Comprehensive Guide to Ltz 400 Repair Manual

Owning a high-performance vehicle requires not only an understanding of its features but also the ability to maintain and troubleshoot its systems effectively. A well-crafted resource can serve as a vital companion for enthusiasts and operators alike, providing essential insights into preserving optimal functionality.

With a focus on practical advice and technical specifications, this guide aims to empower users to tackle common issues and perform necessary upkeep. By breaking down complex processes into manageable steps, individuals can confidently engage with their machinery, ensuring longevity and peak performance.

Whether you are addressing minor repairs or conducting routine inspections, the right information is crucial. This comprehensive resource will delve into various aspects of maintenance, offering clarity and support to enhance your experience and proficiency with your vehicle.

Understanding the Ltz 400 Design

The design of this all-terrain vehicle embodies a harmonious blend of functionality and aesthetic appeal. Engineers have meticulously crafted each component to enhance performance while ensuring user comfort and safety. A thorough examination reveals several key aspects that contribute to its overall effectiveness in various environments.

- Frame Structure: The chassis is built from robust materials, providing durability and stability. Its lightweight nature ensures agility while maintaining strength.

- Suspension System: The advanced suspension setup is designed to absorb shocks and provide a smooth ride, crucial for off-road conditions.

- Engine Configuration: A powerful engine with an efficient layout enables impressive acceleration and torque, allowing for versatile terrain navigation.

- Control Mechanisms: Intuitive controls enhance maneuverability, ensuring riders can react swiftly to changing conditions.

- Ergonomic Design: The seating and handlebars are positioned for comfort, reducing fatigue during extended use.

Each of these elements plays a vital role in the vehicle’s capability, making it a reliable choice for enthusiasts and professionals alike. Understanding the intricacies of its design can greatly enhance the user experience, allowing individuals to maximize the potential of this versatile machine.

Common Issues in Ltz 400 Models

Understanding the frequent challenges that arise in specific off-road vehicles can significantly enhance maintenance and longevity. Owners often encounter a variety of performance and mechanical difficulties that may require attention. This section explores some of the most prevalent problems associated with these models, providing insights into their resolution and prevention.

