Ultimate Guide to Repairing Your Ryobi Cordless Drill

In the world of home improvement and construction, the importance of a reliable, battery-operated power instrument cannot be overstated. These tools not only enhance productivity but also provide the flexibility to work in various environments without the constraint of cords. However, like any mechanical device, they can encounter issues that may impede their performance.

Understanding the common challenges associated with these instruments and how to address them is essential for anyone who relies on them regularly. This section will provide a comprehensive overview of troubleshooting techniques, essential maintenance tips, and effective solutions to ensure your device remains in optimal working condition.

By equipping yourself with the right knowledge, you can extend the lifespan of your equipment, minimize downtime, and enhance your overall efficiency on the job. Whether you’re a seasoned professional or a DIY enthusiast, having a solid grasp of these concepts will empower you to tackle any problem with confidence.

Understanding Ryobi Cordless Drills

This section aims to provide a comprehensive overview of battery-powered tools designed for drilling and driving tasks. These versatile devices are essential for both DIY enthusiasts and professionals, offering convenience and efficiency in a variety of applications.

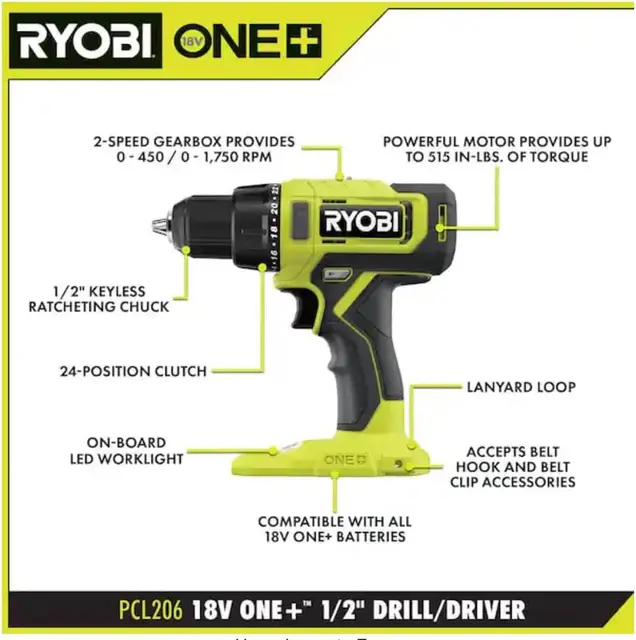

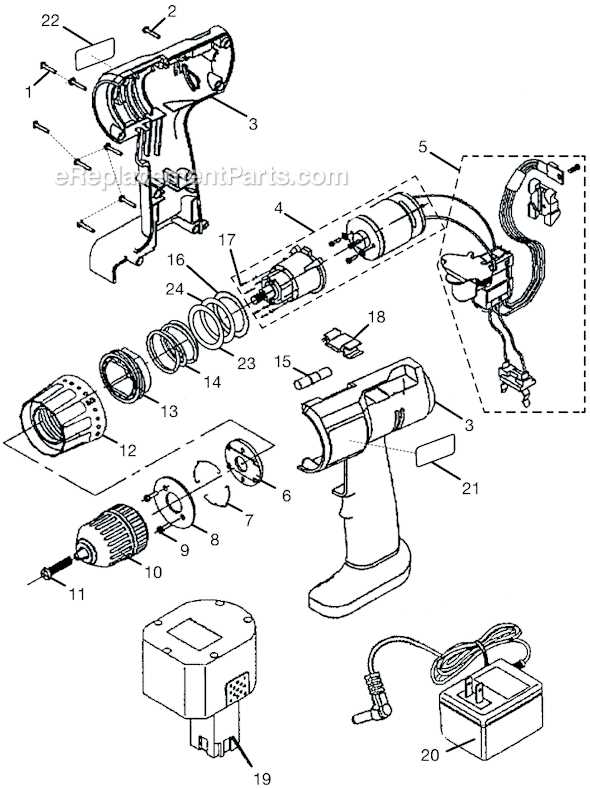

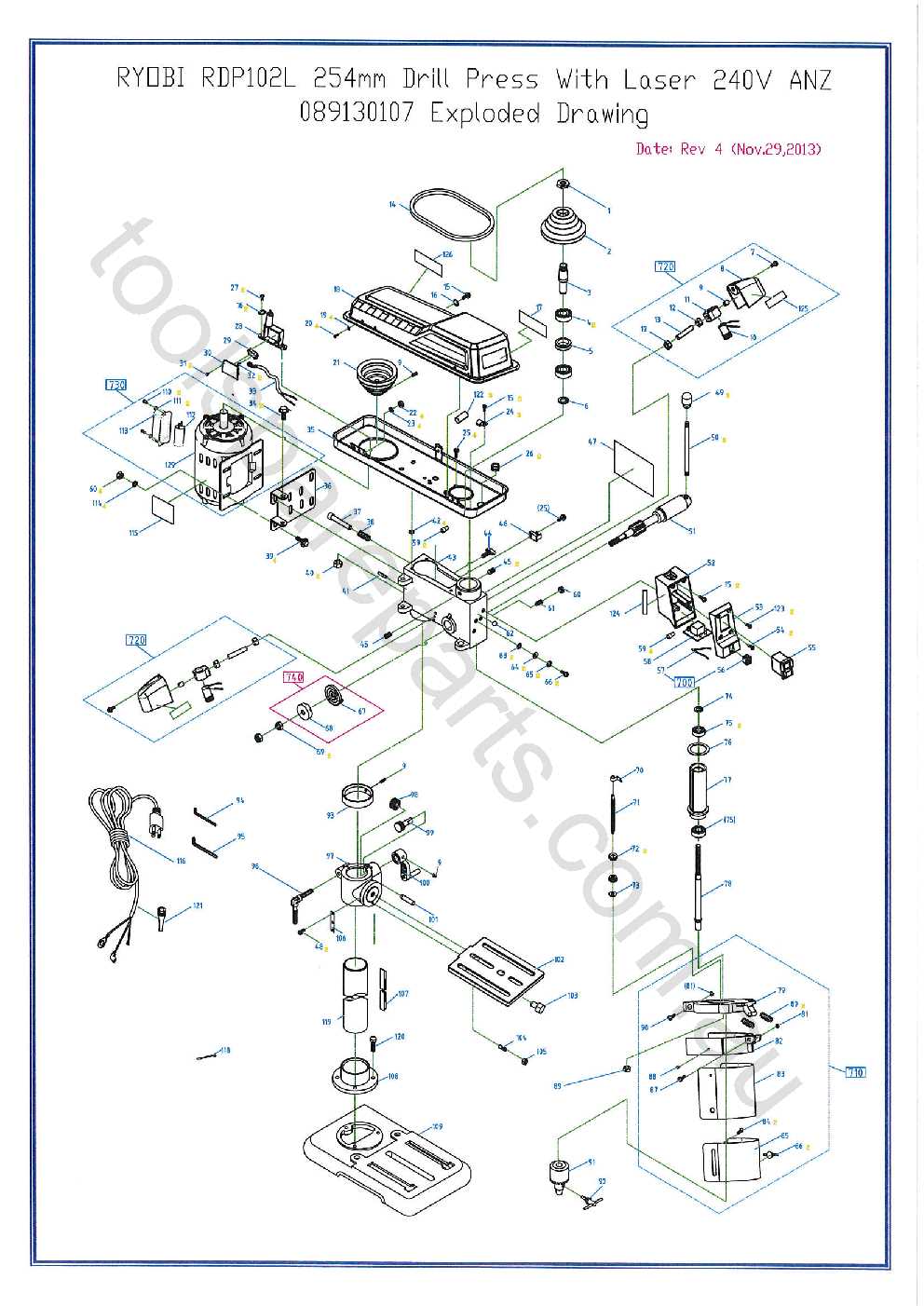

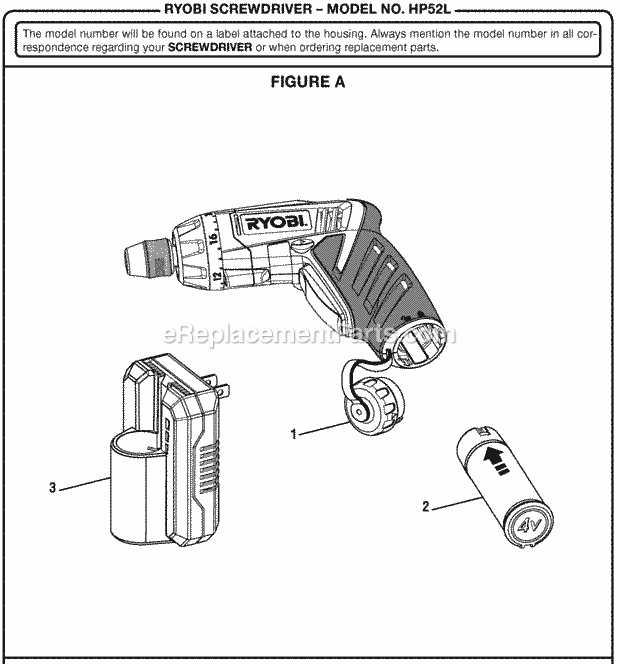

The primary components of these tools include a motor, a battery pack, and a chuck mechanism. The motor converts electrical energy into mechanical energy, enabling rotation and driving power. The battery pack supplies energy, and advancements in technology have led to longer run times and faster charging capabilities. The chuck mechanism allows for the quick change of bits, accommodating various tasks.

