Massey Ferguson 1533 Comprehensive Repair Guide

Maintaining heavy machinery is essential for ensuring optimal performance and longevity. Proper upkeep not only minimizes the risk of unexpected breakdowns but also enhances efficiency during operation. This section aims to provide comprehensive guidance for operators seeking to understand the intricacies of their equipment.

Detailed insights into troubleshooting, routine servicing, and component replacement are vital for keeping machinery running smoothly. Familiarity with these processes can empower operators to tackle common issues and perform necessary tasks with confidence.

By following a structured approach to maintenance, users can significantly reduce downtime and increase productivity. Understanding the fundamentals of equipment care will ultimately lead to more effective management of resources and improved operational outcomes.

Massey Ferguson 1533 Overview

This section provides a comprehensive look at a compact utility machine designed for various agricultural tasks. Known for its efficiency and reliability, this model is particularly favored by small to medium-sized farm operators. Its robust construction and versatile features make it an essential asset for both farming and landscaping activities.

The equipment is equipped with a powerful engine that delivers exceptional performance while ensuring fuel efficiency. With various attachments and implements available, it can tackle a wide range of jobs, from plowing and tilling to mowing and hauling. This adaptability enhances productivity, making it suitable for diverse tasks across different terrains.

Additionally, the intuitive controls and ergonomic design allow for ease of operation, reducing operator fatigue during extended use. Maintenance requirements are straightforward, enabling owners to keep the machine in optimal working condition with minimal effort. This combination of functionality and user-friendly features solidifies its position as a preferred choice in the agricultural community.

Common Issues and Solutions

In the world of agricultural machinery, several frequent challenges can arise, impacting performance and efficiency. Addressing these issues promptly is crucial to ensure smooth operation and prolong the lifespan of the equipment. Below are some of the most commonly encountered problems along with effective solutions.

Overheating Problems

One prevalent concern is overheating, which can lead to severe engine damage. This issue often stems from insufficient coolant levels or a malfunctioning radiator. Regularly checking the coolant and ensuring proper circulation can help prevent this situation. If overheating persists, it may be necessary to inspect the thermostat or water pump for potential faults.

Starting Difficulties

Another common issue is difficulty in starting the engine, which can be attributed to various factors such as a weak battery or faulty ignition components. To resolve this, ensure the battery is fully charged and connections are clean and secure. Additionally, examining the starter motor and ignition system can help identify any underlying problems that may hinder starting.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan of agricultural machinery. Implementing a structured maintenance routine not only enhances performance but also prevents costly repairs and downtime. By focusing on key aspects of care, operators can significantly improve the reliability and efficiency of their equipment.

Routine Inspections

Conducting periodic checks is vital for identifying potential issues before they escalate. Regularly examine critical components such as the engine, hydraulic system, and electrical connections. Look for signs of wear or leaks, and address them promptly. This proactive approach helps maintain optimal functionality and reduces the risk of unexpected failures.

Proper Lubrication

Ensuring all moving parts are adequately lubricated is crucial for minimizing friction and wear. Utilize the recommended oils and greases, and adhere to the specified intervals for application. Consistent lubrication not only enhances performance but also contributes to the longevity of various components, ultimately leading to smoother operation.

Engine Specifications and Features

This section delves into the vital characteristics and functionalities of the power unit that drives the machinery. Understanding these aspects is essential for optimal performance and maintenance, ensuring that the equipment operates efficiently in various conditions.

Technical Overview

The engine typically boasts a robust design, providing ample torque and horsepower. It is equipped with advanced features such as direct fuel injection, which enhances combustion efficiency, leading to reduced emissions and better fuel economy. Additionally, the cooling system plays a crucial role in maintaining optimal operating temperatures, ensuring longevity and reliability during demanding tasks.