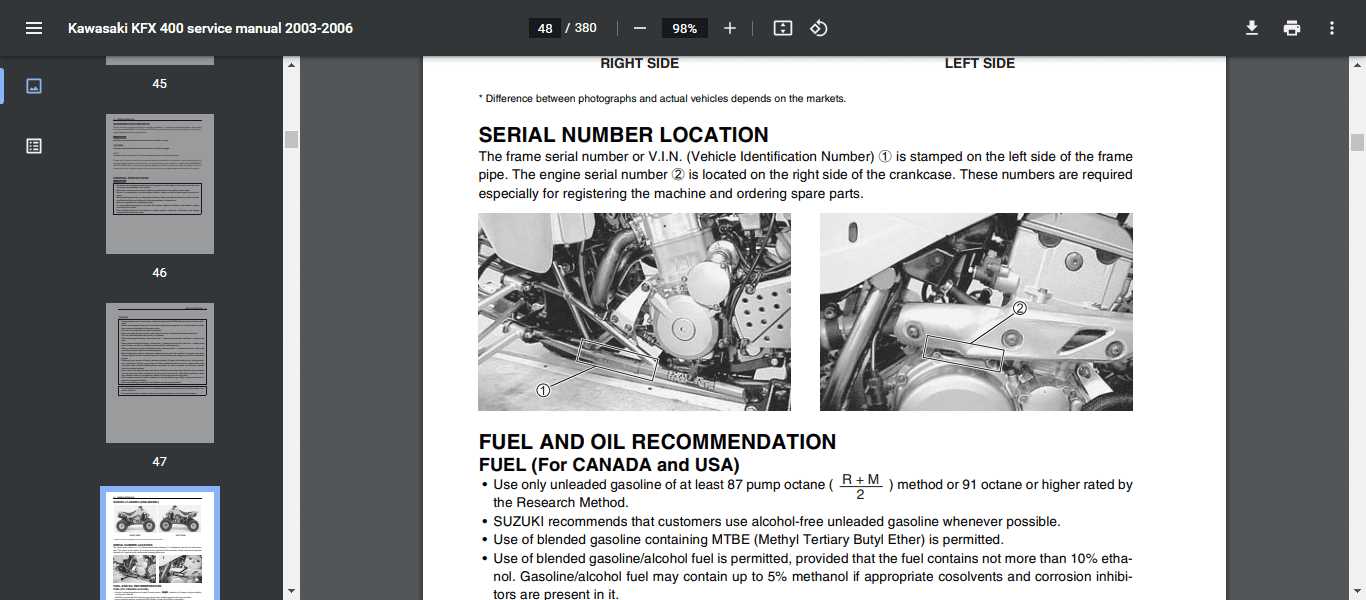

Electrical System Failures

One of the most common concerns relates to electrical components, which can lead to starting issues or inconsistent power delivery. Problems often stem from wiring harness faults, corroded connectors, or battery malfunctions. Regular inspection and maintenance of the electrical system can mitigate these issues.

Engine Performance Issues

Engine-related problems can manifest in several ways, including poor acceleration, unusual noises, or stalling. These symptoms are frequently linked to fuel system blockages, air filter obstructions, or ignition failures. Timely diagnosis and repairs are essential to maintain optimal performance.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Electrical Failures | Starting issues, flickering lights | Inspect wiring, replace corroded connectors |

| Engine Problems | Poor acceleration, stalling | Clean fuel system, check ignition components |

| Suspension Wear | Unstable handling, excessive noise | Inspect and replace worn parts |

Essential Tools for Repairs

Having the right instruments at your disposal is crucial for efficient maintenance and troubleshooting. A well-equipped workspace not only enhances productivity but also ensures safety and precision during each task. Below is a list of indispensable tools that every enthusiast should consider for successful interventions.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening various fasteners. |

| Wrenches | Essential for gripping and turning nuts and bolts. |

| Screwdrivers | Used for driving screws; both flat-head and Phillips types are recommended. |

| Plier Set | Useful for gripping, bending, and cutting wires or other materials. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Multimeter | For measuring voltage, current, and resistance; vital for electrical diagnostics. |

| Jack and Stands | For lifting and securing heavy components safely. |

| Work Light | Illuminates the workspace, allowing for better visibility in tight areas. |

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle. This section outlines a series of systematic tasks designed to keep your machine in peak condition. Following these procedures diligently will not only enhance functionality but also prevent potential issues down the line.

Routine Checks

Implementing regular inspections can identify wear and tear before it becomes problematic. Below is a checklist to guide you through these essential evaluations:

| Task | Frequency | Notes |

|---|---|---|

| Oil Level Check | Every 50 hours | Ensure proper lubrication to avoid engine damage. |

| Air Filter Inspection | Every 100 hours | Clean or replace as needed to maintain airflow. |

| Tire Pressure Check | Before each use | Maintain recommended pressure for safety and performance. |

Seasonal Maintenance

In addition to routine checks, seasonal care is vital. The following steps should be taken at least twice a year:

| Task | Frequency | Notes |

|---|---|---|

| Battery Condition Assessment | Every 6 months | Clean terminals and check for corrosion. |

| Fluid Replacement | Annually | Replace coolant, brake fluid, and hydraulic fluid. |

| Inspection of Belts and Hoses | Every 6 months | Look for cracks or wear to prevent failures. |

Electrical System Troubleshooting Guide

This section provides a comprehensive approach to diagnosing and resolving issues related to the electrical components of your vehicle. Understanding the intricacies of the electrical system is essential for efficient performance and reliability. By following systematic steps, you can identify problems and implement effective solutions.

Common Electrical Issues

Several common challenges may arise within the electrical framework. These can include:

- Battery Failure: Symptoms may involve difficulty starting the engine or dimming lights.

- Wiring Problems: Damaged or corroded wires can lead to intermittent failures or complete loss of power.

- Faulty Connectors: Loose or oxidized connections can cause erratic behavior in electrical components.

Troubleshooting Steps

To effectively troubleshoot electrical issues, follow these steps:

- Visual Inspection: Begin by examining all visible wiring and connectors for signs of wear or damage.

- Battery Check: Measure the battery voltage to ensure it is within the normal range.

- Use of Diagnostic Tools: Employ multimeters or test lights to assess voltage and continuity throughout the system.

- Component Testing: Isolate and test individual components, such as relays and fuses, to confirm their functionality.

