Comprehensive Guide to Polaris 360 Repair Manual

Understanding the intricacies of your outdoor equipment is essential for ensuring its longevity and optimal performance. This section provides valuable insights into the various components and systems that require attention, enabling you to maintain your machinery effectively. Whether you are dealing with routine upkeep or specific issues, having a thorough grasp of the underlying mechanics is crucial.

As you delve into the specifics of your device, you will uncover essential techniques and procedures that can enhance its functionality. This guide aims to equip you with the knowledge necessary to address common challenges, from basic adjustments to more complex interventions. With the right approach, you can easily navigate the process and restore your equipment to its prime condition.

Moreover, understanding the components involved will not only assist in problem-solving but will also empower you to perform preventative maintenance. By familiarizing yourself with the essential practices and troubleshooting steps, you can extend the lifespan of your machinery and improve its efficiency. Let this guide serve as your trusted resource in mastering the care and upkeep of your outdoor equipment.

Overview of Polaris 360 Repair Manual

This section provides a comprehensive understanding of the documentation designed to assist users in maintaining and troubleshooting their aquatic cleaning device. It covers essential guidelines, step-by-step procedures, and helpful tips that ensure efficient operation and longevity of the equipment.

The documentation serves as a crucial resource for both novice and experienced users, offering insights into various aspects of device upkeep. From routine maintenance tasks to in-depth troubleshooting techniques, it is structured to enhance user familiarity and confidence with the product.

| Section | Description |

|---|---|

| Introduction | An overview of the device and its features. |

| Maintenance | Guidelines for routine care and upkeep. |

| Troubleshooting | Common issues and solutions for effective problem resolution. |

