Comprehensive Guide to Newnes Motor Repair Manuals

In the realm of automotive care, having access to detailed resources is crucial for enthusiasts and professionals alike. These comprehensive guides offer valuable insights into the intricacies of vehicle systems, ensuring that users are equipped with the knowledge necessary for effective upkeep.

With a focus on troubleshooting and restoration techniques, these references serve as indispensable tools for anyone looking to enhance their understanding of mechanical processes. They empower individuals to tackle various tasks with confidence, ultimately leading to improved performance and longevity of their vehicles.

Moreover, the structured information provided in these resources promotes a systematic approach to maintenance. By breaking down complex concepts into manageable sections, users can easily navigate through various topics, making the learning process both efficient and enjoyable.

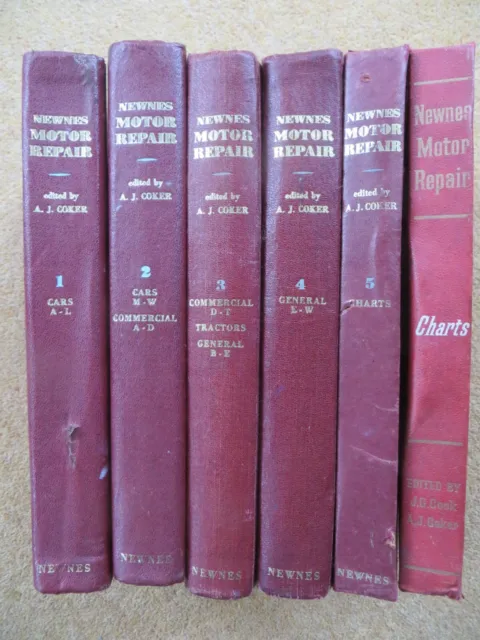

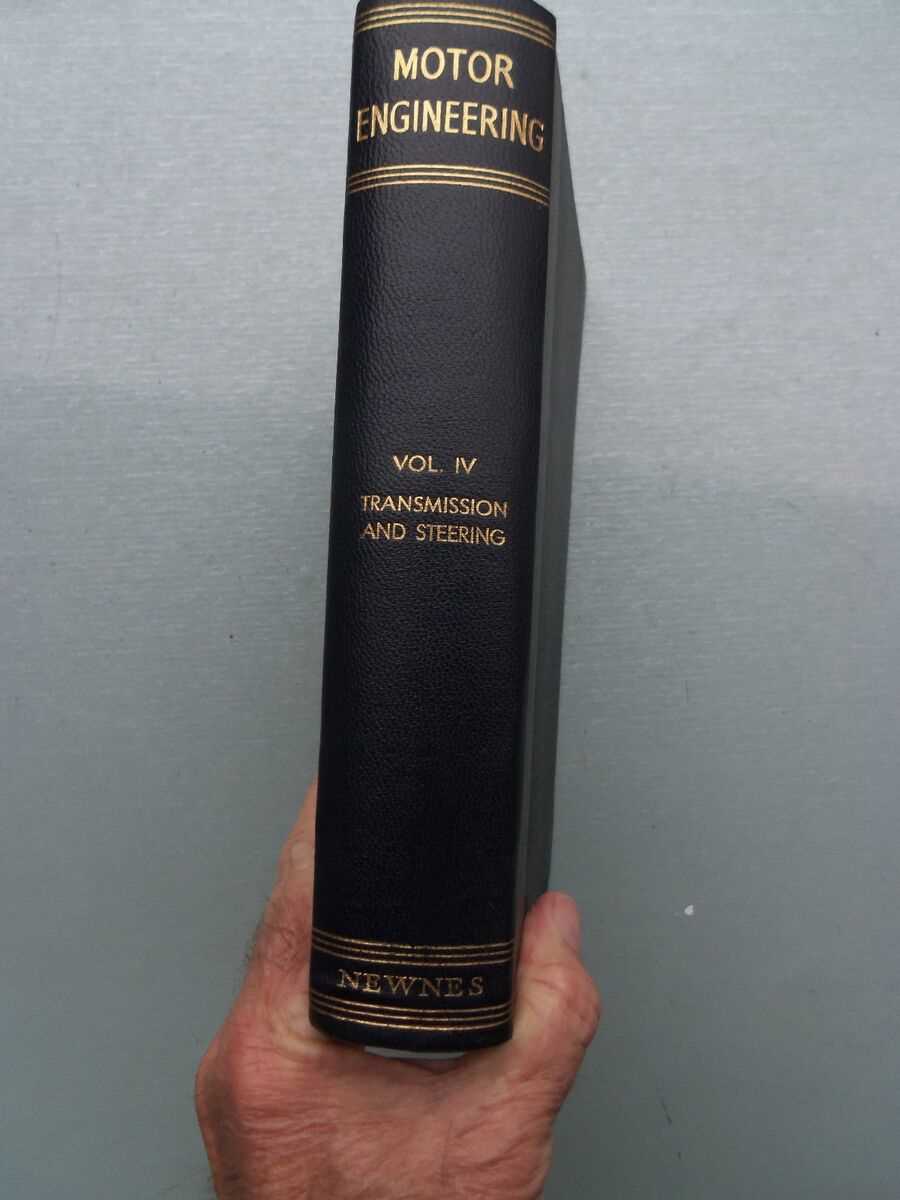

Overview of Newnes Manuals

This section provides an insightful look into a series of comprehensive guides designed for individuals seeking knowledge in the field of machinery maintenance. These resources are invaluable for both enthusiasts and professionals alike, offering structured information that caters to a wide range of technical requirements.

Each volume within this collection is meticulously organized, featuring detailed instructions and illustrations that simplify complex processes. The approach ensures that users can easily navigate through various topics, enhancing their understanding and skills. Moreover, the content is crafted to address both foundational principles and advanced techniques, making it suitable for users at different experience levels.

In addition to practical advice, these guides often include troubleshooting tips, safety precautions, and best practices, ensuring that users are well-prepared for any challenges they may encounter. Overall, this series serves as a crucial resource for those dedicated to mastering the intricacies of machinery upkeep.

Importance of Motor Repair Guides

