Penn Reel Repair Guide

Understanding the intricacies of fishing equipment is essential for every enthusiast. This section delves into the essential techniques and practices that ensure your gear remains in optimal condition. By following these guidelines, you can extend the life of your devices and enhance your overall fishing experience.

Regular upkeep is vital to avoid common issues that may arise during use. Here, we will explore practical steps for identifying and addressing potential malfunctions. With careful attention to detail and a bit of patience, you can master the art of caring for your equipment.

Whether you are facing minor hiccups or more significant challenges, having the right knowledge empowers you to tackle problems effectively. Embracing a proactive approach not only saves time but also enhances your enjoyment of this rewarding hobby.

This section aims to provide a comprehensive overview of the intricate workings behind a popular fishing tool, focusing on its fundamental components and operational principles. Understanding these mechanics is essential for enthusiasts looking to enhance their skills in maintaining and troubleshooting these devices effectively.

- Introduction to Fishing Equipment

Overview of different types of fishing gear and their purposes.

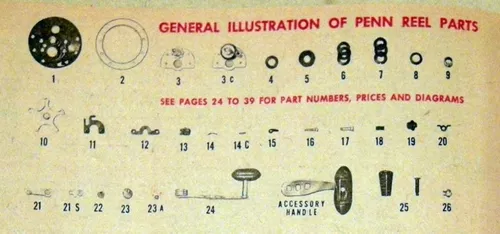

- Key Components

A breakdown of the main parts that make up the device, including gears and spools.

- Mechanics of Operation

Explanation of how each component interacts during use.

- Common Issues

Identification of typical problems users may encounter while using their gear.

- Troubleshooting Techniques

Guidelines on diagnosing issues and determining their causes.

- Maintenance Tips

Best practices for keeping the equipment in optimal condition.

- Tools Needed

A list of essential tools and supplies for maintenance and repairs.

- Step-by-Step Repair Process

Detailed instructions for addressing specific common problems.

- Testing Functionality

Methods for ensuring the device operates correctly after adjustments.

- Long-Term Care

Strategies for prolonging the lifespan of the equipment.

- Conclusion

Summary of the importance of understanding the mechanics for effective maintenance and enjoyment.

Common Issues with Penn Reels

Various challenges can arise when using fishing equipment, impacting its performance and longevity. Recognizing these frequent problems can help enthusiasts maintain their gear effectively and ensure a smoother fishing experience.

Typical Problems Encountered

- Drag Malfunction: Difficulty in adjusting the drag system can lead to inadequate line control, causing frustration during fishing.

- Line Twist: Line tangles and twists often occur, affecting casting distance and accuracy.

- Noise during Operation: Unusual sounds may indicate worn components or insufficient lubrication, signaling the need for maintenance.

- Corrosion: Exposure to saltwater can lead to rust and deterioration, which compromises the functionality of the gear.

Maintenance Tips

- Regularly clean the equipment after each use, especially when used in saltwater environments.

- Lubricate moving parts with appropriate oils to prevent wear and ensure smooth operation.

- Inspect the drag system periodically to ensure it functions correctly and make adjustments as needed.

- Store the gear in a dry, cool place to minimize the risk of corrosion and damage.

Essential Tools for Repairs

Having the right equipment is crucial for effectively addressing maintenance tasks. A well-equipped toolkit not only enhances efficiency but also ensures precision during the process. Whether tackling minor adjustments or comprehensive overhauls, understanding which instruments are necessary can greatly simplify the undertaking.

Basic Hand Tools

Fundamental hand instruments such as screwdrivers, pliers, and wrenches form the backbone of any toolkit. These tools are essential for loosening or tightening components, enabling access to internal parts. A set of varied sizes will help accommodate different fasteners, making tasks more manageable.

Specialized Instruments

In addition to basic tools, specialized instruments like line cutters and oil applicators play an important role in the maintenance process. Line cutters help ensure clean cuts for fishing lines, while oil applicators assist in lubricating moving parts. Investing in these specialized tools can enhance the longevity and performance of your gear.

