Ultimate Guide to RC Helicopter Repair and Maintenance

For enthusiasts of aerial gadgets, maintaining the functionality of your remote-controlled flying machines is essential. Over time, these intricate devices may encounter various issues that hinder their performance. Understanding how to troubleshoot and address these challenges can greatly enhance your flying experience.

In this guide, we will explore the common problems faced by users and the necessary steps to bring your craft back to life. Whether it’s a minor malfunction or a more significant breakdown, having a thorough understanding of the components involved will empower you to take action confidently.

With the right knowledge and tools at your disposal, you can ensure that your flying companion remains in optimal condition. This resource aims to equip you with the skills needed to tackle repairs, ultimately allowing you to enjoy the thrill of flight without interruptions.

Understanding RC Helicopter Components

In the world of remote-controlled flight, the intricacies of the various parts play a crucial role in overall performance and functionality. Each element is designed to work harmoniously, contributing to the stability, maneuverability, and responsiveness of the model. A thorough comprehension of these components is essential for enthusiasts and operators alike.

The primary structure, often referred to as the airframe, serves as the foundation for all other parts. It provides the necessary support and houses vital systems. Attached to this framework are the rotor assemblies, which generate lift and control movement in the air. These assemblies consist of blades that require precise balancing to ensure optimal flight dynamics.

Another critical aspect is the propulsion system, which includes motors and batteries. This combination delivers the power required for ascension and sustained flight. Understanding the specifications and capacities of these components is key to achieving desired performance levels.

Control mechanisms, including servos and receivers, facilitate interaction between the pilot and the model. These elements interpret commands and adjust the movement of the rotor assemblies accordingly. Mastering the integration of these systems is vital for effective navigation and handling.

Lastly, additional accessories like landing gear and stabilizers enhance the overall functionality, ensuring safety during landings and takeoffs. By gaining insight into these various components, operators can enhance their flying experience and address any issues that may arise effectively.

Common Issues in RC Helicopters

Remote-controlled flying devices often encounter various challenges that can affect their performance and usability. Understanding these common problems is essential for enthusiasts who wish to maintain and enhance their flying experience. By identifying these issues early, pilots can take appropriate measures to ensure smooth operation.

Electrical Problems

One of the most frequent difficulties involves electrical components. Faulty connections, battery malfunctions, and issues with the receiver can lead to erratic behavior or complete failure to respond. Regular checks of wiring and power sources are crucial to avoid these setbacks.

Mechanical Failures

Mechanical components can also be susceptible to wear and tear. Issues such as misalignment of rotors, damaged gears, or worn bearings can significantly impact flight stability. Routine maintenance and careful handling can help mitigate these concerns.

| Issue | Description | Possible Solution |

|---|---|---|

| Battery Failure | Inability to hold charge or provide power | Replace or recharge batteries |

| Signal Loss | Loss of control during flight | Check antenna and receiver connections |

| Worn Gears | Grinding noises or jerky movements | Inspect and replace damaged gears |

| Unbalanced Rotors | Inconsistent flight performance | Adjust rotor blade weights |

Tools Needed for Repairs

When it comes to maintaining your aerial model, having the right equipment is essential for efficient troubleshooting and restoration. The following tools will help ensure that you can address any issues that arise, keeping your craft in optimal condition.

| Tool | Purpose |

|---|---|

| Hex Driver Set | To tighten or loosen screws on various components. |

| Soldering Iron | For electrical connections and repairs. |

| Precision Screwdriver | To work with small screws in tight spaces. |

| Wire Cutters | To trim and shape wires for connections. |

| Heat Shrink Tubing | To insulate and protect electrical joints. |

| Calipers | For precise measurements of components. |

| Multimeter | To test electrical circuits and diagnose issues. |

Equipping yourself with these tools not only facilitates effective maintenance but also enhances your overall experience with your flying model. Each item plays a vital role in ensuring that you can tackle any challenges that may arise during operation.

Step-by-Step Repair Process

This section outlines a systematic approach to restoring your remote-controlled aerial device to optimal condition. Following a structured procedure ensures that each component is addressed thoroughly, minimizing the risk of future issues and enhancing overall performance.

1. Initial Assessment: Begin by inspecting the unit for visible damage or malfunctioning parts. Take note of any unusual sounds or movements during operation.