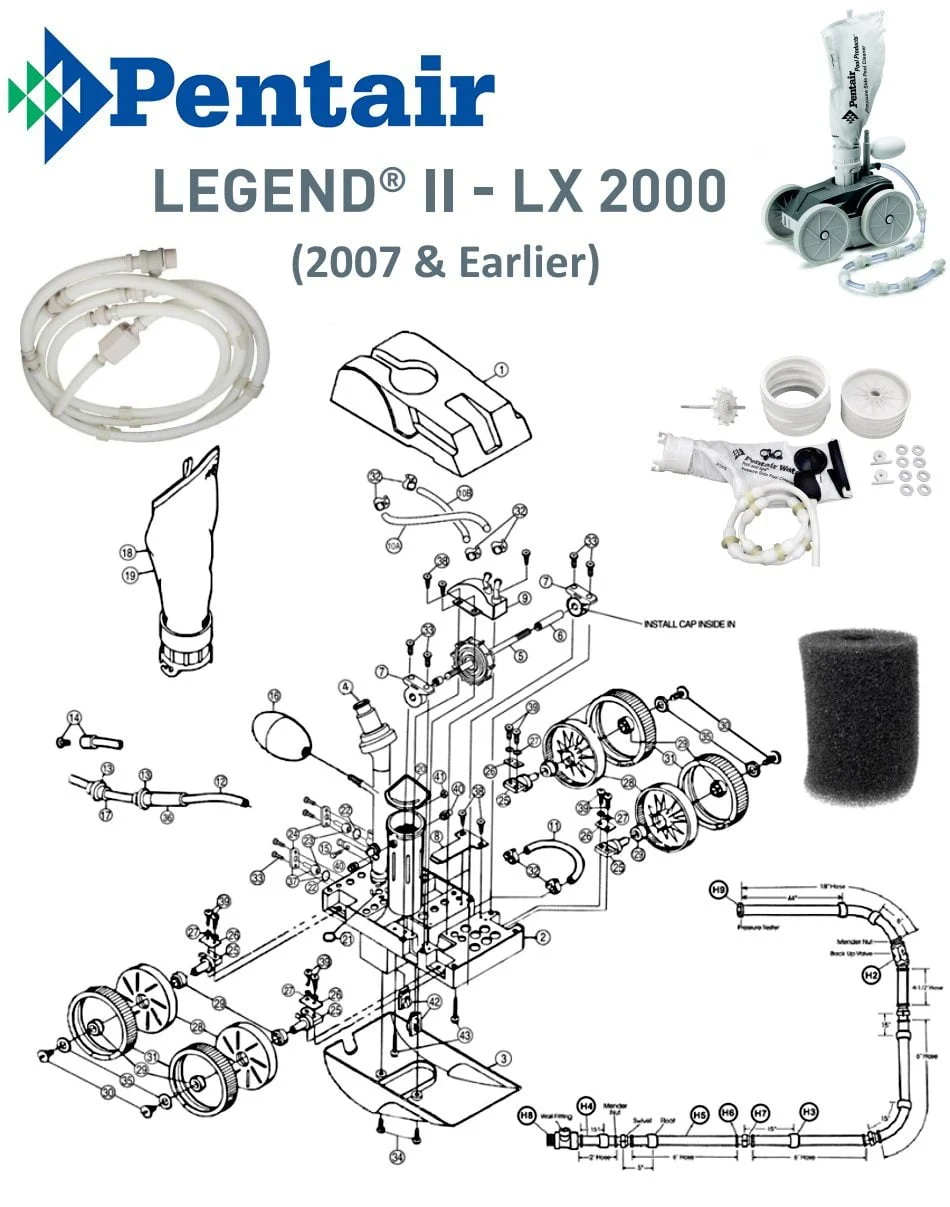

| Parts List | A detailed inventory of components for easy reference. |

| Safety Information | Important safety protocols to follow during operation. |

Common Issues with Polaris 360

When dealing with aquatic cleaning devices, users often encounter several prevalent challenges that can affect performance and efficiency. Understanding these issues is crucial for maintaining optimal functionality and ensuring a smooth operation.

Clogged Filters: One of the most frequent problems is the blockage of filters. Debris can accumulate over time, restricting water flow and diminishing cleaning effectiveness. Regularly inspecting and replacing filters is essential to prevent this issue.

Hose Malfunctions: Another common concern is the deterioration of hoses. Cracks or kinks can disrupt water flow, leading to inefficient cleaning cycles. Ensuring that hoses are in good condition and free from obstructions can help mitigate this problem.

Power Supply Issues: Devices may experience difficulties related to their power sources. Fluctuations or interruptions can lead to operational failures. Checking connections and ensuring the power supply is stable is vital for consistent performance.

Navigation Problems: Many users report challenges with navigation. The device may struggle to move freely or get stuck in corners. Keeping the cleaning area clear of obstacles and ensuring proper setup can help improve movement and efficiency.

By addressing these common challenges, users can enhance the longevity and performance of their cleaning units, ensuring they operate effectively for years to come.

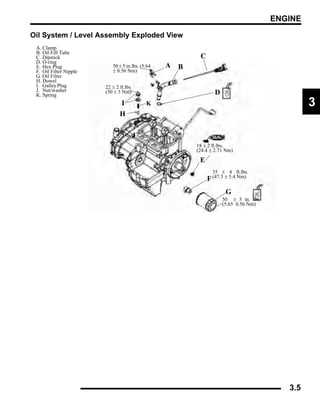

Step-by-Step Repair Process

This section outlines a systematic approach to troubleshooting and fixing issues effectively. By following these sequential steps, users can ensure a thorough examination and resolution of problems, enhancing the longevity and performance of their equipment.

1. Assessment: Begin by carefully inspecting the unit for any visible damage or wear. Identify any unusual noises or operational inconsistencies. Make a note of all findings to guide the subsequent steps.

2. Disassembly: Safely take apart the unit, ensuring that all components are organized. Use appropriate tools to avoid causing further damage. Keep track of screws and small parts to facilitate reassembly.

3. Cleaning: Once disassembled, clean each component thoroughly. Remove dirt, grime, and debris using suitable cleaning agents. This step is crucial for ensuring optimal performance after reassembly.

4. Replacement: Identify any worn-out or faulty parts. Procure high-quality replacements that meet specifications. Ensure compatibility with the existing system to avoid future issues.

5. Reassembly: Carefully reassemble the unit in the reverse order of disassembly. Double-check that all components are properly fitted and secured. Pay special attention to any seals or gaskets to prevent leaks.

6. Testing: Once reassembled, conduct a series of tests to verify functionality. Monitor for any irregularities and ensure that the equipment operates smoothly under various conditions.

7. Final Inspection: Perform a comprehensive check to ensure everything is in place and functioning correctly. Document the process and any changes made for future reference.

Essential Tools for Repairs

When tackling maintenance tasks, having the right equipment is crucial for efficiency and effectiveness. A well-equipped workspace not only streamlines the process but also enhances safety, enabling one to address issues with confidence and precision.