Having access to comprehensive resources is crucial for effectively maintaining and servicing machinery. These resources provide essential insights that help individuals troubleshoot issues, understand components, and ensure optimal functionality.

Enhancing Knowledge and Skills

Utilizing detailed resources contributes significantly to skill development. By engaging with structured information, individuals can:

- Gain a deeper understanding of complex systems.

- Learn best practices for efficient maintenance.

- Improve problem-solving abilities through practical examples.

Ensuring Safety and Efficiency

Access to reliable documentation plays a vital role in promoting safety and efficiency. It allows users to:

- Identify potential hazards and preventive measures.

- Follow systematic procedures to minimize risks during servicing.

- Ensure that all tasks are performed correctly, enhancing overall performance.

Types of Motors Covered

This section explores the various categories of engines addressed in the available resources. Each type is designed for specific applications, ensuring optimal performance and efficiency.

AC and DC Variants

Engines can be broadly classified into alternating current (AC) and direct current (DC) types. AC units are commonly used in industrial settings due to their robustness and reliability, while DC devices are favored for their precise control and adaptability in various environments.

Specialized Applications

Beyond the basic classifications, there are specialized engines tailored for unique tasks. These include synchronous and asynchronous designs, as well as stepper and servo configurations, each offering distinct advantages depending on the operational requirements.

Key Features of Newnes Manuals

This section explores the essential characteristics that distinguish these comprehensive guides, highlighting their utility for individuals engaged in the upkeep of machinery. The focus is on the various elements that contribute to their effectiveness in providing detailed assistance.

Comprehensive Coverage: These guides encompass a wide range of topics, ensuring users have access to extensive information necessary for understanding complex systems. This thoroughness allows for informed decision-making and efficient troubleshooting.

