Kubota L2800 Repair Manual Comprehensive Guide

Maintaining heavy-duty farming equipment is crucial for ensuring optimal performance and longevity. Proper understanding of its components and mechanisms can significantly enhance the efficiency of operations in the field. This section aims to provide comprehensive insights into troubleshooting, maintenance, and the overall upkeep of these powerful machines.

With detailed instructions and practical tips, this guide will help you navigate the complexities of machinery care. By following systematic approaches to identify issues, you can prevent minor problems from escalating into major repairs, ultimately saving time and resources.

Furthermore, understanding the intricacies of your equipment not only promotes better functionality but also contributes to safety during operation. Whether you’re a seasoned professional or a novice, having access to valuable information ensures that you can make informed decisions regarding maintenance practices.

Kubota L2800 Overview and Specifications

This section provides a comprehensive examination of a popular compact tractor, detailing its key features and technical specifications. Understanding these elements is essential for both current owners and potential buyers looking to assess its capabilities and suitability for various agricultural tasks.

The machine is designed for versatility, making it suitable for a range of applications such as farming, landscaping, and property maintenance. Below are some of its notable specifications:

- Engine Type: Diesel engine with a robust design for durability.

- Horsepower: Approximately 28 HP, providing sufficient power for various tasks.

- Transmission: Hydrostatic transmission for smooth operation and ease of use.

- Weight: Around 1,500 lbs, contributing to stability and traction.

- Fuel Capacity: 6.6 gallons, allowing for extended work periods without frequent refueling.

Additional features include:

- Compact size, facilitating maneuverability in tight spaces.

- Four-wheel drive for enhanced traction on challenging terrains.

- Comfortable operator station, designed for ease during long working hours.

- Variety of compatible attachments, expanding its functionality.

Overall, this compact tractor is engineered for efficiency and reliability, making it an excellent choice for both hobbyists and professionals in the agricultural sector.

Common Issues with Kubota L2800

When operating a compact utility vehicle, users may encounter several recurring problems that can impact performance and efficiency. Understanding these common challenges can aid in early detection and troubleshooting, ensuring that the machine runs smoothly and effectively.

Frequent Problems

- Starting Difficulties

- Hydraulic System Failures

- Overheating Issues

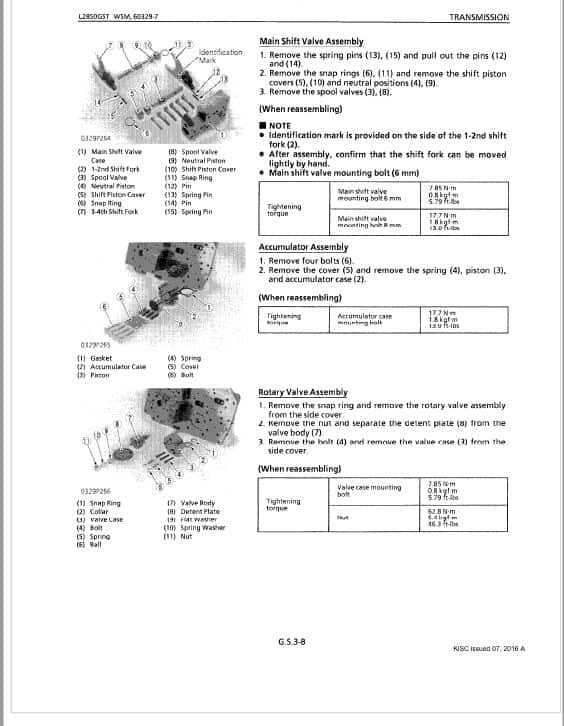

- Transmission Irregularities

- Electrical Malfunctions

Possible Solutions

- Regularly check and maintain battery connections.

- Inspect hydraulic fluid levels and look for leaks.

- Ensure the cooling system is functioning properly.

- Examine transmission fluid and replace as needed.

- Test electrical components and wiring for faults.

By addressing these typical concerns promptly, operators can extend the lifespan of their equipment and enhance overall productivity.

Maintenance Tips for Longevity

Ensuring the prolonged performance of your machinery requires consistent care and attention. Implementing a regular maintenance routine can significantly enhance the lifespan of your equipment, minimizing the likelihood of unexpected breakdowns and costly repairs. By adhering to a few essential practices, you can keep your machine operating efficiently for years to come.

Regular Inspections

Proper Lubrication

Maintaining adequate lubrication is vital for reducing friction and wear on moving parts. Use high-quality lubricants and follow the manufacturer’s guidelines regarding application frequency. Regularly greasing pivot points and joints can significantly enhance overall functionality and reduce the risk of premature failure.

Step-by-Step Repair Procedures

This section outlines a comprehensive approach to addressing mechanical issues, providing a clear, systematic method to tackle various problems effectively. Following these steps will help ensure that the process is efficient and the desired results are achieved.

1. Diagnose the Issue: Begin by thoroughly examining the equipment to identify any symptoms of malfunction. Listen for unusual sounds, check for leaks, and inspect components for wear and damage. Document your findings to keep track of potential concerns.