Understanding the features and specifications of these instruments can significantly enhance their usage. Factors such as torque, speed settings, and ergonomic design play crucial roles in determining the suitability of a tool for specific tasks. Additionally, many models come with various attachments and accessories, expanding their functionality.

Regular maintenance is vital to ensure longevity and optimal performance. Familiarity with common issues and troubleshooting techniques can empower users to address minor problems independently, ultimately prolonging the life of these essential devices.

Common Issues with Cordless Drills

Battery-powered tools are invaluable for a variety of tasks, yet they can encounter several recurring problems that may hinder performance. Understanding these common issues can help users troubleshoot effectively and maintain their equipment in optimal condition.

Battery Problems

The most frequent challenge involves the power source. Over time, batteries may lose their ability to hold a charge, leading to diminished runtime or complete failure. Factors contributing to this issue include age, excessive heat, and improper storage. Regular maintenance and following the manufacturer’s guidelines can prolong battery life significantly.

Mechanical Failures

Another common concern is mechanical malfunction, which can manifest as unusual noises, reduced torque, or erratic performance. These symptoms often indicate wear and tear on internal components such as gears or the motor. Periodic inspection and timely replacement of worn parts are essential to ensure reliable operation.

Essential Tools for Repairing Drills

When it comes to fixing power tools, having the right equipment is crucial for ensuring effective and safe maintenance. A well-equipped toolkit not only streamlines the process but also enhances the quality of repairs. Below is a comprehensive list of indispensable instruments that every enthusiast should consider having on hand.

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, will help you access different types of screws.

- Wrenches: Adjustable wrenches or socket sets are vital for loosening and tightening nuts and bolts.

- Pliers: Needle-nose and standard pliers are useful for gripping and manipulating small components.

