Comprehensive Guide to Polaris 9450 Repair Manual

In the world of aquatic cleaning technology, proper upkeep and troubleshooting are crucial for ensuring optimal performance and longevity of your equipment. Understanding the intricacies of these devices empowers users to tackle issues effectively, preventing minor setbacks from escalating into significant problems. This guide aims to provide essential insights and practical solutions for common challenges faced by users.

Whether you are a seasoned owner or a newcomer to this innovative cleaning solution, familiarity with its components and operation is vital. Knowledge of assembly, disassembly, and routine checks can significantly enhance the efficiency of your equipment. This resource will delve into step-by-step processes and offer helpful tips to streamline maintenance tasks.

By equipping yourself with the right information, you can save time, reduce costs, and enhance the overall experience of maintaining a clean and inviting aquatic environment. Let’s explore the fundamental aspects that contribute to the seamless functioning of your device.

Overview of Polaris 9450 Features

This section delves into the remarkable attributes of a high-performance cleaning device designed for effortless maintenance of swimming pools. Its innovative technology and user-friendly features set it apart in the market, making it an essential tool for pool owners seeking efficiency and convenience.

Key Features

| Feature | Description |

|---|---|

| Advanced Navigation | Utilizes smart mapping technology to efficiently cover the entire pool surface, ensuring no area is overlooked. |

| Energy Efficiency | Engineered to minimize energy consumption while delivering optimal cleaning performance. |

| Multi-Functionality | Capable of tackling various types of debris, from leaves to fine dirt, thanks to its versatile cleaning capabilities. |

| User-Friendly Controls | Equipped with a simple interface that allows for easy programming and operation, even for beginners. |

Benefits

The device not only simplifies the cleaning process but also enhances the overall swimming experience by maintaining crystal-clear water. Its reliability and durability further contribute to a long-lasting investment for pool care, ensuring that users can enjoy their aquatic spaces without the hassle of constant upkeep.

Common Issues Faced by Users

Users often encounter a range of challenges with their automated cleaning devices, which can impact performance and efficiency. Understanding these prevalent issues can help in troubleshooting and maintaining optimal functionality.

Frequent Problems

Several users report recurring issues that may arise during the operation of these devices. Identifying these common problems is the first step towards resolving them effectively.

| Issue | Possible Cause | Solution |

|---|---|---|

| Device not starting | Power supply failure | Check power connections and ensure the outlet is functioning. |

| Poor cleaning performance | Clogged filters or brushes | Clean or replace filters and brushes as needed. |

| Unexpected shutdowns | Overheating | Allow the device to cool down and check for obstructions. |

| Remote control issues | Battery depletion | Replace batteries in the remote control. |

Maintenance Tips

Regular upkeep can significantly reduce the likelihood of these issues. Simple actions such as cleaning the unit after each use and checking components periodically can enhance longevity and performance.

Step-by-Step Repair Instructions

This section provides a detailed guide for troubleshooting and fixing common issues that may arise with your equipment. By following these organized steps, you can efficiently address problems and ensure optimal performance.

- Identify the Issue:

- Observe any unusual behavior or performance problems.

- Listen for unusual sounds or vibrations.

- Check for visible wear or damage on the exterior.

- Gather Necessary Tools:

- Screwdrivers (flathead and Phillips)