By diligently applying these techniques, you can restore the integrity of the electrical system and enhance the overall performance of your vehicle.

Engine Performance Enhancements

Improving the efficiency and power of your engine can significantly enhance overall vehicle performance. By implementing a range of modifications and upgrades, enthusiasts can achieve greater throttle response, increased horsepower, and improved fuel efficiency. This section will explore various strategies for boosting engine capabilities effectively.

Optimizing Airflow

One of the most crucial aspects of engine performance is ensuring optimal airflow. Upgrading the intake system can facilitate better air entry, allowing for a more efficient combustion process. Additionally, a performance exhaust system can reduce back pressure, enabling exhaust gases to exit more freely. Together, these enhancements can lead to noticeable improvements in power and responsiveness.

Tuning and Engine Management

Another vital factor in maximizing engine potential is proper tuning. Utilizing advanced engine management systems can optimize fuel delivery and ignition timing, tailoring performance to specific driving conditions. Fine-tuning these parameters not only boosts power output but also enhances fuel efficiency, providing a well-rounded driving experience. Implementing these modifications with precision is essential for achieving the desired results.

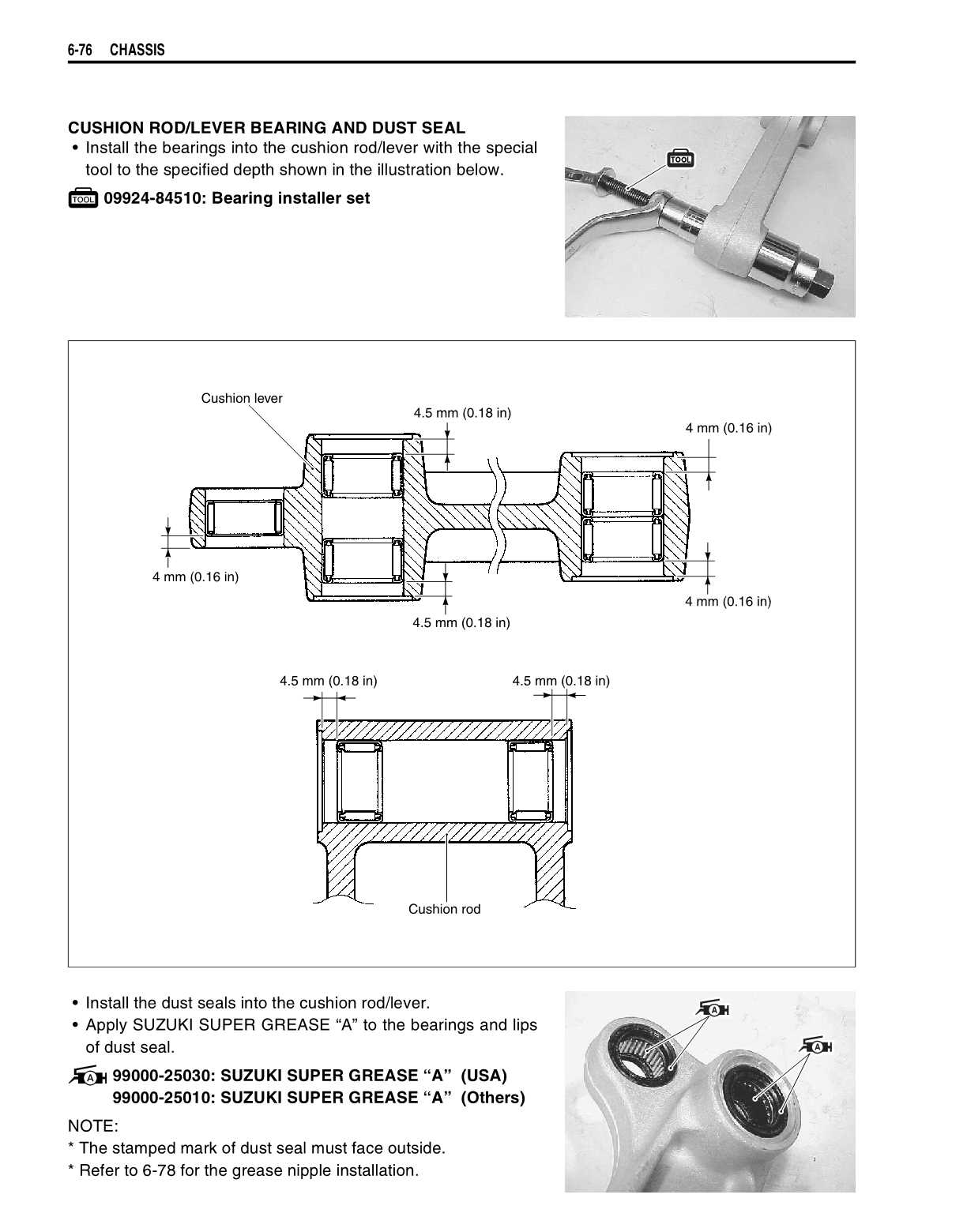

Suspension System Overview

The suspension system plays a crucial role in enhancing the vehicle’s performance and ensuring a comfortable ride. It serves as the connection between the vehicle’s body and its wheels, allowing for better handling and stability. A well-designed system minimizes the impact of road irregularities while providing necessary support for various driving conditions.

Key functions of the suspension system include:

- Maintaining tire contact with the road surface.

- Absorbing shocks from bumps and uneven terrain.

- Improving vehicle handling and stability.

- Enhancing overall passenger comfort.

The suspension system is typically composed of several components, each serving a specific purpose:

- Springs: These absorb and store energy from road impacts.

- Dampers: Also known as shock absorbers, they control the rebound and compression of the springs.

- Control arms: These link the vehicle’s chassis to the wheels, allowing for controlled movement.

- Sway bars: These reduce body roll during cornering, improving stability.

Understanding the intricacies of the suspension system is vital for maintaining optimal performance and safety. Regular inspections and timely replacements of worn components are essential for ensuring that the vehicle remains responsive and comfortable during operation.

Transmission and Gearbox Care Tips

Maintaining the performance and longevity of your vehicle’s transmission and gearbox is essential for smooth operation and efficiency. Regular care not only enhances driving experience but also prevents costly repairs. Understanding the best practices for upkeep can make a significant difference in the overall functionality of your machine.

