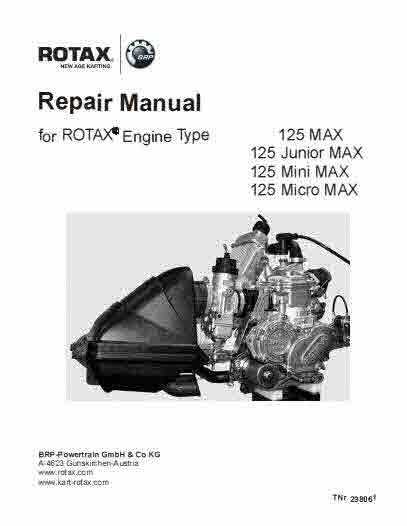

Essential Guide to Rotax Max Repair Manual

When it comes to ensuring optimal performance of your motorized equipment, understanding the intricacies of its upkeep is essential. This segment delves into essential practices that can help maintain the efficiency and longevity of your engine, focusing on key components and troubleshooting techniques. Whether you’re a seasoned enthusiast or a novice, having a solid grasp of maintenance procedures can significantly enhance your experience.

Knowledge of engine components is crucial. Familiarity with each part’s function and how they interact can help you identify issues before they escalate. This guide will provide insights into common problems and their solutions, empowering you to tackle challenges with confidence.

Additionally, regular maintenance routines are vital for performance enhancement. From routine checks to more detailed inspections, adhering to a systematic approach ensures that your equipment remains in peak condition. Through careful attention to these details, you can avoid unnecessary repairs and prolong the life of your engine.

Understanding Rotax Max Engine Basics

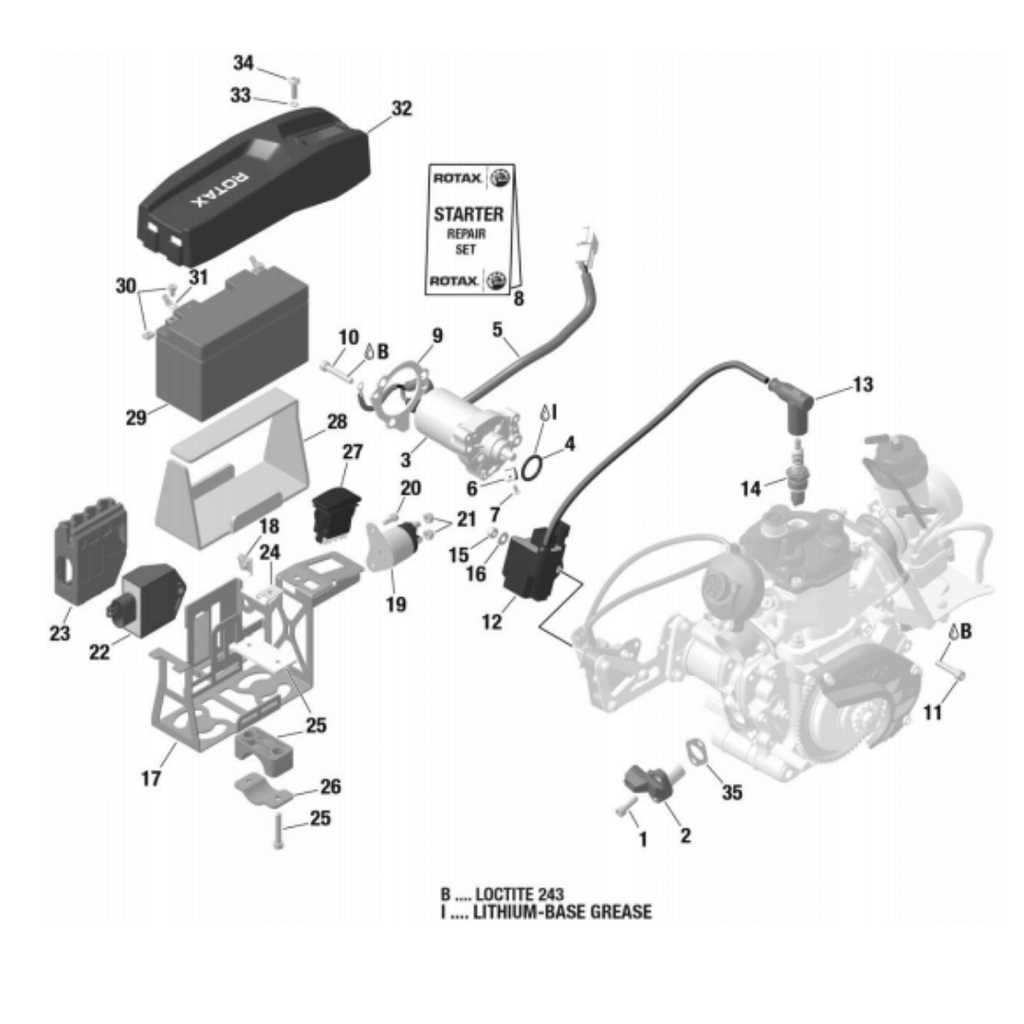

This section delves into the fundamental concepts surrounding a specific type of high-performance engine commonly used in various racing applications. Recognizing its key components and operational principles is essential for enthusiasts and mechanics alike. A solid understanding can enhance maintenance practices and improve performance outcomes.