Basic Tools

The foundation of any successful maintenance endeavor lies in basic tools. These include screwdrivers, wrenches, and pliers, which are essential for loosening, tightening, and manipulating various components. Investing in high-quality versions of these tools can make a significant difference in both ease of use and durability.

Specialized Equipment

In addition to the basics, certain specialized implements can greatly aid in more complex tasks. Tools such as multimeters for electrical diagnostics and torque wrenches for precise adjustments ensure that repairs are performed to the highest standards. Familiarizing oneself with these devices can enhance troubleshooting skills and overall proficiency.

Understanding the Components

This section delves into the essential parts of a particular system, highlighting their roles and interconnections. Grasping the functionality of each element is crucial for effective troubleshooting and maintenance, ensuring optimal performance and longevity of the equipment.

Key Elements Overview

Each component plays a specific role in the overall mechanism, contributing to its efficiency and reliability. Recognizing how these parts work together can simplify the diagnostic process and facilitate smoother repairs.

Component Table

| Component Name | Function |

|---|---|

| Motor | Drives the main operations, providing the necessary power. |

| Control Unit | Manages the settings and operations, ensuring precise functionality. |

| Sensor | Monitors performance parameters and provides feedback for adjustments. |

| Battery | Supplies electrical energy to the system, supporting mobility and operation. |

| Chassis | Provides structural support and houses the internal components securely. |

Understanding these core components enables users to identify issues more effectively, ensuring that necessary adjustments or replacements can be made promptly to maintain peak performance.

Preventive Maintenance Tips

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By adhering to a structured maintenance routine, you can prevent unexpected failures and enhance efficiency. This section outlines key practices that can help keep your machinery in peak condition.

Routine Inspections

Conducting frequent inspections is crucial. Look for signs of wear and tear, loose connections, or any unusual noises. Pay attention to fluid levels and filter conditions, as these can indicate potential issues. Timely identification of problems can save time and costs in the long run.

Cleaning and Lubrication

Keeping your equipment clean is vital for performance. Regularly remove dirt and debris that can impede functionality. Additionally, ensure that moving parts are adequately lubricated to minimize friction and wear. Using the right lubricants can significantly enhance operational efficiency and extend the lifespan of components.

Troubleshooting Electrical Problems

When dealing with issues related to electrical systems, it is essential to approach the situation methodically. Understanding the common symptoms and their underlying causes can greatly enhance the efficiency of the diagnostic process. This section will provide guidance on identifying and resolving frequent electrical malfunctions.

1. Check the Battery: A weak or dead battery is often the root of many electrical failures. Ensure the battery is charged and connections are secure. Inspect for corrosion on terminals, which can impede the flow of electricity.

2. Examine Fuses and Relays: Fuses serve as safeguards against overloads. If a circuit is not functioning, inspect the fuses for any signs of damage or burnout. Relays should also be checked, as faulty relays can disrupt the electrical flow.

3. Inspect Wiring and Connectors: Frayed or damaged wiring can lead to shorts and interruptions. Carefully examine all wiring and connectors for signs of wear, breaks, or loose connections. Repair or replace as needed to restore proper function.

4. Test Switches and Components: Malfunctioning switches can cause systems to behave erratically. Use a multimeter to test the functionality of switches and various components. Ensure that all parts are operating within their specified ranges.

5. Utilize Diagnostic Tools: Advanced tools such as scan tools or oscilloscopes can provide deeper insights into electrical issues. Utilizing these devices can help pinpoint specific problems that are not easily detectable with basic inspections.

By following these steps, you can systematically address electrical challenges, ensuring a thorough and effective resolution to the problems at hand.

Replacing Damaged Parts

Maintaining optimal performance of your equipment often requires the timely substitution of worn or damaged components. Addressing these issues promptly not only enhances functionality but also prolongs the lifespan of the machinery. Understanding the process and recognizing when replacements are necessary is crucial for effective upkeep.

Identifying Damaged Components

Before initiating the replacement process, it is essential to accurately identify the affected parts. Look for the following signs:

- Visible wear or cracking

- Unusual noises during operation

- Leaking fluids

- Decreased performance or efficiency

Replacement Process

Once damaged parts have been identified, follow these steps for replacement:

- Gather the necessary tools and replacement components.

- Disconnect power and ensure the equipment is safe to work on.

- Carefully remove the damaged part, taking note of its position and any attached elements.

- Install the new component, ensuring proper alignment and secure attachment.

- Reassemble any other parts that were removed and double-check connections.

- Test the equipment to confirm that the replacement has resolved the issue.

