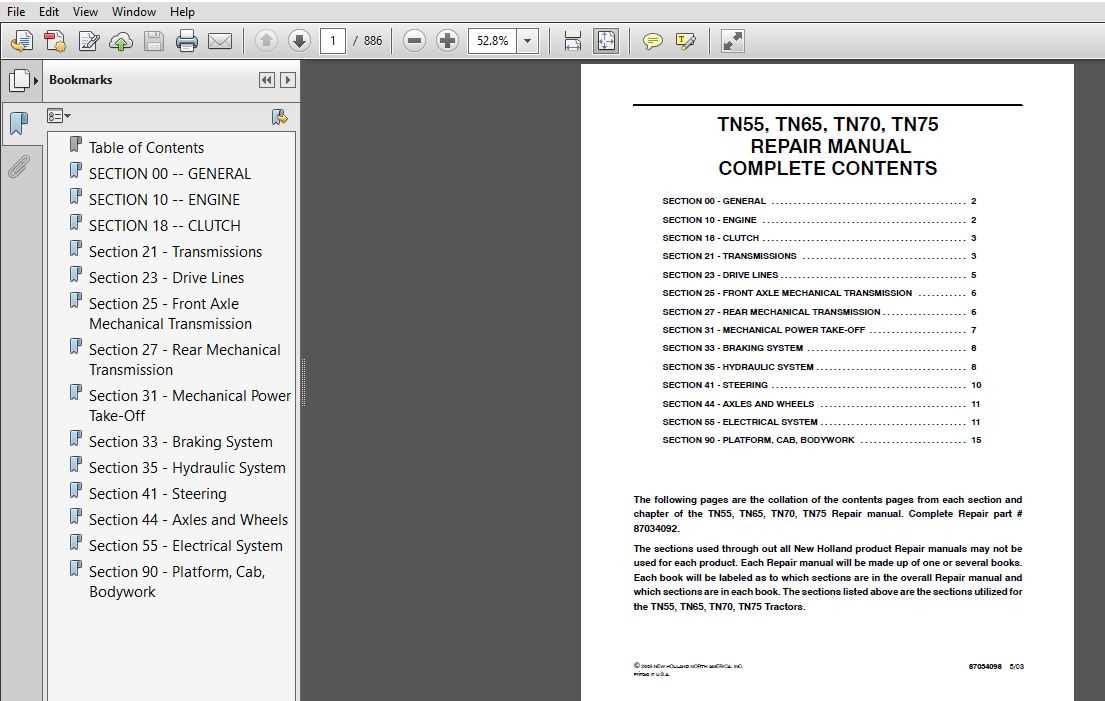

Comprehensive Guide to New Holland TN 55 Repair

The upkeep of agricultural machinery is essential for optimal performance and longevity. Proper knowledge and guidance are crucial in ensuring that operators can effectively address common issues that arise during use. This section aims to provide insights into the essential aspects of maintenance for this specific tractor model.

With a focus on practical advice and systematic procedures, users can familiarize themselves with the critical components that require regular attention. By adhering to recommended practices, operators can enhance both efficiency and safety while utilizing their equipment. Comprehensive understanding leads to proactive measures that mitigate potential malfunctions.

Furthermore, utilizing resources that outline necessary steps fosters confidence in handling routine tasks. Familiarity with the intricacies of the machinery not only supports performance but also contributes to a deeper appreciation of the equipment’s capabilities. Emphasizing preventative measures can significantly reduce downtime and repair costs in the long run.