Key Components

- Cylinder: The core area where fuel and air mixture combusts to produce power.

- Piston: A crucial part that moves up and down within the cylinder, converting combustion energy into mechanical motion.

- Crankshaft: This component translates the linear motion of the piston into rotational energy, driving the vehicle forward.

- Fuel System: Comprises the carburetor or fuel injection system that ensures the correct mixture of air and fuel for optimal combustion.

- Ignition System: Responsible for igniting the fuel-air mixture, typically featuring a spark plug that creates the necessary spark.

Operational Principles

Understanding how these engines function involves several key processes:

- Intake: The engine draws in a mixture of air and fuel.

- Compression: The piston compresses the mixture within the cylinder, raising its temperature and pressure.

- Combustion: The spark ignites the compressed mixture, creating an explosion that pushes the piston down.

- Exhaust: The engine expels the burnt gases, allowing for the intake of a new air-fuel mixture.

Familiarity with these basics lays the groundwork for effective troubleshooting and optimization of engine performance in competitive environments.

Common Issues with Rotax Max Engines

Engines of this type are known for their performance and reliability, but like any mechanical system, they can encounter a variety of challenges. Understanding these common problems can help enthusiasts maintain optimal function and longevity. Awareness of potential issues allows for proactive measures, ensuring that the engine operates smoothly and efficiently.

One frequent concern is overheating, which can stem from inadequate cooling or poor airflow. This can lead to severe damage if not addressed promptly. Additionally, fuel-related problems such as contamination or incorrect mixture ratios can hinder performance, causing misfires or stalling. Regular checks on fuel quality and proper setup are essential.

Another common issue involves ignition system failures, which may result from worn components or poor connections. Symptoms often include starting difficulties or erratic performance. Regular inspection and timely replacement of ignition parts can mitigate these risks.

Furthermore, wear and tear on moving parts is a natural occurrence over time. Components like bearings and seals may degrade, leading to leaks or unusual noises. Routine maintenance and timely replacements are critical to avoiding more extensive repairs down the line.

Lastly, electrical issues can also arise, affecting various systems within the engine. Corroded connections or faulty wiring can lead to inconsistent operation. Maintaining clean and secure electrical contacts is crucial for reliable performance.

Tools Needed for Rotax Max Repairs

Having the right instruments is essential for effective maintenance and troubleshooting of any engine system. The appropriate gear not only facilitates the repair process but also ensures that every component functions optimally, extending the lifespan of the engine. This section outlines the necessary tools to achieve efficient results in servicing tasks.

Basic Hand Tools

Begin with a collection of fundamental hand tools, including wrenches, pliers, and screwdrivers. A comprehensive set of sockets in various sizes will allow for the adjustment of bolts and fasteners. Torque wrenches are particularly important for achieving the correct tightness, preventing potential damage during assembly.

Specialized Equipment

In addition to standard tools, specialized equipment is crucial for precise diagnostics and adjustments. An engine stand can provide stability during repairs, while a multimeter helps in checking electrical components. Having a good quality compression tester is also valuable for assessing the engine’s health and performance.

Step-by-Step Repair Procedures

This section provides a detailed guide to effectively troubleshoot and address common issues that may arise in your engine. By following these structured instructions, you can ensure optimal performance and longevity.

Preparation

Before starting any work, it’s essential to gather the necessary tools and materials. Follow these steps to prepare:

- Ensure the engine is cool and has been powered down.

- Gather tools: wrenches, screwdrivers, and pliers.

- Obtain replacement parts as needed.

- Read through the entire procedure before beginning.

Procedure Steps

- Disconnect the Battery: Safely remove the battery connections to prevent any electrical accidents.

- Inspect for Leaks: Check all hoses and connections for signs of fluid leaks. Replace any damaged components.

- Remove the Cover: Use the appropriate tools to carefully take off the engine cover. Keep track of all screws and components.

- Replace Worn Parts: Identify and replace any worn or damaged parts according to the specifications.

- Clean the Components: Use a suitable cleaning agent to remove any dirt or residue from the engine parts.