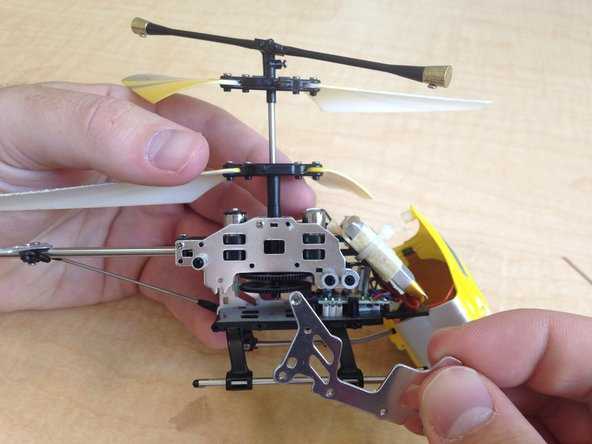

2. Disassembly: Carefully take apart the device, documenting each step to avoid confusion during reassembly. Use appropriate tools to prevent damage to sensitive components.

3. Component Inspection: Examine each part for wear and tear. Look for cracks, bent pieces, or any signs of electrical issues. Testing individual components may help identify the root cause of the malfunction.

4. Replacement of Parts: If any components are found to be faulty, replace them with compatible parts. Ensure that you choose high-quality replacements to guarantee longevity and reliability.

5. Cleaning: Clean all parts thoroughly to remove dust and debris. This step can improve performance and extend the life of the unit.

6. Reassembly: Following your documentation, reassemble the device carefully. Make sure all components fit snugly and securely to prevent any loose connections.

7. Testing: Once reassembled, conduct a series of tests to ensure everything is functioning correctly. Monitor for any unusual behavior and make adjustments as necessary.

8. Final Adjustments: If issues persist, revisit earlier steps. Fine-tuning may be required to achieve optimal performance.

This structured approach not only aids in effectively addressing current issues but also equips you with the knowledge to prevent future complications.

Maintaining Your RC Helicopter

Proper upkeep is essential for the longevity and performance of your remote-controlled flying machine. Regular attention to various components not only enhances functionality but also ensures safety during operation. Understanding the key aspects of maintenance can significantly improve your flying experience.

Routine Checks

Implementing a schedule for routine inspections can prevent minor issues from becoming major problems. Begin by examining the blades for any signs of wear or damage. Balancing the rotor system is crucial for stable flight, so be sure to check that as well. Additionally, inspect the body for cracks or loose parts, which could impact overall performance.

Cleaning and Lubrication

Keeping your device clean is vital. Dust and debris can accumulate in various parts, leading to malfunctions. Use a soft brush to gently remove any particles from the surface and crevices. Regularly applying lubricant to moving parts helps reduce friction and wear. Focus on the gears and bearings to maintain smooth operation.

Replacing Helicopter Blades

Ensuring optimal performance and safety of your aerial model involves regular maintenance, including the replacement of rotor components. This task is essential to enhance flight stability and responsiveness. Understanding the steps and techniques involved can help achieve a successful outcome.

Preparation is Key. Before beginning, gather all necessary tools, including a wrench, screwdriver, and replacement parts. Make sure to work in a well-lit and spacious area to avoid any mishaps. It is also advisable to consult the specifications for your specific model to ensure compatibility.

Step-by-Step Process. Start by carefully detaching the existing rotor blades. Use a wrench to loosen the mounting screws, taking care not to damage any surrounding components. Once removed, examine the new blades for any defects before proceeding to attach them. Align the new blades with the mounting points and secure them firmly using the screws.

Final Checks. After installation, conduct a thorough inspection to ensure everything is securely fastened. Rotate the blades manually to confirm smooth operation. Finally, conduct a test flight in a controlled environment to verify performance before resuming regular usage.

