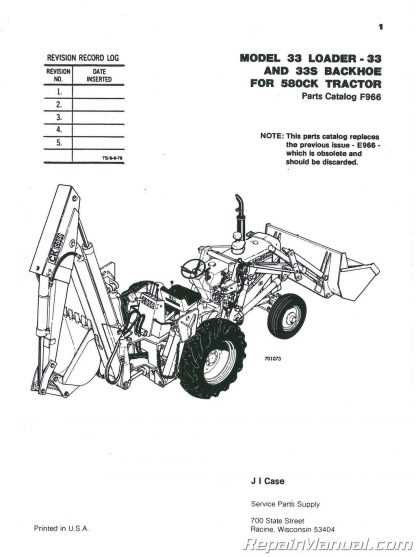

Comprehensive Guide to Case 580 Backhoe Parts Diagram

In the world of heavy equipment, comprehending the various elements that constitute a machine is crucial for effective operation and maintenance. A thorough exploration of these components can significantly enhance the longevity and efficiency of the equipment. This section delves into the intricate relationships among the various segments that make up a specific type of machinery.

By familiarizing oneself with the configuration and functionality of these elements, operators can better address any challenges that may arise. Knowledge of each segment’s role not only aids in smooth functioning but also empowers individuals to perform necessary upkeep tasks confidently. Acquiring this understanding is essential for maximizing the performance and durability of your machinery.

Moreover, having access to visual representations of these components can further clarify their arrangement and interconnections. Such insights allow users to grasp the complexity of machinery design, promoting informed decision-making and proactive management. Ultimately, the mastery of these details will contribute to a more seamless operational experience.

Understanding the Case 580 Backhoe

The powerful machine discussed here is essential for various construction and excavation tasks. It integrates multiple functions, allowing operators to tackle a wide range of projects efficiently. Its design incorporates advanced features that enhance productivity and ease of use, making it a preferred choice for professionals in the industry.

This equipment is characterized by its robust structure, which ensures durability and reliability in demanding environments. Its versatility is evident through its ability to perform different operations, from digging to lifting, thereby optimizing workflow on job sites.

Furthermore, familiarity with the components and their functions is crucial for maximizing performance. Understanding how each element contributes to the overall operation can lead to better maintenance and enhanced efficiency during use.

Essential Components of the Backhoe

Understanding the key elements of this versatile machinery is crucial for efficient operation and maintenance. These components work together to ensure functionality, enabling various tasks such as digging, lifting, and moving materials.

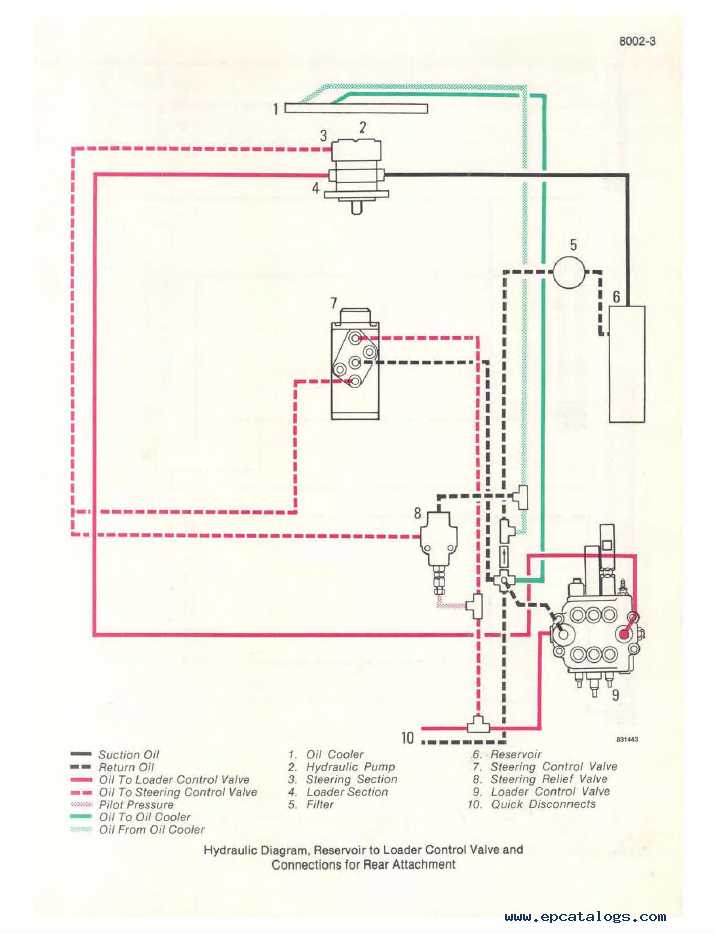

One of the most significant elements is the hydraulic system, which provides the necessary power for movement and operation. This system relies on fluid mechanics to facilitate the lifting and lowering of attachments.

