Ultimate Guide to Polaris RZR Repair Manual

Maintaining the performance and longevity of your off-road vehicle is crucial for any enthusiast. Understanding the intricacies of your machine not only enhances your riding experience but also ensures safety on rugged terrains. This guide serves as a comprehensive resource for troubleshooting, upkeep, and modifications to keep your vehicle in top shape.

In this section, we delve into the critical components of off-road vehicles, outlining key procedures and offering insights into common issues that may arise. Whether you are dealing with mechanical failures or simply looking to enhance your vehicle’s capabilities, having a thorough understanding of its workings is paramount. Knowledge is power, and being well-prepared can save you time and money.

Equipped with detailed information, you will be empowered to take on various challenges, from routine checks to more complex tasks. Emphasizing safety and efficiency, this guide is designed to support both novice and seasoned riders in maintaining their machines with confidence. Get ready to explore the essential practices that will keep your adventures on track.

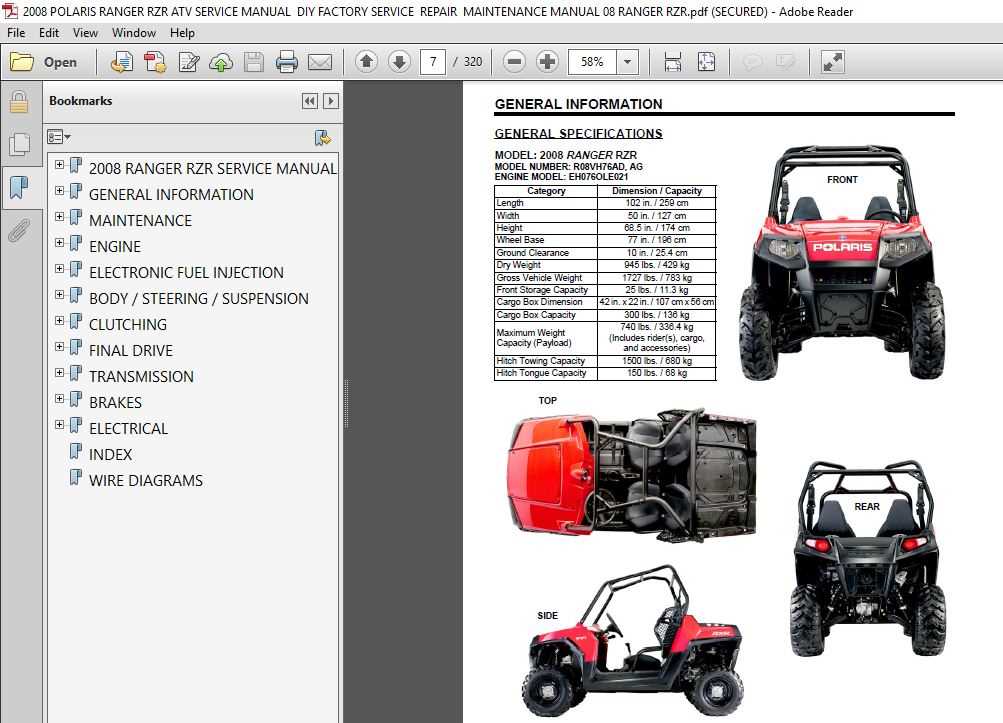

Understanding Polaris RZR Models

In the realm of off-road vehicles, various models cater to diverse needs and preferences. Each variant is designed with unique features that enhance performance and adaptability across different terrains. By delving into the specifications and capabilities of these machines, enthusiasts can better appreciate their offerings and select the right fit for their adventures.

Typically, these vehicles can be categorized based on their engine power, seating capacity, and intended use. For instance, some models prioritize speed and agility, making them ideal for racing, while others focus on utility, featuring additional cargo space and towing capacity. Understanding these distinctions is crucial for maximizing the driving experience.

Moreover, advancements in technology have led to innovations in safety and comfort. Features such as advanced suspension systems, enhanced braking mechanisms, and user-friendly interfaces are now commonplace. These improvements not only contribute to the overall ride quality but also ensure that operators can navigate challenging environments with confidence. Familiarity with these enhancements is essential for both new and seasoned users.

Ultimately, a thorough comprehension of the various models allows potential owners to make informed decisions, ensuring that their selection aligns with their intended use and lifestyle. As the market continues to evolve, staying updated on the latest developments is vital for anyone looking to invest in these remarkable off-road machines.

Common Issues Faced by RZR Owners

Owners of off-road vehicles often encounter a variety of challenges that can affect performance and reliability. Understanding these common problems is essential for maintaining optimal function and ensuring a smooth ride. From mechanical failures to electrical issues, each aspect requires attention and knowledge to address effectively.