- Wrenches and pliers

- Replacement parts, if needed

- Cleaning supplies

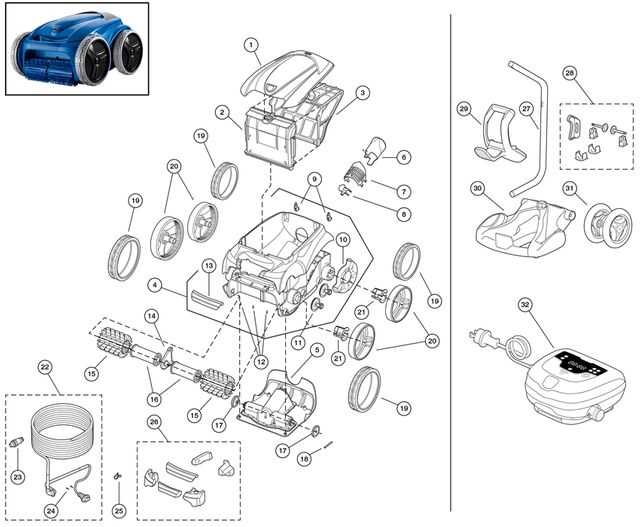

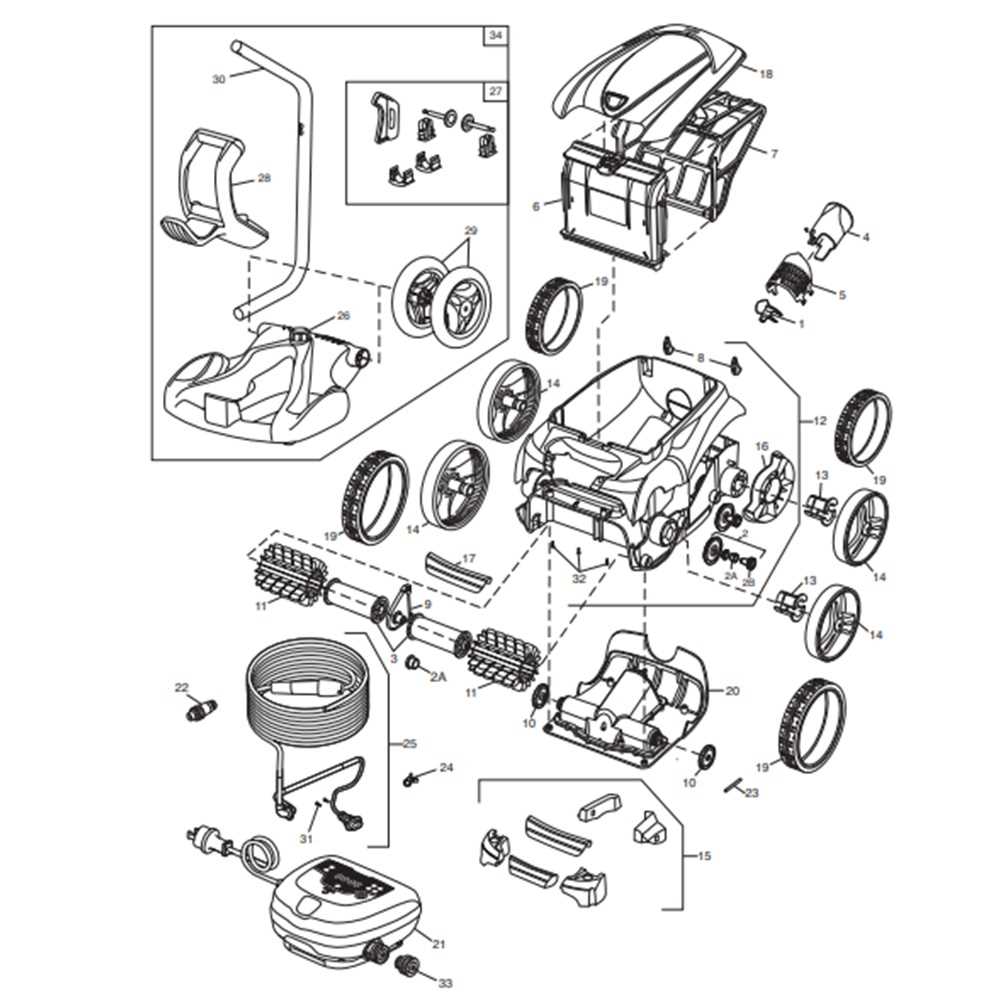

- Disassemble the Unit:

- Turn off and unplug the device for safety.

- Carefully remove screws and components in the correct order.

- Keep track of all parts to simplify reassembly.

- Inspect Internal Components:

- Look for signs of damage or wear on critical parts.

- Check connections and wiring for integrity.

- Clean any dirt or debris that may affect performance.

- Replace or Repair Parts:

- If a component is faulty, replace it with a new one.

- For minor repairs, apply appropriate fixes as needed.

- Ensure all replacements are compatible with your model.

- Reassemble the Equipment:

- Follow the reverse order of disassembly carefully.

- Ensure all screws are tightened properly.

- Double-check that no parts are left over.

- Test the Functionality:

- Reconnect and power on the device.

- Observe its performance and check for any remaining issues.

- Make adjustments as necessary based on the test results.

By following these structured steps, you can effectively troubleshoot and restore your unit to optimal working condition, ensuring longevity and reliability.