Step-by-Step Disassembly Process

This section provides a comprehensive guide to carefully dismantling the fishing apparatus for maintenance and cleaning. Following these instructions will help ensure that each component is handled properly, allowing for thorough inspection and servicing. Proper disassembly techniques will help prevent damage and facilitate reassembly.

1. Prepare Your Workspace: Ensure your workspace is clean and organized. Gather necessary tools such as screwdrivers, pliers, and a soft cloth to protect the components during the process.

2. Remove the Side Plate: Start by locating the screws securing the side plate. Use a screwdriver to carefully unscrew and remove them. Gently lift the side plate away from the main body to expose the internal mechanisms.

3. Take Out the Spool: Next, locate the spool assembly. Depending on the design, you may need to remove additional screws or clips. Carefully detach the spool from its housing, ensuring not to damage any attached components.

4. Disconnect the Drag System: Once the spool is removed, access the drag system. Identify the drag washers and any associated parts. Remove them systematically, taking note of their arrangement for reassembly.

5. Extract Internal Gears: With the drag system detached, focus on the internal gear assembly. Unscrew any fasteners holding the gears in place and carefully lift them out. Handle each gear with care to avoid bending or breaking.

6. Document the Process: As you disassemble, take notes or photos of each step. This documentation will serve as a valuable reference for reassembling the unit accurately and efficiently.

7. Clean and Inspect Components: After disassembly, clean all parts using appropriate solvents and tools. Inspect for wear or damage that may require attention before reassembling.

By following these steps meticulously, you can effectively dismantle the apparatus, paving the way for successful maintenance and extended lifespan of the equipment.

Cleaning and Maintenance Techniques

Proper upkeep of fishing equipment is essential for ensuring longevity and optimal performance. Regular cleaning and maintenance not only enhance functionality but also prevent issues that can arise from neglect. Implementing effective techniques can keep your gear in top shape, allowing for a more enjoyable fishing experience.

Routine Cleaning

Systematic cleaning of your apparatus after each use is vital. Rinse the exterior with fresh water to remove salt, dirt, and debris. Use a soft cloth to wipe down all surfaces, paying close attention to any crevices where grime may accumulate. Additionally, check for any signs of corrosion and treat them promptly to prevent further damage.

Lubrication and Storage

After cleaning, it is important to apply a suitable lubricant to moving parts. This reduces friction and ensures smooth operation. Store your equipment in a cool, dry place to avoid moisture buildup, which can lead to rust and deterioration. Properly maintaining your gear will not only extend its lifespan but also improve your overall fishing experience.

Replacing Worn Parts Effectively

Maintaining optimal functionality in fishing equipment involves the timely replacement of components that have experienced wear and tear. Ensuring that each part operates smoothly is crucial for enhancing performance and prolonging the lifespan of the entire assembly.

When identifying parts that require replacement, it is essential to focus on common indicators of degradation. These may include unusual noises, decreased efficiency, or visible signs of damage. By systematically assessing these elements, users can determine which components need attention.

| Component | Signs of Wear | Replacement Recommendations |

|---|---|---|

| Drag Washer | Slipping or uneven resistance | Upgrade to a high-quality composite washer for better performance. |

| Spool Bearing | Rough rotation or noise | Consider ceramic or stainless-steel options for enhanced smoothness. |

| Handle Grip | Cracked or worn surface | Replace with an ergonomic grip for improved comfort and control. |

| Line Guide | Frayed edges or cracks | Install a durable ceramic guide to reduce line wear. |

To ensure successful replacements, it’s advisable to follow manufacturer specifications for each component. Utilizing the correct tools and techniques will facilitate a seamless transition from the old to the new, maintaining the integrity of the setup. Regular maintenance checks will also help in preemptively identifying issues before they escalate.

