Comprehensive Guide to New Holland T1510 Repairs

Understanding the intricacies of machinery upkeep is essential for optimal performance and longevity. This section will delve into essential information that aids users in effectively managing their equipment. By exploring comprehensive strategies, operators can ensure that their machines remain in top condition, ready to tackle various tasks.

Regular attention to maintenance not only enhances functionality but also minimizes the risk of unexpected breakdowns. This guide offers valuable insights into troubleshooting techniques and routine checks that are vital for sustaining peak efficiency. Engaging with these practices empowers users to take control of their machinery’s health and performance.

In the following sections, we will highlight key components and procedures that contribute to effective oversight. By familiarizing yourself with these elements, you will be well-equipped to handle common challenges and make informed decisions regarding your equipment’s care.

This section provides a comprehensive look at a specific agricultural machine designed for various farming tasks. Its robust features and user-friendly design make it a valuable asset for enhancing productivity in agricultural operations.

The following table outlines key specifications and features of this versatile equipment:

| Feature | Details |

|---|---|

| Engine Type | 4-Cylinder Diesel |

| Power Output | 25 HP |

| Transmission | Manual |

| Weight | 1,100 kg |

| Fuel Capacity | 30 liters |

Common Issues with T1510 Model

This section highlights frequent challenges faced by users of this particular agricultural machine. Understanding these problems can aid in troubleshooting and enhance overall performance.

- Engine Performance: Users often report difficulties with starting and inconsistent power output.

- Transmission Issues: Gear shifting may become rough, leading to operational inefficiencies.

- Hydraulic System: Leaks and pressure fluctuations are common, affecting lifting capabilities.

- Electrical Problems: Faulty wiring or battery issues can disrupt functionality.

- Cooling System: Overheating may occur, necessitating regular maintenance to avoid damage.

Addressing these concerns promptly can ensure better reliability and longevity of the equipment.

Essential Tools for Repairs

Having the right instruments is crucial for maintaining and fixing machinery effectively. A well-equipped toolkit can make a significant difference in both efficiency and outcomes during maintenance tasks.

Basic Hand Tools: A selection of wrenches, pliers, and screwdrivers forms the foundation of any toolkit. These items are vital for loosening and tightening various components, ensuring secure connections throughout the system.

Power Tools: Electric drills and impact wrenches can speed up tasks that would otherwise require considerable manual effort. These tools enhance productivity and allow for more intricate work to be completed with ease.

Diagnostic Equipment: Utilizing specialized devices such as multimeters and pressure gauges can help identify underlying issues. These instruments are essential for troubleshooting and ensuring that all systems function optimally.

Investing in high-quality tools not only improves repair processes but also extends the lifespan of the machinery, making maintenance tasks smoother and more reliable.

Step-by-Step Maintenance Guide

This section offers a detailed approach to the upkeep of your machinery, ensuring optimal performance and longevity. By following these systematic procedures, you can effectively maintain functionality and prevent potential issues.

Essential Tasks

- Regularly inspect fluid levels and top off as necessary.

- Check and clean air filters to ensure proper airflow.

- Examine belts and hoses for signs of wear and replace if needed.

Maintenance Schedule

- Weekly: Inspect tires for pressure and condition.

- Monthly: Change engine oil and replace the oil filter.

- Every 100 hours: Review hydraulic fluid levels and functionality.

