Comprehensive Guide to Ryobi Generator Repair

Ensuring the longevity and optimal performance of portable energy devices requires a systematic approach to upkeep and diagnostics. Regular checks and timely interventions can prevent minor issues from escalating into significant problems, ultimately enhancing the efficiency of the unit.

Proper care involves familiarizing oneself with the device’s components and functionalities. Knowledge about common challenges and their solutions can empower users to address concerns independently, saving both time and resources.

In this section, we will explore essential strategies for managing device issues. By following a structured process, users can confidently maintain their equipment and enjoy uninterrupted power supply when needed.

This section delves into the various classifications of portable power sources, emphasizing their unique characteristics and applications. Understanding these distinctions is essential for anyone looking to maintain or troubleshoot their equipment effectively.

Types of Power Sources

Power sources can be categorized based on several criteria, including fuel type, size, and intended usage. Below are the primary classifications:

- Gas-Powered Units: These are typically favored for their high output and mobility.

- Electric Variants: Ideal for quieter operations, these models rely on battery or grid power.

- Hybrid Models: Combining multiple power sources, these offer versatility in various environments.

Key Features to Consider

When selecting a portable power solution, several factors should influence your decision:

- Output Capacity: Measured in watts, this determines what devices can be powered.

- Portability: The weight and design affect how easily the unit can be transported.

- Noise Level: Some models operate quietly, making them suitable for residential use.

Common Issues with Ryobi Generators

Power sources can encounter various challenges that affect their performance and reliability. Understanding these typical problems is essential for maintaining optimal functionality and extending the lifespan of the equipment.

- Starting Difficulties: Users often face issues when attempting to initiate the power unit, which may stem from fuel-related concerns or battery malfunctions.

- Noise Levels: Excessive noise during operation can indicate underlying mechanical issues, potentially requiring attention.

- Fuel Consumption: Unusually high fuel usage can signal inefficiencies, possibly due to clogged filters or incorrect settings.

- Electrical Output: Inconsistent power supply or fluctuations may arise from wiring problems or component failures.

- Overheating: Prolonged usage without proper ventilation can lead to overheating, risking damage to the internal components.

Identifying and addressing these concerns promptly can significantly enhance performance and ensure longevity.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting of any machinery. Whether you are addressing minor issues or conducting thorough inspections, a well-equipped toolkit can make a significant difference in the efficiency and success of your efforts.

Basic Hand Tools

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, are essential for loosening and tightening fasteners.

- Wrenches: Adjustable wrenches and socket sets are necessary for tackling nuts and bolts of various sizes.

- Pliers: Needle-nose and standard pliers can help grip and manipulate components effectively.

Specialized Instruments

- Multimeter: This device is vital for measuring voltage, current, and resistance, helping diagnose electrical issues.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

- Cleaning Supplies: Brushes, cloths, and appropriate solvents are essential for maintaining cleanliness and functionality.

Step-by-Step Troubleshooting Guide

This section offers a systematic approach to identify and resolve issues effectively. By following a structured method, users can pinpoint the source of malfunction and implement appropriate solutions.

Identifying Common Issues

Start by observing the symptoms displayed. Look for unusual noises, failure to start, or irregular performance. These indicators often reveal underlying problems that require attention. Document any specific patterns, as they can provide valuable insights during the troubleshooting process.

Implementing Solutions

Once issues are identified, proceed to implement potential fixes. This may involve checking connections, inspecting fuel levels, or examining electrical components. Testing each change can help isolate the problem and ensure that it is resolved effectively. Be thorough and patient, as some solutions may require multiple attempts to achieve optimal functionality.

Maintaining Fuel Systems Effectively

Ensuring optimal performance of fuel systems is crucial for the longevity and efficiency of equipment. Regular maintenance helps prevent issues that can arise from neglect, such as clogs or leaks. Understanding how to properly care for these systems will enhance their reliability and functionality.

- Regular Inspections: Periodically check all components for signs of wear or damage.

- Fuel Quality: Use high-quality fuel to minimize contamination and degradation.

- Filter Maintenance: Replace fuel filters according to the manufacturer’s recommendations to ensure clean fuel flow.

- Check Hoses and Connections: Inspect hoses for cracks or leaks and ensure all connections are secure.

- Prevent Stale Fuel: Avoid using fuel that has been stored for extended periods; consider adding a fuel stabilizer.

By implementing these strategies, users can significantly extend the life of their fuel systems while maintaining consistent performance.

Understanding Electrical Components

This section delves into the vital elements that form the backbone of electrical systems. Grasping the roles and functions of these components is essential for anyone aiming to maintain or troubleshoot equipment effectively. Each part contributes to the overall performance, ensuring reliable operation and safety.

Key Electrical Parts

The following table highlights some of the primary components found in many electrical systems, along with their functions:

| Component | Function |

|---|---|

| Battery | Stores energy for powering devices. |

| Alternator | Generates electricity by converting mechanical energy. |

| Inverter | Converts direct current (DC) to alternating current (AC). |

| Fuse | Protects circuits from overload by breaking the connection. |

Importance of Component Functionality

Understanding how these elements interact is crucial for ensuring optimal performance. Each component plays a specific role, and a failure in one can lead to a cascade of issues within the entire system. Regular inspection and maintenance of these parts can prevent unexpected breakdowns and enhance longevity.