Performance Highlights

One of the standout features includes an innovative air intake system that maximizes airflow, improving overall engine responsiveness. Coupled with a high-capacity oil filtration system, these components work together to prolong engine life and minimize maintenance intervals. The integration of electronic control systems further optimizes power delivery, allowing for seamless operation across various terrains.

Hydraulic System Troubleshooting

Troubleshooting hydraulic systems is essential for maintaining optimal performance and efficiency. Identifying issues early can prevent further complications and costly repairs. This section outlines common problems, their symptoms, and potential solutions to ensure smooth operation.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Fluid Leakage | Puddles under the machine, low fluid levels | Inspect hoses and connections; replace damaged components |

| Unresponsive Controls | Slow or no movement of attachments | Check fluid levels; examine control valves for blockages |

| Overheating | Excessive heat from the reservoir, reduced efficiency | Ensure proper fluid levels; clean or replace filters |

| Noisy Operation | Excessive noise during operation | Check for air in the system; inspect for worn components |

| Inconsistent Performance | Fluctuating speed or power | Examine fluid quality; replace old or contaminated fluid |

Regular maintenance and prompt attention to these issues can greatly enhance the lifespan of the hydraulic system and ensure reliable functionality. Always refer to specific guidelines for thorough diagnostics and repairs.

Electrical System Basics

The electrical system of agricultural machinery plays a crucial role in ensuring efficient operation and functionality. Understanding the core components and their interactions can significantly enhance maintenance and troubleshooting efforts. This section will explore the essential elements that constitute the electrical setup in such equipment.

Power Supply: At the heart of the electrical framework lies the power supply unit, which converts energy from the battery into usable voltage for various systems. This component is vital for starting the engine and powering electrical accessories.

Wiring Harness: The wiring harness serves as the nervous system of the equipment, connecting all electrical components. It is designed to withstand harsh conditions while ensuring reliable transmission of electricity throughout the machinery.

Control Modules: These electronic control units manage various functions, including engine performance, lighting, and safety features. They process input from sensors and relay commands to actuators, maintaining optimal operation.

Lighting and Indicators: Proper illumination and indicator systems enhance visibility and safety. These components not only assist during operation but also provide critical information about the machinery’s status.

By gaining a deeper understanding of these fundamental aspects, operators can improve their ability to diagnose issues and perform necessary interventions effectively.

