Norcold RV Refrigerator Repair Guide

In the realm of mobile living, ensuring the functionality of cooling appliances is crucial for comfort and convenience. Understanding the intricacies of these essential units can significantly enhance your overall experience while on the road. This section delves into the common issues faced by users and offers effective strategies to address them.

Proper maintenance not only extends the lifespan of these devices but also optimizes their performance. Familiarizing yourself with the key components and typical malfunctions will empower you to take charge of any challenges that may arise. From temperature fluctuations to power issues, recognizing the symptoms can lead to timely solutions.

Equipped with the right knowledge, you can confidently navigate the troubleshooting process. This guide aims to provide a clear and structured approach to resolving various complications, enabling you to maintain a reliable cooling source during your travels. Embracing these insights will ensure a seamless journey, allowing you to focus on the adventures that lie ahead.

Norcold RV Refrigerator Overview

This section provides a comprehensive introduction to a popular cooling appliance used in mobile living spaces. Designed for efficiency and reliability, this unit caters to the needs of travelers and outdoor enthusiasts. Understanding its key features and functionality can greatly enhance the experience of using it in various environments.

Key Features

The unit boasts several important characteristics that make it suitable for use in recreational vehicles. It typically operates on multiple power sources, including propane and electric, allowing for flexibility based on available resources. Additionally, its design often incorporates advanced insulation technology, ensuring optimal performance even in varying temperatures.

Common Applications

Common Issues in RV Refrigerators

Many travelers encounter challenges with their mobile cooling units, which are essential for maintaining food and beverage freshness during road trips. Understanding typical problems can help in identifying solutions and ensuring efficient operation.

Temperature Fluctuations

One frequent concern is inconsistent temperature levels inside the unit. This can be attributed to various factors, such as inadequate ventilation, blocked air passages, or malfunctioning thermostats. Regular maintenance is crucial to prevent these issues and ensure stable cooling performance.

Unusual Noises

Unexpected sounds can signal potential trouble. Common noises include hissing, popping, or buzzing, which may indicate issues with the cooling system or internal components. Addressing these sounds promptly can help prevent more significant malfunctions and extend the lifespan of the appliance.

Identifying Cooling Problems

Effective temperature regulation is crucial for optimal performance in any cooling unit. When issues arise, it is essential to recognize the signs that indicate a malfunction. A variety of symptoms can point to inadequate cooling, necessitating a thorough assessment to diagnose the underlying causes.

One common indicator is the presence of unusual noises, which may suggest internal disturbances affecting the cooling process. Additionally, fluctuating temperatures can signal potential issues, especially if the environment remains consistent. Monitoring condensation levels is also vital; excessive moisture can indicate inefficiency in the cooling mechanism.

It’s important to inspect the airflow, as blockages or obstructions can hinder proper functioning. Regularly checking for accumulated dust or debris around vents can help maintain efficient operation. Lastly, observing any changes in energy consumption patterns may reveal inefficiencies, prompting further investigation into the cooling system’s integrity.

Maintenance Tips for Longevity

To ensure the extended lifespan of your cooling unit, regular upkeep is essential. By following a few straightforward practices, you can enhance performance and prevent premature failures. Maintaining optimal conditions not only saves on energy but also reduces the likelihood of costly issues down the line.

Regular Cleaning

Keeping the unit clean is vital for efficient operation. Dust and debris can obstruct airflow and reduce cooling effectiveness. Follow these steps:

- Unplug the unit before cleaning.

- Use a soft brush or cloth to remove dust from the exterior.

- Check and clean vents and coils to ensure proper airflow.

Temperature Monitoring

Consistent temperature checks are crucial for optimal functionality. Ensuring the right environment helps prevent strain on the components:

- Set the thermostat to recommended levels.

- Avoid overloading the storage space to maintain airflow.

- Regularly check the internal temperature with a reliable thermometer.