Essential Tools for Maintenance

Proper upkeep of your equipment not only ensures optimal performance but also extends its lifespan. Having the right set of instruments at your disposal is crucial for effective servicing and troubleshooting. This section outlines the necessary tools that can aid in regular maintenance tasks, ensuring that everything operates smoothly.

| Tool | Purpose |

|---|---|

| Screwdriver Set | Used for loosening and tightening screws during assembly and disassembly. |

| Wrench Set | Essential for adjusting bolts and nuts, ensuring secure fittings. |

| Socket Set | Facilitates easy access to fasteners in tight spaces. |

| Pliers | Helpful for gripping, twisting, and cutting wires or other materials. |

| Cleaning Supplies | Includes brushes and cloths to maintain cleanliness and prevent buildup. |

| Lubricants | Essential for reducing friction and wear on moving parts. |

| Multimeter | Used for diagnosing electrical issues by measuring voltage, current, and resistance. |

Equipped with these essential tools, you can tackle maintenance tasks efficiently and keep your equipment in peak condition.

Understanding the Electrical System

The electrical system of a robotic pool cleaner plays a crucial role in its overall functionality. This complex network of components is responsible for powering various features, enabling efficient operation, and ensuring user safety. A solid understanding of this system can help in troubleshooting and maintenance, ultimately extending the lifespan of the device.

Key Components of the Electrical System

At the heart of the electrical network are several essential elements, including the motor, control board, and sensors. The motor drives the movement of the unit, allowing it to navigate through the pool efficiently. The control board acts as the brain of the operation, processing inputs from the user and coordinating the actions of the cleaner. Lastly, various sensors provide feedback on the unit’s position and environment, ensuring optimal performance.

Troubleshooting Electrical Issues

Identifying and resolving electrical issues can often be straightforward if one understands the system’s layout. Begin by checking the power supply to ensure that the unit is receiving the appropriate voltage. If problems persist, examine connections and components for signs of wear or damage. Regular inspections can prevent minor issues from escalating into major failures, thereby maintaining operational efficiency.

How to Clean and Maintain Filters

Regular cleaning and maintenance of filtration systems are crucial for optimal performance and longevity. Proper care not only ensures efficiency but also prevents potential issues that can arise from neglecting these essential components.

Step 1: Disassembly – Begin by carefully removing the filters from the unit. Consult the manufacturer’s guidelines for specific disassembly instructions to avoid damaging any parts during the process.

Step 2: Rinsing – Rinse the filters under warm water to remove loose debris and dirt. A gentle stream is recommended to avoid harming the filter material. If the filters are heavily soiled, a mild soap solution can be used to aid in the cleaning process.

Step 3: Drying – After rinsing, allow the filters to air dry completely. Ensure that they are placed in a well-ventilated area away from direct sunlight, which can cause damage to some materials.

Step 4: Reassembly – Once the filters are thoroughly dry, reattach them to the unit carefully, making sure that they fit securely in their designated slots.

Maintenance Tips – Regular inspection is key. Check filters monthly and clean them as necessary, especially during peak usage seasons. Keeping a maintenance schedule will help prolong the lifespan of the filtration system and ensure effective operation.

Troubleshooting Navigation Problems

Effective navigation is crucial for optimal performance. Issues in this area can arise from various factors, and identifying the root cause is essential for restoring functionality. This section outlines common problems and solutions to help you regain seamless operation.

Common Symptoms and Causes

One of the most frequent issues is erratic movement or an inability to follow the intended path. This can often be traced back to sensor malfunctions, obstructions in the path, or incorrect calibration. Additionally, interference from nearby electronic devices may also disrupt navigation capabilities.

Steps to Resolve Issues

To address navigation challenges, first inspect the sensors for cleanliness and proper alignment. Remove any debris that may obstruct their function. If issues persist, check for software updates that could enhance performance. Lastly, recalibrate the system according to the manufacturer’s guidelines to ensure accurate tracking and movement.

Replacing Worn-Out Parts

Maintaining optimal performance in any mechanical system often requires the timely substitution of components that have experienced wear and tear. Regular inspections help identify parts that may be degraded, ensuring efficiency and longevity of the entire unit. This section outlines the process and considerations involved in replacing these essential elements.

Identifying Worn Components

Before proceeding with any replacements, it is crucial to accurately diagnose which parts need attention. Here are some signs to look for:

- Unusual noises during operation

- Decreased performance or efficiency

- Visible damage such as cracks or fraying

- Increased vibrations or instability

Replacement Process

Once you have identified the components that require replacement, follow these steps to ensure a successful swap:

- Gather necessary tools and replacement parts.

