Understanding the Essentials of a Part 145 Repair Station Manual

The establishment of comprehensive guidelines for aviation maintenance facilities is essential for ensuring safety and compliance within the industry. These frameworks serve as a foundation for operations, detailing procedures, responsibilities, and standards that must be upheld to maintain airworthiness.

In this context, the documentation provides an ultimate resource for managers and technicians alike, outlining the critical practices necessary for effective maintenance and oversight. By delving into these specifics, organizations can foster a culture of safety and efficiency, reducing the risks associated with aircraft operations.

Furthermore, these directives play a pivotal role in regulatory compliance, ensuring that facilities meet the expectations set by aviation authorities. Understanding and implementing these principles is not just about following rules; it is about committing to excellence in every aspect of maintenance practices.

Understanding Part 145 Regulations

The framework governing the maintenance and alteration of aviation-related components is crucial for ensuring safety and compliance within the industry. Familiarity with these regulations equips professionals with the knowledge necessary to uphold operational standards and quality control.

Key Objectives of the Regulations

- Establish minimum safety standards for maintenance organizations.

- Ensure proper training and certification of personnel.

- Facilitate regular audits and inspections to maintain compliance.

- Promote accountability and traceability of maintenance activities.

Core Requirements

- Compliance with documentation and record-keeping practices.

- Implementation of quality assurance programs.

- Adherence to specified maintenance procedures and protocols.

- Regular updates and training for staff on regulatory changes.

Understanding these components not only enhances operational integrity but also fosters a culture of safety and responsibility within the aviation sector.

Key Requirements for Repair Stations

Establishing a facility dedicated to maintenance and overhaul services demands adherence to a set of essential criteria that ensure safety, efficiency, and regulatory compliance. These standards are critical in promoting operational excellence and fostering trust among stakeholders.

- Certification: Facilities must obtain the necessary credentials from relevant authorities, demonstrating their capability to perform specific tasks.

- Quality Management System: Implementing a structured approach to manage quality ensures consistency in services offered.

- Personnel Qualifications: Staff must possess appropriate training and certifications to guarantee proficient operations.

- Equipment Standards: Tools and machinery used must meet specific regulatory and performance criteria to maintain safety and reliability.

- Documentation: Accurate record-keeping is vital for tracking maintenance activities and ensuring compliance with regulations.

By focusing on these foundational elements, facilities can effectively operate while meeting industry standards and customer expectations.

Importance of a Repair Station Manual

A comprehensive guide is essential for any maintenance facility to ensure consistency, safety, and regulatory compliance. This document serves as a cornerstone for operational procedures, providing a structured framework that helps personnel perform their duties effectively and efficiently. By outlining standards and practices, it promotes a culture of excellence within the organization.

Ensuring Compliance and Safety

Adhering to established guidelines is critical in the aviation industry. A well-crafted document facilitates compliance with industry regulations, reducing the risk of violations and enhancing safety measures. It not only protects the organization from legal ramifications but also ensures the well-being of employees and customers alike.

Training and Consistency

Having a dedicated resource for training new staff members is invaluable. It helps instill a shared understanding of procedures and expectations, leading to consistent performance across the board. When everyone operates from the same playbook, the quality of service improves, and the potential for errors diminishes significantly.

Components of an Effective Manual

Creating a comprehensive guide is essential for ensuring that all procedures and practices are clearly defined and easily accessible. An effective document not only serves as a reference point for compliance and safety but also fosters a culture of continuous improvement and accountability within the organization.

Key elements should include clarity, organization, and accessibility, all of which contribute to a well-structured framework that supports operational excellence. Below are the primary components that should be included in any effective guide:

| Component | Description |

|---|---|

| Purpose Statement | Clearly outlines the objectives and scope of the document, establishing its relevance. |

| Procedures | Delineates step-by-step instructions to ensure consistency and accuracy in operations. |

| Responsibilities | Defines roles and responsibilities to ensure accountability and clarity in tasks. |

| References | Includes applicable regulations, standards, and best practices for compliance and guidance. |

| Revision History | Tracks changes and updates to maintain the document’s relevance and accuracy over time. |

Incorporating these elements will enhance the effectiveness of the guide, promoting a safer and more efficient working environment.

Documentation and Record-Keeping Practices

Effective documentation and meticulous record-keeping are essential components of maintaining operational integrity and compliance in any aviation-related environment. These practices ensure that all activities are traceable and verifiable, fostering a culture of accountability and safety. A robust system for managing records not only supports regulatory requirements but also enhances overall organizational efficiency.

Importance of Accurate Records

Maintaining accurate and up-to-date records is crucial for demonstrating adherence to safety standards and operational protocols. Complete documentation serves as a safeguard against potential discrepancies and provides evidence of compliance during audits. Moreover, precise records facilitate informed decision-making and help identify trends that may require corrective actions.

