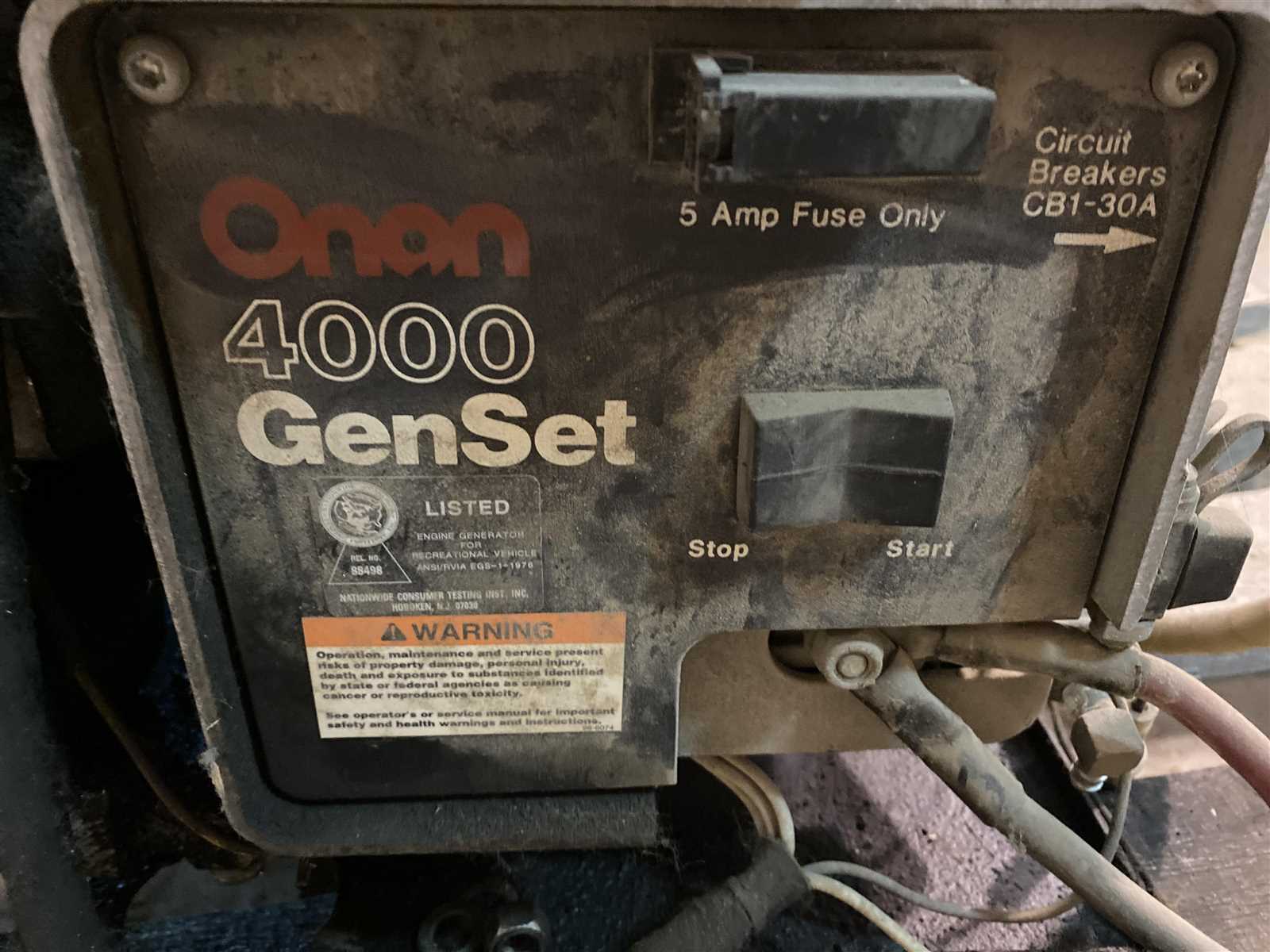

Complete Guide to Repairing the Onan 4000 Generator

Understanding the intricacies of energy-producing machinery is essential for ensuring optimal performance and longevity. This section delves into the essential practices that contribute to the smooth operation of these vital devices. Proper upkeep not only enhances efficiency but also prevents unexpected breakdowns that can lead to costly interruptions.

