Comprehensive Guide to Repairing Siemens Piezo Injectors

Understanding the intricacies of modern fuel delivery systems is essential for ensuring optimal engine performance. These components play a crucial role in the precise regulation of fuel flow, directly influencing efficiency and emissions. A thorough knowledge of their functionality and potential issues can empower technicians and enthusiasts alike to maintain and troubleshoot these vital parts effectively.

In this section, we will delve into the specifics of maintaining and addressing common problems associated with advanced fuel delivery systems. With an emphasis on practical solutions and step-by-step procedures, this guide aims to equip you with the necessary skills to diagnose and resolve issues that may arise. Armed with the right techniques and tools, you can ensure that your engine operates at peak performance.

Whether you are a professional mechanic or a dedicated DIYer, mastering the nuances of these critical components is invaluable. By the end of this guide, you will have a deeper understanding of their construction, function, and the common pitfalls to avoid, enabling you to extend the lifespan and reliability of your vehicle’s fuel system.

Understanding Siemens Piezo Injectors

The technology behind advanced fuel delivery systems plays a crucial role in enhancing engine performance and efficiency. This section explores the intricate components and mechanisms that contribute to optimal fuel atomization and precise injection timing.

Fundamentals of these systems lie in their ability to control the flow of fuel with remarkable accuracy. Employing electromechanical principles, they utilize minimal energy to achieve rapid and precise movements, ensuring effective combustion and reduced emissions.

Maintenance and troubleshooting of these sophisticated devices require a deep understanding of their operational dynamics. By delving into their functionality, one can appreciate the importance of regular checks and adjustments to maintain peak performance and longevity.

Common Issues with Piezo Injectors

In modern fuel systems, certain components are prone to malfunction, leading to various performance issues. Understanding these common problems is essential for effective troubleshooting and maintenance. Identifying the signs of wear or failure can help ensure optimal engine performance and efficiency.

1. Electrical Failures: One of the prevalent challenges involves the electrical components that control the functioning of the device. Faulty wiring or issues with the control unit can disrupt operation, resulting in inconsistent fuel delivery.

2. Contamination: Foreign particles in the fuel can cause blockages, leading to reduced efficiency. Contaminants can damage delicate parts, compromising the overall functionality and necessitating thorough cleaning or replacement.

3. Calibration Issues: Misalignment or improper calibration of the device can lead to incorrect fuel metering. This often manifests as poor engine performance, increased emissions, or difficulty starting the engine.

4. Mechanical Wear: Over time, moving parts may experience wear due to constant operation. This wear can lead to leaks or reduced pressure, which affects the performance of the fuel delivery system.

5. Heat Damage: Excessive temperatures can adversely affect the internal components, resulting in warping or breakdown of materials. Heat damage often leads to failure of the assembly, requiring immediate attention to prevent further issues.

Tools Required for Repair

When undertaking the restoration of precision components, having the right equipment is crucial for ensuring efficiency and effectiveness. Proper tools not only streamline the process but also enhance the overall quality of the work performed. Below is a detailed list of essential instruments that will aid in the task.

Essential Equipment

- Precision Screwdrivers

- Torque Wrench

- Caliper

- Cleaning Solutions

- Magnifying Glass or Microscope

- Multimeter

Specialized Tools

- Ultrasonic Cleaner

- Heating Gun

- Compression Testing Tool

- Diagnostic Software

- Sealing Tools

Having these tools at your disposal will facilitate a more systematic and thorough approach to the work at hand, ultimately leading to improved performance and longevity of the components involved.

Step-by-Step Repair Process

This section outlines a systematic approach for restoring functionality to a specific component, ensuring optimal performance and reliability. Following these detailed instructions will facilitate a comprehensive understanding of the tasks involved.

- Preparation

- Gather necessary tools and materials.

- Ensure a clean, well-lit workspace.

- Review safety precautions before beginning.

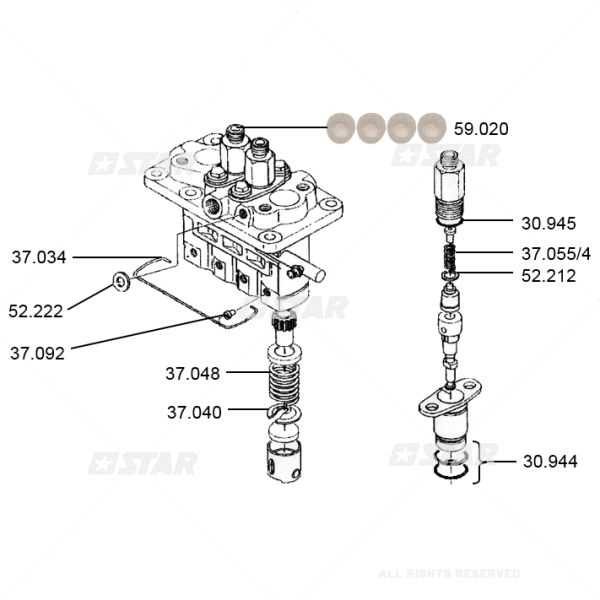

- Disassembly

- Carefully remove any external covers or housings.