1. Engine Performance Issues

One of the frequent concerns involves engine performance. Owners may notice reduced power or unusual noises, which could indicate problems such as fuel delivery issues or ignition system failures. Regular maintenance checks can help identify these issues before they escalate.

2. Suspension Complications

A well-functioning suspension system is crucial for off-road stability. Common complications include worn-out shock absorbers or misaligned components, leading to a rough ride. Regular inspections and timely replacements can enhance handling and comfort.

3. Electrical Failures

Electrical systems in off-road vehicles can be susceptible to failures, often manifesting as issues with lighting, starting, or dashboard displays. Corroded connections or faulty batteries are typical culprits. Ensuring clean, secure connections can prevent many of these electrical setbacks.

4. Tire Wear and Damage

Tires face significant wear due to rough terrains, leading to punctures or uneven wear patterns. Monitoring tire pressure and regularly inspecting for damage can prolong tire life and improve safety.

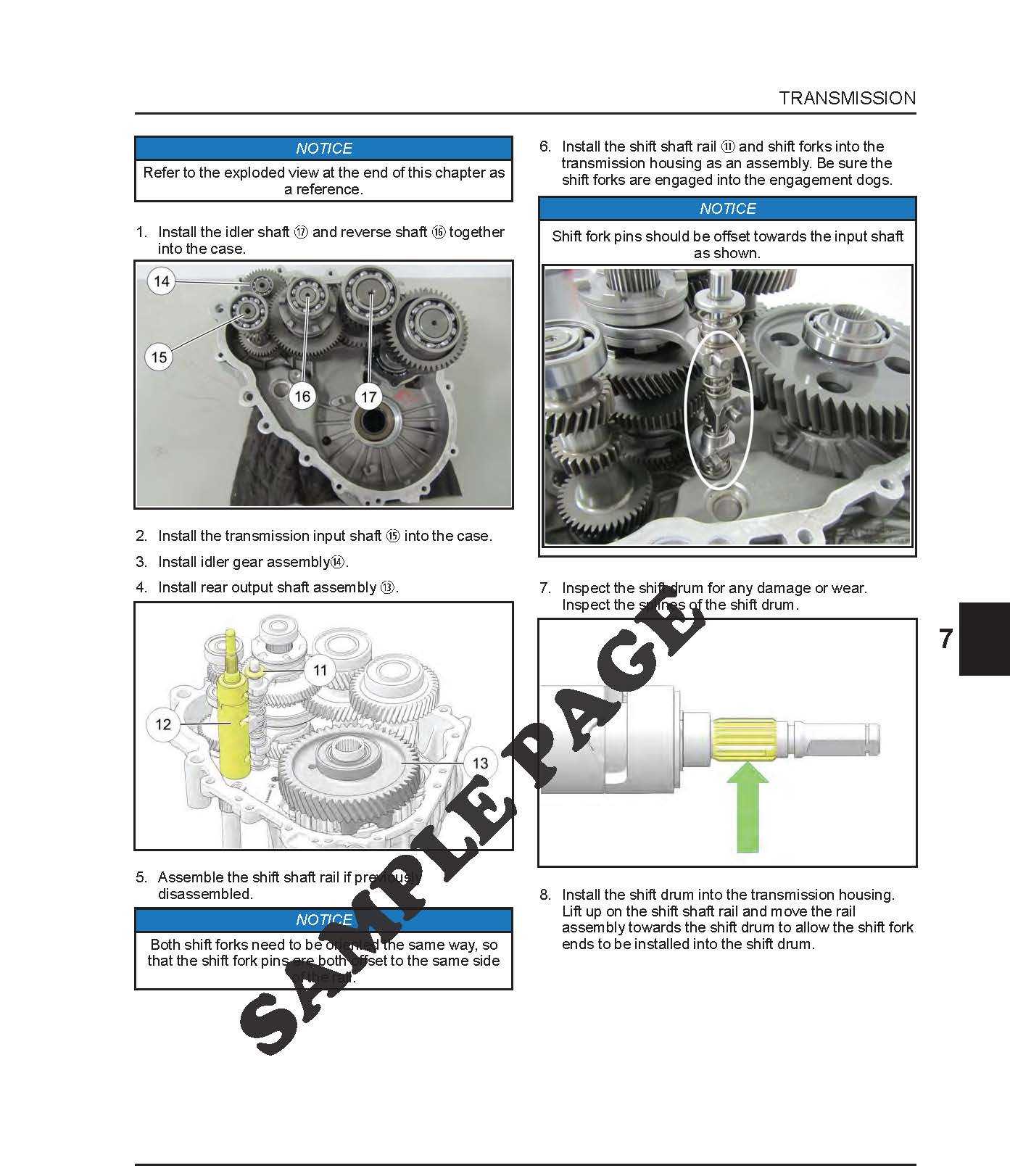

