Essential Guide to LG Fridge Repair Manual

When it comes to ensuring the longevity and efficiency of your household cooling unit, having a solid understanding of its operation is crucial. This guide aims to provide you with essential insights and troubleshooting techniques that can help you manage your appliance effectively. By familiarizing yourself with its components and common issues, you can take proactive steps toward maintaining optimal performance.

Understanding the intricacies of your cooling device can save you time and money. From basic upkeep to identifying more complex problems, this resource offers a wealth of information tailored specifically for LG models. Embracing these guidelines will empower you to tackle challenges head-on, fostering a smoother experience in your daily life.

Whether you’re dealing with minor hiccups or seeking to enhance the efficiency of your appliance, this guide serves as a comprehensive tool. It will equip you with practical knowledge, allowing you to navigate various situations with confidence. By staying informed, you can ensure that your unit continues to operate seamlessly for years to come.

Understanding Common LG Fridge Issues

When it comes to household appliances, certain challenges can frequently arise, causing inconvenience and concern. Recognizing these common problems can help in addressing them efficiently and ensuring your device functions optimally. This section delves into typical complications that users may encounter, offering insights to facilitate resolution.

Temperature Fluctuations

One prevalent issue is irregular temperature control. This can result in food spoilage or freezing, disrupting daily routines. Factors contributing to this problem may include faulty thermostats, blocked vents, or even improper door sealing. Identifying the root cause is crucial for maintaining consistent conditions within the unit.

Noisy Operation

Another concern is excessive noise during operation, which can be unsettling. Common sources of sound include compressor vibrations, fan malfunctions, or debris accumulation within the appliance. Understanding these origins can aid in implementing effective solutions, restoring peace in your kitchen.

Essential Tools for Refrigerator Repair

When it comes to maintaining and fixing household cooling appliances, having the right equipment is crucial. A well-equipped toolkit not only streamlines the process but also enhances safety and efficiency. Whether addressing minor issues or more significant challenges, understanding the necessary instruments can make a significant difference.

Basic Hand Tools: Every technician should start with a set of essential hand tools. This includes screwdrivers, both flathead and Phillips, which are vital for accessing various components. Pliers, wrenches, and a utility knife also play important roles in disassembling parts and making adjustments.

Multimeter: A multimeter is indispensable for diagnosing electrical issues. It allows users to measure voltage, current, and resistance, providing insights into the appliance’s functionality and helping to identify faults.

Thermometer: An accurate thermometer is essential for monitoring temperature levels. It helps ensure that the cooling unit is operating within the recommended range, which is critical for optimal performance.

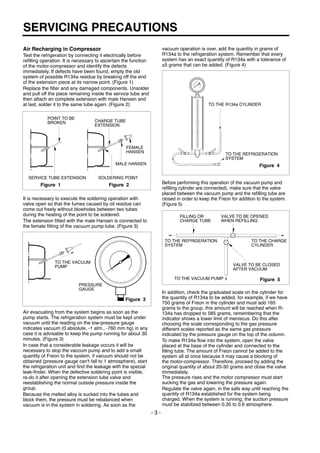

Vacuum Pump: For those dealing with refrigerant systems, a vacuum pump is necessary to remove moisture and air from the lines. This step is vital before recharging the system to prevent potential damage.

Manifold Gauge Set: A manifold gauge set is crucial for working with refrigerants. It helps in checking pressure levels and ensures the system is properly charged, which is essential for effective operation.

Safety Gear: Safety should always come first. Protective gloves, goggles, and masks are necessary to safeguard against potential hazards while handling refrigerants and sharp components.

Equipped with these essential tools, anyone can approach the challenges of maintaining cooling appliances with confidence and skill. Proper preparation not only improves the likelihood of success but also enhances the overall experience.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identifying and resolving common issues that may arise with your cooling appliance. By following these steps, you can efficiently diagnose problems and implement solutions to restore optimal functionality.

Identifying the Problem

Begin by observing the unit for any unusual signs. Check for unusual noises, inconsistent temperatures, or error messages on the display. Make a note of any specific symptoms to narrow down potential causes.

Basic Checks and Solutions

Start with fundamental checks: ensure that the device is plugged in and the power source is functioning. Inspect the door seals for proper closure and clean the condenser coils to enhance efficiency. If issues persist, consult the troubleshooting chart for specific error codes or symptoms, and follow the corresponding solutions.

In some cases, resetting the appliance can resolve temporary glitches. Simply unplug the unit for a few minutes and then reconnect it to see if the issue has been alleviated.

Identifying Cooling Problems in LG Fridges

Understanding the signs of inadequate cooling can help address issues early, ensuring optimal performance of your appliance. Identifying these problems involves a systematic approach, paying attention to both temperature inconsistencies and unusual noises.

Common Symptoms

- Food spoilage or frost buildup

- Inconsistent internal temperatures

- Unusual sounds like buzzing or clicking

Steps to Diagnose Issues

- Check the thermostat settings for accuracy.

- Inspect door seals for proper closure.

- Examine the condenser coils for dust and debris.

Repairing Ice Maker Malfunctions

Ice production issues can be frustrating, leading to inconvenience in daily life. Understanding the common problems and their potential solutions is essential for restoring functionality. This section outlines key troubleshooting steps and remedies for typical ice maker difficulties.

Common Issues and Symptoms

- No ice production

- Ice cubes are too small or irregular

- Ice is stuck or jams in the bin

- Water leaks around the unit

Troubleshooting Steps

- Check the water supply line for kinks or blockages.

- Inspect the ice maker’s on/off switch to ensure it’s activated.

- Examine the temperature settings; they should be appropriate for ice formation.

- Clear any ice jams in the ejector arm and ice bin.