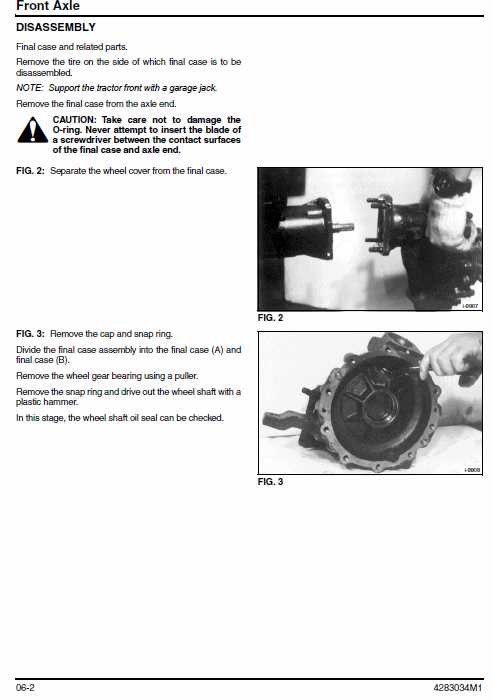

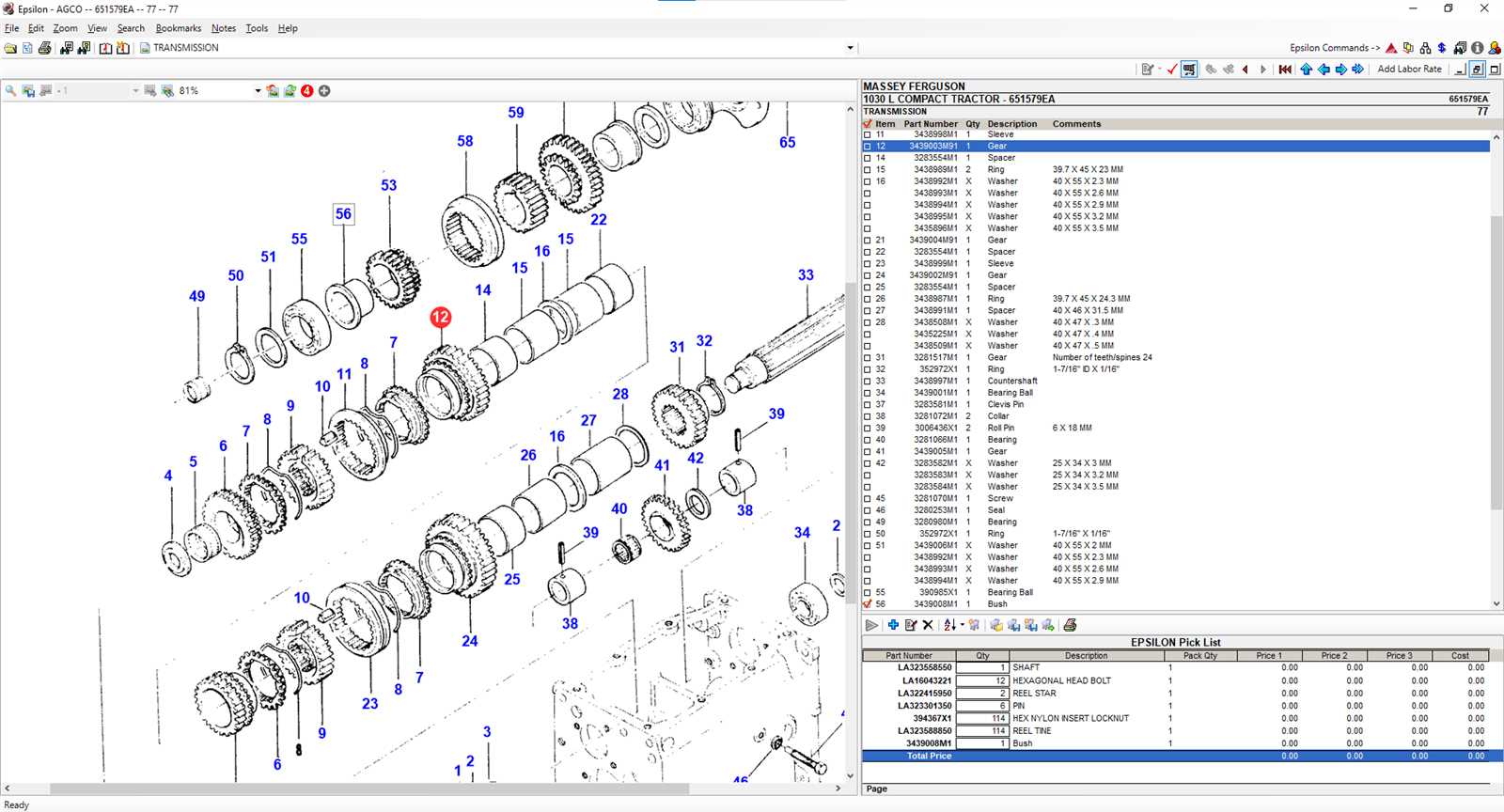

Replacing Worn-Out Parts

Maintaining the functionality of agricultural machinery requires attention to the condition of its components. Over time, various elements may experience wear and tear, leading to decreased performance and potential malfunctions. Identifying and replacing these worn parts is essential for ensuring optimal operation and longevity.

Identifying Worn Components

Regular inspection of machinery is crucial in pinpointing parts that may need replacement. Look for signs of damage such as cracks, excessive wear, or misalignment. Components like belts, hoses, and filters often show visible signs when they are nearing the end of their lifespan. Listening for unusual noises during operation can also indicate issues that require immediate attention.