Another critical aspect is the engine, which serves as the powerhouse. Its performance directly influences the machine’s overall capability and efficiency.

The bucket plays a vital role in executing tasks, offering different shapes and sizes to accommodate various functions. Additionally, the frame provides structural support, ensuring stability and durability during operations.

Finally, understanding the controls and their arrangement is essential for seamless operation, allowing the operator to navigate the machine’s functions with ease.

Common Issues and Solutions

Understanding frequent challenges that can arise with machinery is crucial for maintaining optimal performance. By identifying these issues early, operators can implement effective remedies, ensuring longevity and efficiency in operation.

One common problem involves unexpected vibrations during operation. This can indicate misalignment or wear in critical components. Regular inspections and timely adjustments can significantly mitigate this issue.

Another frequent concern is reduced power output, which may stem from fuel system blockages or air intake restrictions. Routine maintenance, including filter replacements and system cleanings, can enhance performance and prevent further complications.

Leaking fluids often signal underlying issues that require immediate attention. Ensuring proper sealing and regularly checking connections can help address this problem before it escalates.

Operators may also notice excessive noise, which could be a sign of worn bearings or loose parts. Regular lubrication and tightening of fasteners can alleviate these sounds and enhance overall functionality.

Maintenance Tips for Longevity

Ensuring the durability of machinery requires consistent attention and proper care. By following essential guidelines, operators can enhance performance and extend the lifespan of their equipment, reducing downtime and costly repairs.

| Tip | Description |

|---|---|

| Regular Inspections | Conduct frequent assessments to identify any wear or damage early on. This proactive approach helps in addressing potential issues before they escalate. |

| Fluid Checks | Monitor and maintain optimal fluid levels. This includes checking oil, hydraulic fluid, and coolant to ensure efficient operation. |

| Clean Components | Keep all parts clean from debris and contaminants. Regular cleaning prevents buildup that can lead to malfunctions. |

| Proper Lubrication | Apply the correct lubricants to moving parts as recommended by the manufacturer. This reduces friction and wear. |

| Follow Operating Guidelines | Adhere to the manufacturer’s operating instructions to avoid misuse that could lead to premature failure. |

Parts Replacement: Step-by-Step Guide

This section provides a comprehensive overview of the process involved in swapping out components in heavy machinery. Understanding the sequence of actions is crucial for achieving optimal performance and ensuring the longevity of the equipment.

Preparation for Replacement

- Gather all necessary tools and components.

- Ensure you have a clean workspace to avoid contamination.

- Review any available technical documentation for reference.

Step-by-Step Procedure

- Begin by disconnecting power sources to ensure safety.

- Remove any protective coverings to access the component.

- Carefully detach the existing part, taking note of its connections.

- Install the new component, ensuring all connections are secure.

- Reattach any coverings and restore power to the system.

- Conduct a thorough inspection to verify proper installation.

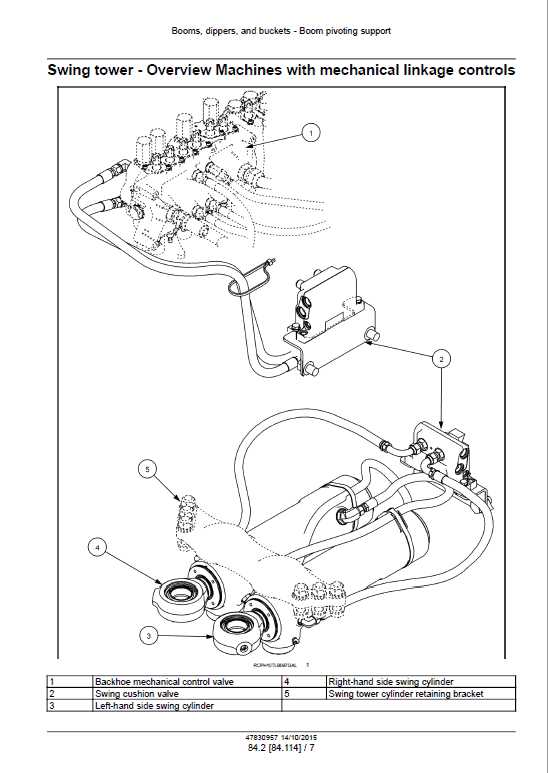

Diagram Overview of Key Parts

This section provides a comprehensive look at the essential components involved in the machinery’s operation. Understanding these elements is crucial for effective maintenance and functionality.