- Test the water filter; replacing it may resolve flow issues.

By following these steps, you can identify and address many common ice maker issues effectively.

Fixing Door Seal Issues Effectively

Ensuring an airtight closure is crucial for maintaining optimal performance in any cooling appliance. Problems with the door seal can lead to energy loss and temperature fluctuations. This section outlines effective strategies to address common seal-related issues, enhancing efficiency and preserving food quality.

Identifying Common Problems

- Visible cracks or tears in the seal

- Misalignment of the door

- Loss of elasticity over time

- Accumulation of dirt or debris

Steps for Effective Resolution

- Inspect the Seal: Examine the entire perimeter for any signs of wear or damage.

- Clean the Seal: Use a mild detergent and warm water to remove any dirt or buildup that may affect the seal’s function.

- Adjust the Door Alignment: Check hinges and adjust screws as necessary to ensure the door closes properly.

- Replace if Necessary: If the seal is severely damaged, consider replacing it with a new, compatible seal.

By proactively addressing these issues, one can ensure the longevity and efficiency of the cooling unit.

Cleaning Condenser Coils for Efficiency

Maintaining optimal performance in cooling appliances is crucial for energy efficiency and longevity. One key aspect of this maintenance is the regular cleaning of the condenser coils. Dust and debris can accumulate on these components, leading to reduced efficiency and increased energy consumption. By keeping them clean, you ensure your unit operates smoothly and effectively.

Why Clean Condenser Coils?

Understanding the importance of cleaning these coils can help prevent potential issues:

- Improves energy efficiency

- Reduces operational costs

- Extends the lifespan of the appliance

- Enhances cooling performance

Steps for Effective Cleaning

Follow these simple steps to clean your coils properly:

- Unplug the appliance to ensure safety.

- Locate the condenser coils, typically found at the back or bottom.

- Use a vacuum cleaner with a brush attachment to remove loose dirt.

- For stubborn debris, gently wipe the coils with a damp cloth.

- Reassemble any removed panels and plug the unit back in.

Regular maintenance of the condenser coils will lead to better performance and energy savings in the long run.

Replacing Faulty Thermostats Safely

Ensuring optimal temperature control is crucial for efficient appliance performance. When a temperature regulation device becomes defective, it can lead to improper functioning, causing potential issues. This section outlines safe procedures for replacing these essential components, ensuring a seamless and secure process.

Before beginning the replacement process, it is essential to gather the necessary tools and materials. Here’s a quick checklist:

| Tool/Material | Description |

|---|---|

| Screwdriver | To remove screws securing the panel. |

| Replacement Thermostat | Ensure compatibility with your device. |

| Multimeter | For testing electrical continuity. |

| Insulated Gloves | To protect against electric shock. |

Start by disconnecting the appliance from the power source to eliminate any risk of electrical shock. Carefully remove the access panel to locate the malfunctioning component. It’s important to take note of the wiring connections; labeling them can simplify reinstallation.

Once the defective device is identified, detach it from its housing and disconnect the wiring. Use the multimeter to verify that the power is off before proceeding. Install the new device by connecting the wires as per your earlier notes, ensuring secure connections to prevent future issues.

After installation, reassemble the access panel and reconnect the appliance to the power source. Monitor the temperature settings to confirm that the new device operates correctly. This careful approach will not only enhance performance but also extend the lifespan of your appliance.

Understanding Error Codes on LG Models

Error codes serve as vital indicators for diagnosing issues in various appliances. They simplify the process of identifying malfunctions by providing specific numeric or alphanumeric signals. Recognizing these codes can lead to quicker resolutions and enhance the overall performance of the unit.

Each model from LG is equipped with its unique set of error indicators, reflecting different operational challenges. Familiarity with these codes empowers users to take informed actions, whether it’s adjusting settings or seeking professional assistance. Typically, a user manual or online resources can offer detailed explanations for each code, enabling a clearer understanding of potential problems.

Common codes often relate to temperature discrepancies, door sensor failures, or compressor malfunctions. For instance, codes indicating high or low temperatures might suggest issues with the cooling system, while others may signal electrical faults. By paying attention to these indicators, one can maintain optimal functionality and extend the lifespan of the appliance.

In conclusion, being aware of error codes not only facilitates timely interventions but also fosters a deeper connection with the appliance. Understanding these signals can transform a potentially frustrating experience into a manageable one, ensuring that any disruptions are addressed promptly and effectively.

Preventive Maintenance Tips for Longevity

Ensuring the prolonged functionality of your cooling appliance requires a proactive approach to maintenance. By adopting simple yet effective practices, you can enhance performance, reduce energy consumption, and extend the lifespan of your unit.

Regular Cleaning: Keep the exterior and interior surfaces clean. Dust and debris can hinder airflow and efficiency. Wipe down shelves and compartments regularly, and don’t forget to clean the door seals to prevent leaks.

Check Temperature Settings: Maintain optimal temperature settings. The ideal range is usually between 37°F (3°C) and 40°F (4°C). Regularly monitor these settings to ensure they remain consistent.

Inspect Condenser Coils: Periodically check the condenser coils located at the back or underneath the unit. Cleaning them of dust and dirt can significantly improve energy efficiency and cooling performance.

Ensure Proper Ventilation: Make sure there is adequate space around your appliance for air circulation. A cramped environment can lead to overheating and reduced efficiency.

Monitor Noise Levels: Pay attention to any unusual sounds. Odd noises can be early indicators of potential issues. Addressing these promptly can prevent more significant problems down the line.

Schedule Professional Servicing: Consider arranging routine inspections by a qualified technician. Professional servicing can identify potential issues before they escalate, ensuring your unit remains in optimal condition.