Singer 1036 Repair Guide for Beginners

Maintaining the longevity and optimal function of sewing devices can bring significant benefits to their users. Over time, even the most reliable models may encounter challenges that affect their performance. This section will provide insights into the upkeep and adjustment of vintage sewing machines, ensuring they continue to serve effectively for years to come.

The process of refurbishing and optimizing such machines requires a thorough understanding of their unique components and mechanisms. By exploring various approaches to cleaning, adjusting, and tuning these parts, one can restore the machine’s functionality and precision. In addition, we will discuss essential techniques for diagnosing and addressing any operational hiccups.

Attention to detail is critical in managing potential issues. Through this guide, readers will gain confidence in recognizing signs of wear and identifying

Guide for Restoring and Maintaining the 1036 Model

Understanding the key aspects of restoring and maintaining this classic sewing machine model ensures consistent performance and longevity. This guide will walk through essential tasks to address common issues and optimize functionality without requiring advanced technical skills.

- Component Examination: Regularly inspect individual parts, particularly the needle and bobbin systems. Checking these elements can prevent minor issues from becoming major problems.

- Thread Path Care: Keeping the threading route clean and free of buildup is essential fo

Understanding the Basics of Singer 1036

Exploring this sewing model offers insight into essential functions and mechanisms that make it efficient for a variety of stitching needs. Grasping the primary components and their interactions is key to achieving smooth operation and high-quality results.

Key Features include a range of settings allowing for customization in stitch types, lengths, and widths, making it adaptable to different fabric types and projects. Each control dial is designed for precision adjustments, essential for tasks from simple seams to more intricate patterns.

Maintenance is fundamental to keep the device performing reliably. Regular attention to areas prone to wear, such as the needle plate and feed system, will help prevent common issues and prolong the machine’s lifespan.

Essential Tools for Singer Machine Repairs

Maintaining sewing machines effectively relies on having the right set of instruments to address common issues and ensure long-lasting performance. A well-equipped toolkit helps streamline adjustments, making the maintenance process smoother and more efficient.

One crucial tool for this work is a precision screwdriver set, which allows you to handle small, delicate screws without damaging components. A pair of needle-nose pliers is also indispensable for reaching tight spaces and managing tricky adjustments. Having a reliable set of tweezers aids in handling small parts and removing thread jams from tight spots.

Additional helpful items include a lint brush to clear away fabric debris, ensuring optimal function, and sewing machine oil to keep parts running smoothly. A mult

Common Issues and Simple Fixes

Understanding typical malfunctions and straightforward ways to address them can help maintain functionality over time. Below are a few frequent complications and practical solutions that can be applied easily without extensive technical expertise.

Frequent Threading Complications

Threading challenges can disrupt smooth operation, leading to skipped stitches or fabric jams. Addressing these issues involves ensuring correct threading paths and adjustments in tension.

- Verify that the upper thread follows the correct path and is securely in place.

- Check the bobbin to ensure it

Troubleshooting Power Problems

Power issues are common and can disrupt smooth operation. Addressing these challenges involves identifying the source, which may stem from connectivity, component faults, or external influences. Systematic checks help isolate and resolve the root causes efficiently.

- Check Power Source: Verify that the power outlet is functioning correctly by testing it with another device. Power fluctuations or an inactive outlet can often be the primary reason for issues.

- Inspect the Power Cord: Examine the cord for any visible signs of wear, fraying, or damage. Damaged cords can lead to inconsistent power delivery and should be replaced if necessary.

- Evaluate the Switch: E

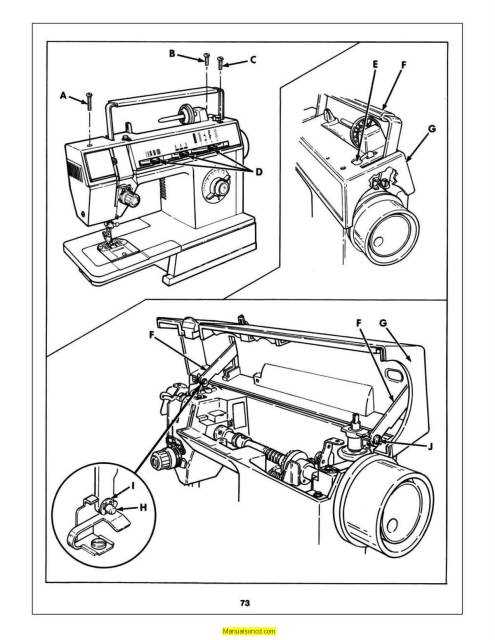

Maintaining the Motor and Belts

Ensuring the longevity and optimal performance of a sewing machine requires regular attention to its motor and drive components. Proper care not only enhances functionality but also prevents common issues that can arise from neglect. Regular maintenance routines should focus on lubrication, inspections, and timely replacements of worn parts to keep the machine running smoothly.

Lubrication of the Motor

Lubrication is essential for maintaining the motor’s efficiency and minimizing wear. It is advisable to use a high-quality oil specifically designed for sewing machines. Apply a few drops to the motor’s moving parts, ensuring that all friction areas are adequately lubricated. This practice helps reduce overheating and prolongs the motor’s life.

Inspecting and Replacing Belts

Belts play a crucial role in transferring power from the motor to the needle mechanism. Regular inspections can identify signs of wear, fraying, or damage. If any irregularities are detected, it is essential to replace the belts promptly to avoid further complications. Follow the manufacturer’s recommendations for the appropriate type and size of belts.

