Comprehensive Guide to La Pavoni Repairs

In the world of coffee enthusiasts, understanding the intricacies of espresso machines is vital for optimal performance. This guide serves as a comprehensive resource for individuals seeking to enhance their knowledge about maintaining and troubleshooting these beloved appliances. With a focus on effective practices, readers will learn to keep their equipment in peak condition.

Every machine has its nuances, and being aware of these can significantly extend its lifespan. By familiarizing oneself with common issues and their resolutions, users can enjoy the rich flavors of their brews without interruption. This document aims to empower coffee lovers with the information needed to ensure their devices operate smoothly and efficiently.

Knowledge is power, and understanding the care required for such machines is crucial. Whether it’s routine upkeep or addressing unexpected challenges, this guide will provide the insights necessary to navigate any situation confidently. Dive in to explore best practices that will elevate your coffee experience.

La Pavoni Maintenance Tips

Proper care and regular upkeep of your espresso machine are essential for ensuring its longevity and optimal performance. By following a few simple guidelines, you can keep your appliance in top condition, allowing you to enjoy delicious beverages for years to come.

Daily Cleaning Routine

Start each day by performing a quick cleaning routine. This includes rinsing the portafilter and baskets, as well as wiping down the exterior surfaces. Ensuring that no coffee residues remain will prevent buildup and maintain the machine’s appearance.

Periodic Deep Cleaning

In addition to daily maintenance, it’s crucial to conduct a thorough cleaning every few weeks. This should involve descaling the unit to remove mineral deposits and ensuring that all internal components are free from residue. Using appropriate cleaning agents designed for espresso machines will help preserve functionality and taste.

Regular attention to these tasks will enhance the performance and lifespan of your machine, making every cup of coffee a delightful experience.

Common Issues with La Pavoni

Users often encounter various challenges while operating these classic espresso machines. Understanding these frequent complications can lead to better troubleshooting and enhanced performance.

- Inconsistent Brew Temperature: A common complaint is fluctuating water temperature, affecting extraction quality.

- Pressure Problems: Issues with maintaining optimal pressure can lead to under-extraction or over-extraction of coffee.

- Leaks: Water leakage around seals or connections may occur, often requiring careful inspection and maintenance.

- Steam Wand Malfunctions: Difficulty in producing steam can hinder the ability to froth milk properly, impacting drink quality.

Addressing these issues often involves routine checks and simple maintenance practices to ensure a satisfying coffee-making experience.

Essential Tools for Repairs

When it comes to maintaining and restoring coffee brewing equipment, having the right instruments at your disposal is crucial. The proper tools not only facilitate efficient work but also ensure that tasks are carried out safely and effectively. Below is an overview of key items that every enthusiast should consider for their toolkit.

Basic Hand Tools

Having a selection of hand tools can significantly enhance your ability to address various issues. Here are some fundamental items:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For removing and tightening screws in various components. |

| Wrench | To adjust and secure fittings and connections. |

| Plier | For gripping and bending wires or small parts. |

Cleaning Supplies

Keeping your equipment clean is just as important as having the right tools. Here are some essential cleaning supplies:

- Soft Cloths – For gentle wiping without scratching surfaces.

- Brush Set – To reach into tight spaces and remove debris.

- Descaling Solution – For removing mineral buildup in water systems.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues encountered during the operation of your equipment. By following a structured method, you can effectively address problems and ensure optimal performance.

Identifying Common Issues

Start by observing any unusual behavior or performance anomalies. Common signs include inconsistent output, unusual noises, or failure to start. Documenting these symptoms will assist in pinpointing the source of the problem.

Systematic Approach to Solutions

Once you have noted the symptoms, follow a logical sequence of checks. Begin with power supply verification, followed by examining connections and components. Regular maintenance and careful inspection are key to preventing future malfunctions.

Cleaning and Care Instructions

Proper maintenance of your brewing equipment is essential to ensure optimal performance and longevity. Regular cleaning and careful handling will not only enhance the flavor of your beverages but also prolong the life of your device.

Daily Maintenance

After each use, follow these steps to keep your appliance in top condition:

- Rinse all removable parts with warm water.

- Wipe the exterior with a soft cloth to remove any spills or stains.

- Check for any coffee residues and clean accordingly.

Deep Cleaning Schedule

In addition to daily care, periodic deep cleaning is recommended. This helps to prevent the buildup of oils and minerals:

| Frequency | Task |

|---|---|

| Weekly | Soak and clean all detachable parts in warm, soapy water. |

| Monthly | Run a cleaning solution through the machine to eliminate any residues. |

By following these guidelines, you can ensure that your equipment remains in excellent working condition, providing you with delightful beverages for years to come.