- Torx Bits: These specialized bits are essential for dealing with specific fasteners found in many models.

- Multimeter: A digital multimeter allows for testing electrical connections and diagnosing issues effectively.

In addition to these core items, consider including the following:

- Hex Key Set: Useful for handling screws with hexagonal sockets.

- Heat Gun: Ideal for loosening adhesives and removing stuck components.

- Work Gloves: Protect your hands from sharp edges and other hazards during the process.

- Lubricants: Essential for ensuring smooth operation and longevity of moving parts.

By assembling these essential tools, you will be well-prepared to tackle a variety of maintenance tasks, ensuring that your equipment continues to perform at its best.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues encountered with your power tool. By following these structured steps, you can efficiently diagnose problems and restore functionality, ensuring optimal performance for your equipment.

Begin with a thorough inspection of the device to pinpoint any visible signs of damage or wear. Pay close attention to the battery, motor, and internal components. Utilize the table below for a systematic troubleshooting process that covers various scenarios:

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Device won’t start | Dead battery, faulty switch, internal malfunction | Charge or replace the battery, test the switch, inspect internal wiring |

| Inconsistent power | Dirty contacts, weak battery, motor issues | Clean battery contacts, replace battery, check motor connections |

| Unusual noises | Lubrication needed, damaged gears, loose parts | Apply lubricant, inspect gears for damage, tighten loose components |

| Overheating | Blocked vents, excessive load, poor ventilation | Clear vents, reduce workload, ensure proper airflow |

By methodically addressing each potential issue, you can effectively restore your tool’s performance and extend its lifespan. Always remember to prioritize safety while handling electrical equipment.