Inspection Checklist Action Required Check motor lubrication Apply oil if needed Inspect belts for wear Replace if damaged Examine motor connections Tighten any loose fittings Fixing Threading and Tension Issues

Addressing problems with thread placement and tension is essential for achieving optimal performance in any sewing device. These challenges can manifest as uneven stitches, thread breakage, or fabric puckering. Understanding how to troubleshoot and resolve these issues can significantly enhance your sewing experience.

To start, ensure that the thread is correctly threaded through the various guides and tension discs. Incorrect threading can lead to inconsistent tension and poor stitch quality. Always refer to your device’s guidelines for the correct threading path.

If you encounter tension problems, examine the tension dial. Adjust it gradually, making small changes until the desired stitch quality is achieved. It’s also important to check the bobbin area; a poorly wound bobbin can contribute to tension discrepancies. Ensure that the bobbin is inserted properly and that the thread unwinds smoothly.

Finally, consider the type of thread and fabric you are using. Different materials may require specific threads or adjustments in tension settings. Experimenting with these elements can help in fine-tuning the sewing process and achieving the best results.

Replacing Worn Out Parts

Over time, certain components of your sewing machine may experience wear and tear, affecting its overall performance. Addressing these issues promptly can enhance functionality and extend the lifespan of the device. This section outlines essential steps to identify and replace these components effectively.

It is crucial to regularly inspect key parts to determine their condition. Common areas to check include the needle, presser foot, and bobbin case. Recognizing signs of damage or excessive wear can help prevent further complications during operation.

Part Symptoms of Wear Replacement Options Needle Bending or dullness Standard or specialty needles Presser Foot Difficulty in fabric feeding Universal or specialized presser feet Bobbin Case Thread bunching or breaking Compatible bobbin cases When selecting replacement components, ensure compatibility with your device. Consult the product specifications or manufacturer guidelines for the best results. Proper installation of new parts is essential for optimal machine performance.

Cleaning and Lubricating Key Components

Maintaining the essential parts of your sewing machine is crucial for optimal performance and longevity. Regular cleaning and lubrication can prevent wear and tear, ensuring smooth operation. This section outlines effective practices to care for vital components, enhancing their functionality.

Initial Cleaning is the first step in the maintenance process. Begin by removing any lint, dust, and debris from the machine. Use a soft brush or a lint roller to reach difficult areas, particularly around the feed dogs and bobbin case. A clean environment will facilitate better stitching and overall efficiency.

Lubrication is equally important. After cleaning, apply a small amount of suitable oil to the moving parts, such as the needle bar, hook, and any exposed gears. Ensure to use the correct lubricant specified for the machine to avoid damage. Proper lubrication reduces friction, promoting smoother movement and extending the lifespan of components.

It is advisable to consult the guidelines specific to your device to identify which parts require regular attention. Keeping a consistent schedule for maintenance will significantly improve the reliability and functionality of your equipment.

Diagnosing Bobbin and Needle Jams

When dealing with issues related to thread jams, it is essential to identify the underlying causes. These problems often manifest as difficulty in stitching or complete machine stoppage. Understanding how to troubleshoot these issues will help maintain smooth operation and prevent further complications.

Here are some common signs of thread jams:

- Uneven stitching or skipped stitches

- Thread breaking frequently during operation

- Unusual noises from the machine

- Difficulty in pulling the fabric through

To effectively diagnose these jams, consider the following steps:

- Check the bobbin case for any tangled or incorrectly wound thread.

- Ensure the needle is properly installed and not damaged.

- Examine the upper threading path for any obstructions or misalignments.

- Clean the machine regularly to prevent lint buildup.

Addressing these factors can significantly reduce the likelihood of encountering thread jams and enhance the overall performance of your sewing device.

Electrical Issues and Safe Repairs

Addressing electrical complications in sewing devices is essential for maintaining their functionality and ensuring user safety. Understanding potential problems and adhering to proper handling methods can significantly enhance performance and longevity.

Common Electrical Problems

- Power supply interruptions leading to device malfunctions

- Faulty wiring that may cause short circuits

- Burnt fuses or blown circuit breakers

- Overheating components affecting operational efficiency

Guidelines for Safe Interventions

- Always disconnect the device from the power source before starting any examination.

- Use appropriate tools designed for electrical work to avoid damage.

- Inspect wires and connections for visible wear and tear, replacing damaged parts immediately.

- Consult a professional technician if the issue persists after basic troubleshooting.

Extending the Lifespan of Singer

Maintaining the longevity of your sewing device is essential for ensuring optimal performance and efficiency. By following a few key practices, you can significantly enhance its durability and functionality over time.

Regular cleaning is crucial. Dust and fabric fibers can accumulate and hinder the operation of the machine. Make it a habit to clean the interior and exterior regularly, using appropriate tools to reach all areas.

Additionally, proper lubrication is necessary. Using the correct oil at recommended intervals keeps moving parts functioning smoothly. Always refer to guidelines to determine the best lubrication practices.

Storage conditions also play a vital role. Keeping the equipment in a dry and dust-free environment protects it from damage. Using a cover when not in use can prevent dust accumulation and potential scratches.

Lastly, ensure that you are using the right materials and accessories for your projects. This prevents unnecessary strain on the device, promoting a longer lifespan and optimal results.