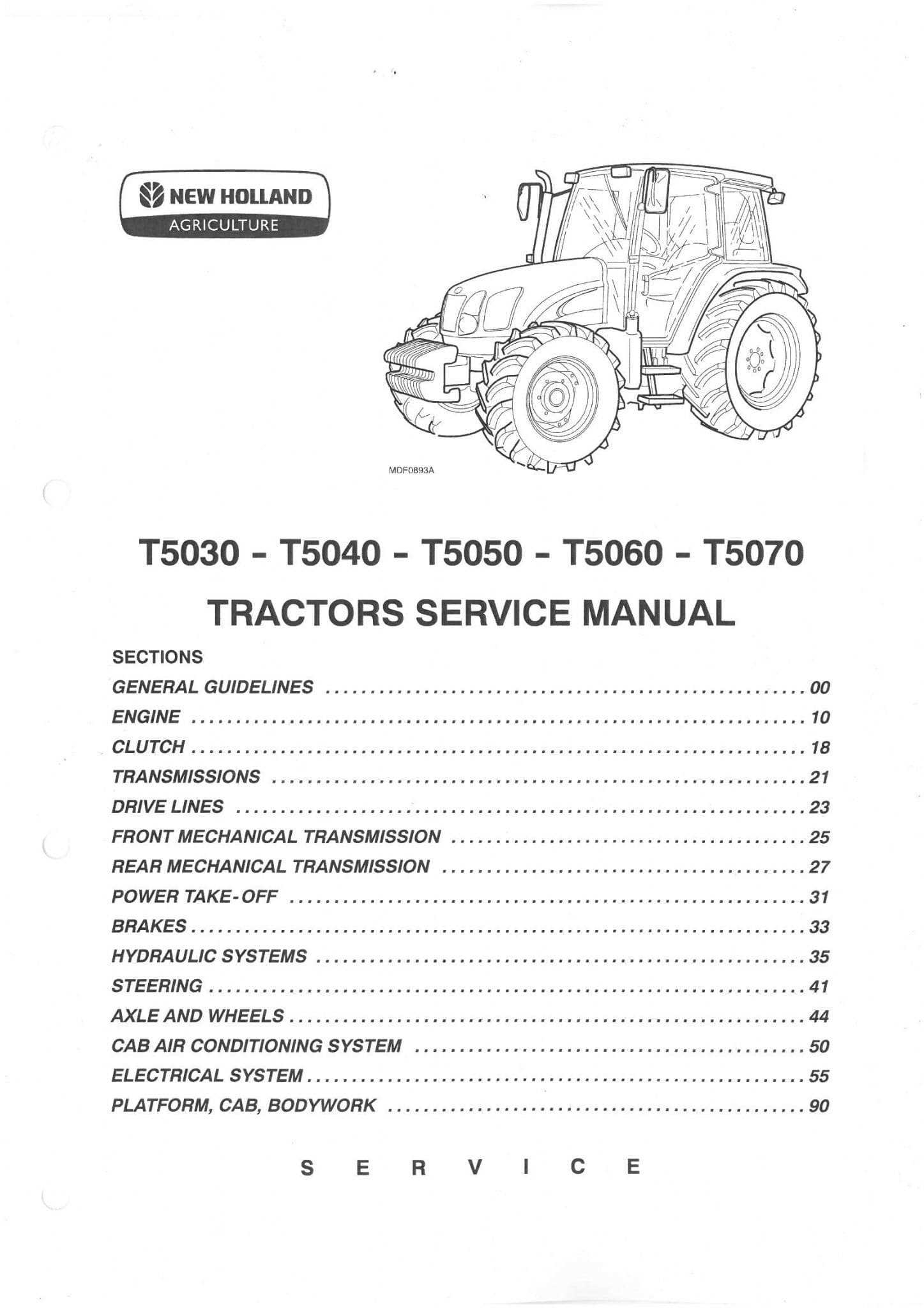

Understanding the TN 55 Model

The TN 55 model represents a significant achievement in agricultural machinery, blending advanced technology with user-friendly design. This equipment is tailored for a variety of tasks, making it an essential tool for both small and large-scale operations.

Key Features: The TN 55 is known for its reliability and efficiency, featuring a robust engine that ensures optimal performance under various conditions. Its ergonomic layout allows for comfortable handling, which is crucial during extended use.

Maintenance Considerations: Regular upkeep is vital for maximizing the lifespan of this equipment. Understanding the essential components and their functions can greatly enhance operational efficiency and reduce downtime.

Common Issues with TN 55 Tractors

The TN 55 tractors are generally reliable machines, but like any equipment, they can experience various challenges. Understanding these common problems can help owners maintain optimal performance and extend the lifespan of their vehicles.

One frequent issue is related to the hydraulic system. Users may encounter leaks or diminished performance, often stemming from worn seals or inadequate fluid levels. Regular inspection and timely replacement of faulty components can mitigate these issues.

Another common concern involves electrical systems. Faulty wiring or aging batteries can lead to starting difficulties or intermittent power losses. Routine checks of electrical connections and battery health are essential for ensuring smooth operation.