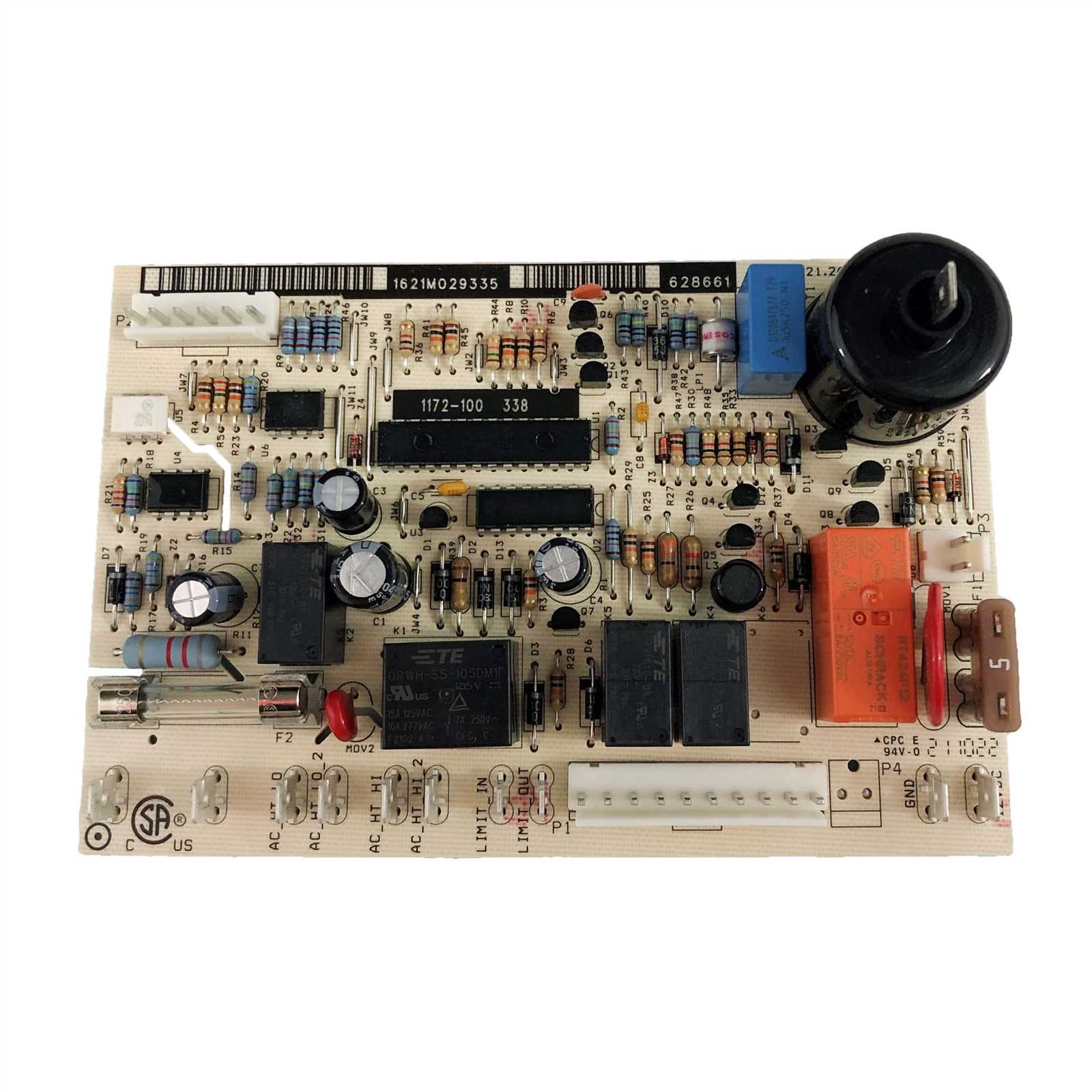

Understanding Electrical Components

Electrical systems in appliances play a crucial role in their functionality and efficiency. A solid grasp of the various components can help diagnose issues and ensure optimal performance. This section will explore key elements found in these systems, emphasizing their significance and interconnections.

Key Components

Among the primary elements are circuits, which direct the flow of electricity, and power sources, providing the necessary energy. Understanding how these components interact is vital for troubleshooting and maintenance. For example, a malfunctioning circuit can disrupt operations, making it essential to recognize the symptoms of potential failures.

Safety Considerations

When dealing with electrical components, safety is paramount. Always ensure that the power supply is disconnected before attempting any inspections or repairs. Familiarity with common hazards, such as short circuits and overloads, can significantly reduce risks. Knowledge of proper handling techniques not only safeguards the equipment but also enhances user safety.

