Comprehensive Guide to Kubota RTV 500 Repairs

Ensuring the longevity and optimal performance of your vehicle requires a comprehensive understanding of its components and systems. This section aims to provide valuable insights into effective practices for upkeep and potential issues that may arise during operation.

Regular maintenance is crucial in preventing breakdowns and enhancing reliability. Familiarizing yourself with essential procedures will empower you to take proactive steps in addressing minor problems before they escalate.

In addition, understanding the common challenges faced by users can streamline your troubleshooting efforts. By learning how to identify symptoms and implementing appropriate solutions, you can minimize downtime and maintain productivity.

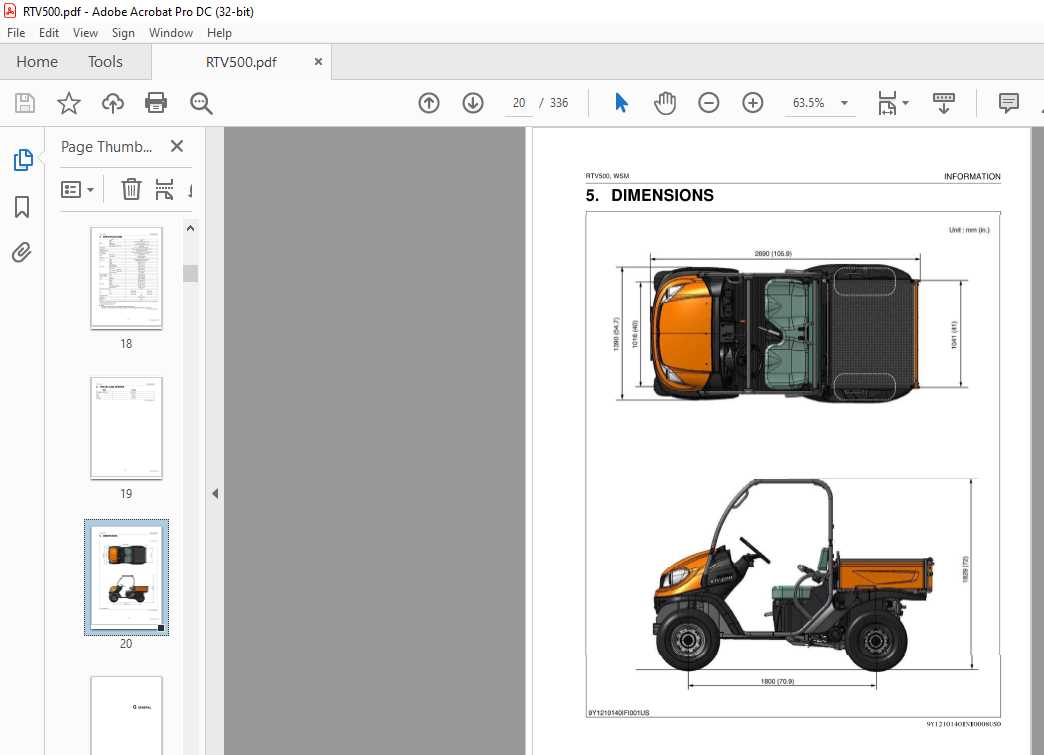

This section provides a comprehensive understanding of a versatile utility vehicle designed for a variety of tasks. With its robust features, this model stands out in the market, appealing to both professionals and hobbyists alike.

Key Features and Specifications

The vehicle is equipped with numerous features that enhance its functionality and user experience:

- Powerful engine for efficient performance

- All-terrain capabilities suitable for various environments

- Spacious cargo area for transporting goods

- Comfortable seating arrangements for operator and passengers

- Advanced safety features for secure operation

Applications and Uses

This utility vehicle can be utilized in numerous settings, making it an invaluable asset:

- Agricultural tasks, such as transporting materials

- Landscaping and grounds maintenance

- Recreational activities, including off-road adventures

- Emergency response scenarios for quick mobility

Common Issues and Troubleshooting

When operating a utility vehicle, users may encounter various challenges that affect performance and reliability. Identifying and addressing these issues promptly can help maintain efficiency and prolong the lifespan of the machine.