2. Gather Necessary Tools: Assemble all required tools and parts before starting the work. This includes wrenches, screwdrivers, and replacement components. Having everything on hand will streamline the process and minimize interruptions.

3. Prepare the Workspace: Ensure that your workspace is clean and organized. Remove any obstacles that might hinder movement or access to the machinery. Adequate lighting is essential for detailed inspections and repairs.

4. Follow Safety Precautions: Always prioritize safety by wearing appropriate protective gear such as gloves and goggles. Ensure that the equipment is turned off and properly secured before beginning any work.

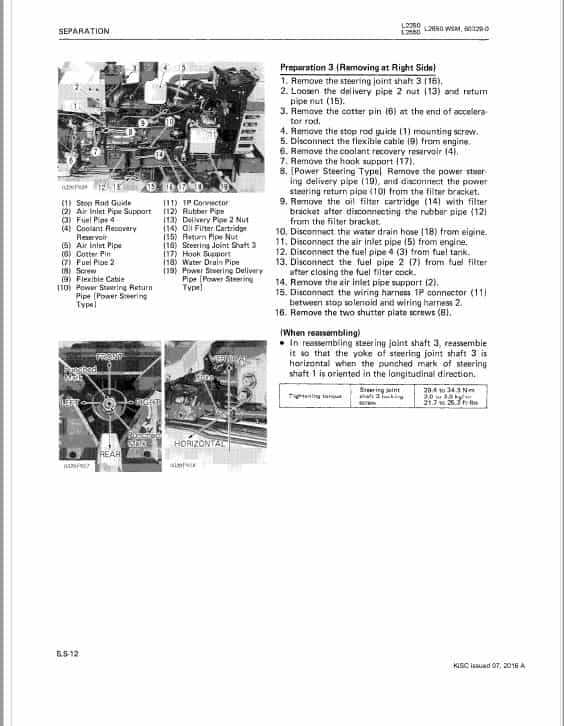

5. Disassemble Components: Carefully take apart the necessary components to access the area of concern. Keep track of all screws and parts, using containers or labels to avoid losing them during reassembly.

6. Inspect and Replace Parts: Examine each component for signs of wear or damage. Replace any defective parts with high-quality alternatives. Make sure that all replacements are compatible with the equipment specifications.

7. Reassemble and Test: After replacing the necessary components, carefully reassemble the equipment in reverse order. Once everything is in place, conduct a thorough test to ensure that the issue has been resolved and that the machinery operates smoothly.

8. Document the Process: Keep a detailed record of the work performed, including any parts replaced and observations made during the procedure. This documentation will be valuable for future reference and maintenance.

Essential Tools for Repairs

When it comes to maintaining machinery, having the right equipment is crucial for ensuring efficient and effective work. A well-stocked toolkit not only enhances productivity but also simplifies the troubleshooting process. Each tool serves a specific purpose, allowing for precise adjustments and quick fixes.

Wrenches are fundamental in any toolkit. They come in various sizes and types, enabling you to tackle nuts and bolts of different dimensions. A good set includes both adjustable and socket wrenches for versatility.

Screwdrivers are another vital component. Having a range of Phillips and flathead screwdrivers ensures you can handle a variety of screws. Magnetic tips can further ease the process by preventing screws from slipping.

Pliers are indispensable for gripping and manipulating objects. Whether you’re cutting wires or bending materials, a sturdy pair of needle-nose pliers can make intricate tasks much simpler.

Torque wrenches are essential for achieving the correct tightness on fasteners. This precision tool prevents damage from over-tightening, ensuring that connections remain secure without compromising the integrity of components.

Multimeters provide invaluable assistance in diagnosing electrical issues. By measuring voltage, current, and resistance, they help pinpoint problems in the system, streamlining the repair process.

Lastly, tool organizers are key to maintaining an efficient workspace. Keeping tools neatly arranged allows for easy access and reduces downtime, ultimately leading to a more productive maintenance experience.

Safety Precautions During Repairs

Ensuring a secure environment while performing maintenance tasks is crucial for both personal safety and the integrity of the machinery. Proper precautions minimize risks and enhance efficiency, allowing for a smoother working process. Adhering to established safety protocols not only protects the individual but also extends the lifespan of the equipment being serviced.

Personal Protective Equipment

Always wear appropriate personal protective gear, including gloves, goggles, and sturdy footwear. This equipment safeguards against potential hazards, such as sharp edges and hazardous materials. Additionally, long sleeves and pants can help prevent skin injuries from accidental contact with hot or rough surfaces.

Work Area Safety

Keep the workspace organized and free from clutter to reduce the likelihood of accidents. Ensure that tools are in good condition and stored properly when not in use. Adequate lighting is essential; a well-lit area helps identify potential dangers and makes tasks easier to perform. Furthermore, always be aware of your surroundings and the position of others when operating machinery or handling tools.

Finding Genuine Replacement Parts

When maintaining machinery, the importance of sourcing authentic components cannot be overstated. Using original pieces ensures optimal performance and longevity, providing peace of mind for operators. Counterfeit or substandard items may lead to inefficiencies or even further damage.