Replacement Process

Once worn parts are identified, proceed with the replacement process carefully. First, gather all necessary tools and replacement components. Refer to the specifications for correct sizing and compatibility. During the replacement, ensure that new parts are installed correctly and securely to prevent future issues. After installation, it’s advisable to run the equipment briefly to confirm proper functionality before returning it to regular use. Taking these steps can significantly enhance performance and reliability.

Operator Safety Guidelines

Ensuring a safe working environment is crucial when operating heavy machinery. Adhering to safety protocols not only protects the operator but also enhances the overall efficiency of operations. This section outlines essential practices to minimize risks and promote safe handling of equipment.

- Wear Personal Protective Equipment (PPE): Always don appropriate gear, including helmets, gloves, and eye protection.

- Conduct Pre-Operation Inspections: Before use, thoroughly check the equipment for any defects or malfunctions.

- Understand Operating Controls: Familiarize yourself with all controls and functions to prevent mishaps.

- Maintain a Clean Workspace: Keep the area around the machinery free from obstacles and debris.

- Follow Manufacturer Instructions: Adhere to guidelines provided by the equipment manufacturer for safe operation.

- Be Aware of Surroundings: Stay alert to people and objects in proximity while operating the machinery.

- Use Caution on Slopes: Exercise care when working on inclines to prevent tipping or sliding.

- Stay Hydrated and Rested: Ensure you are physically fit and alert to operate machinery safely.

By implementing these safety guidelines, operators can significantly reduce the likelihood of accidents and ensure a more secure working environment for themselves and their colleagues.

Adjustments for Optimal Performance

Achieving peak efficiency in machinery operations involves careful calibration of various components. Proper adjustments enhance functionality and longevity, ensuring that the equipment performs at its best under different conditions. Regular tuning and inspection are essential for maintaining optimal performance and preventing unnecessary wear and tear.