Below are some typical problems along with their potential causes and solutions:

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Engine won’t start | Dead battery or fuel issue | Check battery charge and fuel levels; replace if necessary. |

| Poor acceleration | Clogged air filter or fuel line | Inspect and clean or replace filters as needed. |

| Unusual noises | Worn or loose components | Examine parts for wear and tighten or replace as required. |

| Overheating | Low coolant level or blockage | Check coolant levels and clear any obstructions in the cooling system. |

Regular maintenance and awareness of these common issues can enhance the performance of the vehicle, ensuring a smoother and more reliable operation.

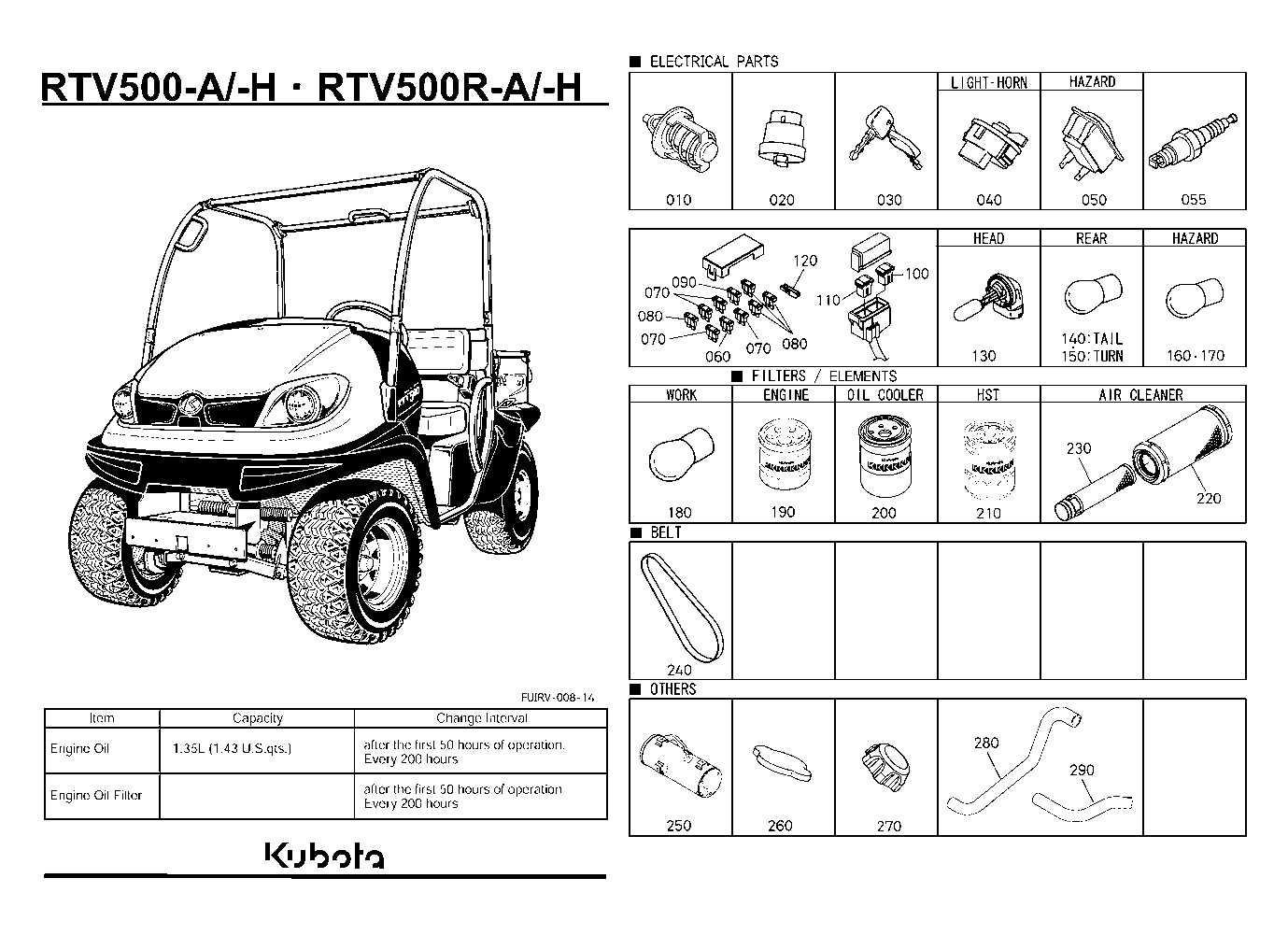

Maintenance Schedule and Recommendations

Regular upkeep of your utility vehicle is essential for ensuring optimal performance and longevity. Following a structured maintenance routine can help prevent unexpected breakdowns and enhance efficiency. This section outlines a recommended schedule and best practices for maintaining your equipment effectively.