Fixing Electrical System Problems

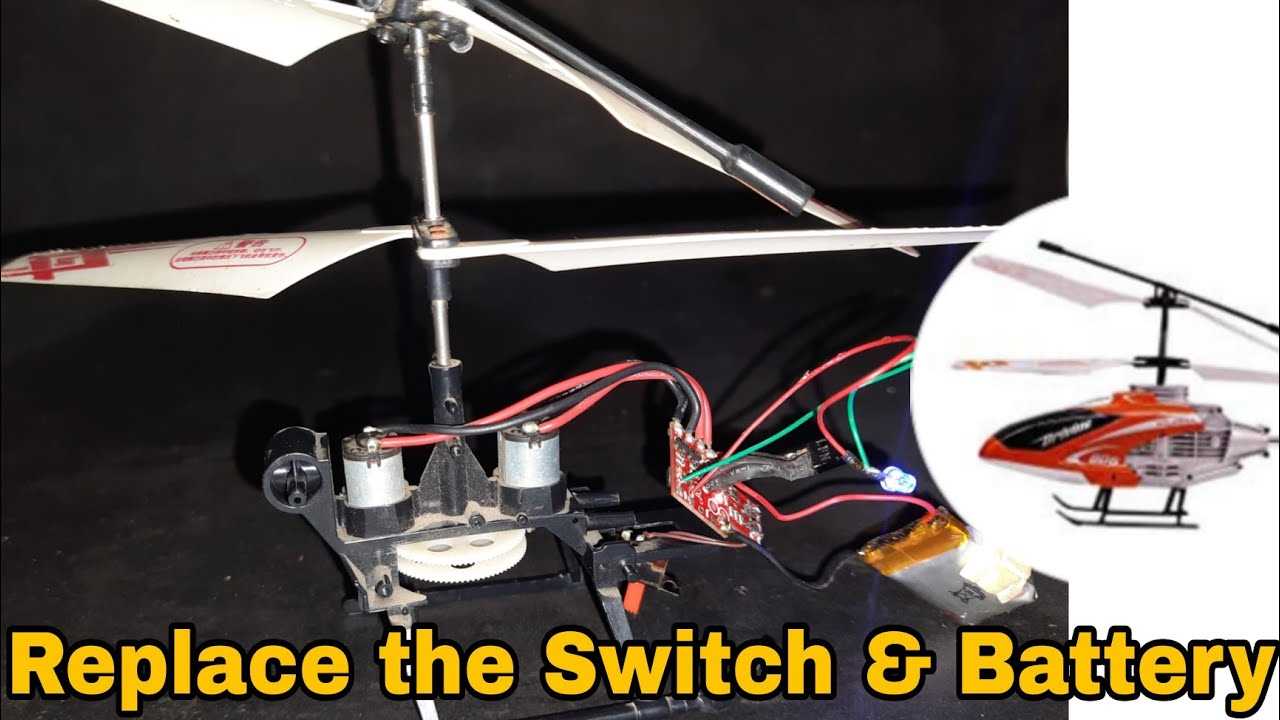

Electrical system issues can significantly impact performance and functionality. Addressing these challenges requires a systematic approach to identify and resolve underlying causes effectively. Understanding the components involved is essential for ensuring optimal operation.

Identifying Common Symptoms

Start by observing any irregularities in performance. Common signs include erratic behavior, loss of power, or unresponsive controls. These symptoms often indicate problems within the circuitry or connections.

Inspecting Connections

Begin troubleshooting by examining all connections. Loose or corroded wires can disrupt the flow of electricity. Ensure that all connectors are secure and free from oxidation. Tightening and cleaning connections can often restore functionality.

Testing Components

Utilize a multimeter to test various electrical components, such as switches, motors, and batteries. Check for continuity and voltage levels to determine if any part is malfunctioning. Replacing faulty components can resolve many issues.

Assessing Power Supply

A reliable power source is crucial. Verify that the battery is fully charged and in good condition. Inspect the power leads for any signs of damage or wear. If the power supply is insufficient, it may require replacement or upgrading.

Revisiting the Circuit Layout

Examine the circuit layout for any signs of damage or improper connections. Ensure that the wiring adheres to recommended configurations. Making adjustments to the layout can enhance overall efficiency and reliability.

By systematically addressing these aspects, you can resolve electrical issues and restore optimal performance. Regular maintenance and vigilance are key to preventing future complications.

Adjusting the Rotor Pitch

Properly tuning the angle of the blades is crucial for achieving optimal performance and stability. This adjustment influences how the model responds to control inputs and can greatly enhance flight characteristics. Understanding the principles behind blade angle modification allows enthusiasts to tailor their craft for specific flying styles and conditions.

Understanding Pitch Angle

The pitch angle determines how much lift the blades generate during flight. A positive pitch increases lift, while a negative pitch decreases it. Striking the right balance is essential for smooth transitions and responsive maneuvers. Regularly checking and adjusting this angle ensures that your model maintains its desired performance over time.

Adjustment Process

To adjust the blade angle, start by loosening the blade grips slightly. Use a pitch gauge to measure the current angle accurately. Gradually increase or decrease the angle as needed, then securely tighten the grips. Always verify the settings by performing test flights, making further adjustments as necessary. Regular maintenance of the pitch will lead to enhanced control and a more enjoyable flying experience.