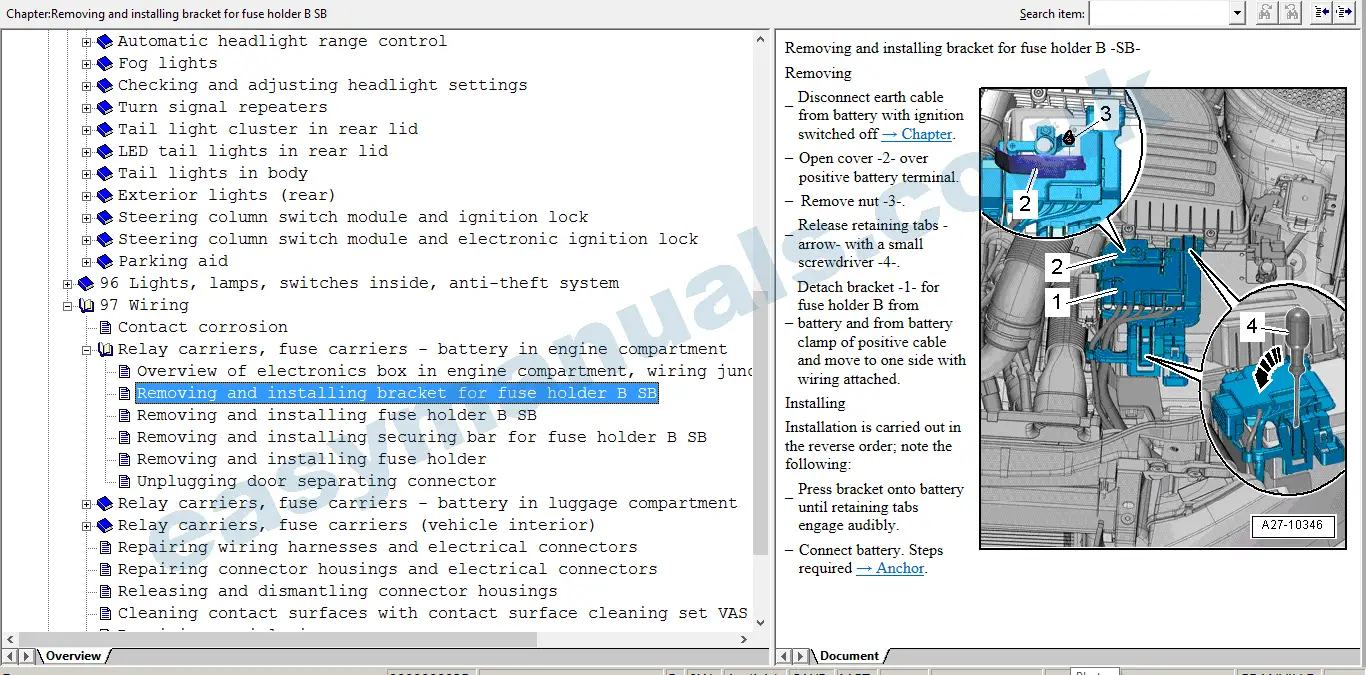

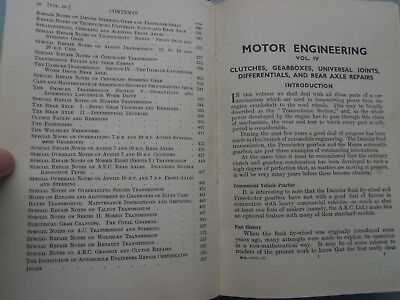

Clear Illustrations: Visual aids play a crucial role in enhancing comprehension. Each guide includes detailed diagrams and photographs, facilitating better understanding of intricate processes and components.

Step-by-Step Instructions: Users benefit from sequential guidance that simplifies challenging tasks. This structured approach ensures that even those with limited experience can follow along confidently, reducing the likelihood of errors.

Expert Insights: Contributions from industry professionals enrich the content, providing valuable perspectives and tips. This expertise enhances the reliability of the information presented and supports users in achieving optimal results.

Accessibility: Designed with user-friendliness in mind, these guides are organized logically, making it easy to locate relevant information quickly. This accessibility is essential for efficient problem-solving and maintenance activities.

Understanding Repair Techniques

This section delves into various methodologies employed to troubleshoot and restore functionality to devices. Grasping these techniques is essential for achieving optimal results and extending the lifespan of equipment.

When approaching the task of restoring devices, consider the following fundamental strategies:

- Diagnostic Assessment: Begin with a thorough examination to identify the underlying issues.

- Component Testing: Evaluate individual parts to determine their operational status and functionality.

- Systematic Disassembly: Carefully dismantle the equipment to access internal components, ensuring all parts are documented.

- Fault Isolation: Focus on pinpointing specific failures by testing various sections systematically.

- Replacement and Refurbishment: Decide whether to replace faulty components or restore them to working order, based on assessment findings.

Incorporating these practices not only facilitates a more efficient workflow but also enhances the overall quality of the restoration process.

Common Motor Issues Addressed

Understanding typical challenges encountered in electrical devices is crucial for effective maintenance and longevity. This section highlights prevalent problems that can arise, along with insights into their resolution.

Frequent Complications

- Overheating due to inadequate cooling

- Unusual noises indicating mechanical distress

- Inconsistent power output leading to performance issues

- Electrical faults caused by damaged wiring

Troubleshooting Techniques

- Inspect cooling systems for blockages or failures.

- Listen for abnormal sounds and identify their source.

- Monitor voltage and current to ensure stable performance.

- Examine wiring connections and replace any damaged components.