Routine Maintenance Tasks

Engaging in consistent maintenance tasks will significantly prolong the life of your vehicle. Key activities include checking fluid levels, inspecting tires, and cleaning air filters. Establishing a timetable for these tasks ensures that nothing is overlooked.

| Task | Frequency |

|---|---|

| Oil Change | Every 100 hours of operation |

| Tire Inspection | Every 50 hours of operation |

| Air Filter Cleaning | Every 100 hours of operation |

| Brake System Check | Every 200 hours of operation |

Additional Recommendations

In addition to routine tasks, it’s crucial to follow manufacturer recommendations regarding seasonal checks and specialized services. Regularly reviewing the user guide for specific guidelines related to your vehicle can also provide valuable insights for maintaining its condition.

Essential Tools for Repairs

Having the right equipment is crucial for maintaining and fixing utility vehicles. A well-equipped workshop enables you to perform tasks efficiently and effectively. Below is a list of fundamental tools that will assist you in handling various maintenance activities.

Basic Hand Tools

- Wrenches: Adjustable and socket types for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips for various fasteners.

- Pliers: Essential for gripping and bending tasks.

- Hammers: Useful for driving nails or fixing components.

Specialized Equipment

- Torque Wrench: Ensures proper tightening of bolts to specifications.

- Jack and Stands: Necessary for lifting the vehicle safely during maintenance.

- Diagnostic Tools: For troubleshooting and identifying issues effectively.

- Grease Gun: Important for lubricating moving parts to reduce wear.