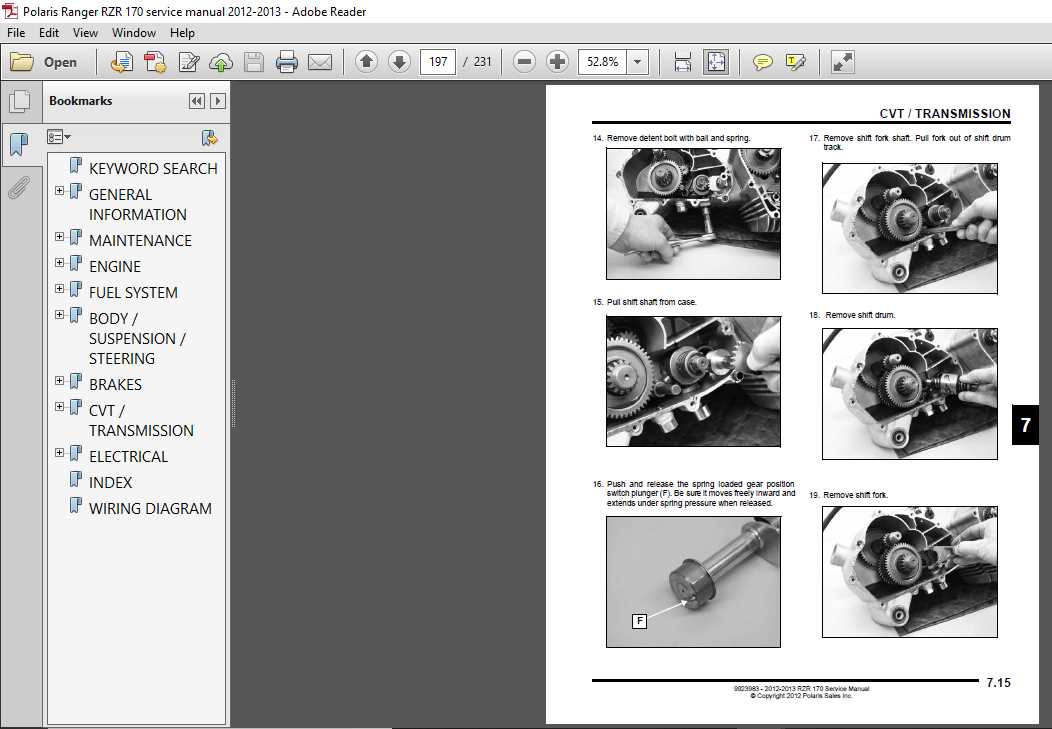

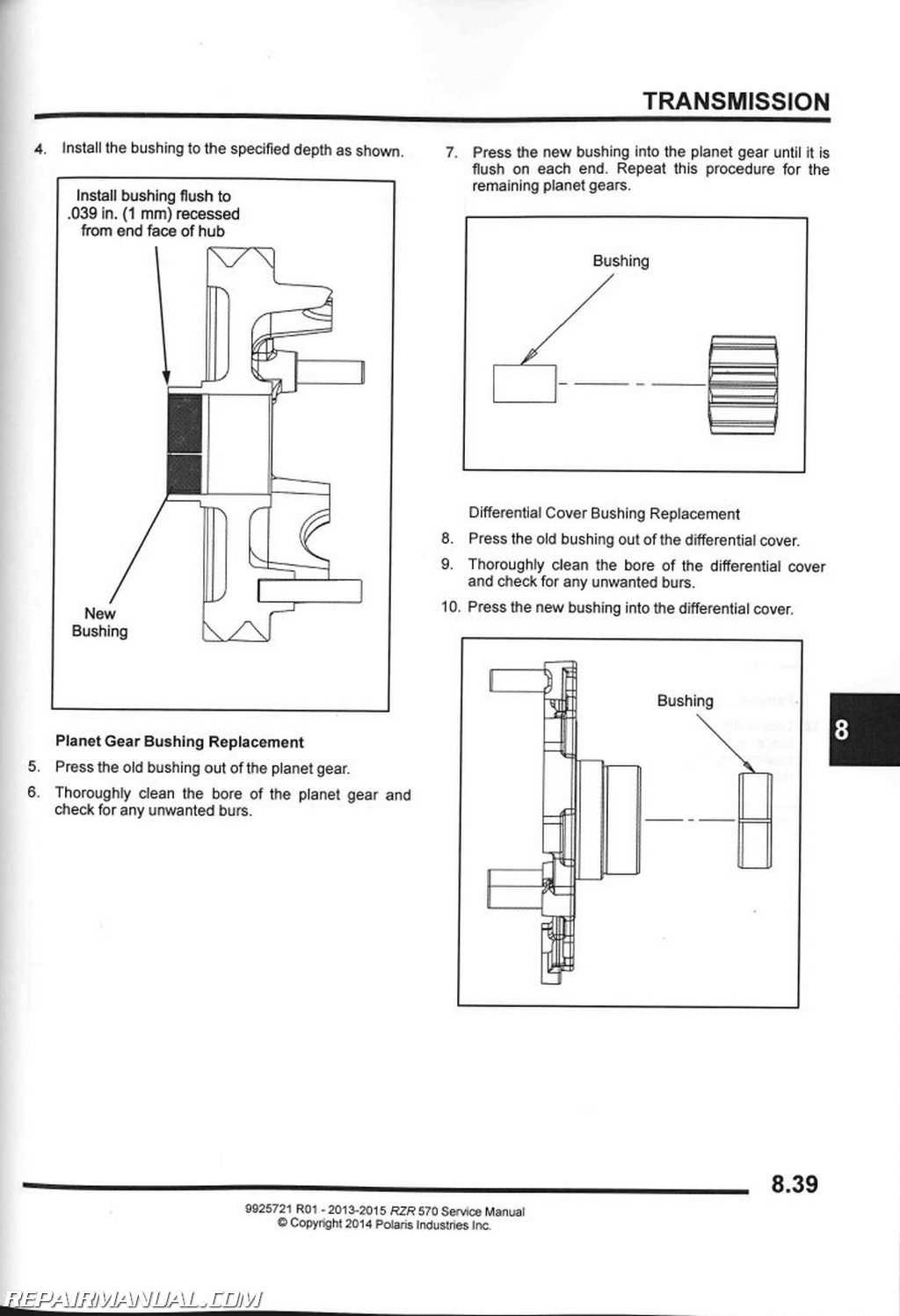

5. Transmission Problems

Transmission complications can manifest as slipping gears or delayed engagement. Regular fluid checks and changes are crucial in preventing severe damage to the transmission system, ensuring smooth operation.

Being proactive and knowledgeable about these common issues can significantly enhance the longevity and reliability of your off-road vehicle. Addressing concerns promptly helps maintain peak performance and ensures an enjoyable riding experience.

