. Damaged lines can lead to brake failure.

- Calipers: Check for proper operation. Calipers should move freely and not show signs of corrosion.

Follow these steps for a comprehensive evaluation:

- Remove the wheel to access brake components.

- Inspect each part carefully, noting any irregularities.

- Clean the brake area to remove dust and debris.

- Replace worn or damaged parts with quality replacements.

- Reassemble components and test the braking function before finalizing the job.

Regular maintenance of the braking system not only ensures safety but also improves the overall riding experience.

Electrical System Diagnostics for Duke

The electrical system of any motorcycle is crucial for its optimal performance. Proper diagnostics ensure that all components function harmoniously, preventing unexpected failures and enhancing reliability. Understanding the intricacies of the electrical framework is essential for effective troubleshooting.

To initiate the diagnostic process, begin by verifying the battery condition. A weak or faulty battery can lead to a myriad of issues, including starting problems and erratic behavior of electronic components. Use a multimeter to measure voltage levels; ideally, the reading should be around 12.6 volts when fully charged.

Next, inspect the wiring harness for signs of wear or damage. Look for frayed wires, corrosion, or loose connections. Each of these can cause significant electrical failures and may lead to intermittent issues that are often hard to pinpoint. Ensure all connectors are secure and free from dirt.

Testing individual components is also vital. Start with the ignition system, ensuring that the spark plugs are firing correctly. A faulty spark plug can lead to poor engine performance. Similarly, check the voltage regulator to ensure it’s maintaining appropriate output, as an unstable voltage can affect various systems.

Additionally, utilize diagnostic tools to scan for error codes. Modern motorcycles often have integrated diagnostic systems that can reveal underlying issues. Addressing these codes promptly can save time and prevent further complications.

In summary, thorough diagnostics of the electrical system involves checking the battery, inspecting the wiring, testing components, and utilizing diagnostic tools. By systematically addressing each aspect, you can ensure the reliability and performance of the motorcycle’s electrical system.

Suspension Setup and Maintenance Guide

The proper adjustment and upkeep of the suspension system are crucial for optimizing ride quality and handling performance. This guide outlines essential practices to ensure that your vehicle’s suspension operates efficiently and adapts to various riding conditions.

Adjusting Suspension Settings

To achieve the best performance, it’s important to adjust the suspension according to your weight, riding style, and terrain. Here are key parameters to consider:

| Parameter | Adjustment Method | Recommended Range |

|---|---|---|

| Preload | Adjust the spring tension | 10-15 mm sag |

| Compression | Modify the damping settings | 3-5 clicks from soft |

| Rebound | Adjust the rebound damping | 10-15 clicks from fully closed |

Maintenance Practices

Regular maintenance is essential for the longevity of the suspension system. Follow these steps to keep it in top condition:

- Inspect seals and bushings for wear.

- Change fork oil every 10,000 miles or as needed.

- Check for proper alignment and tightness of bolts.

- Clean the suspension components regularly to prevent dirt buildup.

Upgrading Components for Enhanced Performance

Improving the functionality of a motorcycle can significantly enhance its overall riding experience. Upgrades can lead to better handling, increased power, and more efficient operation. By focusing on key components, enthusiasts can tailor their machines to better suit their individual riding styles and preferences.

Key Areas for Improvement

- Exhaust System: Upgrading to a performance exhaust can reduce weight and improve engine efficiency.

- Suspension: Enhancing the suspension setup can provide better handling and comfort on varied terrains.

- Brakes: Investing in high-performance brake pads and rotors ensures superior stopping power and safety.

- Fuel Management: Optimizing fuel delivery systems can lead to better throttle response and increased horsepower.

Benefits of Upgrading

- Improved power-to-weight ratio.

- Enhanced rider control and stability.

- Increased lifespan of engine components.

- Personalized riding experience tailored to preferences.

By selecting the right upgrades and performing them with care, riders can enjoy a machine that not only performs better but also reflects their unique style and needs.

Preparing for Seasonal Maintenance Tasks

As the seasons change, it’s essential to ensure that your two-wheeled vehicle remains in optimal condition. Seasonal upkeep not only enhances performance but also prolongs the lifespan of your machine. By adhering to a structured approach, you can effectively tackle various maintenance challenges that arise with shifting weather conditions.

Checklist for Effective Upkeep

Begin by compiling a thorough checklist to guide your maintenance efforts. This should encompass crucial areas such as:

- Fluid Levels: Check and replace engine oil, coolant, and brake fluid as necessary.

- Tire Inspection: Assess tire pressure and tread wear to ensure safe handling.

- Battery Care: Inspect terminals and charge the battery to prevent starting issues.

Seasonal Adjustments

Different seasons may require specific adjustments to your vehicle. For instance, switching to a more suitable type of oil for colder temperatures can enhance engine efficiency. Additionally, ensuring that all lights and signals are functioning correctly is vital for safety, especially during darker months.