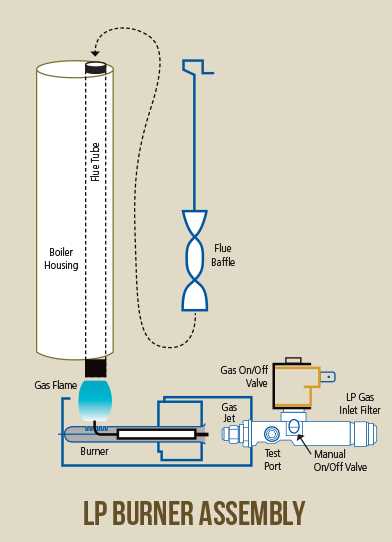

Checking Gas Connections Safely

Ensuring the integrity of gas connections is essential for safe operation and efficiency in any appliance utilizing gas. Regular inspections can prevent leaks and potential hazards, allowing for a smooth and worry-free experience. This section outlines crucial steps for examining these connections safely.

Preparation for Inspection

Before proceeding, gather the necessary tools, including a gas leak detector, adjustable wrench, and soapy water. Make sure to turn off the gas supply and ventilate the area to avoid any buildup of harmful fumes. Wearing safety goggles and gloves can provide additional protection during the inspection.

Inspection Process

Start by visually inspecting all visible connections for signs of wear, corrosion, or damage. Use the gas leak detector to check joints and fittings; a hissing sound may indicate a leak. Alternatively, apply soapy water to the connections. If bubbles form, it signifies escaping gas. Tighten any loose fittings with an adjustable wrench, but avoid over-tightening, as this can lead to further damage.

After completing the inspection, ensure that all tools are removed from the area and that the gas supply is restored carefully. Regular checks will enhance safety and prolong the lifespan of the appliance.

Cleaning Techniques for Efficiency

Maintaining optimal performance in cooling units requires regular attention to cleanliness. Accumulated dirt and debris can impede functionality and reduce efficiency. By implementing effective cleaning methods, users can ensure their units operate smoothly and last longer.

Essential Cleaning Steps

To maintain peak performance, follow these steps:

| Step | Description |

|---|---|

| 1 | Unplug the unit to ensure safety before starting any cleaning process. |

| 2 | Remove any food items and shelves to access all surfaces easily. |

| 3 | Use a soft brush or vacuum to eliminate dust from vents and coils. |

| 4 | Wipe down surfaces with a mild detergent solution to remove stains and odors. |

| 5 | Rinse with clean water and dry thoroughly before reassembling. |

Preventive Measures

In addition to regular cleaning, implementing preventive practices can enhance efficiency:

- Ensure proper ventilation around the unit to promote air circulation.

- Avoid overcrowding, as this can hinder cooling efficiency.

- Schedule periodic professional inspections to address potential issues early.

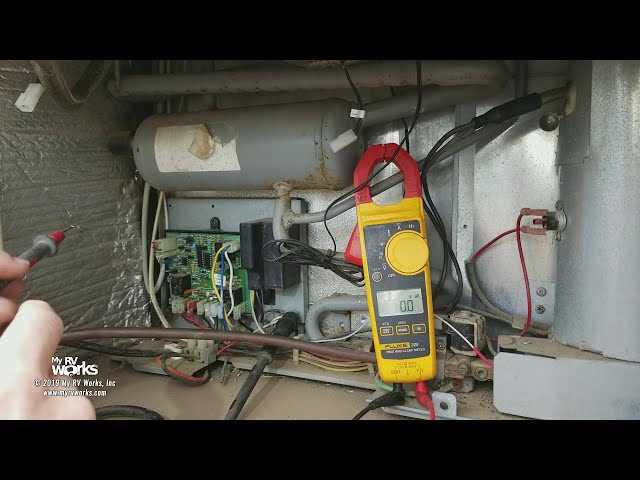

Tools Required for Repairs

Effective troubleshooting and maintenance of cooling appliances require a selection of essential instruments. These tools facilitate accurate diagnostics and enable the execution of various tasks efficiently.

Below is a list of vital items you should consider having on hand:

- Multimeter: For checking electrical connections and diagnosing power issues.

- Screwdrivers: A set of both flathead and Phillips screwdrivers to access internal components.

- Socket Set: For loosening and tightening bolts and nuts during disassembly.

- Wrenches: Useful for securing or adjusting fittings.

- Thermometer: To monitor temperature levels and ensure optimal performance.