Engine performance can also be a point of concern, particularly if there are irregularities in fuel delivery or air intake. Owners should keep an eye on filters and fuel lines, ensuring they are clean and unobstructed for optimal efficiency.

Lastly, tire wear is a typical issue that can affect overall traction and handling. Regularly monitoring tire pressure and tread depth can help prevent uneven wear and maintain safety during operation.

Tools Required for TN 55 Repairs

When maintaining and servicing machinery, having the right equipment is essential for ensuring efficiency and safety. Various instruments and devices are necessary to tackle different tasks effectively, from routine checks to more complex issues.

Basic Hand Tools: Essential items such as wrenches, screwdrivers, and pliers are fundamental for any maintenance job. These tools allow for adjustments and replacements of various components.

Diagnostic Equipment: Specialized tools, including multimeters and pressure gauges, are crucial for identifying underlying problems. They help assess the functionality of electrical systems and fluid levels.

Safety Gear: Protective equipment, such as gloves, goggles, and ear protection, is vital to ensure the safety of the operator during all servicing activities.

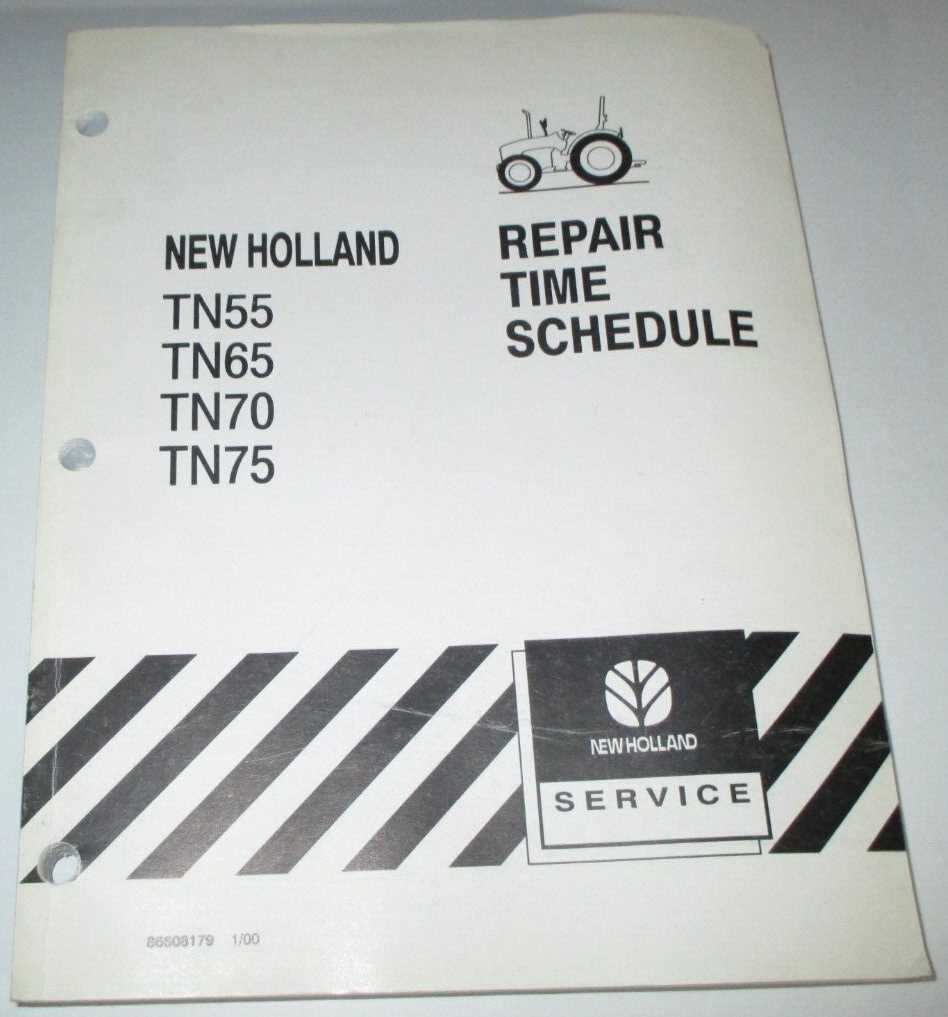

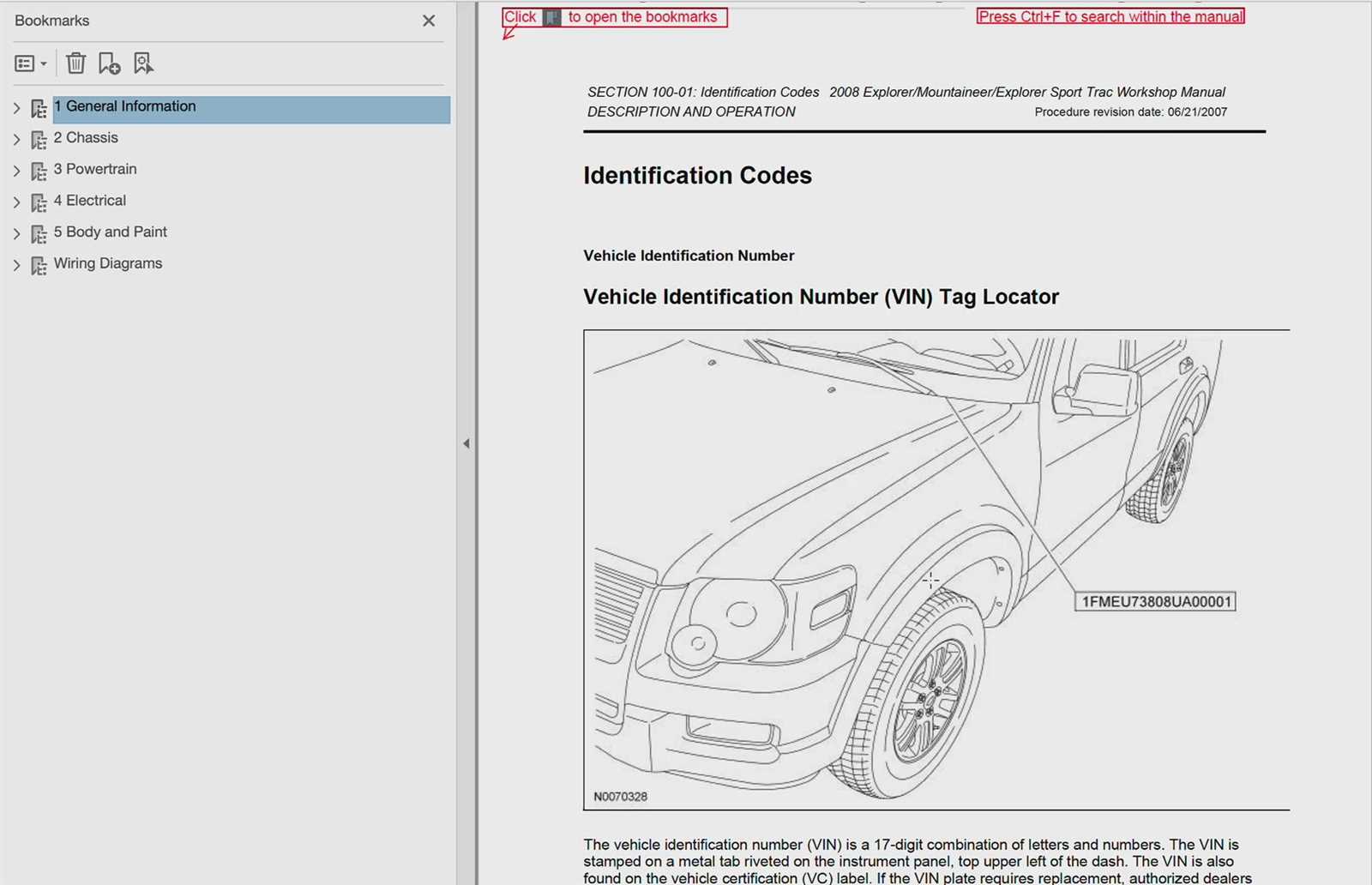

Service Manuals: While not tools in the traditional sense, having access to detailed documentation provides guidance on procedures and specifications, aiding in successful maintenance practices.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your equipment. By following a systematic procedure, users can enhance reliability and minimize potential issues.

1. Regular Inspection: Start with a thorough check of all components. Look for signs of wear, leaks, or damage. Early detection of minor problems can prevent larger repairs.

2. Fluid Changes: Replace oil and other essential fluids at recommended intervals. Clean fluids improve efficiency and reduce engine wear.

