Essential Guide to Repairing Your Ryobi String Trimmer

In the realm of outdoor equipment, understanding how to maintain and troubleshoot your tools can greatly enhance their performance and longevity. This section delves into the fundamental aspects of care, offering insights that will empower users to tackle common issues effectively.

Regular upkeep not only ensures optimal functionality but also prevents minor problems from escalating into major setbacks. By familiarizing yourself with the intricacies of your equipment, you can navigate challenges with confidence and skill.

Whether you’re a seasoned gardener or a weekend warrior, knowing the essential techniques and solutions will allow you to keep your devices in peak condition. This guide will provide step-by-step instructions and valuable tips to make the process as straightforward as possible.

Overview of Ryobi String Trimmers

This section provides a comprehensive look at a popular line of outdoor tools designed for maintaining lawns and gardens. These devices are essential for achieving clean edges and managing overgrowth, making them a favorite among homeowners and professionals alike.

Key features of these gardening tools include:

- Lightweight design for ease of use

- Adjustable handles for comfort during extended tasks

- Various cutting widths to accommodate different areas

- Power options including electric and gas for versatility

- Easy string replacement mechanisms for convenience

These tools are designed to tackle various landscaping tasks, providing users with reliable performance and efficiency. The blend of technology and user-friendly features ensures that both novice and experienced gardeners can achieve optimal results.

When selecting a device, consider:

- Type of power source: electric or gas

- Weight and ergonomics for personal comfort

- Cutting diameter to suit your needs

- Availability of accessories and replacement parts

By understanding these aspects, users can make informed choices, ensuring their gardening tasks are completed effectively and efficiently.

Common Issues with String Trimmers

Gardening tools designed for cutting grass and weeds often encounter various challenges during their operation. Understanding these common problems can help users troubleshoot effectively and maintain optimal performance. Below are some frequent complications that may arise, along with potential solutions.

1. Difficulty Starting

One of the most prevalent issues is the inability to start the equipment. This can be caused by several factors, including a faulty ignition system, stale fuel, or a clogged air filter. Regular maintenance of these components can significantly reduce starting problems.

2. Uneven Cutting

When the cutting performance becomes inconsistent, it may indicate dull blades or improper tension settings. Checking and sharpening the blades, as well as adjusting the tension, can improve cutting efficiency and ensure a uniform appearance.

3. Overheating

Overheating can lead to a decrease in performance and potential damage. This issue is often linked to prolonged use without breaks or inadequate lubrication. Allowing the tool to cool down periodically and ensuring proper lubrication can help mitigate this risk.

4. Excessive Vibration

Excessive shaking during operation can not only be uncomfortable but may also signal mechanical issues. Loose components or worn parts can contribute to this problem. Regular inspections and tightening of screws can enhance stability and comfort.

5. Fuel Leaks

Fuel leaks are not only inconvenient but also hazardous. This issue often arises from damaged fuel lines or improper sealing of the tank. Inspecting for cracks or wear and replacing faulty parts can prevent leaks and ensure safe operation.

By being aware of these common issues and their potential solutions, users can prolong the lifespan of their gardening tools and maintain their effectiveness in outdoor tasks.

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues encountered with garden maintenance tools. By following these organized steps, you can effectively troubleshoot and resolve various malfunctions, ensuring your equipment operates efficiently.

-

Identify the Problem: Begin by observing the symptoms. Common issues include:

- Inconsistent power

- Difficulty starting

- Unusual noises

- Unresponsive controls

-

Gather Necessary Tools: Before starting, ensure you have the required tools. Typical items include:

- Screwdrivers

- Wrenches

- Replacement parts

- Protective gloves

-

Safety First: Always prioritize safety by wearing appropriate gear and ensuring the equipment is turned off and disconnected from power sources.