Battery Care and Replacement Tips

Maintaining and replacing power sources is essential for optimal performance and longevity. Understanding how to properly care for these components ensures they function efficiently and helps prevent unexpected failures. Here are some crucial guidelines to keep in mind.

Proper Maintenance Practices

- Regularly check the voltage levels to ensure they are within the recommended range.

- Keep terminals clean and free from corrosion to ensure good connectivity.

- Avoid exposing the power source to extreme temperatures, as this can shorten its lifespan.

- Store in a cool, dry place when not in use, ideally at a partial charge (around 40-60%).

Signs It’s Time for a Replacement

- Noticeable decrease in performance or run time.

- Swelling or physical deformities in the casing.

- Overheating during charging or use.

- Frequent need for recharging, indicating reduced capacity.

By following these tips, you can ensure that your power sources remain reliable and perform at their best. Regular attention to their condition will help avoid potential issues and enhance your overall experience.

Troubleshooting Flight Control Issues

When operating a remote-controlled aircraft, encountering flight control problems can be frustrating. Understanding the common issues that can arise and knowing how to address them is crucial for a smooth flying experience. This section will guide you through identifying and resolving these challenges effectively.

Common Symptoms of Control Issues

- Unresponsive inputs: The model does not respond to transmitter commands.

- Erratic movements: Unexpected changes in direction or altitude occur.

- Drifting: The craft does not maintain a steady hover and shifts positions on its own.

- Stability problems: The aircraft feels wobbly or unstable during flight.

Steps to Diagnose and Fix Problems

- Check the Transmitter and Receiver:

- Ensure the transmitter is powered and properly calibrated.

- Inspect the connections between the receiver and control surfaces.

- Inspect the Battery:

- Verify that the battery is fully charged and securely connected.

- Look for any signs of damage or swelling.

- Examine Control Surfaces:

- Make sure all control surfaces are moving freely and are not obstructed.

- Check for any mechanical binding or damage.

- Assess Environmental Factors:

- Evaluate wind conditions and avoid flying in strong gusts.

- Ensure that you are operating within the recommended temperature range.

By following these steps, you can identify the root causes of flight control issues and implement effective solutions, ensuring a better performance for your aerial model.

Upgrading Your Helicopter Parts

Enhancing the performance of your remote-controlled flying device can significantly improve its overall functionality and enjoyment. Upgrades can lead to better stability, increased speed, and enhanced maneuverability, allowing for a more thrilling experience in the air. In this section, we will explore various components that can be upgraded to maximize your model’s capabilities.

| Component | Description | Benefits |

|---|---|---|

| Motor | Upgrade to a high-performance motor for increased thrust. | Enhanced power and faster acceleration. |

| Batteries | Use lightweight, high-capacity batteries to extend flight time. | Longer duration and improved energy efficiency. |

| Blades | Replace stock blades with precision-engineered options for better lift. | Improved responsiveness and stability during flight. |

| Frame | Consider a lightweight, durable frame for increased agility. | Better handling and reduced weight for enhanced performance. |

| Receiver/Transmitter | Upgrade to advanced radio systems for better control range. | Increased range and reduced signal interference. |

Investing in these enhancements not only improves your model’s performance but also elevates your piloting skills. Carefully selecting upgrades based on your flying style and needs will yield the best results and make each flight a rewarding experience.

Safety Precautions During Repairs

When engaging in maintenance activities, it is essential to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual working on the device but also ensure the longevity and performance of the equipment. Following certain guidelines can create a safer environment for any hands-on tasks.

Before beginning any work, it is advisable to equip yourself with the right tools and protective gear. This minimizes risks associated with potential hazards during the process. Understanding and adhering to safety protocols can significantly reduce the likelihood of mishaps.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use safety goggles, gloves, and appropriate clothing to protect yourself from debris and harmful substances. |

| Work in a Well-Lit Area | Ensure your workspace is adequately illuminated to avoid mistakes and accidents caused by poor visibility. |

| Disconnect Power Sources | Before starting, make sure to disconnect any power supplies to prevent electrical hazards. |

| Keep Workspace Organized | A tidy area reduces the risk of tripping and makes it easier to locate tools and parts. |

| Follow Manufacturer Instructions | Adhere to guidelines provided by the manufacturer to avoid damaging components and ensure proper assembly. |

By implementing these safety measures, you can significantly enhance your protection and ensure a smoother experience while performing maintenance tasks. Remember, a cautious approach is key to successful and safe operations.