3. Filter Maintenance: Regularly clean or replace filters to ensure proper airflow and fluid flow. Clogged filters can lead to performance drops.

4. Tire Care: Check tire pressure and tread depth regularly. Maintaining the correct pressure enhances fuel efficiency and prolongs tire life.

5. Battery Maintenance: Inspect the battery connections and clean terminals. Ensure the battery is charged and secure to avoid starting issues.

6. Safety Checks: Test all safety features and controls before operation. Ensuring that everything is functional is crucial for safe usage.

7. Record Keeping: Maintain a log of all maintenance activities. Keeping track of services performed helps in identifying patterns and scheduling future maintenance.

Engine Troubleshooting Tips

When dealing with engine performance issues, it’s essential to identify and resolve common problems effectively. Understanding the symptoms and employing systematic approaches can lead to quicker diagnostics and solutions, ensuring optimal functionality.

Common Symptoms to Look For

Pay attention to unusual noises, vibrations, or changes in engine behavior. These can indicate various underlying issues, such as fuel delivery problems, ignition failures, or mechanical wear. Regularly inspecting for leaks or abnormal exhaust emissions can also provide valuable insights into the engine’s condition.

Basic Diagnostic Steps

Begin troubleshooting by checking the basics. Ensure the fuel system is functioning correctly by verifying fuel levels and inspecting filters. Examine the electrical components, including batteries and ignition systems, for any signs of wear. A thorough review of these elements can help isolate the problem before further investigation is necessary.