- Take note of the arrangement of internal components.

- Use appropriate tools to detach sensitive parts without causing damage.

- Inspection

- Examine each component for signs of wear or malfunction.

- Identify any parts that may require replacement.

- Document findings for reference during reassembly.

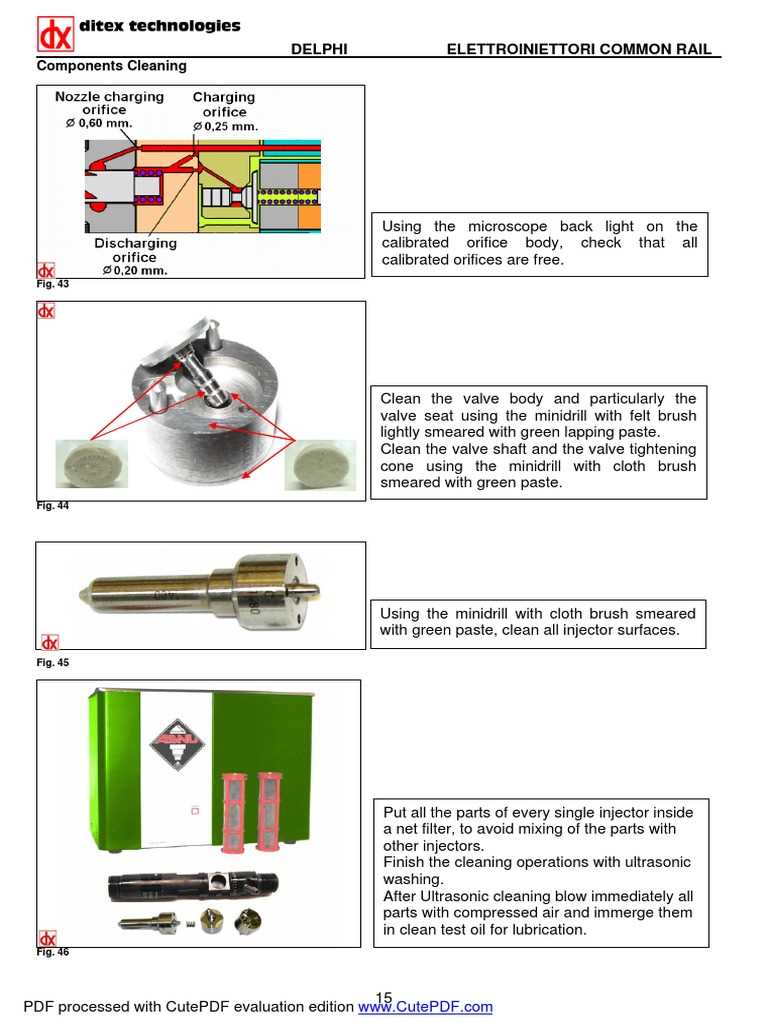

- Cleaning

- Utilize suitable solvents to remove debris and residue.

- Ensure all surfaces are dry before proceeding.

- Inspect cleaned components for any remaining issues.

- Reassembly

- Follow the documented arrangement of components.

- Ensure all parts are securely fastened.

- Reconnect any electrical connections with care.

- Testing

- Conduct functionality tests to ensure proper operation.

- Monitor for any unusual sounds or performance issues.

- Make adjustments as needed based on test results.

- Final Inspection

- Perform a thorough check of the reassembled unit.

- Verify that all tools and materials are cleared from the workspace.

- Document the completion of the process for future reference.

Testing Injectors After Repair

Ensuring optimal performance after servicing fuel delivery components is crucial. Testing these devices allows technicians to confirm functionality and efficiency, preventing future issues that could arise from improper operation.

Key Steps in the Testing Process

- Visual Inspection: Check for any physical damage or signs of wear.

- Electrical Testing: Verify the electrical connections and ensure they meet specified voltage requirements.

- Flow Rate Measurement: Assess the flow rate to ensure it aligns with manufacturer specifications.

- Leak Testing: Conduct tests to identify any leaks that could compromise performance.

- Spray Pattern Evaluation: Observe the atomization pattern to confirm proper distribution of fuel.

Equipment Needed

- Multimeter for electrical testing.

- Flow bench for measuring output.

- Pressure gauge for leak detection.

- Test stand to simulate operational conditions.

By following these steps and using the appropriate equipment, technicians can ensure that fuel delivery components operate reliably and efficiently, contributing to the overall performance of the engine.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires consistent care and attention. By following a set of best practices, you can extend the life of critical components and maintain efficiency in operation.

Regular Inspections

- Conduct visual checks for signs of wear and tear.

- Look for leaks or irregularities in performance.

- Inspect connectors and seals for any signs of degradation.

Cleaning Protocols

- Use appropriate cleaning agents to remove deposits and contaminants.

- Ensure all components are dried thoroughly after cleaning.

- Schedule cleaning based on operational hours or usage frequency.

Implementing these maintenance strategies will help you achieve reliable performance and reduce the risk of unexpected failures.