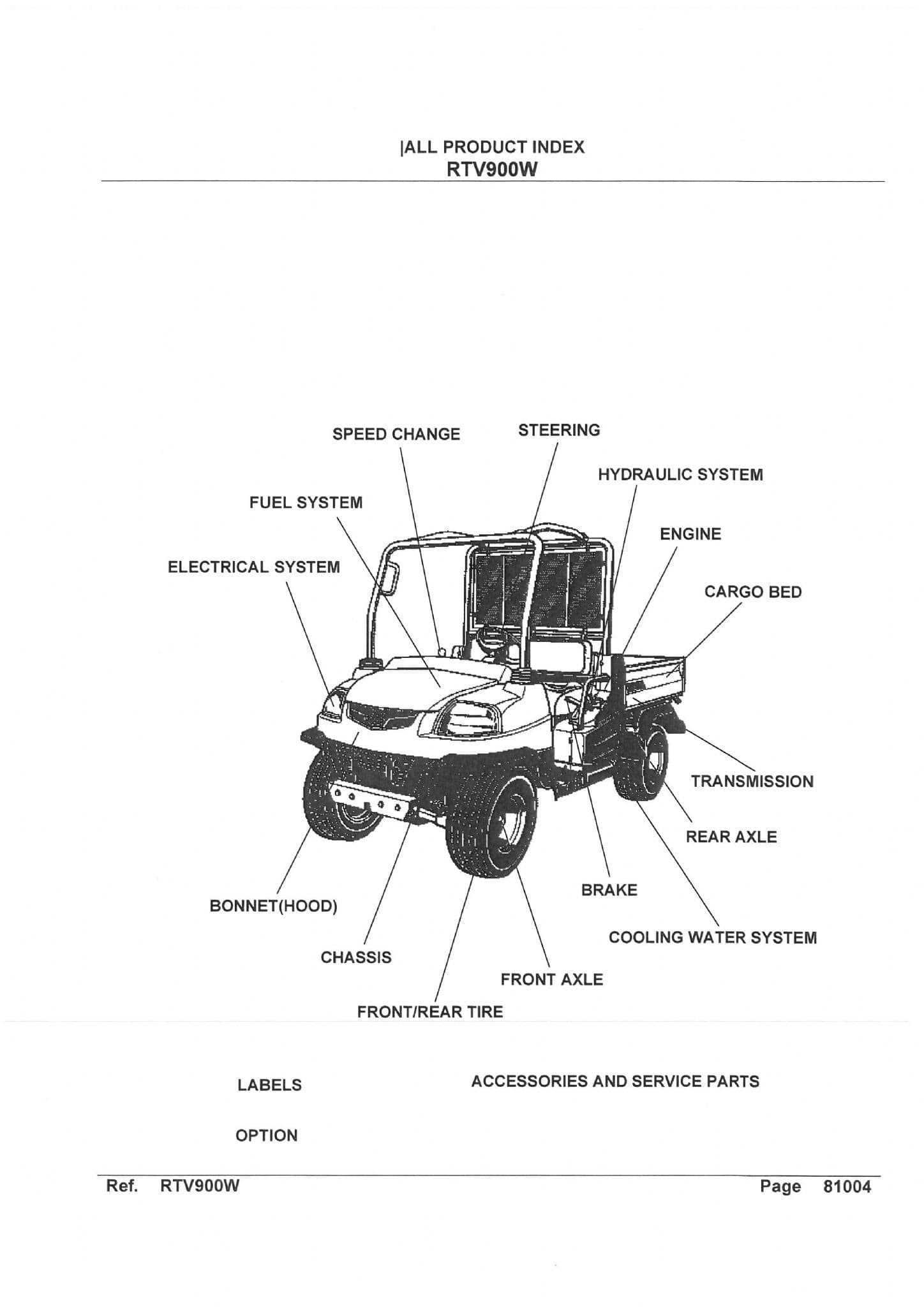

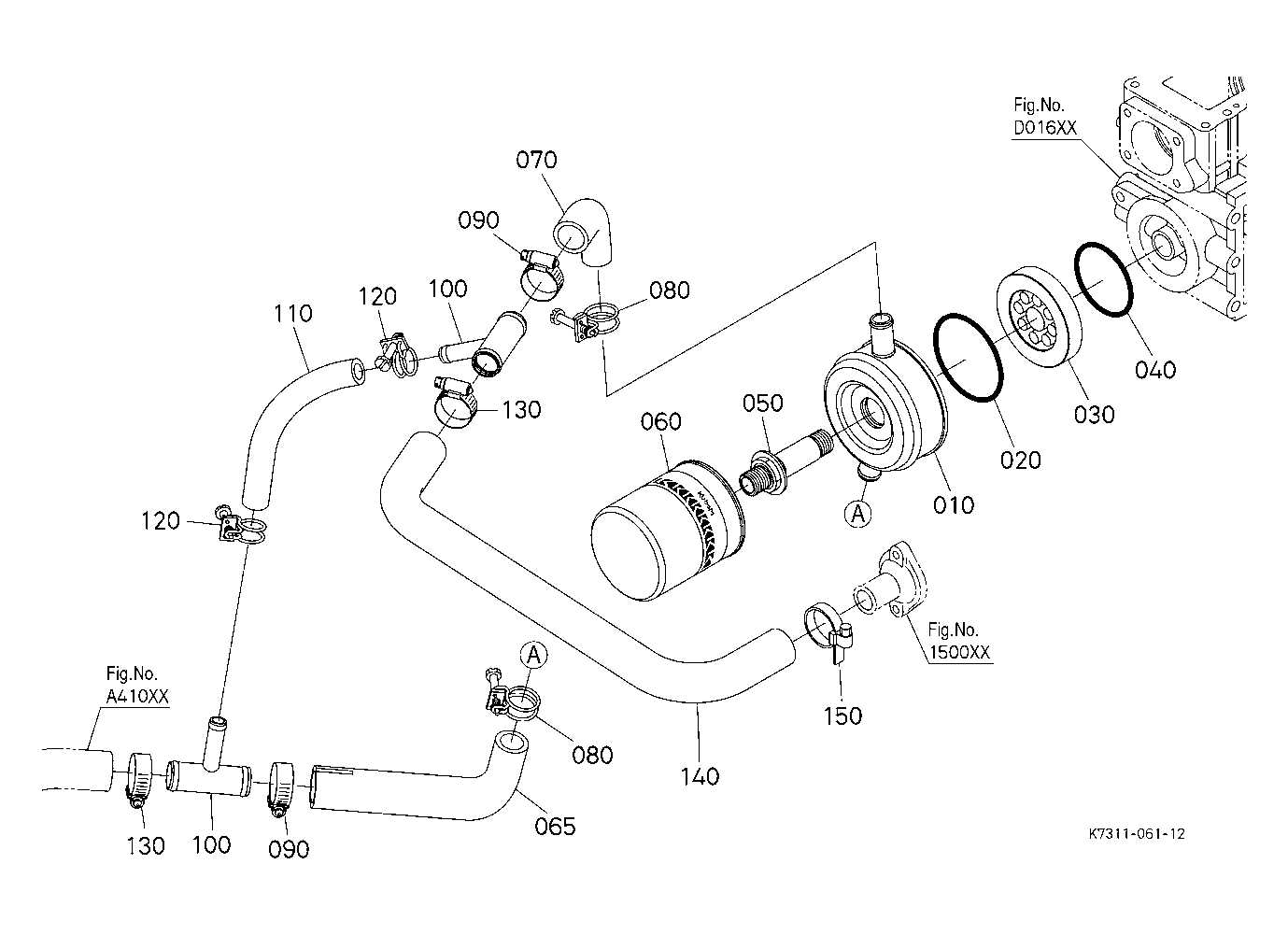

Engine Components and Functions

The engine is a vital part of any machinery, playing a crucial role in its overall performance. Understanding the various components and their functions can greatly enhance maintenance and operational efficiency. Each element contributes uniquely to the power generation and operation of the unit.

Power Unit: The core of the engine, this component converts fuel into mechanical energy. It is essential for initiating motion and powering various systems within the machine.

Fuel System: This system delivers the necessary fuel to the engine. It consists of the fuel tank, fuel lines, and injectors, ensuring a steady supply for optimal performance.

Cooling System: To prevent overheating, the cooling system circulates coolant throughout the engine. It maintains an appropriate operating temperature, safeguarding components from thermal damage.

Lubrication System: This system minimizes friction between moving parts. By distributing oil throughout the engine, it ensures smooth operation and prolongs the lifespan of critical components.

Exhaust System: After combustion, gases must be expelled efficiently. The exhaust system channels these gases away from the engine, reducing emissions and enhancing overall performance.

By familiarizing oneself with these key components and their roles, operators can better understand how to maintain and optimize the functioning of their equipment.