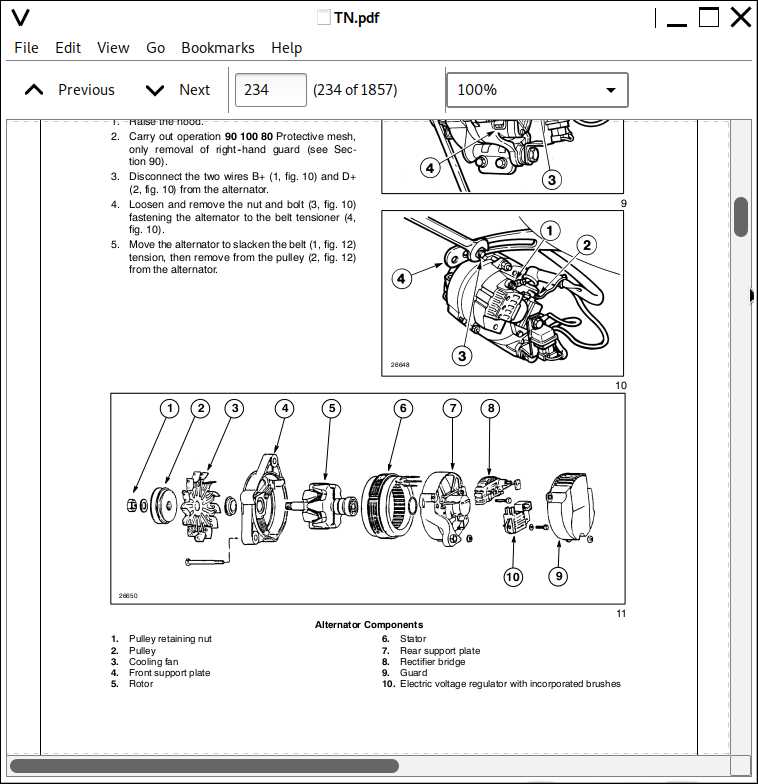

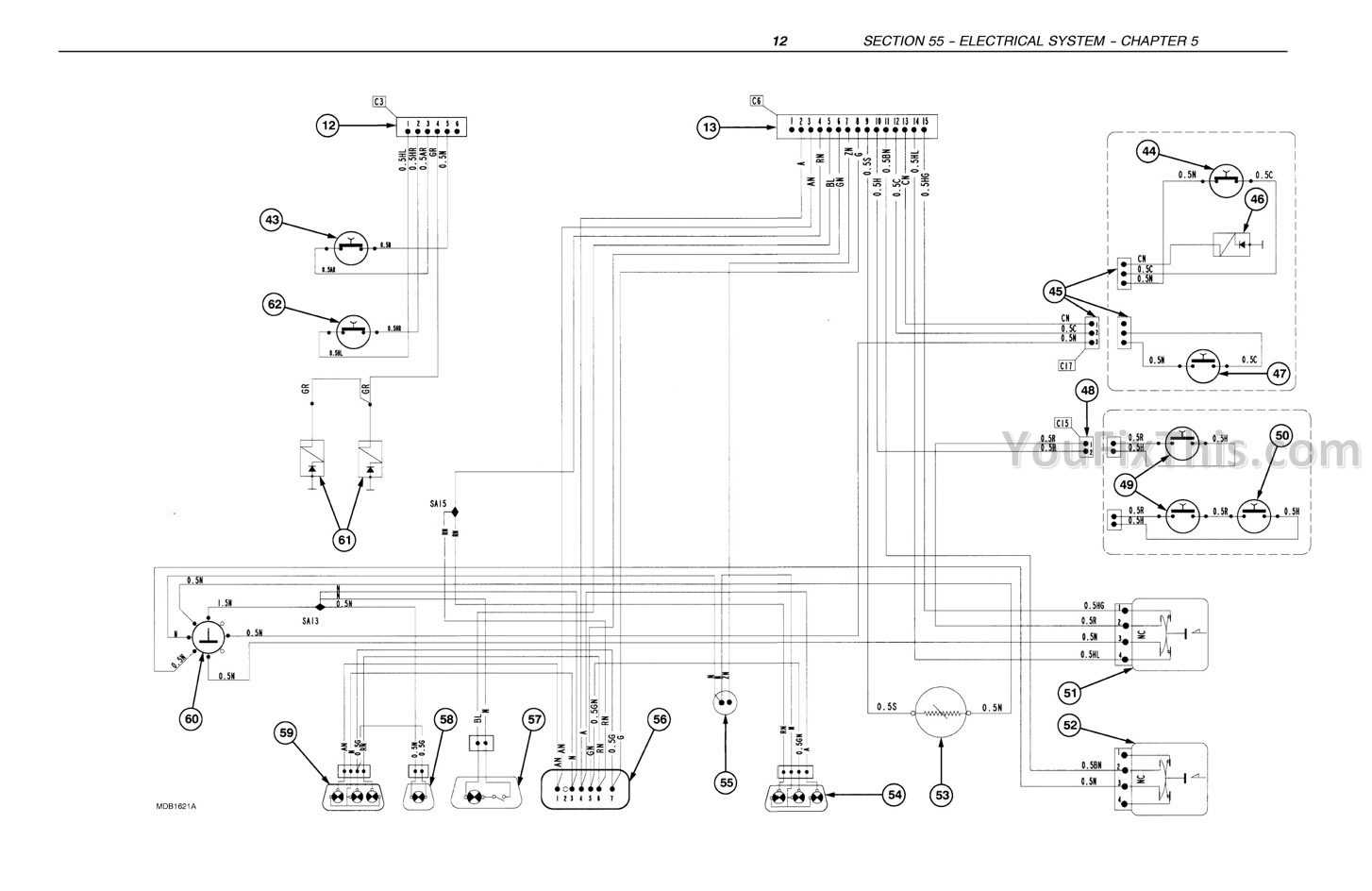

Electrical System Diagnostics

This section focuses on the evaluation and troubleshooting of electrical systems in agricultural machinery. Understanding the components and their functionalities is crucial for maintaining optimal performance and preventing failures.

Common Issues in Electrical Systems

- Poor connections leading to voltage drops

- Faulty wiring or insulation breakdowns

- Malfunctioning sensors or actuators

- Battery and charging system failures

Diagnostic Steps

- Inspect all wiring and connections for signs of wear or damage.

- Utilize a multimeter to measure voltage and resistance at various points.

- Check the condition of the battery and ensure proper charging.

- Test individual components like switches and sensors for functionality.

Hydraulic System Maintenance

Ensuring the proper functioning of the hydraulic system is crucial for optimal performance. Regular upkeep prevents potential issues that may arise from wear and tear. This section emphasizes the significance of routine inspections and timely interventions to maintain efficiency.

Start by checking fluid levels and quality, as contamination can lead to serious malfunctions. Replace filters as needed to ensure the system operates smoothly. Additionally, inspect hoses and connections for leaks or damage, addressing any problems promptly to avoid further complications.