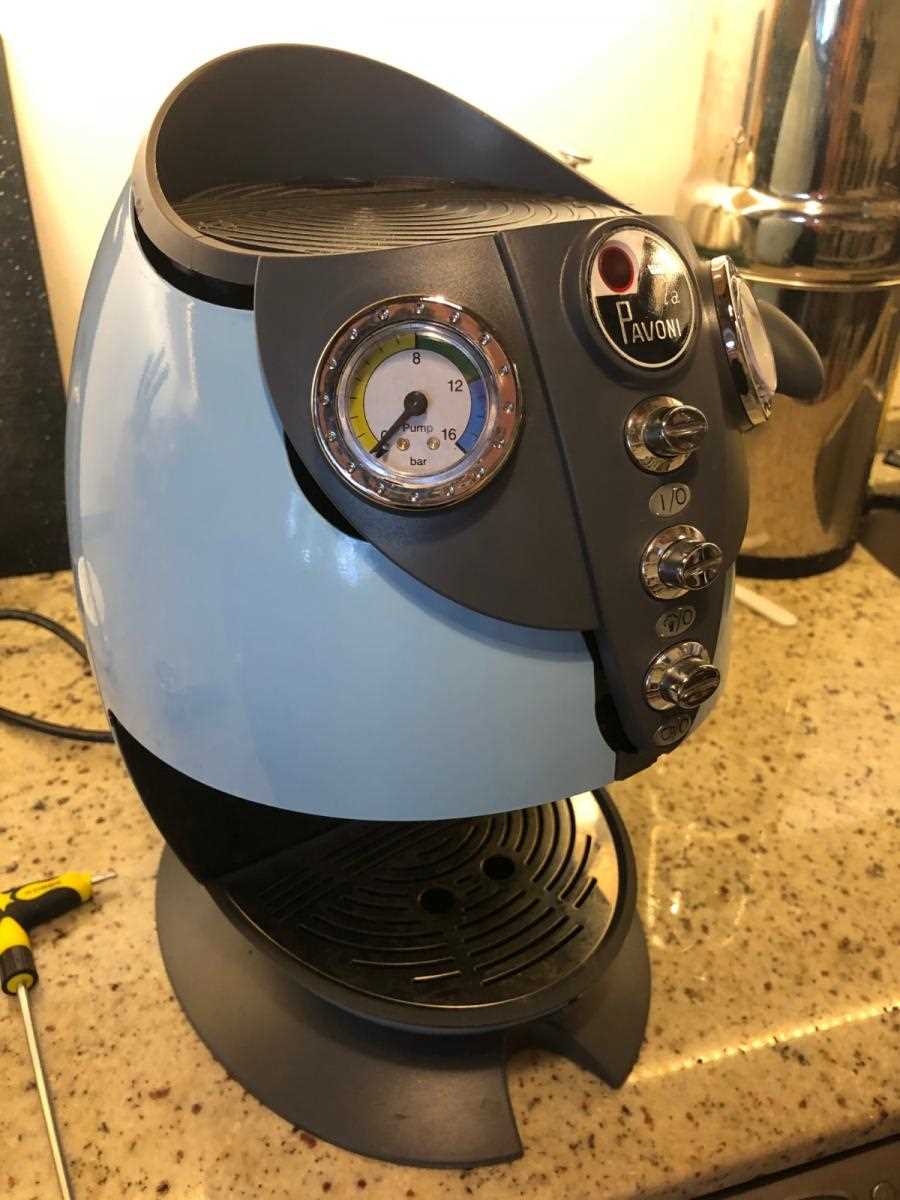

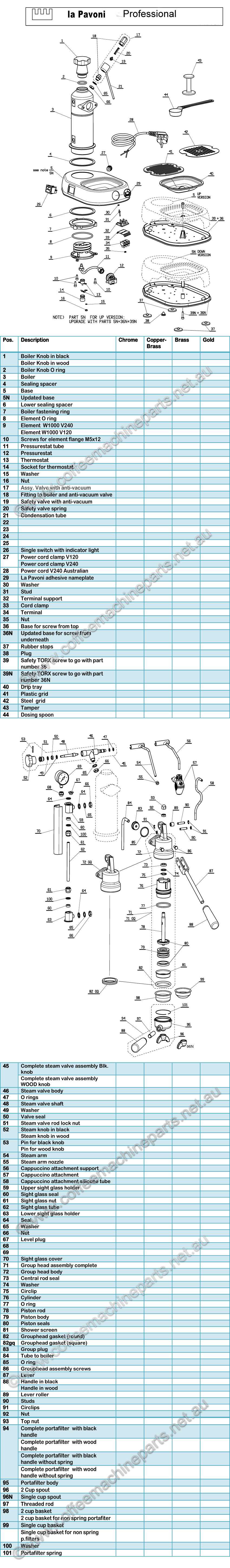

Understanding the Machine Components

The intricacies of any brewing apparatus can often be overwhelming, yet familiarizing oneself with its parts is essential for optimal functionality. Each element plays a crucial role in the overall performance and efficiency of the system, ensuring that the desired outcomes are achieved consistently.