- Reassemble: Carefully reattach the cover and ensure all connections are secure. Double-check that all tools are removed from the work area.

- Reconnect the Battery: Attach the battery connections securely and test the engine to ensure proper functionality.

Following these steps will help maintain the engine in peak condition, enabling it to perform efficiently and reliably.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and optimal performance of any engine. Adopting a consistent maintenance routine can significantly extend the lifespan of your equipment, reduce the likelihood of malfunctions, and enhance overall efficiency. Here are several key practices to consider for effective care.

Regular Inspections

Conducting routine inspections is vital for early detection of wear and tear. Look for signs of damage, loose components, or fluid leaks. Keeping a checklist can help streamline this process and ensure that no aspect is overlooked.

Fluid Changes

Regularly replacing fluids is crucial for engine health. Fresh oil and coolant help maintain optimal operating temperatures and reduce friction. Adhere to recommended intervals for fluid changes based on usage and manufacturer guidelines.

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 25 hours of operation |

| Coolant Check | Every 50 hours of operation |

| Filter Replacement | Every 50 hours of operation |

| Visual Inspection | Weekly |

By adhering to these maintenance strategies, you can ensure your engine remains in peak condition, leading to a longer and more reliable service life.

Replacing Components: What You Need

When it comes to maintaining your engine’s performance, understanding the process of component replacement is crucial. This section outlines the essential items and tools you will require to ensure a smooth and efficient replacement process. Proper preparation can help minimize downtime and enhance the longevity of your engine.

Before you begin, make sure you have gathered all necessary components and tools. Below is a list that will guide you through the essentials:

| Item | Description | Purpose |

|---|---|---|

| Replacement Parts | OEM or high-quality aftermarket components | To ensure compatibility and performance |

| Basic Hand Tools | Sockets, wrenches, and screwdrivers | For loosening and tightening fasteners |

| Torque Wrench | Precision tool for applying specific torque | To avoid over-tightening or under-tightening |

| Clean Cloths | Lint-free cloths or rags | For cleaning surfaces before assembly |

| Lubricants | Engine oil or assembly grease | To reduce friction and wear during operation |

| Container for Fasteners | A small bin or tray | To keep track of screws, bolts, and nuts |

| Service Manual | Manufacturer’s guide | For specifications and procedures |

By ensuring that you have all the necessary components and tools at your disposal, you will be well-equipped to carry out the replacement process efficiently and effectively.

Tuning Your Rotax Max for Performance

Enhancing the efficiency and output of your engine involves a series of strategic modifications and adjustments. By focusing on key areas such as airflow, fuel delivery, and ignition timing, you can significantly boost performance and responsiveness. Each adjustment should be carefully considered to ensure that it complements the overall setup of your machine.

One of the first steps in optimization is to improve the intake and exhaust systems. Upgrading to high-performance filters can increase airflow, while tuning the exhaust system can reduce back pressure, allowing for smoother and more powerful engine operation. These changes not only enhance power but also contribute to better throttle response.

Another critical aspect is the fuel delivery system. Ensuring that your engine receives the correct mixture of fuel and air is essential for maximizing performance. Consider adjusting the carburetor settings or, if applicable, upgrading to a more advanced fuel injection system. Proper calibration will ensure that your engine runs efficiently under various conditions.

Additionally, fine-tuning the ignition system can lead to significant gains. Adjusting the timing can optimize combustion, resulting in improved torque and horsepower. Experimenting with different spark plugs may also yield better performance, as certain types are designed to handle higher temperatures and pressures.

Lastly, regular maintenance is vital. Keeping the engine well-tuned and addressing wear and tear will prevent performance loss over time. By systematically evaluating and enhancing these components, you can unlock the full potential of your engine, ensuring a thrilling and competitive experience on the track.

Safety Precautions During Repairs

Ensuring a secure environment while performing maintenance tasks is essential for both the technician and the equipment. Adhering to safety measures can significantly reduce the risk of accidents and enhance the effectiveness of the work being done. This section outlines key guidelines to follow during service procedures.

Personal Protective Equipment

Using appropriate protective gear is crucial to safeguard against potential hazards. The following items are recommended:

- Safety goggles to protect the eyes from debris and chemicals.

- Gloves to prevent skin contact with harmful substances.

- Ear protection when working in noisy environments.

- Steel-toed boots to protect feet from falling objects.

Workspace Organization

A well-organized workspace minimizes distractions and potential dangers. Consider these practices:

- Keep tools and materials neatly arranged and easily accessible.

- Ensure the work area is well-lit to avoid accidents.

- Remove any unnecessary items that could cause tripping hazards.

- Utilize proper storage for hazardous materials to prevent spills and exposure.

By following these safety guidelines, individuals can create a secure environment conducive to effective maintenance work.