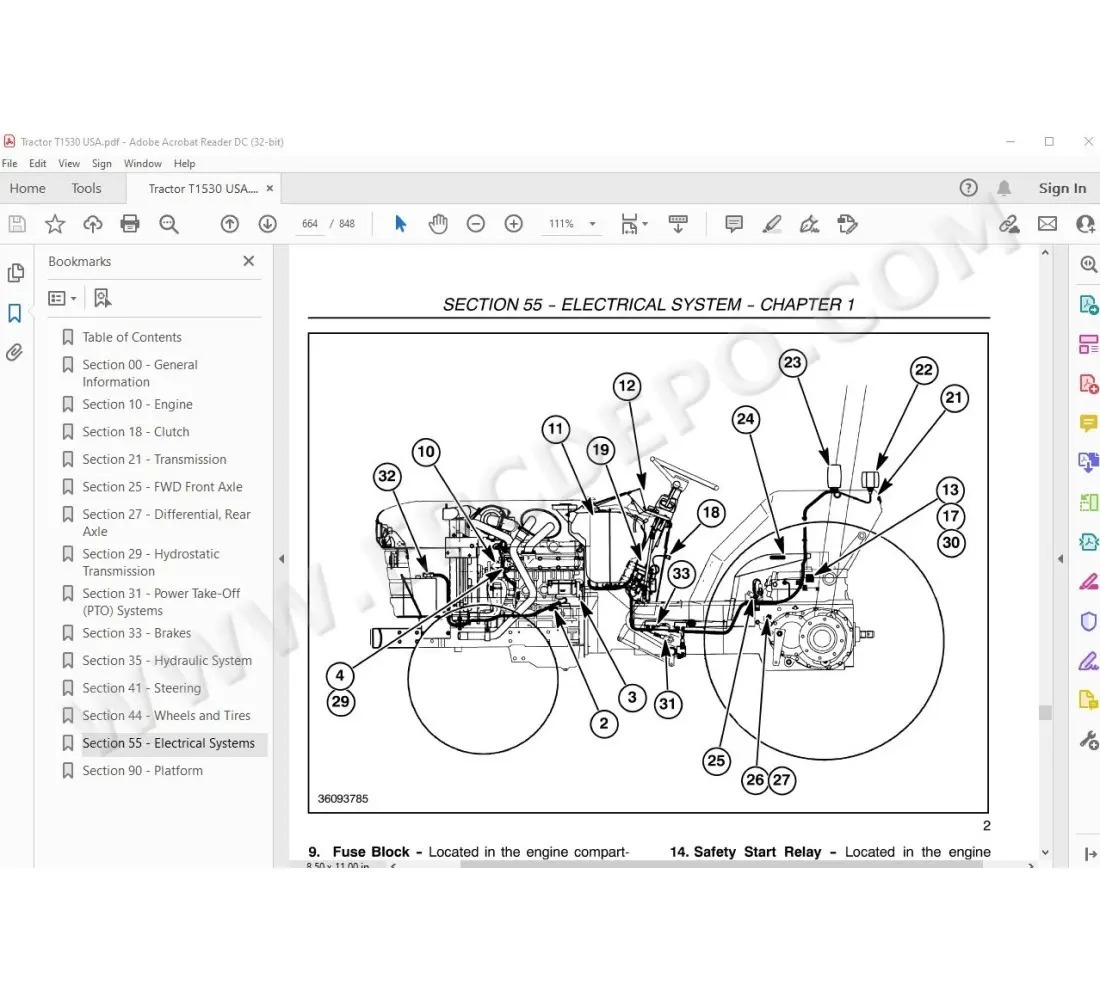

Electrical System Troubleshooting

This section provides an overview of diagnosing issues related to the electrical framework of agricultural machinery. Understanding the common problems and their indicators can significantly aid in maintaining optimal performance and ensuring longevity.

Identifying Common Issues

Frequent symptoms such as inconsistent power delivery or malfunctioning components can indicate underlying faults. Checking connections, inspecting wires for damage, and testing circuit integrity are essential initial steps in the diagnostic process.

Steps for Effective Diagnosis

Begin by verifying the battery condition and ensuring it is fully charged. Next, examine fuses and relays for functionality. Utilizing a multimeter to check voltages at various points can provide further insights into potential faults. Keeping a systematic approach helps isolate and address specific issues effectively.

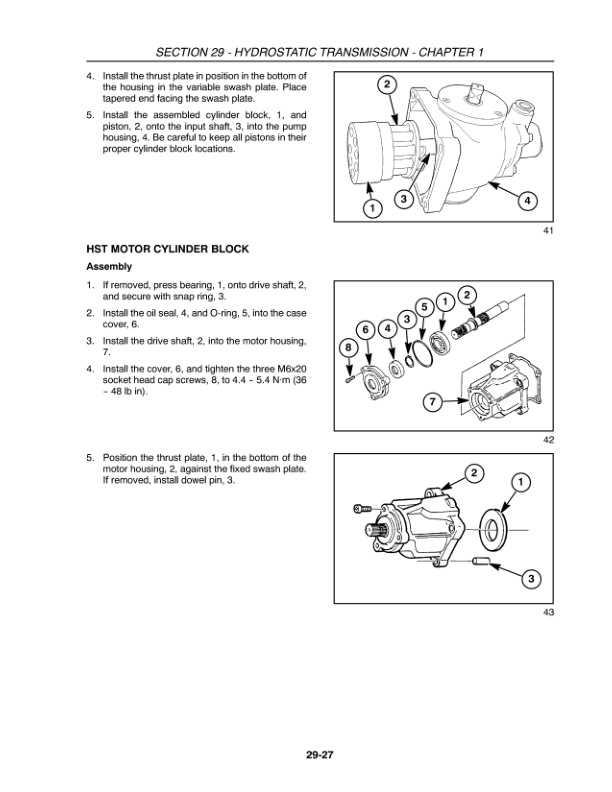

Engine Component Overview

This section provides an insightful look into the essential parts that constitute a powerful machinery unit. Understanding these elements is crucial for efficient operation and maintenance.

Key Elements

- Cylinder Block: The main structure housing various components.

- Pistons: Responsible for converting pressure into mechanical energy.

- Crankshaft: Transforms linear motion from pistons into rotational energy.

- Valves: Control the flow of air and fuel into the combustion chamber.

- Fuel Injectors: Deliver fuel directly into the combustion chamber for optimal performance.

Supporting Parts

- Timing Belt: Synchronizes the movement of the engine’s internal components.

- Oil Pump: Circulates lubricant to reduce friction and wear.

- Cooling System: Maintains optimal operating temperature to prevent overheating.

- Exhaust System: Directs harmful gases away from the engine.