Regular examination and troubleshooting are key components in maintaining high-functioning units. By familiarizing oneself with the common issues that can arise, operators can tackle problems proactively, rather than reactively. This approach not only saves time but also minimizes the need for professional intervention, empowering users to manage their equipment effectively.

Equipping oneself with the right knowledge and techniques is crucial for anyone looking to extend the lifespan of their machinery. In this guide, we will explore various methods and tips that cater to both novice users and seasoned professionals. Whether it’s performing routine checks or addressing specific malfunctions, having a comprehensive understanding will ensure that these machines continue to operate at their best.

Understanding Onan 4000 Generator Basics

This section delves into the fundamental principles of a portable energy source commonly used in various applications. By grasping these essential concepts, users can enhance their understanding of operation, maintenance, and troubleshooting, ensuring optimal performance and longevity.

Key Components

Every energy unit consists of several critical elements that work in harmony. The heart of the system is the engine, which generates mechanical power. This power is then converted into electrical energy through a alternator. Additional parts, such as the fuel system, cooling system, and control panel, are vital for efficient functionality and user control.

Operational Principles

Understanding how this equipment functions involves recognizing the conversion process from fuel to electricity. When fuel is ignited within the engine, it produces energy that drives the alternator. The resulting electrical output can then be harnessed for various tools and appliances. Regular maintenance and monitoring of the system are crucial to prevent common issues and ensure reliable performance.

Common Issues with Onan Generators

Owners often encounter various challenges with their portable power units, which can affect performance and reliability. Understanding these frequent problems can help in troubleshooting and maintaining optimal functionality.

Frequent Problems

Several issues tend to arise, ranging from fuel supply complications to electrical system failures. Here are some of the most common concerns:

| Issue | Description |

|---|---|

| Fuel Starvation | Insufficient fuel flow due to clogged filters or lines can lead to stalling or poor performance. |

| Electrical Failures | Problems with wiring or connections may cause the unit to fail to start or operate intermittently. |

| Overheating | Inadequate ventilation or low coolant levels can lead to overheating, affecting the overall efficiency. |

| Battery Issues | Dead or weak batteries can result in starting difficulties or failure to hold a charge. |

Troubleshooting Tips

Regular maintenance and timely troubleshooting can help mitigate these issues. Checking fuel lines, inspecting electrical connections, and ensuring proper ventilation are key steps in maintaining efficiency.

Tools Needed for Repairs

When tackling maintenance tasks on a power supply unit, having the right instruments at your disposal is crucial for effective troubleshooting and servicing. This section outlines essential tools that will facilitate the process, ensuring efficiency and precision.

Essential Tools

- Socket set

- Wrenches (both standard and metric)

- Screwdriver set (including Phillips and flathead)

- Multimeter

- Wire strippers and crimpers

- Pliers (needle-nose and adjustable)

- Flashlight or work light

- Torque wrench

Additional Supplies

- Safety gloves

- Safety goggles

- Cleaning supplies (cloths, brushes)

- Electrical tape

- Heat shrink tubing

- Lubricants and greases

Equipping yourself with these tools will not only enhance your capability to perform necessary adjustments but also promote safety and efficiency during the process.

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Following a systematic approach to maintenance can prevent issues and enhance reliability. This guide will walk you through key procedures to keep your unit in top shape.

1. Initial Inspection: Start by examining the exterior for any visible damage. Check for leaks, cracks, or loose components. Ensure that all connections are secure.

2. Oil Check and Change: Verify the oil level using the dipstick. If necessary, drain the old oil and replace it with fresh oil that meets the specifications outlined in the manufacturer’s recommendations.