By following these guidelines, you can effectively manage the replacement of damaged parts, ensuring your equipment remains in top condition.

Seasonal Maintenance Guidelines

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment throughout the changing seasons. Adhering to a systematic maintenance schedule can help prevent issues and enhance the overall functionality, making your experience more enjoyable and efficient.

Spring Maintenance: As temperatures rise, it’s crucial to inspect components for wear and tear that may have occurred during the winter months. Check the battery charge and connections, clean the air filter, and ensure fluids are at appropriate levels. A thorough examination of tires and suspension systems is also advisable.

Summer Care: The heat can take a toll on machinery. Monitor cooling systems to prevent overheating. Regularly check the condition of belts and hoses, and keep an eye on tire pressure, as it may fluctuate with higher temperatures. Ensure that all moving parts are well-lubricated to avoid friction-related issues.

Autumn Preparations: As leaves fall, it’s essential to clear debris from all vents and screens to maintain airflow. Inspect the braking system and perform any necessary adjustments to ensure safety. Additionally, begin planning for winter storage by cleaning the equipment thoroughly and considering protective covers.

Winter Readiness: Before winter sets in, drain fuel systems to prevent condensation and consider using a stabilizer for any remaining fuel. It’s also wise to check battery health and consider maintenance charging. Covering the equipment can protect it from harsh weather conditions, ensuring it remains in prime condition for the next season.

By following these seasonal guidelines, you can ensure that your equipment remains reliable and ready for any challenges that arise, allowing for smooth operation year-round.

Cost-Effective Repair Solutions

When facing maintenance challenges, finding budget-friendly alternatives is crucial for effective restoration. Utilizing smart strategies can significantly reduce expenses while ensuring quality outcomes. This section explores practical methods and resources that empower individuals to tackle issues without overspending.

Utilizing DIY Techniques

Engaging in do-it-yourself methods can lead to substantial savings. By researching online tutorials and guides, enthusiasts can gain valuable insights into common problems. Embracing hands-on solutions not only fosters learning but also enhances confidence in handling future challenges. Consider starting with minor tasks to build expertise gradually.

Leveraging Local Resources

Community resources play a vital role in minimizing costs. Local workshops and trade schools often offer assistance or classes for those eager to learn. Additionally, connecting with fellow owners can provide access to shared tools and advice. By fostering a sense of community, individuals can save money while enhancing their skills.

Upgrading Your Polaris 360

Enhancing your aquatic cleaner can significantly improve its performance and efficiency. By implementing various upgrades, you can ensure a more effective cleaning process, ultimately extending the life of your device. This section will explore several key enhancements that can elevate your equipment’s functionality.

1. Enhanced Filtration System: Consider replacing the standard filter with a high-efficiency model. A superior filtration system can capture finer debris and contaminants, ensuring that your water remains crystal clear.

2. Improved Drive Mechanism: Upgrading the drive components can lead to better maneuverability and speed. Look for high-quality replacement parts that offer greater durability and responsiveness.

3. Advanced Software Features: Some modern devices come with software that allows for customized cleaning schedules and patterns. Check if there are firmware updates available for your model that can enhance its programming capabilities.

4. Additional Accessories: Consider investing in accessories such as remote controls or smart connectivity options. These can provide greater control and convenience, allowing for a more personalized cleaning experience.

By focusing on these upgrades, you can transform your aquatic cleaner into a more powerful and efficient tool, making your maintenance tasks easier and more effective.

Resources for Further Assistance

When tackling maintenance or troubleshooting tasks, having access to additional resources can significantly enhance your understanding and efficiency. Whether you are seeking expert advice, detailed guides, or community support, there are numerous avenues available to help you navigate challenges effectively.

Online Forums and Communities

Engaging with fellow enthusiasts can provide valuable insights and support. Consider the following platforms:

- Dedicated Forums: Websites focused on specific topics often have active members willing to share their knowledge.

- Social Media Groups: Platforms like Facebook and Reddit host groups where users discuss common issues and solutions.

- YouTube Channels: Many creators offer tutorials and walkthroughs that can visually guide you through processes.

Official Support and Documentation

Utilizing official resources can ensure you are following best practices. Explore these options:

- Manufacturer Websites: Check for downloadable resources and FAQs that address common inquiries.

- Customer Support: Reach out to official representatives for personalized assistance with specific concerns.

- Instructional Videos: Many manufacturers provide video content that details procedures and maintenance tips.