How to Replace Drill Batteries

When the power tool starts losing its efficiency, it may be time to replace the energy source. Understanding the process of swapping out the batteries can help restore functionality and extend the life of your equipment. This guide will walk you through the steps to successfully make this change.

Tools and Materials Needed

| Item | Purpose |

|---|---|

| Replacement Batteries | To provide new energy supply |

| Screwdriver | To remove screws if needed |

| Safety Goggles | To protect eyes during the process |

| Work Gloves | To ensure safety while handling components |

Step-by-Step Process

First, ensure that the device is turned off and disconnected from any power source. Remove the old power unit by locating the release mechanism, which may involve pressing a button or sliding a latch. Once the old unit is detached, insert the new energy source firmly into the designated slot until it clicks into place. If necessary, secure it with screws. Finally, perform a test to ensure that the new unit functions correctly.

Fixing Motor Problems in Drills

Addressing issues with the power source in handheld tools is crucial for maintaining their functionality. Understanding the common signs of malfunction can help users troubleshoot effectively and restore performance without professional assistance.

Identifying Symptoms

Common indicators of motor trouble include unusual noises, overheating, and inconsistent power delivery. If the device struggles to operate or exhibits erratic behavior, these could be symptoms of deeper issues.

Troubleshooting Steps

Start by inspecting the connections and ensuring they are secure. Cleaning any dust or debris around the motor can also enhance performance. If problems persist, consider replacing worn components or checking the battery’s health to ensure it provides adequate energy.

Maintaining Your Ryobi Drill

Proper upkeep of your power tool ensures optimal performance and longevity. Regular maintenance can prevent issues and enhance efficiency, allowing for a smoother experience during tasks. By following a few straightforward steps, you can keep your equipment in excellent condition.

| Task | Frequency | Description |

|---|---|---|

| Cleaning | After each use | Remove dust and debris from vents and surfaces to prevent overheating. |

| Battery Check | Monthly | Inspect battery for signs of wear or damage; clean terminals to ensure good connections. |

| Lubrication | Every 6 months | Apply lubricant to moving parts to reduce friction and wear. |

| Inspection | Quarterly | Examine all components for signs of damage; replace parts as necessary. |

By adhering to these simple maintenance tasks, you can significantly extend the lifespan of your equipment and ensure it operates at peak efficiency. Regular attention will save you time and money in the long run.

Identifying Worn-Out Parts

Recognizing components that have lost their effectiveness is crucial for maintaining optimal performance of your power tool. Over time, various elements can wear down due to regular use, leading to decreased efficiency and potential malfunctions. Identifying these parts early can save time and improve the longevity of the equipment.

Common Signs of Wear

Several indicators can suggest that a part is approaching the end of its lifespan. Listen for unusual noises during operation, as they may signal that internal components are no longer functioning smoothly. Additionally, if you notice a decrease in power output or inconsistent performance, it may be time to inspect specific parts for wear.

Visual Inspection Techniques

Conducting a thorough visual examination is essential in pinpointing worn elements. Look for cracks, discoloration, or unusual wear patterns on visible components. Pay attention to any signs of damage, such as fraying wires or excessive buildup of dust and debris, which can impede performance. Regular checks can help catch issues before they escalate, ensuring your tool remains reliable for all your projects.

Cleaning and Care Techniques

Maintaining the longevity and performance of your power tool involves regular cleaning and care. Proper upkeep not only enhances functionality but also ensures safety during operation. Following a few simple techniques can keep your equipment in optimal condition, allowing you to achieve the best results in your projects.

Routine Cleaning Steps

Begin by disconnecting the battery or power source to ensure safety. Use a soft brush or cloth to remove dust and debris from the exterior. Pay special attention to vents and moving parts, as these areas can accumulate particles that may hinder performance. For stubborn grime, a damp cloth with mild soap can be used, but avoid soaking any components.