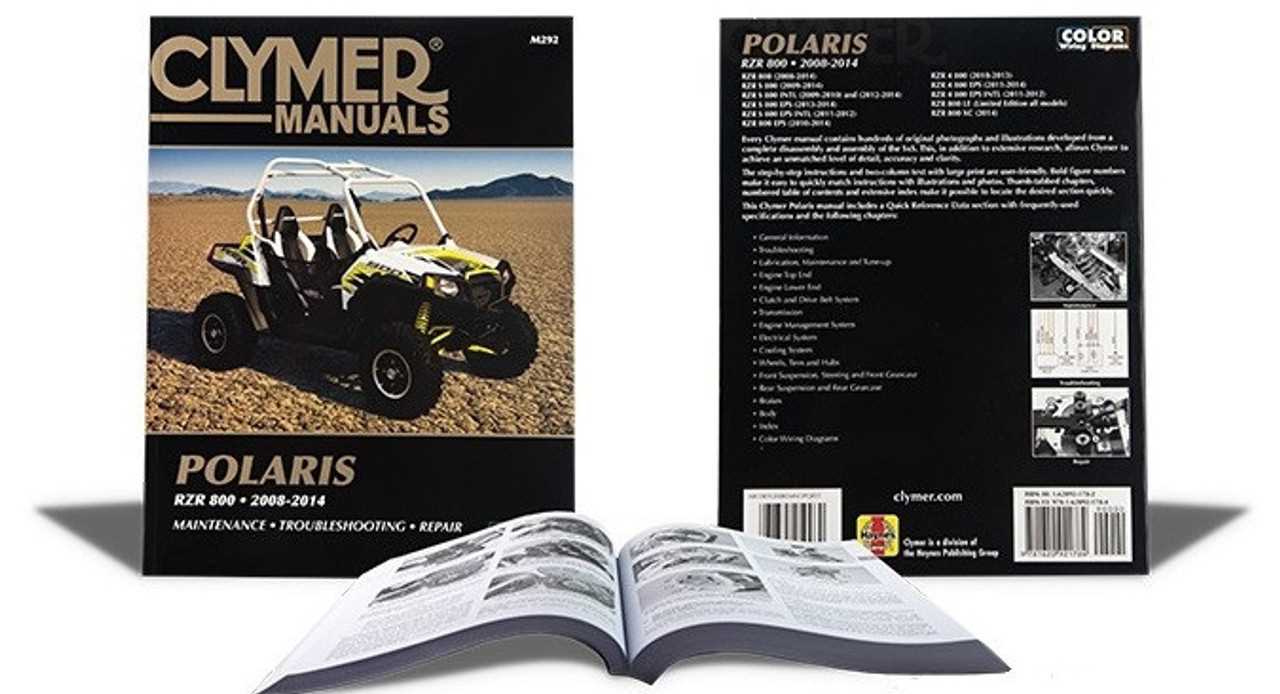

Importance of a Repair Manual

A comprehensive guide for maintenance and troubleshooting is crucial for any vehicle owner. Such documentation serves as a valuable resource, ensuring that users can address issues effectively and maintain optimal performance. By providing detailed instructions and diagrams, it empowers individuals to undertake repairs with confidence, enhancing both safety and longevity of the machine.

Enhancing Knowledge and Skills

Access to a thorough reference not only aids in immediate repairs but also fosters a deeper understanding of the vehicle’s mechanics. Users can learn about various components, their functions, and potential problems, ultimately improving their technical skills. This knowledge enables proactive maintenance, reducing the likelihood of future breakdowns.

Cost-Effectiveness and Time Efficiency

Utilizing a detailed guide can significantly cut costs associated with professional services. By performing tasks independently, owners save money while also gaining the ability to tackle issues promptly. This efficiency minimizes downtime, allowing for more time spent enjoying the vehicle rather than waiting for repairs.

Tools Required for RZR Repairs

When tackling maintenance or troubleshooting on off-road vehicles, having the right equipment is crucial for effective and efficient work. This section outlines the essential tools needed to perform various tasks, ensuring that enthusiasts can confidently address any issues that arise during their adventures.

Basic Hand Tools

A solid set of hand tools is the foundation for any maintenance job. This includes wrenches, screwdrivers, pliers, and sockets in various sizes. Each tool plays a vital role in disassembling components and making adjustments. Investing in a high-quality set can save time and effort, making it easier to complete tasks successfully.

Diagnostic Equipment

For more advanced troubleshooting, diagnostic tools are invaluable. These may include multimeters for electrical testing, scan tools for reading error codes, and pressure gauges for fluid systems. Utilizing such equipment allows for precise identification of issues, leading to more effective solutions and prolonged vehicle life.