Periodic testing of the hydraulic components is essential. Utilize appropriate gauges to assess pressure and flow rates, confirming they meet specified standards. If discrepancies are detected, further investigation is necessary to identify underlying causes.

Lastly, always refer to the manufacturer’s guidelines for specific maintenance intervals and procedures. Staying proactive in hydraulic system care will extend the lifespan of the equipment and enhance its reliability.

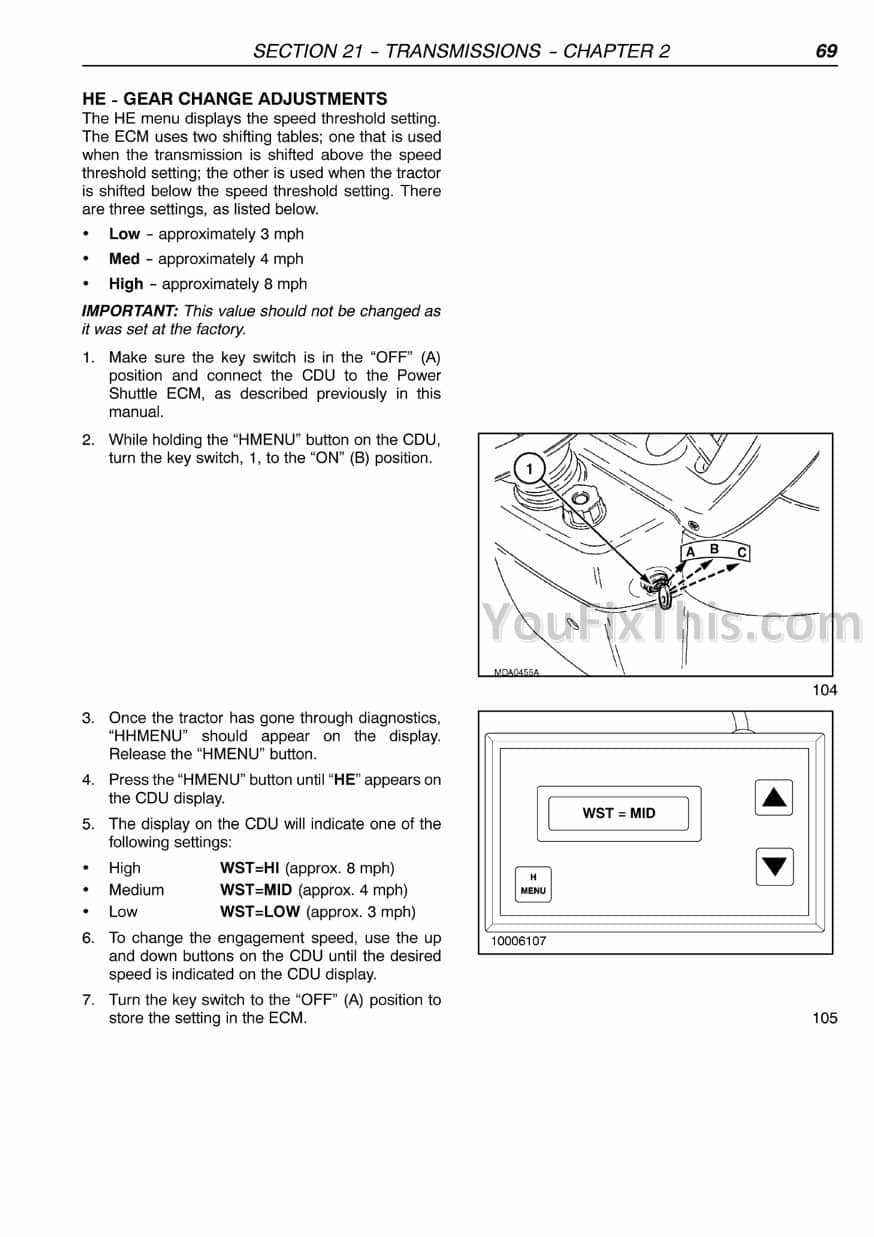

Transmission Repair Techniques

This section explores various approaches to addressing issues within the transmission system of agricultural machinery. Understanding the intricacies involved in maintaining and restoring optimal functionality is crucial for ensuring longevity and efficiency in operation.

Common Issues and Diagnosing Problems

Identifying frequent malfunctions within the transmission can save time and resources. Common symptoms may include unusual noises, difficulty in shifting gears, or fluid leaks. A thorough inspection is essential to pinpoint the exact cause, which may involve checking fluid levels, examining seals, and assessing gear alignment.