- Vacuum Cleaner: For cleaning coils and removing debris that may affect efficiency.

- Flashlight: To illuminate dark areas during inspections.

Having these instruments readily available will streamline the process and enhance the effectiveness of your maintenance tasks.

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing common issues with cooling appliances in recreational vehicles. Following a structured method can ensure effective solutions while minimizing potential complications. Below are detailed steps to guide you through the troubleshooting and resolution stages.

Initial Diagnosis

Begin by assessing the situation. Check for obvious signs of malfunction, such as unusual noises or failure to cool. Ensure the device is properly connected to power sources. It may be beneficial to inspect the surrounding environment for factors that could affect functionality, such as temperature or ventilation issues.

Component Inspection and Troubleshooting

Next, systematically evaluate each component involved in the cooling process. This includes examining electrical connections, seals, and any internal mechanisms. Take note of any anomalies and consider testing individual parts to confirm their operational status. Document your findings to assist in deciding on necessary adjustments or replacements.

When to Seek Professional Help

Knowing when to consult an expert can significantly enhance the longevity and performance of your cooling unit. While many minor issues can be addressed with basic troubleshooting techniques, certain situations warrant professional intervention to ensure safety and effective resolution.

Signs Indicating a Need for Expertise

If you encounter persistent temperature inconsistencies, strange noises, or leaks, these may signal underlying problems that require specialized knowledge. Attempting to fix complex issues without adequate experience can lead to further damage or safety hazards.

Complex Repairs and Safety Concerns

Complicated repairs, such as those involving electrical components or refrigerants, should always be handled by a qualified technician. Inexperience in these areas can pose serious risks, not only to the unit itself but also to personal safety. Engaging a professional ensures that any necessary repairs comply with safety regulations and standards.