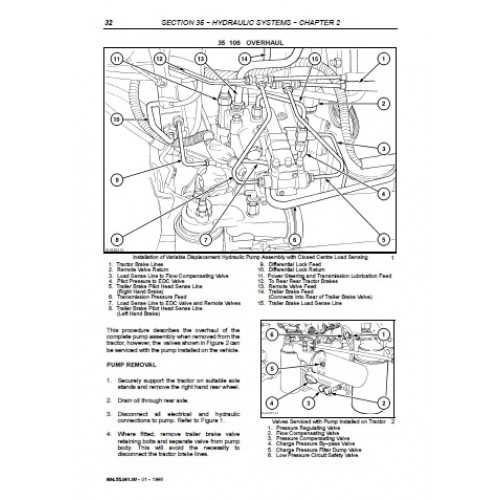

Hydraulic System Inspection Tips

Inspecting hydraulic systems is crucial for ensuring optimal performance and preventing failures. Regular checks can help identify issues early, leading to more efficient operation and reduced maintenance costs.

Here are some essential guidelines for conducting a thorough inspection:

| Inspection Area | Tips |

|---|---|

| Pipes and Hoses | Look for signs of wear, leaks, and loose connections. Ensure all fittings are secure. |

| Fluid Levels | Check the hydraulic fluid levels regularly. Top up if necessary, using the recommended type. |

| Filters | Inspect and replace filters as needed to ensure fluid cleanliness and system efficiency. |

| Cylinders | Examine cylinders for any signs of leakage or damage. Ensure they operate smoothly without sticking. |

By following these tips, you can maintain the integrity of the hydraulic system and enhance the overall reliability of the equipment.

Safety Precautions During Repairs

When performing maintenance or service tasks, prioritizing safety is essential. Proper precautions not only protect the individual working on the equipment but also ensure the longevity of the machinery. Adhering to recommended guidelines minimizes the risk of accidents and promotes a secure working environment.

Essential Safety Measures

- Personal Protective Equipment: Always wear appropriate gear, including gloves, goggles, and helmets.

- Work Environment: Maintain a clean and organized workspace to prevent tripping hazards.

- Tools Inspection: Regularly check tools for defects or wear before use.

Emergency Preparedness

- Familiarize yourself with emergency shutdown procedures.

- Keep a first aid kit readily accessible in case of injuries.

- Have fire extinguishers available and ensure they are functional.

Following these precautions not only enhances personal safety but also contributes to efficient and effective maintenance activities.

Parts Replacement Procedures

This section outlines the essential steps for effectively changing components in your machinery. Following these guidelines will ensure optimal performance and longevity of the equipment, making it crucial for proper upkeep.

Before beginning any replacement task, it is important to gather the necessary tools and components. Ensure that you have a clean workspace to facilitate the process and minimize the risk of losing small parts.

| Step | Description |

|---|---|

| 1 | Prepare the equipment by disconnecting it from any power source to ensure safety during the procedure. |

| 2 | Identify the component that needs to be replaced and consult any available documentation for specific details. |

| 3 | Carefully remove the faulty part using the appropriate tools, taking care not to damage surrounding components. |

| 4 | Install the new component, ensuring it is properly aligned and secured as per the guidelines. |

| 5 | Reconnect the power source and conduct a thorough inspection to verify that the replacement has been successful. |

Regularly following these steps will help maintain the functionality and efficiency of your machinery, ultimately enhancing its reliability.

Best Practices for Preventive Maintenance

Preventive maintenance is essential for ensuring the longevity and optimal performance of equipment. Implementing a proactive approach helps identify potential issues before they escalate, ultimately saving time and resources. By adhering to established practices, operators can maintain their machinery in peak condition.

Regular Inspections: Conducting routine checks allows for the early detection of wear and tear. Inspecting components such as filters, belts, and fluid levels is crucial to prevent unexpected breakdowns.

Scheduled Servicing: Following a maintenance schedule ensures that all necessary tasks are completed in a timely manner. This includes oil changes, lubrication of moving parts, and replacing worn components.

Utilizing Quality Parts: Using high-quality replacement parts is vital for maintaining performance standards. Always opt for parts that meet or exceed manufacturer specifications.

Keeping Records: Documenting maintenance activities provides a valuable history of the equipment. This information can help in identifying recurring issues and planning future maintenance.

Training Personnel: Ensuring that all operators are adequately trained in maintenance procedures promotes a culture of safety and efficiency. Regular training sessions can enhance skills and knowledge regarding proper maintenance techniques.

Where to Find Replacement Parts

Locating suitable components for machinery can be a straightforward process when you know where to look. Numerous resources are available for individuals seeking quality parts that fit their equipment needs.

Online Retailers

One of the most convenient options is to explore online stores. Many websites specialize in machinery components, offering a wide selection.

- Check customer reviews for reliability.

- Look for detailed product descriptions to ensure compatibility.

- Compare prices across different platforms to find the best deal.

Local Dealers

Visiting local dealers can also yield beneficial results. They often have access to a range of products that may not be available online.

- Inquire about special orders if the required part is not in stock.

- Take advantage of their expertise for recommendations on suitable alternatives.

- Ask about warranty options to protect your purchase.