Essential Components

- Powertrain Assembly

- Hydraulic System

- Control Mechanisms

- Chassis Structure

- Transmission Unit

Functional Roles

Each component plays a vital role in ensuring the smooth operation of the equipment. Below are the main functions:

- Powertrain Assembly: Converts energy into motion.

- Hydraulic System: Facilitates lifting and digging actions.

- Control Mechanisms: Direct user inputs for operation.

- Chassis Structure: Provides stability and support.

- Transmission Unit: Transfers power to wheels or tracks.

Tools Needed for Repairs

Having the right equipment is crucial for effective maintenance and restoration tasks. Proper tools not only enhance efficiency but also ensure safety during operations. Understanding which implements to use can greatly simplify the process and lead to successful outcomes.

Essential Equipment

- Wrenches of various sizes

- Socket sets for fasteners

- Screwdrivers with different heads

- Pliers for gripping and twisting

- Hammers for driving and shaping

Specialized Instruments

- Torque wrenches for precise tightening

- Diagnostic tools for troubleshooting

- Measuring tapes for accurate dimensions

- Jacks and stands for lifting

- Safety gear to protect during tasks

Identifying Wear and Tear Signs

Understanding the indicators of deterioration is crucial for maintaining machinery efficiency. Regularly monitoring equipment can help prevent significant issues and extend the lifespan of components. This section outlines key signs to watch for, ensuring that any necessary attention is promptly addressed.

- Visual Inspections: Regularly check for cracks, rust, or unusual discoloration on surfaces.

- Performance Changes: Noticeable declines in performance may suggest underlying issues.

- Unusual Noises: Listen for grinding, clanking, or other irregular sounds during operation.

- Fluid Leaks: Be alert for any leaking fluids, which may indicate seal or gasket failures.

- Increased Vibration: Excessive vibrations can signal imbalance or misalignment within the system.

By staying vigilant and recognizing these signs early, operators can take proactive measures to maintain optimal functionality.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring safety is paramount to prevent accidents and injuries. It is crucial to establish a secure environment before proceeding with any work. This section outlines essential guidelines to follow during such activities.

- Personal Protective Equipment: Always wear appropriate gear such as gloves, goggles, and hard hats to safeguard against potential hazards.

- Work Environment: Keep the workspace organized and free from clutter to reduce the risk of slips and trips.

- Equipment Inspection: Regularly check tools and machinery for any signs of wear or malfunction to prevent unexpected failures.

- Proper Lifting Techniques: Utilize correct methods for lifting heavy objects to avoid strain or injury.

By adhering to these precautions, individuals can significantly reduce risks associated with maintenance tasks, ensuring a safer and more efficient working experience.

Where to Find Replacement Parts

Locating suitable components for machinery can be a daunting task, but with the right approach, it becomes manageable. Understanding where to seek these items is crucial for maintaining optimal functionality. Various avenues are available, catering to different needs and preferences.

One effective option is to explore online marketplaces, which offer a vast array of choices. Websites specializing in equipment and accessories often provide detailed listings, allowing users to compare options conveniently. Additionally, forums and community groups can be invaluable resources, where enthusiasts and professionals share recommendations and insights on reliable sources.

Local suppliers and distributors also play a significant role. Many establishments focus on heavy machinery, offering quality components backed by expert advice. Visiting these stores enables you to inspect items firsthand, ensuring compatibility with your equipment.

Furthermore, manufacturer websites may have dedicated sections for ordering replacements. They often provide specific product numbers, making it easier to find the right match. Engaging with customer service can also yield helpful information regarding availability and potential alternatives.

Lastly, considering salvage yards can be a cost-effective strategy. These places often have used items in good condition, which can serve as a practical solution for those on a budget. By exploring various channels, you can effectively secure the necessary components to keep your machinery running smoothly.

Expert Recommendations for Users

When engaging with complex machinery, it’s crucial to adopt a proactive approach to ensure optimal performance and longevity. Understanding the essential components and their functions can significantly enhance operational efficiency.

Regular Maintenance: Implement a routine schedule for inspections to identify any potential issues early. This can prevent more extensive problems down the line and save time and resources.

Utilize Quality Components: Always opt for high-quality replacements. Using reliable materials not only enhances functionality but also contributes to the overall safety of the equipment.

Consult with Professionals: Don’t hesitate to seek advice from experienced technicians. Their insights can be invaluable, especially when tackling complex tasks or unfamiliar challenges.

Stay Informed: Keeping updated with the latest industry trends and innovations can provide users with useful tips and techniques that can be applied to enhance operational practices.