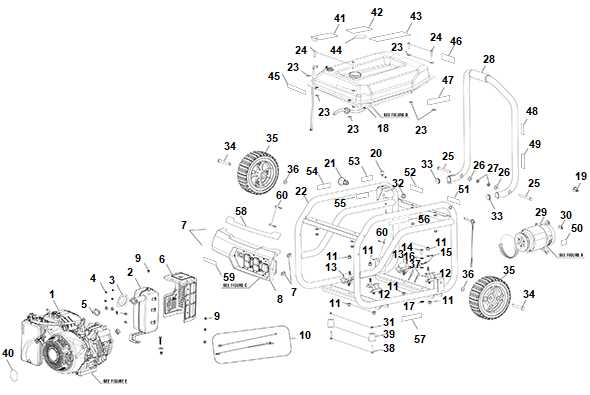

How to Replace Key Parts

Maintaining optimal performance often requires replacing essential components of your equipment. Understanding the process can help ensure reliability and longevity. Below are steps to follow for effective replacement of critical parts.

Preparation Steps

- Gather necessary tools and replacement parts.

- Ensure the device is turned off and disconnected from any power source.

- Consult the specific specifications for the components you plan to replace.

Replacement Process

- Carefully remove the outer casing or cover to access the internal components.

- Identify the part that needs to be replaced.

- Detach the faulty component by unscrewing or unclipping it as required.

- Install the new part by reversing the removal steps, ensuring all connections are secure.

- Replace the casing and ensure everything is properly aligned.

- Test the unit to confirm the new part is functioning correctly.

Importance of Regular Maintenance

Routine upkeep plays a crucial role in ensuring the longevity and efficient performance of any equipment. Neglecting regular checks and servicing can lead to a decline in functionality, potentially resulting in more significant issues over time. By prioritizing consistent maintenance, users can prevent unnecessary expenses and enhance the overall reliability of their devices.

Enhancing Efficiency

Keeping equipment in optimal condition contributes to better performance. Regular inspections allow for early identification of potential problems, ensuring that any necessary adjustments or repairs are made promptly. This proactive approach not only maintains efficiency but can also improve energy consumption, ultimately saving costs.

Extending Lifespan

Consistent care significantly extends the operational life of any apparatus. By adhering to maintenance schedules and following best practices, users can avoid premature wear and tear. This attention to detail fosters a longer lifespan, providing more value from the initial investment.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance on machinery is crucial for both personal well-being and the integrity of the equipment. Adhering to specific guidelines can significantly reduce the risk of accidents and enhance the effectiveness of the work performed.

First and foremost, always disconnect the power source before beginning any service task. This simple step prevents unintended start-ups that could lead to injury. Additionally, it is essential to work in a well-ventilated area to avoid the accumulation of harmful fumes and ensure a safe environment.

Wearing appropriate personal protective equipment is another vital aspect of safety. Gloves, safety glasses, and masks should be used to shield against potential hazards, such as sharp edges or toxic substances. Furthermore, keeping a first aid kit nearby can provide immediate assistance in case of minor injuries.

Lastly, familiarize yourself with the equipment’s specific characteristics and operational guidelines. Understanding these details will not only facilitate smoother maintenance but also help identify potential risks, ensuring a safer working experience overall.

When to Seek Professional Help

Identifying when to call in an expert can be crucial for ensuring safety and effectiveness. While some issues may seem manageable, others might require specialized knowledge and tools.

If you encounter persistent problems that do not resolve with basic troubleshooting, it’s advisable to consider professional assistance. Additionally, any signs of significant damage or unusual behavior should prompt an immediate consultation with a qualified technician.

| Signs to Seek Help | Recommended Action |

|---|---|

| Unusual noises or vibrations | Contact a specialist for diagnosis |

| Frequent stalling or failure to start | Schedule an inspection with a technician |

| Visible damage or leaks | Do not attempt repairs; seek expert help |

| Electrical issues or sparks | Immediately call a professional |

Testing Performance After Repairs

Evaluating the functionality of a device following maintenance is crucial for ensuring its optimal operation. This phase involves systematic assessments to confirm that all issues have been effectively addressed and that the unit performs as expected.

Key steps to consider during the evaluation include:

- Initial Inspection: Check for any visible damage or irregularities.

- Operational Testing: Run the unit under typical conditions to monitor performance.

- Load Testing: Assess how the device handles various loads to determine stability.

- Noise Level Check: Listen for unusual sounds that may indicate underlying issues.

- Safety Features Verification: Ensure all safety mechanisms are functioning correctly.

Conducting these tests will help confirm that the device is reliable and ready for use, ultimately enhancing user satisfaction and performance longevity.

Resources for Further Assistance

When facing challenges with equipment, having access to reliable support resources can be invaluable. Various platforms offer insights, tutorials, and community support to enhance your understanding and address issues effectively.

Online Forums and Communities

Engaging with online forums can connect you with enthusiasts and experts alike. These communities often share experiences, tips, and troubleshooting advice, creating a collaborative environment for problem-solving.

Manufacturer’s Support

Direct assistance from the manufacturer can provide specific guidance tailored to your needs. Accessing official websites often leads to technical documents, FAQs, and contact options for personalized help.