Tuning for Optimal Performance

Achieving peak efficiency in your fishing equipment requires careful adjustments and fine-tuning of various components. These modifications can significantly enhance functionality and responsiveness, ensuring a smoother experience on the water. By focusing on key aspects, you can optimize performance and prolong the lifespan of your gear.

| Component | Adjustment Tips | Expected Outcome |

|---|---|---|

| Drag System | Ensure proper lubrication and set the drag to match line strength. | Smoother line release and better control during fights. |

| Spool Tension | Adjust tension for the line type used, ensuring a snug fit. | Reduces line twist and improves casting distance. |

| Bearings | Regularly clean and lubricate bearings to reduce friction. | Increased casting distance and smoother retrieves. |

| Handle and Knob | Check for looseness and tighten if necessary for stability. | Improved grip and comfort during use. |

Regular attention to these elements will not only enhance the functionality of your gear but also provide a more enjoyable fishing experience. Consistent tuning and maintenance can lead to impressive improvements, making every outing more successful.

Reassembly Tips for Success

Successfully putting together intricate devices requires attention to detail and a methodical approach. Each component plays a crucial role in the overall functionality, so following best practices during the reassembly process ensures optimal performance. This section outlines essential strategies to aid in the seamless reconstruction of your equipment.

Preparation and Organization

Before starting the reassembly, gather all necessary tools and components in a clean, organized workspace. Utilizing small containers or trays can help keep parts sorted and prevent loss. Documenting the disassembly process with photos can serve as a useful reference for reassembly.

Step-by-Step Approach

Adopting a systematic method when putting parts back together minimizes the risk of errors. Following a reverse order of disassembly can simplify the process, allowing for a more straightforward reinstallation of each piece. Additionally, checking each part for wear or damage before reinstallation can enhance the longevity of the device.

| Tip | Description |

|---|---|

| Use a Clean Workspace | Avoid dust and debris by working in a tidy area to protect sensitive components. |

| Take Photos | Document each step during disassembly for easy reference during reassembly. |

| Check Parts | Inspect components for any signs of wear or damage before reinstalling them. |

| Follow a Sequence | Reassemble in the reverse order of disassembly to streamline the process. |

Testing Your Reel After Repair

Once the maintenance process is complete, it’s crucial to ensure that your equipment functions smoothly and efficiently. This step involves a series of checks and tests to confirm that all components are working harmoniously, providing optimal performance on your next fishing adventure.

Initial Functionality Check

Begin by manually inspecting the gear mechanism. Rotate the handle to assess if it moves freely without any obstructions. Pay attention to any unusual noises, as they may indicate underlying issues. Additionally, test the drag system by applying pressure to the line to ensure it engages and releases smoothly.

Water and Load Testing

For a comprehensive evaluation, consider conducting a water test. Submerge the equipment briefly to check for any leaks, ensuring it can withstand exposure to aquatic environments. Finally, load it with fishing line and simulate actual conditions to verify that it performs under stress, confirming its readiness for use.

Preventative Measures for Longevity

Ensuring the long-lasting performance of your fishing equipment requires attention and care. By implementing a series of simple yet effective practices, you can extend the lifespan of your gear and enhance its functionality. Regular maintenance not only prevents potential issues but also ensures a smoother experience during your fishing trips.

- Regular Cleaning: After each use, rinse your gear with freshwater to remove salt, sand, and debris. This helps prevent corrosion and buildup that can impair performance.

- Lubrication: Periodically apply appropriate lubricants to moving parts. This minimizes friction and wear, ensuring smooth operation over time.

- Storage Conditions: Store your equipment in a cool, dry place. Avoid exposing it to extreme temperatures or humidity, which can cause deterioration.

- Inspect for Damage: Regularly check for signs of wear or damage. Addressing minor issues promptly can prevent more significant problems later on.

By incorporating these practices into your routine, you can significantly enhance the durability and reliability of your fishing tools, making each outing more enjoyable.