-

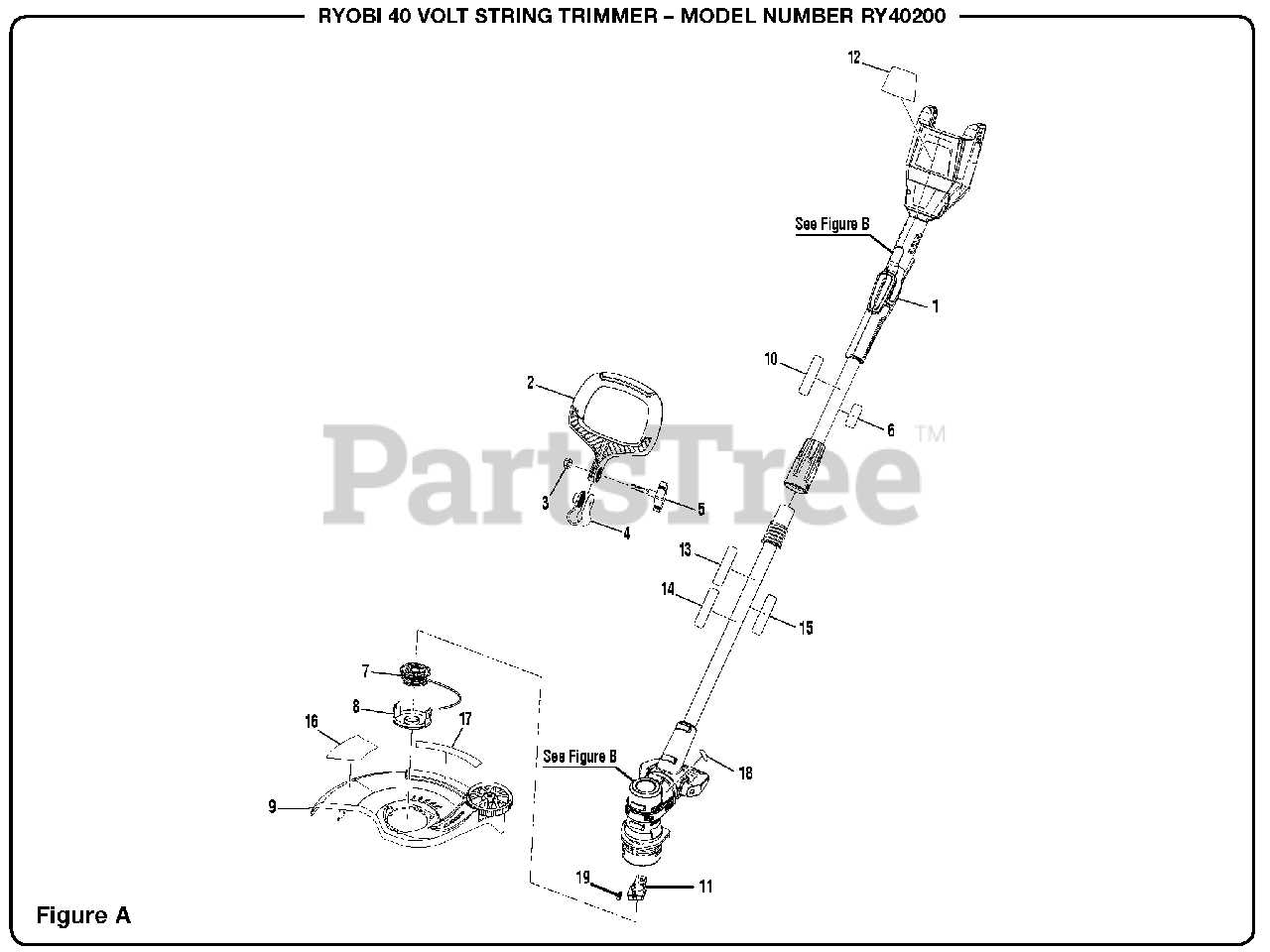

Disassemble the Unit: Carefully take apart the device, noting the order of components for easy reassembly.

-

Inspect for Damage: Examine parts for wear and tear. Common areas to check include:

- Filters

- Fuel lines

- Blades or cutting mechanisms

-

Replace or Repair Components: If you find damaged parts, replace them as necessary or perform repairs if feasible.

-

Reassemble the Tool: Carefully put all components back in their original positions, following the notes you made earlier.

-

Test the Equipment: After reassembly, test the tool to ensure it functions properly. Monitor for any lingering issues.

By adhering to this structured approach, you can tackle most challenges effectively and maintain optimal performance of your gardening equipment.

Essential Tools for Repairs

Having the right equipment is crucial for maintaining and fixing outdoor power tools effectively. This section highlights the fundamental instruments that can assist in diagnosing issues and performing necessary adjustments. Understanding the tools required can simplify the process, ensuring a smoother experience for both novices and seasoned enthusiasts.

Basic Hand Tools

Every toolkit should include a set of basic hand tools. These instruments are vital for most maintenance tasks and can handle a variety of components. Here are some of the essentials:

| Tool | Purpose |

|---|---|

| Screwdriver Set | Used for tightening or loosening screws. |

| Wrench Set | For gripping and turning nuts and bolts. |

| Pliers | Helpful for gripping and bending materials. |

| Utility Knife | For cutting various materials as needed. |

Specialized Instruments

In addition to basic hand tools, specialized instruments can greatly enhance the repair process. These tools help address specific issues that may arise during maintenance.

| Tool | Purpose |

|---|---|

| Multimeter | Used to measure voltage, current, and resistance. |

| Torque Wrench | Ensures proper tension is applied to fasteners. |

| Feeler Gauge | Helps measure gap widths for precision adjustments. |

| Compression Tester | Measures engine compression for diagnostics. |

How to Replace the Trimmer Line

Maintaining your garden equipment involves regular updates to the cutting line, ensuring efficiency and effectiveness during use. This process is straightforward and can greatly enhance performance. Follow these steps to refresh the cutting material, ensuring a smooth and hassle-free operation.

Tools and Materials Needed

| Item | Purpose |

|---|---|

| Replacement line | New cutting material for optimal performance |

| Scissors or line cutter | To cut the line to the appropriate length |

| Screwdriver | To remove the spool cover if necessary |

Step-by-Step Instructions

Begin by disconnecting the power source for safety. Next, locate the spool housing and remove the cover to access the existing line. If there is any old material, carefully detach it. Cut a new piece of line to the recommended length, typically around 10 to 15 feet, and thread it through the spool according to the manufacturer’s guidelines. Finally, reassemble the spool, ensuring everything is secure before reconnecting the power source. Your equipment is now ready for efficient use once more.