- Ensure the unit is powered down and disconnected from any power sources.

- Carefully remove the worn-out parts, taking note of their arrangement for reinstallation.

- Install the new components, making sure they are securely fitted.

- Reassemble any surrounding fixtures or covers that were removed.

- Test the unit to confirm proper functionality.

By regularly monitoring and replacing worn components, you can extend the lifespan of your equipment and maintain peak performance levels.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is essential to prioritize safety to prevent accidents and injuries. Understanding the potential hazards and taking necessary precautions can ensure a smooth and secure working environment. Adhering to safety guidelines not only protects the individual performing the work but also preserves the integrity of the equipment involved.

| Safety Measure | Description |

|---|---|

| Wear Protective Gear | Always use appropriate personal protective equipment, such as gloves, goggles, and masks, to shield against debris and hazardous substances. |

| Ensure Proper Ventilation | Work in a well-ventilated area to avoid inhaling harmful fumes or dust, which can pose health risks. |

| Disconnect Power Sources | Before beginning any task, ensure that all power sources are disconnected to prevent accidental activation. |

| Keep Workspace Organized | A clutter-free environment reduces the risk of tripping hazards and allows for efficient movement while working. |

| Use the Right Tools | Select tools that are suitable for the task at hand to minimize the risk of injury and enhance effectiveness. |

| Follow Instructions Carefully | Adhere to the guidelines provided for any procedures to avoid mistakes that could lead to accidents. |

By implementing these safety measures, individuals can significantly reduce risks associated with maintenance work, ensuring both personal safety and the proper functioning of equipment.

Frequently Asked Questions About Repairs

This section aims to address common inquiries related to maintenance and troubleshooting of pool cleaning devices. Whether you are encountering issues or simply seeking guidance on upkeep, the following questions provide valuable insights to assist you in resolving concerns effectively.

1. What are the most common issues that these devices face?

Users often report problems such as poor cleaning performance, inability to navigate the pool effectively, and recurring error codes. Understanding these frequent challenges can help in identifying solutions more quickly.

2. How can I determine if my device needs servicing?

Signs that maintenance is necessary include unusual noises, diminished suction power, or visible wear on components. Regular inspections can help catch these issues early.

3. Are there specific tools required for troubleshooting?

Basic tools such as screwdrivers, pliers, and a multimeter are generally sufficient for most diagnostic tasks. Familiarizing yourself with your device’s components can enhance your ability to perform checks effectively.

4. Can I fix minor issues on my own?

Many minor repairs can be handled independently, provided you have the right instructions and tools. However, it is essential to ensure safety and avoid voiding any warranties.

5. When should I consider seeking professional help?

If you encounter complex problems that require specialized knowledge or tools, consulting a professional technician is advisable. This ensures that repairs are conducted safely and efficiently.

Where to Find Replacement Parts

Locating suitable components for your equipment can often be a straightforward process if you know where to look. Whether you need spare parts for routine maintenance or specific repairs, there are several reliable sources that cater to your needs. Understanding the available options can save you time and ensure that your device remains in optimal condition.

Authorized Dealers

One of the most reliable sources for acquiring replacement components is through authorized dealers. These retailers typically offer genuine parts that meet the manufacturer’s specifications. You can often find a list of authorized dealers on the manufacturer’s website, making it easy to locate a nearby store or an online option.

Online Marketplaces

Online platforms have become increasingly popular for sourcing spare parts. Websites specializing in equipment components often feature a wide range of options, including both original and aftermarket parts. Always ensure to check customer reviews and ratings to select trustworthy sellers who provide quality products.

Benefits of Regular Maintenance

Routine upkeep is essential for ensuring the longevity and efficiency of any mechanical device. By adhering to a consistent maintenance schedule, users can prevent minor issues from escalating into significant problems, ultimately saving time and resources.

Enhanced Performance

Regular attention to equipment helps maintain optimal performance levels. Consistent checks and adjustments can lead to improved functionality, ensuring that the device operates smoothly and efficiently. This proactive approach minimizes the risk of unexpected breakdowns and enhances overall user satisfaction.

Cost Savings

Investing in routine care often results in substantial cost savings in the long run. By addressing wear and tear early on, users can avoid expensive repairs and replacements. Additionally, efficient equipment consumes less energy, further contributing to lower operational costs. Ultimately, a well-maintained device is an economical choice.