Troubleshooting Electrical Problems

Electrical issues can often arise unexpectedly, leading to performance challenges or complete failures. Identifying the source of these problems is crucial for ensuring optimal functionality and safety. This section will guide you through systematic steps to diagnose and resolve common electrical faults.

Begin by checking the following components:

- Batteries: Ensure connections are clean and secure. Measure voltage to confirm adequate charge.

- Wiring: Inspect for frayed or damaged wires. Look for signs of corrosion at terminals.

- Connectors: Verify that all connectors are firmly attached and free of debris.

Next, utilize these diagnostic steps:

- Visual Inspection: Conduct a thorough visual check of all electrical components for obvious signs of damage.

- Continuity Testing: Use a multimeter to test for continuity in wires and connectors. A lack of continuity indicates a break.

- Voltage Testing: Measure voltage at key points in the system. Ensure readings align with expected values.

If issues persist, consider the following common symptoms:

- No Power: Check the battery and main connections.

- Intermittent Functionality: Inspect for loose connections or damaged components.

- Erratic Behavior: Look for ground faults or short circuits that may cause irregular operations.

By following these steps and paying close attention to details, you can effectively troubleshoot and resolve electrical issues, ensuring reliable performance.

Importance of Regular Oil Changes

Maintaining optimal performance in any engine requires careful attention to the lubricant used within. Regularly changing the oil is a crucial aspect of this maintenance, as it ensures that the engine operates smoothly and efficiently. Over time, oil can become contaminated with dirt, debris, and combustion byproducts, which can lead to diminished performance and increased wear on engine components.

Enhancing Engine Longevity

Frequent oil changes significantly extend the life of the engine. Fresh oil provides better lubrication, reduces friction, and helps prevent overheating. By removing old, degraded oil and replacing it with clean, high-quality lubricant, owners can protect critical parts from unnecessary wear and tear, ultimately saving on costly repairs and replacements.

Optimizing Performance and Efficiency

Regular oil maintenance also plays a key role in ensuring that the engine runs at peak efficiency. Clean oil promotes better fuel combustion and allows the engine to function at its best, leading to improved power output and fuel economy. Neglecting this vital task can result in decreased performance and higher operational costs, making it essential for any owner to prioritize oil changes as part of their routine maintenance schedule.

Finding Quality Replacement Parts

When it comes to maintaining and enhancing performance, sourcing high-quality components is essential. The right parts not only ensure optimal functionality but also prolong the lifespan of your machinery. In this section, we will explore effective strategies for identifying reliable replacements that meet your specific needs.

Research Reputable Suppliers

Start by investigating trusted vendors known for their quality products. Look for companies with positive reviews and a solid reputation within the community. Engaging with other enthusiasts can also provide valuable insights into the best places to purchase components.

Check Specifications and Compatibility

Before making a purchase, ensure that the parts you are considering match the specifications required for your equipment. Compatibility is crucial, as using incorrect components can lead to inefficiency and potential damage.

Evaluate Material Quality

Pay attention to the materials used in the components. Higher-grade materials often result in better performance and durability. Look for parts that are manufactured to stringent standards and offer warranties for added peace of mind.

Compare Prices

While cost should not be the sole determining factor, it is wise to compare prices across different suppliers. This practice can help you find the best deals without compromising on quality. Remember that cheaper options may not always provide the reliability you need.

Seek Expert Advice

Consulting with professionals who have extensive experience can provide valuable guidance. They can recommend specific brands or models that have proven to be reliable, saving you time and money in the long run.

By following these guidelines, you can confidently find top-notch replacement parts that enhance performance and ensure the longevity of your equipment.

Resourceful Repair Manuals and Guides

Accessing comprehensive resources for maintenance and troubleshooting can significantly enhance your understanding of engine systems. Whether you’re a novice or an experienced mechanic, having reliable references at your fingertips is crucial. These guides offer detailed insights into components, operational principles, and practical solutions for common issues.

Structured information is essential for effective diagnostics. Well-organized documentation allows users to navigate complex topics with ease, helping them identify problems quickly. Moreover, step-by-step instructions provide clarity on disassembly, assembly, and adjustment processes, ensuring that tasks are performed accurately and efficiently.

In addition to text-based resources, visual aids such as diagrams and photographs are invaluable. They can simplify complex concepts and offer a clearer understanding of component relationships and configurations. By utilizing a variety of materials, users can enhance their learning and application of maintenance practices.

Lastly, engaging with community forums and discussion platforms can complement formal resources. Sharing experiences and solutions with fellow enthusiasts fosters a collaborative environment where knowledge thrives. This exchange of information can lead to innovative troubleshooting techniques and improved performance outcomes.