Cleaning and Maintenance Tips

Regular upkeep and cleaning are essential for ensuring the longevity and optimal performance of your outdoor equipment. By adhering to a few straightforward practices, you can maintain efficiency and avoid potential issues down the line.

1. Keep It Clean: After each use, take a moment to remove any debris or grass clippings that may have accumulated. This not only prevents rust and corrosion but also helps maintain a clean appearance.

2. Inspect the Components: Periodically check the various parts for wear and tear. Look for any signs of damage or fraying, especially in the cutting mechanisms. Addressing these issues early can prevent more significant problems later.

3. Check the Fuel System: If your device operates on fuel, ensure that it is fresh and free from contaminants. Old or dirty fuel can cause starting issues and decreased performance.

4. Lubricate Moving Parts: Applying a suitable lubricant to the moving components helps reduce friction and wear. Be sure to follow the manufacturer’s guidelines for the appropriate type of lubricant.

5. Store Properly: When not in use, store your equipment in a dry and sheltered area. This helps protect it from the elements and prolongs its lifespan.

By incorporating these simple yet effective maintenance practices into your routine, you can keep your outdoor tools in top condition, ready for any task you undertake.

Diagnosing Engine Problems

Identifying issues with an engine can be a daunting task, yet understanding common symptoms and their potential causes is crucial for effective troubleshooting. This section provides a structured approach to recognizing and addressing various mechanical failures that may arise during operation.

Begin by observing the following common symptoms:

- Starting Difficulties: The engine may fail to start or require multiple attempts.

- Unusual Noises: Listen for knocking, grinding, or excessive vibrations during operation.

- Power Loss: Noticeable reduction in performance or sluggish acceleration can indicate trouble.

- Overheating: An engine running hotter than normal may signal coolant or airflow issues.

Once symptoms are noted, proceed with a systematic evaluation:

- Inspect Fuel Quality: Ensure that the fuel is fresh and free of contaminants.

- Check Air Filter: A clogged filter can restrict airflow, impacting performance.

- Examine Spark Plug: Look for wear or deposits that may prevent ignition.

- Assess Cooling System: Verify that all components are functioning correctly to avoid overheating.

By following these steps and carefully documenting findings, you can effectively narrow down the cause of engine problems and determine the best course of action for resolution.

Electrical Components Troubleshooting

Understanding and diagnosing issues related to electrical components is essential for maintaining optimal performance. This section will guide you through common problems, potential causes, and solutions to restore functionality effectively.

Here are key areas to focus on:

- Power Supply: Ensure that the power source is functional. Check for loose connections and test with a multimeter.

- Wiring: Inspect the wiring for damage, wear, or corrosion. Replace any frayed or broken wires.

- Switches: Test switches for continuity. Faulty switches may need replacement to restore operation.

- Battery: For battery-operated units, assess the battery’s charge and overall health. Consider replacing it if it fails to hold a charge.

By methodically exploring these components, you can often pinpoint the issue and take the necessary steps to address it.

Safety Precautions During Repair

When undertaking maintenance tasks on outdoor equipment, ensuring personal safety is paramount. Proper precautions can prevent accidents and injuries, allowing for a smooth and efficient process. This section outlines essential safety measures to consider before and during the maintenance of your device.

General Safety Measures

Before starting any work, familiarize yourself with the equipment and the tools you will be using. Always wear appropriate personal protective gear to safeguard against potential hazards.

| Protective Gear | Purpose |

|---|---|

| Safety goggles | Protect eyes from debris and chemicals |

| Gloves | Prevent cuts and abrasions |

| Ear protection | Minimize noise exposure |

| Sturdy footwear | Provide support and protection |

Tool Handling and Workspace Safety

Ensure that your workspace is well-lit and organized. Keep tools in good condition and handle them with care to avoid injuries. Always disconnect power sources before beginning any maintenance work to prevent accidental starts.

When to Seek Professional Help

Determining the right moment to consult an expert can save both time and effort. While some issues can be resolved through basic troubleshooting, others may require specialized knowledge or tools. Understanding the signs that indicate a need for professional assistance is essential for maintaining your equipment effectively.

Common Indicators for Professional Assistance

Here are some typical situations where seeking expert help is advisable:

| Indicator | Description |

|---|---|

| Persistent Malfunction | If problems continue after basic adjustments or replacements, it’s time to call a professional. |

| Unusual Noises | Sounds that are out of the ordinary can signal internal damage that requires expert evaluation. |

| Fuel or Oil Leaks | Leaks can pose safety hazards; a specialist should handle these situations to prevent accidents. |

| Electrical Issues | Complications involving wiring or batteries should be addressed by someone with the right skills to avoid risks. |

Benefits of Professional Services

Consulting an expert not only ensures safety but also prolongs the lifespan of your equipment. Professionals can diagnose complex issues more accurately and often have access to parts and tools that may not be readily available to the average user. This investment can lead to more effective and efficient functioning, ultimately saving money in the long run.