Regular Fluid Checks

One of the most crucial aspects of gearbox maintenance is ensuring that the fluid levels are adequate. Regularly check for leaks and monitor the condition of the transmission fluid. If the fluid appears dark or has a burnt smell, it may need to be replaced. Maintaining the correct fluid level helps in reducing friction and ensuring optimal performance.

Scheduled Inspections

Conducting periodic inspections is vital for identifying potential issues before they escalate. Listen for unusual noises and pay attention to shifting patterns. Any signs of slippage or rough shifting should prompt a thorough examination. Additionally, following the manufacturer’s recommendations for service intervals will help keep the system in top shape.

Safety Precautions During Repairs

Ensuring a safe environment while conducting maintenance activities is essential for preventing accidents and injuries. Proper precautions help create a secure workspace, allowing individuals to focus on their tasks without unnecessary risks. This section outlines vital safety measures that should be observed during any technical interventions.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is crucial. Always wear safety goggles to shield your eyes from debris and chemicals. Gloves should be used to protect your hands from sharp objects and hazardous materials. Additionally, steel-toed boots provide foot protection, while earplugs can help mitigate noise exposure during loud operations.

Workspace Organization

Maintaining an organized workspace minimizes the likelihood of accidents. Keep tools and materials neatly arranged to avoid tripping hazards. Ensure that all equipment is functioning correctly before use, and avoid overcrowding the area. A clutter-free environment promotes efficiency and safety, allowing for easier movement and less chance of mishaps.

Where to Find Replacement Parts

Finding the right components for your vehicle can be a challenging task, but there are numerous resources available to assist you. Whether you are looking for OEM parts or high-quality aftermarket options, knowing where to search can save you time and money.

Here are some reliable sources to consider when seeking out parts:

| Source | Description |

|---|---|

| Authorized Dealers | Official dealerships offer genuine parts that meet manufacturer specifications. |

| Online Marketplaces | Websites like eBay and Amazon provide a wide selection of both new and used components. |

| Specialty Shops | Local shops often carry a variety of parts and may offer expert advice on installation. |

| Salvage Yards | These facilities can be a treasure trove of affordable components from older models. |

| Forums and Community Groups | Online communities often have members selling or trading parts, along with recommendations for reliable sources. |

By exploring these options, you can find the necessary components to keep your machine in top condition.