Lubrication and Storage

Lubrication is essential for maintaining moving parts. Apply a few drops of suitable oil to gears and other pivot points to reduce friction and wear. After cleaning and lubricating, store your tool in a dry, cool place, ideally in a protective case. This prevents moisture buildup and potential damage, ensuring your equipment remains ready for use.

Upgrading Your Drill Components

Enhancing the performance of your power tool can significantly improve its efficiency and extend its lifespan. By focusing on key components, you can achieve better results and a more enjoyable user experience. This section will explore various upgrades that can elevate your tool’s capabilities and functionality.

1. Battery Replacement: One of the most impactful upgrades involves replacing the existing energy source with a higher-capacity version. A robust battery can provide longer operational time and faster recharge cycles, allowing for extended use without interruptions.

2. Chuck Upgrade: The chuck plays a crucial role in securing bits. Upgrading to a high-quality, keyless chuck can enhance convenience and ensure a tighter grip, reducing slippage during intense tasks. This simple modification can lead to more precise results.

3. Gearbox Enhancement: Consider enhancing the gearbox for improved torque and speed settings. A more efficient gearbox can adapt better to various materials, making your tool versatile for different projects.

4. Grip and Handle Modifications: Comfort is essential during prolonged use. Upgrading grips with ergonomic designs can significantly reduce fatigue, allowing for better control and precision. Look for non-slip materials that improve handling even in challenging conditions.

5. LED Lighting Addition: Integrating an LED light can be a game-changer. It illuminates dark workspaces, making it easier to see what you are doing and enhancing safety. This small addition can greatly improve accuracy in low-light situations.

By considering these enhancements, you can not only boost your tool’s performance but also tailor it to your specific needs, ensuring it serves you well in a variety of tasks.

Safety Precautions During Repairs

When undertaking maintenance tasks on power tools, ensuring personal safety is paramount. Following essential precautions can help prevent accidents and injuries, making the process smoother and more efficient.

- Wear Protective Gear: Always use safety goggles, gloves, and ear protection to shield against flying debris and loud noises.

- Work in a Well-Lit Area: Ensure your workspace is adequately illuminated to avoid mistakes and enhance visibility.

- Disconnect Power Sources: Before starting any work, unplug the tool or remove the battery to eliminate the risk of accidental activation.

In addition to these basic precautions, consider the following practices:

- Keep Workspace Organized: A tidy environment reduces the likelihood of tripping hazards and misplaced tools.

- Follow Manufacturer Instructions: Adhere to guidelines specific to the equipment to ensure proper handling and maintenance.

- Use the Right Tools: Employ appropriate tools for the task to minimize the risk of damage and injury.

By implementing these safety measures, you can significantly enhance your protection and effectiveness during maintenance activities.

Finding Replacement Parts Online

Locating components for your power tools can be a straightforward process if you know where to look. The internet offers a wealth of resources for sourcing the necessary items, ensuring that your equipment remains functional and efficient.

Popular Online Retailers

- Amazon

- eBay

- Home improvement stores’ websites

- Specialty tool parts suppliers

Tips for Successful Searches

- Use specific terms related to the part you need.

- Check the compatibility of parts with your model.

- Read customer reviews for quality assurance.

- Compare prices across different platforms.

By utilizing these strategies, you can efficiently find and purchase the right components to keep your tools in peak condition.

When to Seek Professional Help

Understanding when to consult an expert can be crucial in maintaining the longevity and functionality of your tools. While many issues can be resolved through basic troubleshooting, certain situations may require specialized knowledge and skills.

Consider seeking assistance from a professional if you encounter the following scenarios:

- Persistent Issues: If the device continues to malfunction despite repeated attempts to fix it, this may indicate a deeper underlying problem.

- Complex Repairs: Tasks that involve intricate components or require specialized tools are best left to trained technicians.

- Electrical Concerns: Any issues involving wiring or battery systems can be hazardous and should be handled by professionals.

- Warranty Considerations: If your equipment is still under warranty, attempting to fix it yourself could void the coverage.

- Lack of Confidence: If you’re unsure about your ability to perform a repair safely and effectively, it’s wise to consult an expert.

Recognizing these signs can help you make informed decisions about the maintenance and service of your tools, ensuring both safety and optimal performance.