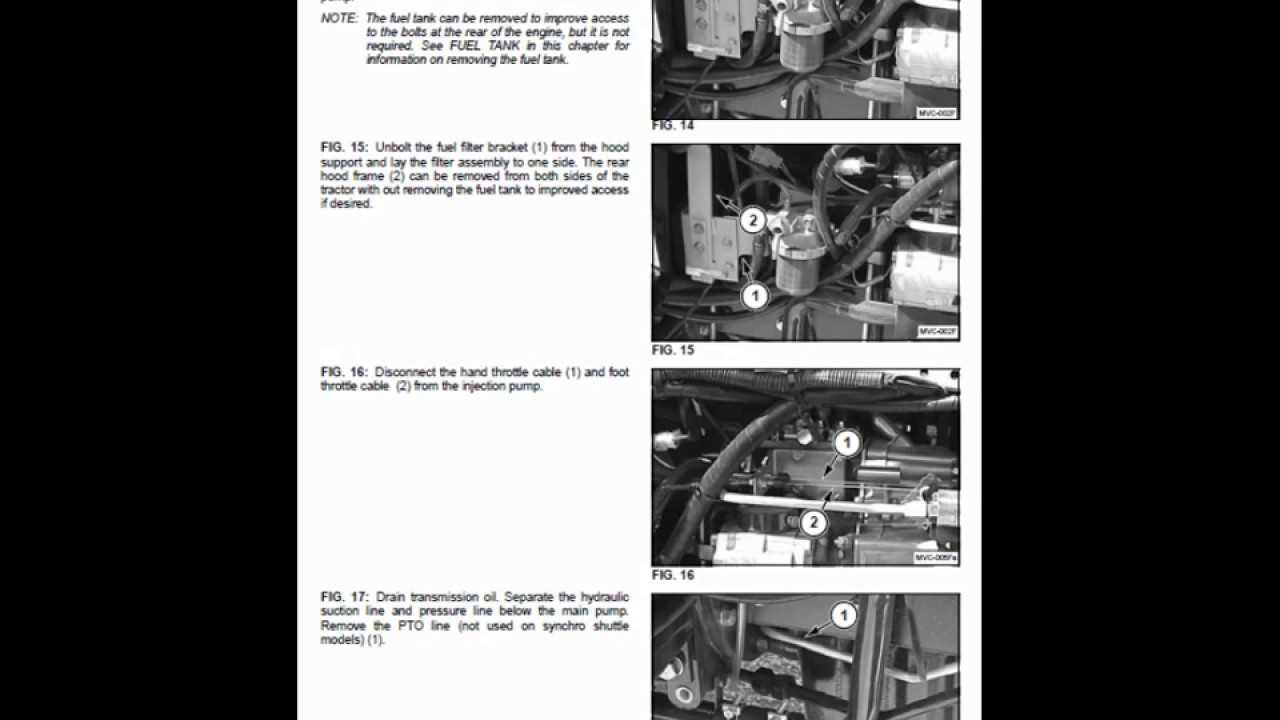

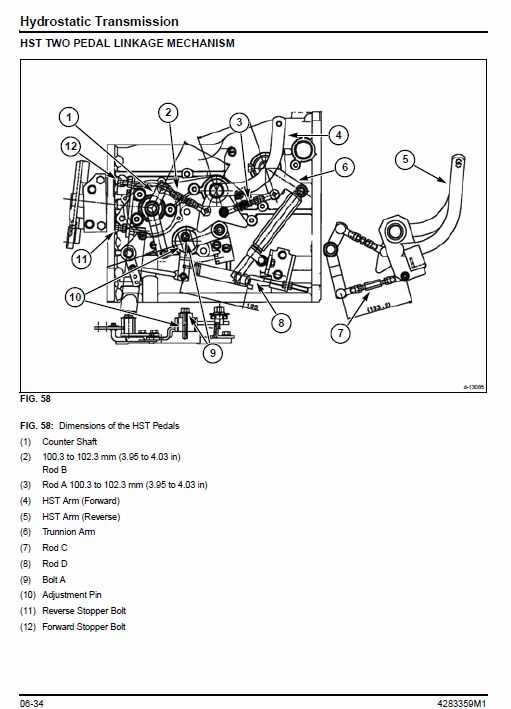

Hydraulic System Calibration

One of the critical areas requiring attention is the hydraulic system. Ensuring that pressure levels are set correctly can significantly impact the responsiveness and effectiveness of the machinery. Regular checks for leaks, along with adjustments to fluid levels and filter cleanliness, contribute to smoother operations.

Engine Tuning

Another vital aspect is engine tuning, which includes checking the timing, fuel mixture, and air intake. Regular adjustments in these areas can lead to improved fuel efficiency and power output. Monitoring exhaust emissions also plays a crucial role in identifying any underlying issues that may affect performance.