Step-by-Step Repair Processes

This section outlines a systematic approach to addressing issues with various types of equipment. A structured methodology ensures that problems are diagnosed accurately and solutions are implemented effectively, leading to improved performance and longevity.

Initial Assessment

The first stage involves gathering information about the device’s symptoms and previous issues. This includes examining any visible damage and checking operational history. Proper documentation at this stage is crucial for informed decision-making later.

Detailed Procedure

After assessing the situation, the next step is to follow a comprehensive procedure to address the identified problems. Each action should be performed methodically, ensuring that all components are handled with care. Below is a table that outlines key stages in this process:

| Stage | Action | Notes |

|---|---|---|

| Diagnosis | Identify the root cause of the issue | Use diagnostic tools as needed |

| Disassembly | Carefully take apart the equipment | Document each step for reassembly |

| Replacement | Replace any faulty components | Ensure compatibility with existing parts |

| Reassembly | Put the equipment back together | Follow the documented procedure |

| Testing | Conduct thorough testing of the unit | Monitor for any recurring issues |

Tools Required for Motor Repairs

When tackling the task of fixing and maintaining various types of machinery, having the right equipment is essential. The effectiveness of the work often hinges on the selection of tools that facilitate the process, ensuring efficiency and accuracy.

Here is a list of essential instruments you may need:

- Wrenches: A variety of sizes, including adjustable and socket types, for loosening and tightening components.

- Screwdrivers: Both flathead and Phillips, available in multiple sizes to fit different screws.

- Pliers: Needle-nose and slip-joint pliers for gripping and bending wires or small parts.

- Multimeter: For testing electrical connections and measuring voltage, current, and resistance.

- Torque wrench: To apply precise torque settings to fasteners, ensuring proper assembly without damage.

In addition to these basic tools, consider the following items that can enhance your ability to work effectively:

- Workbench: A sturdy surface to hold equipment securely while you work.

- Safety gear: Such as gloves and goggles to protect yourself from potential hazards.

- Tool organizer: To keep your instruments easily accessible and prevent misplacement.

Equipping yourself with these essential items not only streamlines the task at hand but also contributes to a safer and more productive working environment.

Maintenance Tips from Newnes

Proper upkeep is essential for ensuring longevity and optimal performance of your equipment. Implementing effective practices can prevent common issues and enhance reliability.

Regular Inspection: Conduct frequent evaluations of your device to identify any wear or damage. Early detection of problems can save time and resources.

Lubrication: Ensure that all moving parts are adequately lubricated. This minimizes friction and helps maintain efficiency during operation.

Cleanliness: Keeping your machinery free from dust and debris is crucial. Accumulation of dirt can lead to overheating and reduced functionality.

Component Replacement: Schedule timely replacements for worn-out components. This proactive approach reduces the risk of unexpected breakdowns and enhances overall performance.

Follow Guidelines: Adhering to manufacturer recommendations for care and service is vital. These instructions provide valuable insights tailored to the specific needs of your equipment.

Comparing Newnes with Other Brands

When evaluating resources for automotive maintenance and troubleshooting, it’s essential to consider various options available in the market. Each brand offers its own strengths and weaknesses, influencing user preference and the effectiveness of the information provided.

One notable aspect is the depth of content. Some companies focus on extensive detail, catering to professionals, while others prioritize simplicity for the casual enthusiast. This can affect the accessibility and usability of the material.

Furthermore, the format and presentation of the information can vary significantly. Certain brands utilize a more structured layout, making it easier to locate specific details, whereas others may have a more traditional approach that could be less intuitive for users seeking quick answers.

Another consideration is the price point associated with these resources. While some brands offer competitive pricing, others may command a premium due to their reputation or perceived quality, which can influence purchasing decisions.

Ultimately, assessing the value and applicability of different sources is crucial. Understanding the unique characteristics of each can aid in selecting the most suitable option for your specific needs.

How to Choose the Right Manual

Selecting the appropriate guide for your needs can significantly impact the effectiveness of your maintenance tasks. Understanding your specific requirements and the characteristics of available resources is crucial to making an informed decision.

Identify Your Needs

Start by assessing the type of equipment you are working with and the issues you might face. Consider the complexity of tasks you intend to perform, as this will help you narrow down your options to resources that cater to your particular situation.

Evaluate Content Quality

Look for guides that offer clear instructions, detailed illustrations, and comprehensive troubleshooting sections. A well-structured resource with concise explanations and visual aids can enhance your understanding and efficiency in handling various tasks.