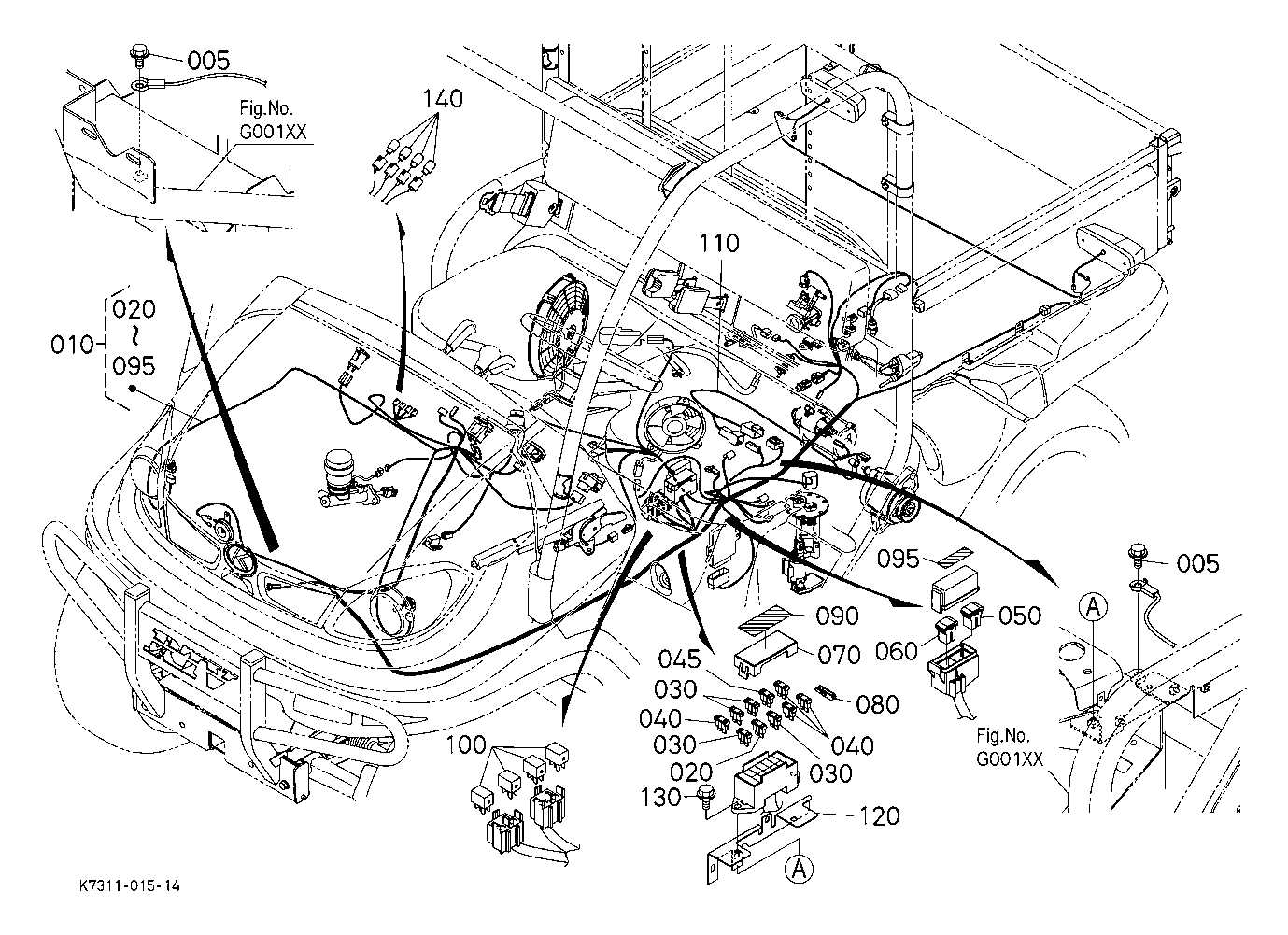

Electrical System Diagnostics

The effective operation of any vehicle relies heavily on its electrical system. Diagnosing issues within this system is crucial for maintaining optimal performance and ensuring reliability. This section will outline essential procedures and techniques for identifying electrical faults, helping to enhance troubleshooting efficiency.

Common Electrical Issues

Electrical problems can manifest in various ways, including malfunctioning lights, inconsistent power delivery, and starting difficulties. These issues often stem from faulty connections, worn-out components, or software malfunctions. Regular inspections and prompt identification of symptoms are key to preventing more significant complications.

Diagnostic Techniques

Utilizing diagnostic tools, such as multimeters and circuit testers, allows for precise evaluation of the electrical components. Begin by checking the battery voltage and connections, ensuring there are no signs of corrosion or looseness. Following this, inspect fuses and relays for continuity. A systematic approach will help pinpoint the source of the problem effectively.

Transmission and Drive System

The transmission and drive system are crucial components of any utility vehicle, responsible for transferring power from the engine to the wheels. Understanding how these systems function and their maintenance requirements can significantly enhance the vehicle’s performance and longevity.

Key elements of the transmission and drive system include:

- Transmission Type: Various types of transmissions are available, including automatic and manual, each offering different benefits in terms of control and efficiency.

- Gear Ratio: The gear ratio plays a vital role in determining the torque and speed, affecting overall performance in diverse terrains.

- Drive Shafts: These components transmit power to the wheels and need regular inspection to prevent wear and ensure effective power delivery.

Regular maintenance practices for the transmission and drive system involve:

- Checking fluid levels and conditions to ensure optimal operation.

- Inspecting belts and hoses for signs of wear or damage.

- Periodically changing fluids as recommended by the manufacturer to prolong the life of the system.

By focusing on these areas, owners can ensure that their vehicles operate smoothly and efficiently, maximizing both performance and reliability.

Safety Features and Guidelines

Ensuring safe operation of utility vehicles is crucial for preventing accidents and enhancing user protection. This section highlights essential safety features and provides guidelines for optimal usage.