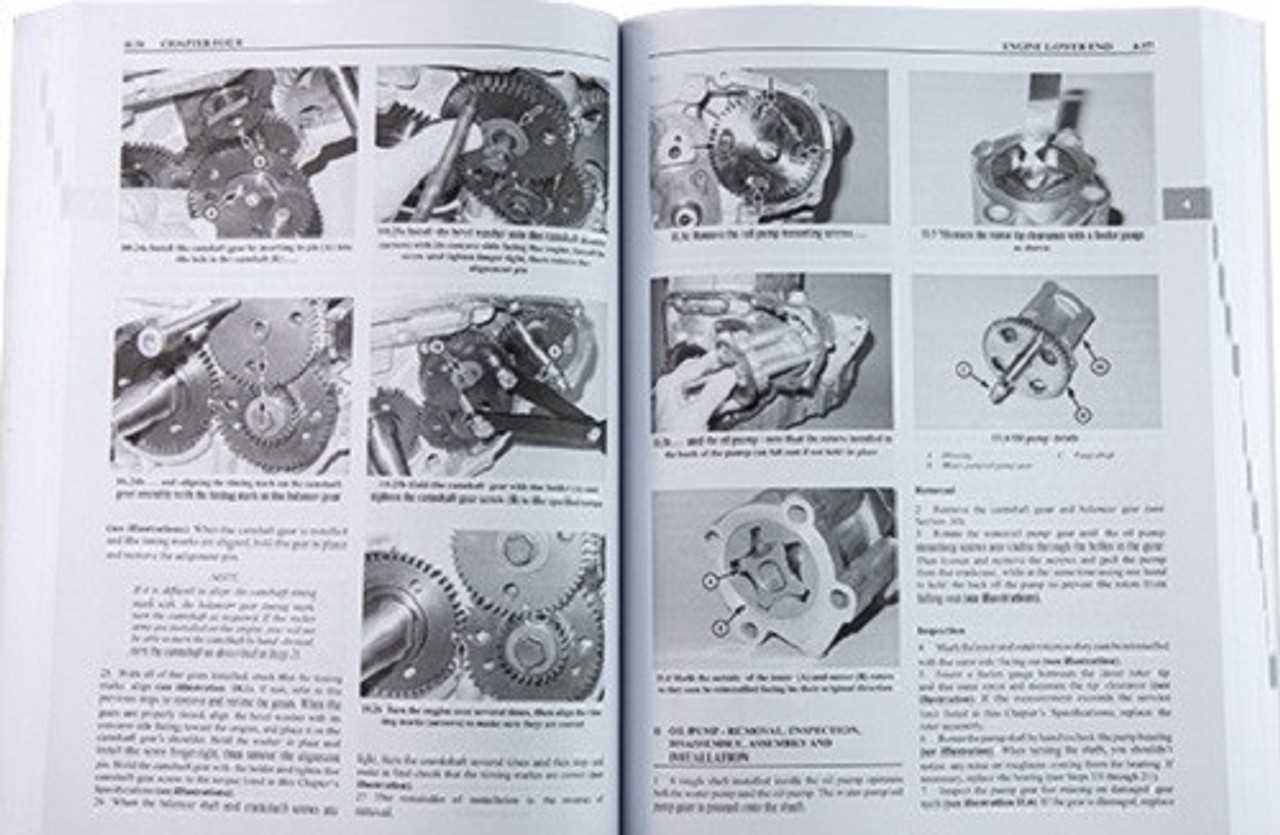

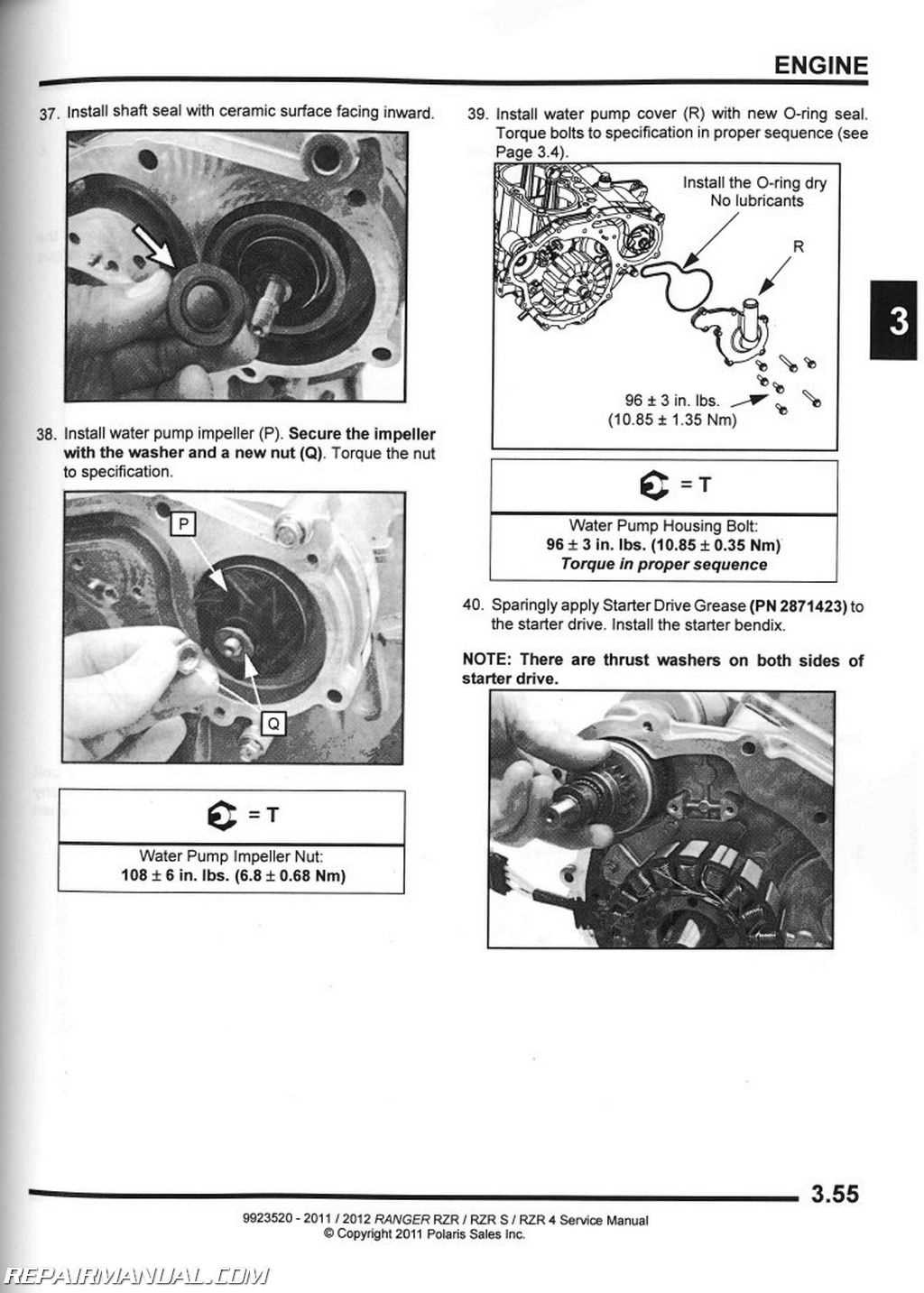

Step-by-Step Repair Guide

This section offers a comprehensive approach to troubleshooting and fixing common issues with your off-road vehicle. By following a structured methodology, you can efficiently identify problems and implement effective solutions, ensuring your vehicle remains in top condition for all your adventures.

Tools and Preparation

Before starting any maintenance task, gather the necessary tools and materials. Here’s a list of essential items:

- Socket set

- Wrenches

- Screwdrivers

- Oil and filters

- Replacement parts

- Cleaning supplies

- Safety gear (gloves, goggles)

Ensure you have a clean workspace and sufficient lighting to facilitate the repair process.

Procedure Overview

- Identify the Issue: Start by observing any unusual sounds or behaviors. Check for leaks, warning lights, or performance issues.

- Consult the Reference Material: Review your reference documentation for specific troubleshooting steps related to your vehicle’s symptoms.

- Disassemble Affected Components: Carefully remove any parts that may be causing the issue, noting the order and orientation for reassembly.

- Inspect and Replace: Examine parts for wear or damage. Replace any faulty components with new ones.

- Reassemble: Follow your notes to put everything back together, ensuring all connections are secure.

- Test the Vehicle: Start the vehicle and check for proper operation. Take it for a test drive to ensure all repairs are successful.

By adhering to this step-by-step guide, you can maintain the functionality and safety of your off-road vehicle, enhancing your outdoor experiences.

Routine Maintenance Tips and Tricks

Regular upkeep of your off-road vehicle is essential for optimal performance and longevity. By implementing a few simple practices, you can ensure that your machine remains in peak condition, ready to tackle any adventure that comes your way. This section provides valuable insights into effective maintenance strategies that can save you time and money in the long run.

1. Check Fluid Levels: Always begin your maintenance routine by inspecting the various fluid levels, including oil, coolant, and brake fluid. Keeping these at recommended levels is crucial for proper function and can prevent overheating or mechanical failures.