Essential Tools and Methods

Utilizing the right tools and techniques is vital for effective service. Key instruments include wrenches, torque gauges, and fluid extractors. Employing systematic methods such as disassembly, inspection, and reassembly ensures that all components are functioning correctly, thereby enhancing the overall performance of the transmission.

Preventive Measures for Longevity

Ensuring the extended lifespan of machinery requires a proactive approach that encompasses regular maintenance and careful operational practices. By adhering to specific guidelines, operators can significantly reduce wear and tear, thus enhancing overall efficiency and reliability.

Key strategies include routine inspections, timely servicing, and adhering to recommended operating conditions. These practices not only prevent unexpected breakdowns but also contribute to optimal performance.

| Preventive Measure | Description |

|---|---|

| Regular Inspections | Conduct periodic checks to identify potential issues before they escalate. |

| Fluid Changes | Replace oils and lubricants according to the specified schedule to ensure proper functioning. |

| Cleaning | Keep components free of debris and contaminants to maintain efficiency. |

| Operator Training | Ensure that all users are adequately trained to operate the equipment safely and efficiently. |

Replacing Worn Out Parts

When machinery components become aged or damaged, it is essential to address these issues promptly to maintain optimal functionality. Identifying and substituting these parts can prevent further complications and ensure the longevity of the equipment.

Identifying Damaged Components

Regular inspections play a crucial role in spotting wear and tear. Look for signs such as unusual noises, vibrations, or decreased performance. By assessing these indicators, one can determine which elements require replacement.

Steps for Replacement

Once the affected parts are identified, the replacement process involves several steps. Begin by securing the necessary tools and components. Carefully detach the worn-out piece, ensuring that all connections are noted. Install the new component, double-checking for secure fittings and proper alignment. Finally, conduct a test run to confirm that everything is functioning correctly.

Safety Precautions During Repairs

When engaging in maintenance tasks on machinery, it is essential to prioritize safety to prevent accidents and ensure a smooth process. Proper preparation and adherence to guidelines can significantly reduce the risk of injury while working with equipment.

Essential Safety Gear

Wearing appropriate personal protective equipment (PPE) is crucial. This includes safety goggles to protect your eyes, gloves to shield your hands, and sturdy footwear to guard against falling objects. Ensure that all gear fits correctly and is in good condition.

Workspace Organization

A well-organized workspace minimizes hazards. Keep tools and materials in designated areas, and eliminate any clutter that could pose a tripping hazard. Ensure adequate lighting to improve visibility and prevent accidents.

Finding Replacement Parts Efficiently

Locating suitable components for machinery can often seem challenging. However, with the right strategies, one can streamline the process and ensure that necessary items are sourced quickly and effectively. This section explores various methods and resources that can facilitate the acquisition of parts, minimizing downtime and enhancing overall efficiency.

Utilizing Online Resources

Online platforms provide a vast array of options for finding components. Various websites specialize in offering parts for different machinery types, allowing users to search by model or category. Utilizing search engines can also yield useful results, connecting individuals with local suppliers or specialized dealers who carry the required items.

Networking with Other Professionals

Engaging with fellow operators and industry professionals can uncover valuable leads on where to find components. Forums, social media groups, and local clubs are excellent avenues for exchanging information about reliable suppliers and potential discounts. Networking can not only lead to cost-effective solutions but also foster relationships that may prove beneficial in future endeavors.

Expert Resources and Communities

When it comes to maintaining and enhancing agricultural machinery, tapping into expert resources and community support can be invaluable. Engaging with knowledgeable individuals and accessing comprehensive information can significantly improve understanding and troubleshooting skills.

Online Forums and Discussion Groups

Participating in online platforms can provide insights and solutions from fellow enthusiasts and experts. These spaces allow users to share experiences, tips, and tricks related to machinery care.

- Dedicated machinery forums

- Social media groups focused on agricultural equipment

- Expert-led discussion boards

Professional Organizations and Associations

Joining industry organizations can open doors to training, resources, and networking opportunities. These institutions often provide access to up-to-date practices and standards in the field.

- Membership in agricultural societies

- Workshops and seminars on equipment maintenance

- Publications with in-depth guides and case studies