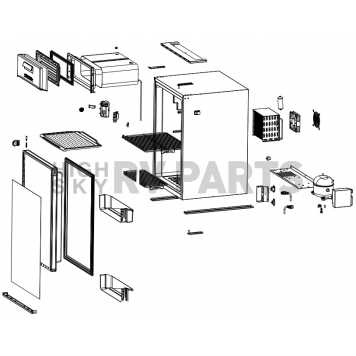

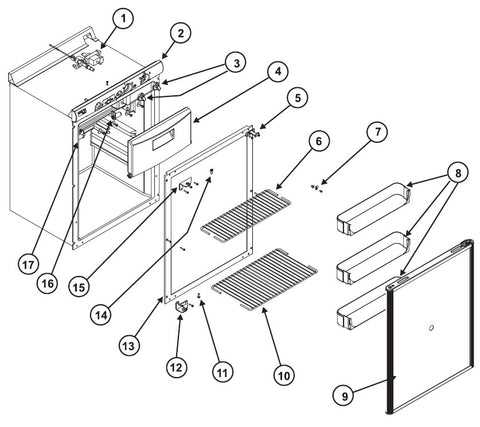

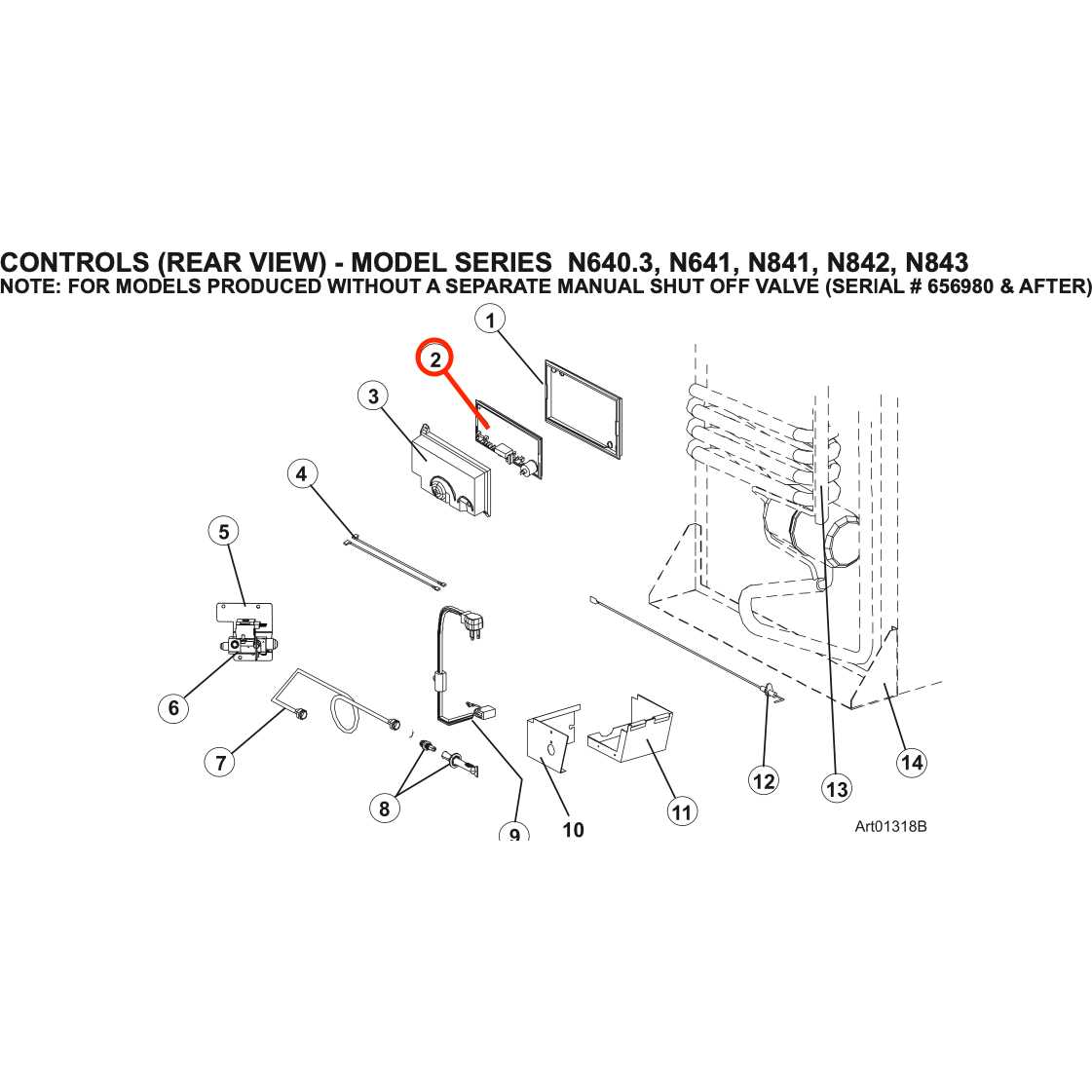

Parts Replacement Guide

When maintaining your cooling appliance, it’s crucial to know how to effectively replace components to ensure optimal performance. This section provides essential information on identifying parts that may need to be exchanged and offers guidance on the replacement process.

Identifying Components

Understanding the specific elements within your device is the first step towards effective maintenance. Common parts that may require replacement include cooling units, thermostats, and fans. Regular inspections can help you identify wear and tear, ensuring timely replacements.

Replacement Process

Once you have identified the parts needing replacement, follow these general steps to proceed:

| Step | Description |

|---|---|

| 1 | Disconnect the power source to prevent any electrical hazards. |

| 2 | Remove any outer panels to access the internal components. |

| 3 | Carefully detach the faulty part, taking note of its connections. |

| 4 | Install the new part, ensuring all connections are secure. |

| 5 | Reassemble the outer panels and reconnect the power source. |

By following these guidelines, you can ensure that your cooling device remains in optimal working condition, enhancing its lifespan and performance.

Warranty and Service Options

Understanding the coverage and assistance available for your appliance can greatly enhance your ownership experience. This section outlines the various types of guarantees and support services that are typically offered, ensuring that you have the necessary resources to address any issues that may arise.

Warranty Coverage

The warranty is designed to provide protection against manufacturing defects and malfunctions for a specified period. Here are some common aspects included in warranty coverage:

- Duration: Most warranties last between one to three years, depending on the manufacturer.

- Components Covered: Typically covers major components such as the cooling system and electrical parts.

- Exclusions: Damage caused by misuse, neglect, or unauthorized modifications is often not included.

Service Assistance

Access to professional assistance is vital for maintaining the optimal performance of your unit. Service options may include:

- Authorized Service Centers: Locations where trained technicians provide repairs and maintenance.

- Customer Support: Helplines and online resources to answer questions and troubleshoot common issues.

- Replacement Parts: Availability of genuine parts to ensure compatibility and performance.