2. Clean Air Filter: A clean air filter is vital for engine efficiency. Regularly inspect and clean or replace the filter as needed to ensure your engine breathes easily and operates smoothly.

3. Inspect Tires: Maintaining proper tire pressure and checking for wear or damage can greatly enhance traction and handling. Rotate tires periodically to promote even wear.

4. Battery Care: Check battery connections for corrosion and ensure that terminals are tight. Cleaning the terminals can help maintain optimal performance and extend battery life.

5. Lubricate Moving Parts: Regularly lubricating components such as joints and bearings can prevent wear and tear. Use the appropriate lubricant recommended for your vehicle.

6. Follow the Schedule: Adhere to the manufacturer’s maintenance schedule for inspections and replacements. This can include checking belts, hoses, and other vital components that wear over time.

By integrating these maintenance practices into your routine, you can enhance your vehicle’s reliability and performance. A little effort goes a long way in ensuring that your machine is always ready for the next challenge.

Diagnosing Electrical Problems

Identifying issues within the electrical system of your vehicle can be challenging yet essential for maintaining optimal performance. Understanding the common symptoms and employing a systematic approach will help you pinpoint the root of the problem effectively.

Initial Observations: Begin by noting any irregularities such as flickering lights, unusual sounds, or difficulty starting the engine. These signs can provide crucial clues about underlying faults in the circuitry or components.

Tools Required: To effectively diagnose electrical faults, you’ll need basic tools such as a multimeter, wire testers, and possibly a scan tool. These instruments will assist in measuring voltage, continuity, and identifying short circuits.

Step-by-Step Diagnosis: Start with checking the battery connections to ensure they are clean and secure. Next, test the voltage at the battery terminals. A reading below the expected range could indicate a weak battery or charging system issue. Proceed to examine fuses and relays, as a blown fuse can disrupt power to essential components.

Wiring Inspection: Inspect wiring for signs of wear, corrosion, or damage. Look for frayed wires or loose connections, which can cause intermittent faults. A visual inspection can often reveal issues that may not be detected through electrical testing alone.