Main Elements

Key components include the heating unit, which generates the necessary temperature for extraction, and the pressure mechanism, responsible for delivering water at the correct force. Additionally, the water reservoir is vital for holding the liquid needed for the brewing process.

Understanding how these parts interact is crucial. The heating unit activates when the machine is powered on, while the pressure system operates in tandem, allowing for an even flow of water. Regular maintenance of these components can significantly enhance longevity and performance.

How to Replace Key Parts

Replacing essential components in a device can significantly enhance its performance and longevity. Understanding the process involved is crucial for successful execution. This section provides guidance on the steps to follow when substituting critical elements.

Before beginning, ensure you have the necessary tools and replacement parts ready. Here are the common components that might need replacement:

| Part | Signs of Wear | Replacement Steps |

|---|---|---|

| Sealing Ring | Leaking fluids |

|

| Heating Element | Inconsistent heating |

|

| Pressure Gauge | Reading inaccuracies |

|

By following these steps, you can effectively replace the critical components and restore optimal functionality. Always consult specific guidelines for your device for the best results.

Safety Precautions During Repairs

Ensuring a safe environment during maintenance tasks is crucial for both the individual performing the work and the equipment itself. Adopting proper safety measures minimizes risks and enhances the effectiveness of the process.

Before commencing any service activities, it is important to familiarize oneself with potential hazards associated with the device. The following table outlines essential safety tips:

| Precaution | Description |

|---|---|

| Disconnect Power | Always unplug the device before starting any work to avoid electric shocks. |

| Use Protective Gear | Wear safety glasses and gloves to protect against any debris or sharp edges. |

| Work in a Ventilated Area | Ensure adequate ventilation to prevent inhalation of fumes or dust generated during maintenance. |

| Keep Workspace Organized | A tidy work area reduces the risk of accidents and helps in locating tools easily. |

| Follow Instructions | Adhere to guidelines provided in any reference materials to avoid errors. |

Adjusting Pressure Settings

Fine-tuning the pressure levels of your espresso machine is crucial for achieving the perfect extraction. Proper adjustments can enhance flavor profiles and ensure optimal performance. This section outlines the steps necessary to modify these settings effectively.

First, identify the recommended pressure range for your specific device. Typically, this is between 8 to 10 bars during extraction. To begin the adjustment, locate the pressure gauge and observe the current readings while the machine is in operation.

Next, if the pressure is too high, you may need to reduce it. This can often be achieved by manipulating the pressure release valve or adjusting the pump settings, depending on the machine’s design. Conversely, if the pressure is too low, increasing it may involve adjusting the input valve or ensuring that all components are functioning correctly.

After making any adjustments, perform a test run to monitor the new pressure readings. It’s essential to observe how these changes affect the extraction process and the final taste of the beverage. Regular maintenance and periodic checks will help maintain consistent performance and flavor quality.

Frequently Asked Questions

This section addresses common inquiries regarding maintenance and troubleshooting of espresso machines. Here, users can find valuable insights and guidance to enhance their experience and ensure optimal performance.

What should I do if my machine is not brewing?

Several factors could contribute to this issue. First, check if the water reservoir is filled and properly seated. Additionally, ensure that the coffee grounds are not too fine, which can clog the filter.

How can I improve the quality of my espresso?

To achieve a richer flavor, consider using freshly ground beans and adjusting the grind size. Experimenting with the water temperature and extraction time can also yield better results.

What maintenance steps should I follow regularly?

Regular cleaning is essential. Ensure that you clean the brew group, water reservoir, and any detachable parts after each use. Additionally, consider descaling your machine every few months to prevent mineral buildup.

Expert Recommendations for Longevity

Ensuring the durability and optimal performance of your equipment requires thoughtful maintenance and care. Adopting certain practices can significantly extend its lifespan and enhance its functionality.

- Regular Cleaning: Frequent cleaning of all components prevents the buildup of residue and ensures smooth operation.

- Proper Calibration: Regular adjustments help maintain the accuracy of performance, leading to better results.

- Routine Inspections: Regular checks for wear and tear allow for early detection of issues, preventing larger problems.

- Use Quality Ingredients: Utilizing high-quality materials during operation reduces strain on the system and promotes longevity.

- Store Safely: Proper storage in a controlled environment protects against damage from external factors.

By implementing these strategies, users can enjoy a reliable and efficient experience for many years to come.