Best Practices for Documentation

Implementing best practices in documentation involves establishing clear procedures for record creation, storage, and retrieval. It is vital to ensure that all personnel are trained in these processes to maintain consistency. Utilizing digital systems can streamline record-keeping efforts, allowing for easier access and enhanced security. Regular reviews and updates of documentation practices can further strengthen the reliability of records and ensure ongoing compliance with industry regulations.

Quality Control Procedures Explained

Quality control is a critical component in maintaining high standards within any organization that undertakes complex tasks. It involves systematic processes to ensure that products and services meet specified requirements and that operational efficiency is maximized. This section delves into the essential procedures that uphold quality and consistency in various activities.

Core Elements of Quality Control

At the heart of effective quality assurance are several core elements that guide the entire process. These include thorough inspections, precise measurements, and comprehensive documentation. Each element plays a vital role in identifying discrepancies and ensuring that all operations adhere to established guidelines. Regular audits and evaluations also contribute to a culture of continuous improvement.

Implementation Strategies

To implement robust quality control procedures, organizations must develop clear protocols and assign dedicated personnel to oversee compliance. Training programs are crucial in equipping staff with the necessary skills to identify issues and uphold standards. Additionally, leveraging technology for monitoring and reporting can enhance accuracy and efficiency, enabling swift corrective actions when needed.

By fostering a proactive approach to quality assurance, organizations not only meet regulatory requirements but also build trust with clients and stakeholders, ultimately leading to greater success in their endeavors.

Employee Training and Qualifications

Ensuring that personnel possess the necessary skills and knowledge is crucial for maintaining high standards of safety and efficiency in the aviation industry. A well-structured training program not only enhances individual capabilities but also contributes to the overall operational excellence of the organization.

The training program should encompass various aspects, including technical skills, safety protocols, and regulatory compliance. It is essential for all employees to undergo initial training followed by regular refresher courses to stay updated with industry standards and practices.

| Training Type | Description | Frequency |

|---|---|---|

| Initial Training | Fundamental skills and knowledge necessary for job performance. | Once at hire |

| Ongoing Education | Advanced topics and updates on industry standards. | Annually |

| Safety Procedures | Protocols for maintaining a safe working environment. | Quarterly |

| Regulatory Compliance | Training on current regulations and legal requirements. | Biannually |

Furthermore, a comprehensive assessment system should be in place to evaluate the effectiveness of the training. This ensures that employees not only complete the required courses but also demonstrate their understanding and application of the material in their daily tasks.

By prioritizing the development and qualification of staff, organizations can foster a culture of safety and accountability, ultimately leading to improved operational performance.