Component Testing: For components such as switches, motors, and sensors, use the multimeter to check for proper operation. Refer to the specifications for each part to ensure they are functioning within the required parameters.

Documenting Findings: Keep a detailed record of your observations and test results. This documentation can be invaluable for future reference and troubleshooting, allowing for more efficient diagnosis if issues arise again.

By following these steps and maintaining a methodical approach, you can effectively diagnose and address electrical challenges, ensuring your vehicle operates smoothly and reliably.

Suspension and Handling Adjustments

Proper tuning of suspension and handling systems is crucial for optimizing vehicle performance and ensuring a smooth ride. By making precise adjustments, drivers can enhance stability, improve comfort, and adapt to various terrains. Understanding the components involved allows for tailored modifications that cater to individual preferences and specific driving conditions.

Understanding Suspension Components

The suspension system consists of several key elements, including shocks, springs, and control arms. Each component plays a significant role in how the vehicle reacts to bumps and turns. Shocks control the damping effect, while springs support the vehicle’s weight and absorb impacts. Regularly inspecting these parts can help identify wear and enable timely replacements or adjustments.

Adjusting for Performance

Fine-tuning your suspension setup can dramatically affect handling. Increasing preload on the springs can provide more support for heavier loads, while adjusting damping settings can improve responsiveness during sharp turns. Experimenting with these adjustments allows drivers to find the ideal balance for their unique driving style and the demands of the terrain.

Engine Troubleshooting Techniques

Diagnosing issues within the power unit of an off-road vehicle requires a systematic approach to identify the root cause of any malfunction. Understanding common symptoms and employing effective methods can significantly streamline the resolution process.

Start by observing any unusual noises or vibrations during operation, as these can indicate internal wear or misalignment. Regularly checking fluid levels and conditions is essential; low oil or coolant can lead to overheating and severe damage. Utilize diagnostic tools to read error codes from the onboard computer, which can pinpoint specific areas of concern.

Conducting visual inspections for leaks, cracks, or corrosion can reveal external problems that may affect performance. Pay attention to the air intake and exhaust systems, ensuring they are unobstructed and functioning properly. Regular maintenance practices, such as cleaning filters and spark plugs, contribute to optimal engine function.

Testing the battery and electrical connections is crucial, as a weak power source can hinder performance. Lastly, don’t overlook the importance of consulting technical resources or experienced professionals when complex issues arise, as collaboration often leads to quicker resolutions.

Aftermarket Parts and Modifications

Enhancing the performance and aesthetic appeal of your off-road vehicle can be an exciting journey. The market offers a vast array of components and upgrades that allow enthusiasts to tailor their machines to their specific needs and preferences. This section delves into various aftermarket options available for those looking to elevate their ride.

When considering enhancements, it is essential to explore different categories of aftermarket parts, including:

- Performance Upgrades: Boosting horsepower and torque through engine modifications.

- Suspension Enhancements: Improving ride quality and handling with upgraded shocks and springs.

- Tires and Wheels: Selecting specialized tires and lightweight wheels for better traction and stability.

- Body Kits: Changing the appearance and aerodynamics with custom panels and accessories.

- Lighting Solutions: Enhancing visibility and style with LED lights and additional fixtures.

Additionally, modifications can improve functionality for specific terrains or activities. Some popular adjustments include:

- Winches: Essential for recovery situations.

- Roof Racks: Increasing storage capacity for gear and equipment.

- Skid Plates: Providing additional protection to vital components during off-road adventures.

Before proceeding with any modifications, it’s crucial to consider compatibility and the potential impact on warranty and vehicle performance. Researching reliable brands and seeking advice from experienced users can ensure that enhancements are both beneficial and safe.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial for both personal well-being and the longevity of the vehicle. Following specific guidelines can prevent accidents and promote a secure working environment. It is essential to be aware of potential hazards and take proactive measures to mitigate risks while engaging in mechanical activities.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) when undertaking any servicing tasks. This includes gloves to shield your hands, safety goggles to protect your eyes from debris, and sturdy footwear to guard against heavy objects. Additionally, wearing a helmet can provide extra protection in case of unexpected incidents.

Work Area Safety

Maintain a clean and organized workspace to reduce the likelihood of accidents. Ensure that tools and equipment are stored properly when not in use. Adequate lighting is also essential to clearly see what you are working on. Furthermore, always ensure proper ventilation in enclosed areas to avoid inhalation of harmful fumes.

By adhering to these safety measures, you can create a safer environment that enhances both efficiency and security during any mechanical endeavors.