3. Air Filter Maintenance: Remove the air filter and inspect it for dirt and debris. Clean or replace it as needed to maintain proper airflow and efficiency.

4. Fuel System Review: Inspect fuel lines for any signs of wear or leaks. Clean the fuel filter to prevent clogging and ensure smooth operation.

5. Battery Examination: Check the battery terminals for corrosion and ensure that the connections are tight. Clean the terminals if needed and test the battery’s charge level.

6. Spark Plug Inspection: Remove and examine the spark plug for wear. Replace it if it appears damaged or excessively worn to ensure efficient ignition.

7. Cooling System Maintenance: Inspect the cooling fins and ensure they are free from debris. Check coolant levels and top up if necessary to prevent overheating.

8. Regular Testing: Periodically run the equipment under load to confirm that it operates correctly. Listen for any unusual sounds and address them promptly.

Following this structured approach will help ensure that your device operates smoothly and efficiently, minimizing the risk of unexpected failures.

Troubleshooting Electrical Problems

When dealing with power generation systems, identifying and resolving electrical issues is crucial for ensuring optimal performance and reliability. A systematic approach can help pinpoint the source of malfunctions, allowing for effective solutions. This guide provides essential steps and common problems encountered, making it easier to diagnose and fix electrical faults.

Common Electrical Issues

Several frequent problems can arise in power systems, each with its own set of symptoms and causes. Understanding these can streamline the troubleshooting process.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Voltage Fluctuations | Poor connections, load imbalance | Check wiring, balance load |

| No Output | Faulty components, low fuel | Inspect components, refill fuel |

| Overheating | Blocked vents, low coolant | Clear vents, add coolant |

| Frequent Shutoffs | Overload, internal faults | Reduce load, check for damage |

Diagnostic Steps

To effectively troubleshoot electrical problems, follow a systematic diagnostic process. Start by examining the basic connections and ensuring everything is secure. Next, test the output with a multimeter to confirm voltage levels. Document any anomalies, and proceed to inspect individual components as needed. This methodical approach not only aids in identifying issues but also helps maintain the longevity of the system.

Fuel System Inspection and Repair

Ensuring the proper functionality of the fuel system is crucial for optimal performance and longevity. Regular checks can prevent issues that lead to inefficiency and potential damage. This section outlines the essential steps for examining and fixing common problems associated with fuel delivery mechanisms.

The primary components of the fuel system include:

- Fuel tank

- Fuel pump

- Fuel lines

- Fuel filter

- Carburetor or injector

Begin the inspection by following these steps:

- Visual Examination: Check for any signs of leaks, cracks, or corrosion on the fuel tank and lines.

- Fuel Quality: Inspect the fuel for contaminants. If it appears cloudy or has particles, consider draining and replacing it.

- Filter Condition: Examine the fuel filter for clogging. Replace it if it’s dirty or hasn’t been changed in a while.

- Pressure Check: Use a pressure gauge to ensure the pump is delivering the correct fuel pressure as specified by the manufacturer.

- Component Testing: Test the fuel pump and injectors for proper operation. Listen for unusual noises and check for any irregularities.

Once issues are identified, address them promptly:

- Replace damaged hoses and fittings.

- Clean or replace the fuel filter.

- Fix any leaks using appropriate sealants or replacement parts.

- If necessary, rebuild or replace the carburetor or injector.

Regular maintenance of the fuel system will help ensure reliable performance and reduce the risk of unforeseen breakdowns. Always refer to the specific guidelines for your equipment when performing any tasks.

Replacing the Generator Battery

Maintaining the power source is crucial for ensuring optimal performance of your equipment. A failing energy unit can lead to interruptions in functionality and reduce the lifespan of your apparatus. This section provides guidance on how to effectively swap out the power unit for seamless operation.

Preparation is key before starting the replacement process. Ensure you have the necessary tools and a suitable replacement unit ready. It is important to disconnect any power supply to prevent electrical shocks. Always wear protective gear to safeguard yourself during the procedure.