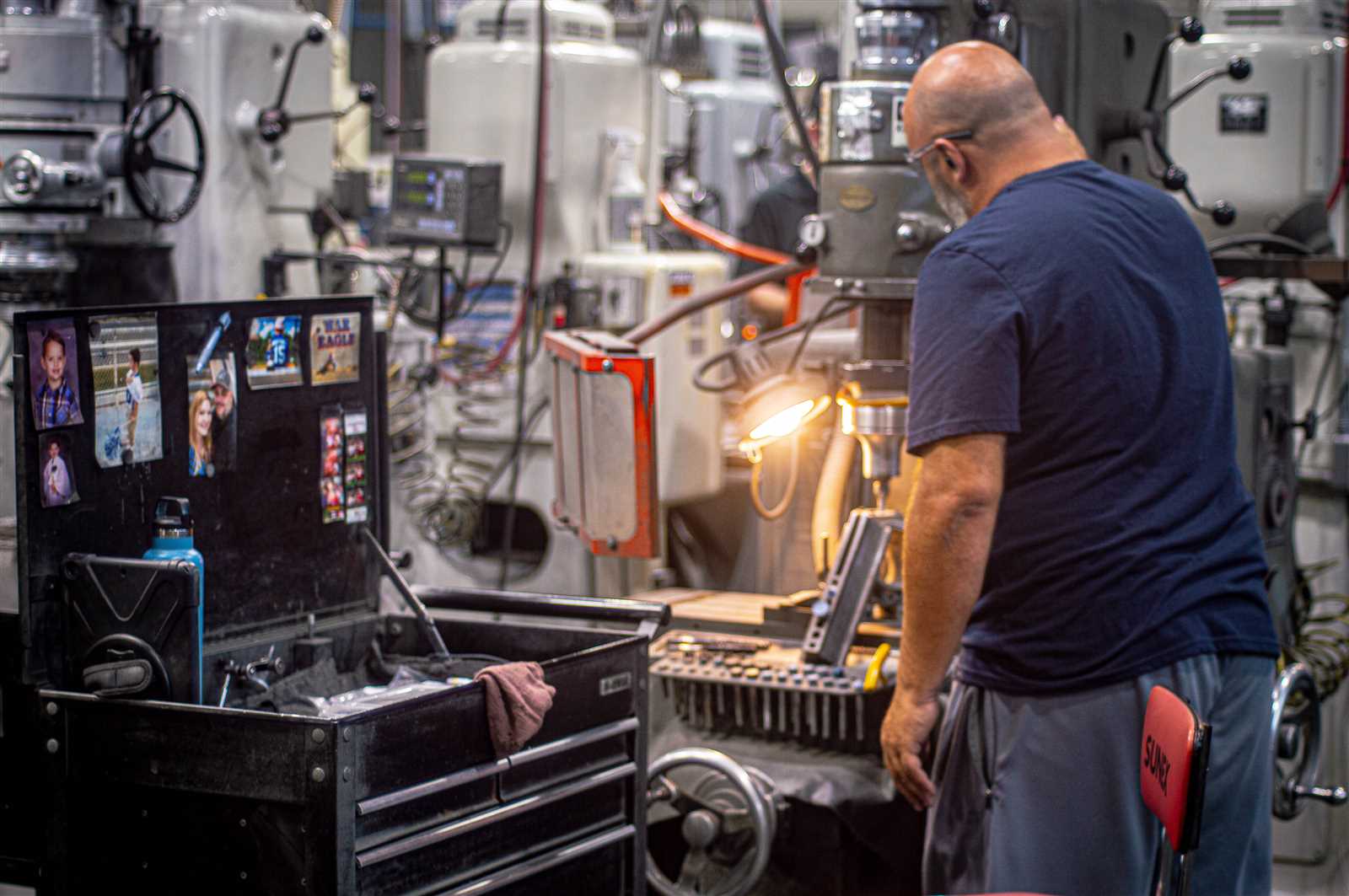

Safety Standards in Repair Operations

Ensuring a high level of safety is paramount in maintenance activities across the aviation industry. Effective safety protocols not only protect personnel but also safeguard equipment and enhance operational efficiency. The adherence to established safety guidelines fosters a culture of responsibility and vigilance, essential for minimizing risks associated with maintenance tasks.

Compliance with safety regulations serves as a foundation for all maintenance activities. Organizations are required to implement systematic procedures that address potential hazards and establish a framework for risk assessment. This includes regular training for personnel to familiarize them with safety practices and emergency response protocols.

Continuous monitoring of safety performance is crucial. Conducting audits and inspections allows for the identification of areas that require improvement. By actively engaging staff in safety discussions and encouraging feedback, organizations can promote a proactive approach to risk management, ultimately leading to a safer working environment.

Furthermore, the integration of technology into maintenance practices enhances safety. Utilizing advanced tools for diagnostics and maintenance tracking helps in identifying issues before they escalate, ensuring that all tasks are carried out with precision and care. Emphasizing the importance of proper equipment handling and maintenance procedures contributes significantly to overall safety.

In summary, establishing robust safety standards within maintenance operations not only protects individuals and assets but also plays a vital role in promoting an organizational culture that prioritizes safety at every level.

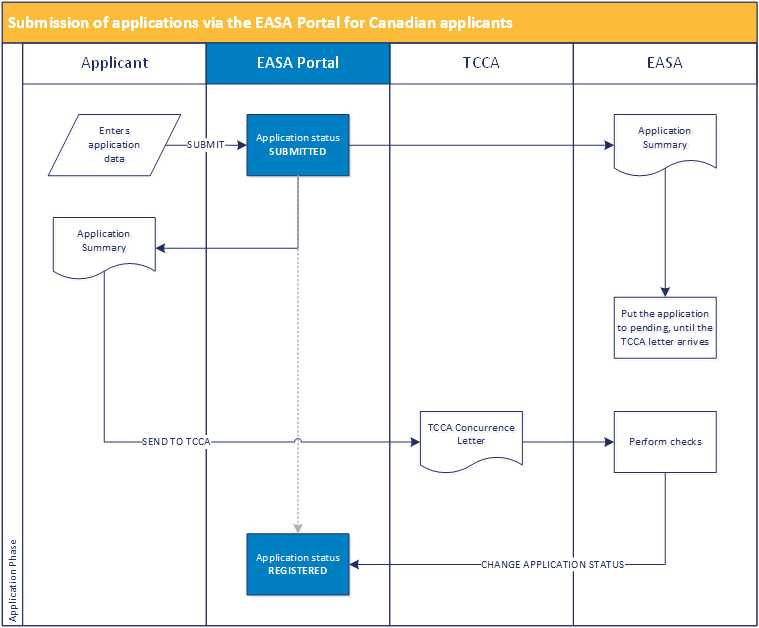

Auditing and Compliance Measures

Effective oversight and adherence to regulatory standards are crucial for maintaining operational integrity and safety. Regular evaluations help identify areas for improvement and ensure that established protocols are being followed meticulously.