Using the Repair Manual Effectively

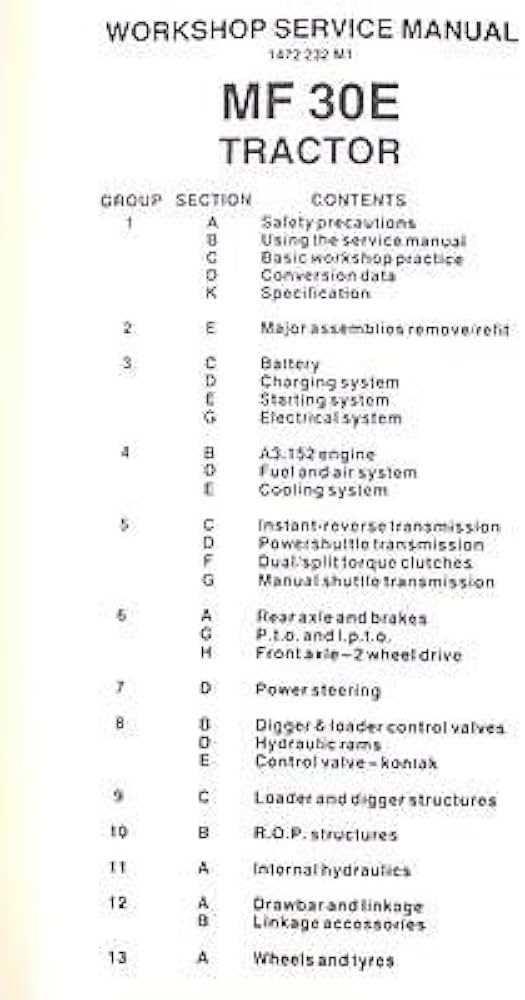

Leveraging a comprehensive guide can significantly enhance your understanding and efficiency in addressing machinery issues. Familiarity with the structure and contents of the document allows for quick navigation, ensuring you find the information you need without unnecessary delays.

Start by familiarizing yourself with the table of contents. This section serves as a roadmap, directing you to specific topics relevant to your tasks. Knowing where to look can save valuable time when troubleshooting or performing maintenance tasks.

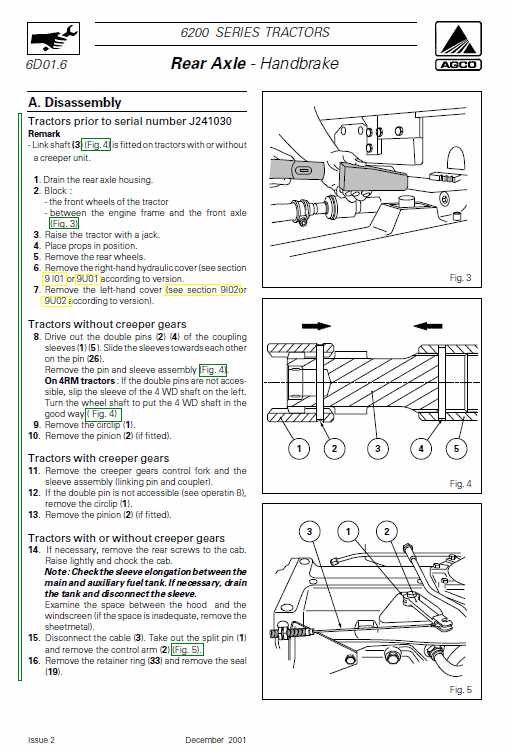

Additionally, pay attention to the illustrations and diagrams provided. Visual aids often clarify complex processes and can be more informative than text alone. Using these resources can help ensure you follow procedures accurately, reducing the likelihood of mistakes.

Take notes or highlight key sections during your review. This practice allows for easy reference in the future and reinforces your learning. Whether you are conducting routine checks or addressing more significant concerns, having personalized notes can enhance your workflow.

Finally, remember to refer back to the document regularly. Continuous consultation can deepen your understanding of the equipment and improve your ability to maintain its functionality over time. By integrating these strategies, you can maximize the benefits of the guide and enhance your operational skills.

Resources for Further Assistance

When seeking support for maintenance and troubleshooting, various resources can provide valuable information and guidance. Accessing these materials can help enhance understanding and facilitate effective solutions for common issues.

Online Forums and Communities

Participating in online forums and community groups dedicated to agricultural machinery can be beneficial. Here, users share their experiences, tips, and advice, creating a collaborative environment for problem-solving. Engaging with fellow enthusiasts can lead to insights that may not be found in traditional documentation.

Professional Services

For complex challenges that require expert knowledge, contacting professional technicians or service centers is advisable. These specialists can offer personalized assistance and are equipped with the tools and expertise necessary to address specific needs. Utilizing professional services ensures that equipment is handled correctly and safely.