Signs Your Injector Needs Attention

Recognizing the early indicators of performance issues can prevent further complications and costly repairs. Certain symptoms can signal that a critical component in your fuel system is not functioning optimally, leading to diminished efficiency and increased emissions. Being aware of these signs is essential for maintaining your vehicle’s overall health.

Unusual Noises

If you hear strange sounds, such as clicking or buzzing, emanating from the engine, it may suggest that the component is struggling. These noises can indicate that the unit is not delivering fuel as intended, affecting engine performance. Addressing these auditory warnings promptly can help avoid more severe damage.

Decreased Performance

A noticeable decline in acceleration or power can indicate that the component is not providing the necessary fuel to the engine. This can manifest as stalling, misfiring, or hesitation during acceleration. If your vehicle’s responsiveness has diminished, it’s advisable to have it checked to ensure optimal functioning.

In conclusion, staying vigilant for these signs can help you maintain your vehicle in peak condition, ensuring smooth operation and longevity.

Comparing Piezo and Solenoid Injectors

This section explores the distinctions between two prevalent technologies used for fuel delivery in modern engines. Each method has its unique advantages and challenges, influencing performance, efficiency, and overall engine behavior. Understanding these differences is crucial for selecting the appropriate system for specific applications.

| Feature | Piezoceramic Technology | Electromagnetic Technology |

|---|---|---|

| Response Time | Faster actuation, allowing for precise control of fuel timing | Slower response, resulting in less precise timing |

| Fuel Atomization | Superior atomization for better combustion efficiency | Generally adequate atomization, but less efficient under certain conditions |

| Power Consumption | Lower energy requirement for operation | Higher energy consumption due to electromagnetic coils |

| Durability | More resilient to wear and tear | Potential for greater wear, especially in high-temperature environments |

| Cost | Typically higher initial investment | Generally more affordable for mass production |

In summary, each technology offers distinct characteristics that can impact engine performance. Careful consideration of these factors can guide decisions for optimal fuel system design.

Upgrading vs. Repairing Injectors

When it comes to enhancing engine performance, enthusiasts often face the dilemma of whether to enhance existing components or opt for refurbishment. Both approaches have their merits, and the decision can significantly impact overall functionality and efficiency.

Upgrading involves replacing older components with newer, often more advanced versions. This can lead to improved performance, better fuel efficiency, and reduced emissions. Enhanced designs may incorporate the latest technologies that cater to higher power demands and optimize combustion processes. However, this option usually comes with a higher cost and may require additional modifications to ensure compatibility with other engine systems.

On the other hand, refurbishing existing components can be a cost-effective solution. This process typically restores functionality by fixing or replacing worn parts, ensuring that the system operates as intended without the need for extensive changes. While this approach may not yield the same level of enhancement as upgrading, it can extend the lifespan of the components and maintain satisfactory performance levels.

Ultimately, the choice between enhancement and refurbishment depends on individual goals, budget constraints, and the specific requirements of the engine. Evaluating the long-term benefits and potential drawbacks of each option is crucial for making an informed decision.

Manufacturer Specifications and Guidelines

This section outlines essential criteria and recommendations provided by the manufacturer for optimal performance and longevity of the components in question. Adhering to these specifications is crucial to ensure reliability and efficiency in operation.

General Requirements

The components must meet specific standards regarding dimensions, materials, and operational parameters. These standards are designed to facilitate seamless integration with various systems and to maintain consistent performance under varying conditions. It is essential to regularly consult the guidelines to ensure compatibility and to avoid potential issues that could arise from deviations.

Maintenance Protocols

Regular maintenance is vital for sustaining the functionality of these components. The manufacturer recommends a routine inspection schedule, focusing on key areas such as sealing integrity and performance metrics. Additionally, appropriate cleaning techniques should be employed to prevent buildup that could hinder performance. Following these protocols not only enhances efficiency but also prolongs the lifespan of the system.

Frequently Asked Questions About Repairs

This section aims to address common inquiries related to the maintenance and restoration of specific components used in various mechanical systems. Understanding these aspects can enhance efficiency and prolong the lifespan of the equipment.

- What are the signs that my component needs attention?

Common indicators include:

- Unusual noises during operation

- Decreased performance or efficiency

- Visible wear or damage

- Fluid leaks

- How often should I perform maintenance?

Regular checks are recommended based on usage. Typically, inspections every 500-1000 operating hours are ideal, but always refer to specific guidelines for your equipment.

- Can I perform the maintenance myself?

While some tasks can be done independently, it is advisable to consult a professional for complex issues to avoid further damage.

- What tools do I need for basic upkeep?

Essential tools may include:

- Wrenches and sockets

- Screwdrivers

- Cleaning supplies

- Diagnostic equipment

- How do I know if a replacement is necessary?

If performance does not improve after basic maintenance or if damage is extensive, a replacement is often the best solution.

- Where can I find replacement parts?

Parts can be sourced from authorized dealers, online marketplaces, or specialty shops that focus on mechanical components.

lessCopy code