The auditing process serves multiple purposes, including verifying compliance, enhancing performance, and fostering a culture of accountability. By implementing robust measures, organizations can mitigate risks and promote continuous development.

- Regular Internal Audits: Conducting frequent assessments to ensure adherence to established procedures.

- Document Review: Scrutinizing records and reports to validate compliance with regulatory requirements.

- Employee Training: Providing ongoing education to staff to keep them informed about current standards and best practices.

- Management Reviews: Involving leadership in the audit process to reinforce commitment to compliance and operational excellence.

In addition to internal evaluations, engaging external auditors can provide an objective perspective and highlight areas that may require further attention. These independent assessments are invaluable for enhancing credibility and ensuring adherence to industry standards.

- Identify Key Compliance Areas

- Develop a Comprehensive Audit Plan

- Execute Audits and Gather Data

- Analyze Findings and Implement Changes

- Monitor Ongoing Compliance and Adjust Strategies

Establishing a proactive compliance culture not only safeguards operational standards but also enhances overall efficiency. By prioritizing auditing and adherence measures, organizations can effectively navigate the complexities of regulatory landscapes.

Common Challenges in Manual Development

Creating comprehensive documentation for aviation maintenance organizations is a complex task that requires careful attention to detail. Various obstacles can arise during the development process, impacting the effectiveness and usability of the final product.

- Regulatory Compliance: Ensuring that all content aligns with industry regulations can be daunting. It requires a thorough understanding of the applicable standards.

- Clarity and Consistency: Achieving clarity in language and consistency in formatting is vital. Ambiguities can lead to misinterpretations and operational errors.

- Technical Accuracy: The information provided must be precise and up-to-date. Inaccuracies can compromise safety and efficiency.

- User-Friendliness: Developing content that is accessible and easy to navigate is essential for users with varying levels of expertise.

- Stakeholder Input: Gathering and integrating feedback from multiple stakeholders can be challenging. Balancing differing opinions is crucial for a cohesive document.

Addressing these challenges requires a structured approach, including thorough research, collaborative efforts, and iterative reviews. By focusing on these aspects, organizations can produce effective documentation that supports safe and efficient operations.

Updates and Revisions to the Manual

Maintaining current documentation is essential for ensuring compliance and operational efficiency. Regular updates are necessary to reflect changes in regulations, procedures, and technologies. This section outlines the importance of timely revisions and the process involved in keeping the documentation accurate and relevant.

Frequency of Updates

It is recommended that revisions occur at regular intervals or whenever significant changes arise. This proactive approach helps in avoiding outdated information that could impact safety and performance.

Review Process

An effective review process involves collaboration among various stakeholders. This includes safety officers, technical staff, and management, who work together to identify areas needing modification. Feedback from personnel using the documentation is also invaluable in this process.

Documentation of Changes

Each update should be meticulously documented to maintain a clear record of revisions. This includes detailing the nature of changes, the date of implementation, and the individuals responsible for the updates. Such transparency aids in tracking the evolution of the documentation over time.

Training and Communication

Once revisions are made, it is crucial to communicate these changes effectively to all relevant personnel. Training sessions may be required to ensure that everyone understands the new protocols and procedures, thereby minimizing the risk of errors.

In conclusion, a systematic approach to updates is vital for fostering a culture of safety and compliance. By prioritizing revisions, organizations can enhance their operational framework and better serve their objectives.

Future Trends in Repair Station Practices

As the aviation industry continues to evolve, the practices surrounding maintenance facilities are also undergoing significant transformations. The integration of advanced technologies, regulatory adaptations, and shifts in market demands are shaping a new era of operational efficiency and safety standards.

Technological Advancements are at the forefront of these changes. The adoption of artificial intelligence and machine learning is streamlining diagnostic processes and enhancing predictive maintenance capabilities. This not only reduces downtime but also improves the overall reliability of aircraft components.

Furthermore, digitalization is revolutionizing documentation and workflow management. The transition to electronic records and cloud-based systems allows for real-time data access and collaboration, which increases transparency and reduces the risk of errors.

Another critical aspect is the growing emphasis on sustainability. As environmental concerns gain prominence, maintenance facilities are exploring eco-friendly practices, such as using alternative materials and optimizing energy consumption. This trend aligns with the industry’s broader commitment to reducing its carbon footprint.

Lastly, workforce development is becoming increasingly important. As new technologies emerge, training programs are evolving to equip personnel with the necessary skills to adapt to these advancements. This focus on continuous learning ensures that the workforce remains proficient and capable of meeting future challenges.