To begin the replacement, locate the energy compartment. Carefully remove any securing mechanisms, such as bolts or clamps, that hold the unit in place. Gently lift the old power source out, taking care not to damage any surrounding components.

Once the old unit is removed, compare it with the new one to confirm compatibility. Place the new power source into the compartment, ensuring it is oriented correctly. Reattach any securing mechanisms, making sure everything is firmly in place.

After installation, reconnect the power supply. Test the system to verify that the new unit is functioning properly. If you encounter any issues, double-check your connections and ensure that all components are securely attached.

Regular maintenance of the power source can prevent unexpected failures in the future, ensuring reliable operation for your equipment.

Cleaning and Maintaining Air Filters

Proper care of air filtration systems is crucial for ensuring optimal performance and longevity of equipment. Regular maintenance not only enhances efficiency but also prevents potential damage caused by dust and debris buildup. Understanding the steps for effective cleaning can significantly improve airflow and prolong the life of your machinery.

Steps for Cleaning Air Filters

To begin the cleaning process, first, ensure the unit is powered down and disconnected from any electrical source. Remove the filter from its housing, taking care to avoid any damage. Use a soft brush or a vacuum cleaner with a brush attachment to gently remove dust and particles. For deeper cleaning, wash the filter with warm, soapy water, ensuring all residues are eliminated. Rinse thoroughly and allow it to dry completely before reinstallation.

Regular Maintenance Tips

It is advisable to inspect air filters regularly, ideally every month, depending on usage conditions. Replace filters that show signs of wear or severe dirt accumulation. Additionally, keep the surrounding area clean to minimize dust ingress. Utilizing high-quality filters can also enhance the overall performance of your equipment. Maintaining a routine will ensure that your machinery operates efficiently and lasts longer.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is paramount to prevent accidents and injuries. Proper precautions must be taken to create a secure working environment. Understanding potential hazards and employing effective safety measures can significantly reduce risks associated with troubleshooting and fixing equipment.

Before starting any maintenance work, it’s essential to assess the workspace for potential dangers. This includes ensuring adequate ventilation, proper lighting, and a clutter-free area. Always have the necessary safety gear on hand, such as gloves, goggles, and ear protection, to safeguard against various risks.

| Precaution | Description |

|---|---|

| Disconnect Power | Always unplug or turn off the power source before beginning any work to prevent electric shock. |

| Use Tools Properly | Employ the right tools for the job and ensure they are in good condition to avoid accidents. |

| Follow Manufacturer Guidelines | Refer to the provided documentation to understand specific safety measures and procedures. |

| Maintain a Clean Workspace | Keep the area tidy to reduce the risk of tripping or falling while performing tasks. |

| Stay Focused | Avoid distractions and maintain concentration to ensure tasks are performed safely and correctly. |

By adhering to these safety precautions, individuals can minimize risks and create a more secure environment during maintenance tasks. Prioritizing safety not only protects oneself but also ensures the longevity and proper functioning of the equipment being serviced.

Finding Replacement Parts Efficiently

Locating components for your equipment can be a daunting task, especially when you’re aiming for reliability and cost-effectiveness. A systematic approach can save both time and money, ensuring that you get the right parts without unnecessary hassle.

Start by identifying the specific components you need. This will often involve checking model numbers, part identifiers, and compatibility details. Once you have this information, you can streamline your search significantly.

| Source Type | Benefits | Considerations |

|---|---|---|

| Authorized Dealers | Genuine parts, expert advice | Higher prices, limited stock |

| Online Retailers | Wide selection, competitive pricing | Quality can vary, check reviews |

| Local Salvage Yards | Cost-effective options, unique finds | Limited availability, may require extra work |

| Manufacturer Websites | Direct access to original parts | Shipping time, sometimes limited to new models |

| Forums and Community Groups | Advice from experienced users, shared resources | Information may be anecdotal, verify before purchasing |

By exploring these various sources, you can effectively locate the components you need. Always compare prices and check for warranties to ensure you are making a well-informed purchase.