- Seat Belts: Always wear seat belts while operating the vehicle to reduce the risk of injury during sudden stops or accidents.

- Roll Over Protection: Vehicles are equipped with structures designed to minimize the risk of injury in case of a rollover. Ensure that these systems are intact and functional.

- Visibility Enhancements: Utilize mirrors and lights effectively to maintain visibility in various conditions. Regularly check that all lighting systems are operational.

- Load Management: Adhere to weight limits and distribute loads evenly to maintain stability and control.

- Safety Warnings: Pay attention to warning labels and indicators on the vehicle that inform users about potential hazards.

Following these guidelines not only promotes individual safety but also ensures the longevity and reliability of the vehicle.

Body and Frame Repair Techniques

Maintaining the integrity of a vehicle’s structure is essential for optimal performance and safety. Various techniques can be employed to address issues with the body and frame, ensuring longevity and reliability. Understanding these methods is crucial for anyone looking to enhance their maintenance skills.

Common Issues and Solutions

Body and frame components can experience several common problems. Identifying these issues early can prevent further damage. Here are a few frequent concerns and their corresponding solutions:

- Dents and Scratches: Utilize tools such as a slide hammer or dent puller to restore the original shape.

- Rust and Corrosion: Sand down affected areas and apply a protective coating to prevent further deterioration.

- Frame Twisting: Use a frame machine to realign the structure to its original specifications.

Preventive Measures

Implementing preventive strategies can significantly reduce the likelihood of future repairs. Consider the following practices:

- Regular Inspections: Conduct periodic checks for signs of wear and tear.

- Proper Cleaning: Regularly wash and wax the vehicle to protect against environmental damage.

- Storage Considerations: Keep the vehicle in a sheltered area to minimize exposure to harsh elements.

Fluid Types and Maintenance

Proper fluid management is crucial for the longevity and optimal performance of any utility vehicle. Different fluids serve specific functions, ensuring that all systems operate smoothly and efficiently. Regular maintenance and timely fluid changes can prevent potential issues and enhance the overall lifespan of the machine.

Here are the key fluid types commonly used in utility vehicles and their maintenance requirements:

| Fluid Type | Function | Maintenance Tips |

|---|---|---|

| Engine Oil | Lubricates engine components | Change every 100 hours or as recommended |

| Transmission Fluid | Facilitates gear shifting | Check level regularly; change as specified |

| Coolant | Prevents overheating | Inspect regularly; replace according to schedule |

| Brake Fluid | Ensures effective braking | Top up as needed; change every 2 years |

Adhering to a strict maintenance schedule and using the correct types of fluids will help ensure the vehicle runs smoothly and effectively. Regular checks can help identify any leaks or inconsistencies in fluid levels, enabling timely action to avoid more significant issues.

Parts Replacement and Sourcing

Ensuring the longevity and optimal performance of machinery often involves the timely replacement of components. Identifying reliable sources for these parts is crucial for maintaining operational efficiency and minimizing downtime.

Identifying Quality Components

When seeking replacement parts, it is essential to prioritize quality over cost. Genuine components typically offer better durability and compatibility. Consider sourcing from authorized dealers or reputable aftermarket suppliers to ensure that the parts meet industry standards.

Where to Find Parts

Various channels are available for sourcing components. Online marketplaces, specialized automotive retailers, and local dealerships can provide a wide range of options. It’s advisable to read reviews and check the reliability of the seller before making a purchase.

Upgrades and Modifications

Enhancing the performance and functionality of your utility vehicle can significantly improve its versatility and efficiency. This section explores various enhancements that can be implemented to elevate your driving experience and adapt the vehicle to specific tasks or terrains.

Performance Enhancements

Improving engine performance is a common goal for many owners. Upgrading components such as the air intake system and exhaust can lead to better airflow, resulting in increased horsepower and torque. Additionally, considering a reprogramming of the engine control unit (ECU) can optimize fuel efficiency and responsiveness.

Accessory Additions

Adding accessories can greatly expand the utility of your vehicle. Consider installing a winch for off-road recovery, a cargo bed extender for extra storage, or upgraded lighting systems for improved visibility during nighttime operations. These modifications not only enhance functionality but also contribute to safety and convenience.