Here are some effective strategies for locating genuine parts:

- Authorized Dealers: Always start by checking with official dealers. They offer certified products and can provide valuable advice.

- Manufacturer Websites: Many brands maintain online catalogs that list available parts. This is a reliable source for verification.

- Local Distributors: Establish relationships with local suppliers who specialize in machinery. They often carry genuine stock or can order it for you.

- Online Marketplaces: When purchasing from e-commerce platforms, ensure the seller is reputable and offers authenticity guarantees.

Before finalizing any purchase, it’s wise to verify part numbers and consult manuals or guides that outline specifications. This diligence prevents costly mistakes and ensures that equipment functions efficiently.

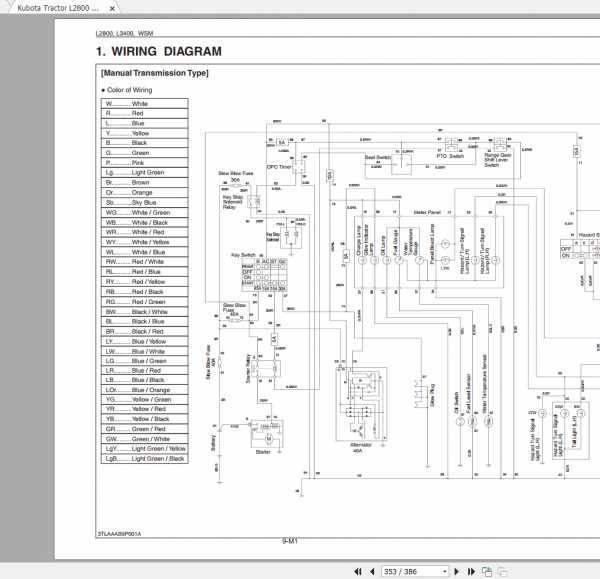

Troubleshooting Electrical Problems

Addressing issues within the electrical system of agricultural machinery can be challenging yet crucial for maintaining optimal performance. This section provides guidance on identifying and resolving common electrical faults that may arise during operation.

Common Symptoms of Electrical Issues

- Inconsistent engine starting or failure to start

- Dim or flickering lights

- Inoperative gauges or warning indicators

- Unresponsive controls

Steps for Diagnosing Electrical Problems

- Check the battery connections for corrosion or loose terminals.

- Inspect fuses and replace any that are blown.

- Examine wiring for signs of wear, fraying, or damage.

- Test the ignition switch for functionality.

- Use a multimeter to verify voltage levels in the circuit.

By systematically addressing these areas, operators can effectively troubleshoot and rectify electrical issues, ensuring the machinery operates smoothly and efficiently.

Hydraulic System Maintenance Guidelines

Regular upkeep of hydraulic systems is crucial for ensuring optimal performance and longevity. Proper maintenance practices not only enhance efficiency but also help prevent costly breakdowns. By following established protocols, operators can maintain the reliability of these systems in various applications.

Fluid Inspection and Replacement: It is essential to routinely check hydraulic fluid levels and quality. Contaminated or low fluid can lead to system failures. Regularly replacing the fluid according to the manufacturer’s recommendations helps maintain system integrity and functionality.

Filter Maintenance: Hydraulic filters play a vital role in removing impurities from the fluid. Periodic inspection and replacement of filters are necessary to prevent clogs and ensure smooth operation. A clean filter reduces wear on components and extends the system’s lifespan.

Leak Detection: Identifying and repairing leaks promptly is crucial for maintaining system pressure and efficiency. Regularly inspecting hoses, connections, and fittings can help detect potential issues before they escalate. Addressing leaks quickly prevents loss of fluid and reduces environmental impact.

Component Checks: Frequent examination of hydraulic components such as pumps, cylinders, and valves is necessary. Look for signs of wear or damage, and replace parts as needed. Keeping these components in optimal condition ensures that the system operates smoothly and effectively.

Temperature Monitoring: Maintaining proper operating temperatures is vital for hydraulic systems. Overheating can lead to fluid breakdown and component failure. Implementing temperature monitoring can help detect issues early and allow for timely corrective actions.

By adhering to these maintenance guidelines, operators can ensure that their hydraulic systems remain efficient and reliable, ultimately enhancing overall performance and reducing downtime.

Customer Reviews and Experiences

This section highlights the voices of users who have engaged with their machinery, sharing valuable insights and feedback based on their hands-on experiences. Understanding the perspectives of others can provide potential owners with a clearer picture of what to expect, from performance to maintenance challenges.

User Feedback

Many users commend the durability and reliability of their equipment, noting that it performs exceptionally well under various conditions. One user remarked: “I’ve put it through tough tasks, and it has never let me down.” This sentiment is echoed by several owners who appreciate its robust design and efficiency.

Challenges and Solutions

While most experiences are positive, some users have encountered challenges that required attention. For instance: “I faced some minor issues with the hydraulic system, but the troubleshooting steps I found online made a big difference.” This showcases the importance of having accessible resources and community support for resolving common problems.