Singer 29 4 Maintenance and Repair Guide

In the world of traditional sewing, preserving vintage tools is an essential skill for those passionate about craftsmanship and functionality. These timeless devices, often cherished for their durability and unique construction, sometimes require specific adjustments and maintenance to continue operating smoothly. Understanding the details of caring for such machines can significantly extend their life and enhance their performance.

Proper upkeep involves more than basic cleaning; it requires knowledge of essential parts and how they interact within the equipment. Learning how to fine-tune components and address common issues is invaluable for anyone seeking to bring out the best in these sewing classics. This guide covers the essential steps for restoring the precision and usability of these unique tools.

For enthusiasts and professionals alike, regular attention to key aspects can prevent wear and help maintain peak condition. This article provides a step-by-step overview of the most crucial techniques, ensuring that every detail is addressed carefully, from basic adjustments to more intricate fixes. By following these insights, users can confidently handle maintenance and small-scale restoration tasks.

Singer 29-4 Sewing Machine Repair Guide

This section provides guidance for restoring and maintaining a well-known leather-stitching machine model from the early 20th century. The instructions below are designed to help you identify common issues, perform necessary adjustments, and ensure consistent functionality over time. Whether for minor tweaks or comprehensive tune-ups, these steps aim to extend the machine’s lifespan and maintain its precision.

- Checking Tension Settings: Over time, the tension may become imbalanced, affecting stitch quality. Regularly inspect and adjust both upper and lower tension points to maintain even stitching.

- Cleaning and Lubricating: Dust and thread debris can accumulate, impacting smooth operation. Ensure each moving part is clean, and apply a few drops of appropriate oil to key points, avoiding excess lubrication.

- Inspecting the Shuttle and Bobbin: The shuttle mechanism is central to stitch formation. Regularly remove, clean, and inspect these components, addressing any visible wear to prevent snagging and thread breakage.

- Replacing Needles: Worn or bent needles can cause skipped stitches or fabric damage. Replace needles as needed, ensuring they are the correct type and size for optimal performance.

- Examining the Drive Belt: The belt’s condition affects the machine’s power transmission. Inspect it periodically for signs of wear or looseness, and replace it if necessary to maintain stable function.

By following these maintenance practices, you’ll help preserve the machine’s effectiveness and prevent potential disruptions during your work. Regular attention to these areas can ensure a more reliable experience and contribute to a longer operating life.

Identifying Common Issues

Understanding frequent operational challenges can help extend the life of your equipment and maintain optimal functionality. This section provides an overview of recurring complications and guidance on recognizing them early.

- Skipped Stitches: One common sign of imbalance. If threads are not forming securely, inspect alignment and needle positioning as these can often cause missed connections in the stitch.

- Thread Bunching: This issue typically indicates an irregularity in tension. Check both the top and bobbin threads for consistent flow and make adjustments as needed.

- Needle Breakage: Frequent breaks may signal issues with fabric compatibility or needle quality. Confirm that the needle is suitable for the material in use and that it is properly secured.

- Irregular Feed: When fabric doesn’t move smoothly, inspect the feed mechanism for blockages or wear. Proper cleaning and occasional lubrication may help resolve this.

- Unusual Noise: Any grinding or ticking sounds can indicate friction or loose parts. Carefully examine the components to ensure everything is tightly in place and moving freely.

Regular attention to these potential challenges can reduce the likelihood of downtime and keep your machine performing reliably over time.

Understanding the Machine’s Mechanics

To effectively handle any sewing apparatus, gaining insight into its essential mechanisms is crucial. This section explores the internal components and their functions, providing a foundational understanding of how the machine operates to produce precise, durable stitches.

| Component | Function | Maintenance Tips |

|---|---|---|

| Needle Bar | Moves the needle up and down, creating stitches as the fabric passes beneath. | Keep clean and oiled for smooth operation. |

| Presser Foot | Holds fabric in place while stitching, allowing accurate and steady movement. | Check alignment regularly to avoid skipped stitches. |

| Bobbin System | Feeds the lower thread, interlocking with the top thread to form stitches. | Keep dust-free and adjust tension as needed. |

| Feed Dogs | Move fabric forward with each stitch, maintaining consistent stitch length. | Ensure they are properly set to avoid fabric slippage. |

With a basic grasp of these core parts, users can make more informed adjustments and ensure the machine operates smoothly. Regular upkeep of each element is essential to maintain peak performance and avoid common sewing issues.

Cleaning and Lubrication Tips

Regular maintenance is essential to ensure smooth performance and prolong the lifespan of your sewing equipment. By keeping all moving parts free from dust and well-lubricated, you can help maintain its efficiency and prevent unnecessary wear.

Start by gently brushing away any fabric lint or debris that may have accumulated in small crevices. Use a soft brush to access these tight spots, as built-up residue can impact functionality over time. Be mindful to remove any residue around the bobbin and needle areas where dust tends to gather.

Lubrication is equally important for optimal operation. Apply a small amount of high-quality sewing oil to the key moving components, following the machine’s structural design. This process reduces friction and keeps mechanisms running seamlessly. Be cautious to avoid over-oiling, as excess lubricant may attract more dust. Regular cleaning and light lubrication can greatly improve the machine’s overall performance and longevity.

Restoring Stitch Quality

Maintaining optimal stitch consistency can significantly improve the overall performance and longevity of your sewing equipment. Achieving high-quality stitches involves inspecting and adjusting various mechanical components to ensure seamless fabric processing and precise thread handling.

Checking and Adjusting Tension

Thread tension plays a critical role in stitch appearance. Imbalanced tension can lead to loose or tight stitches, compromising fabric integrity. To correct this, start by testing tension settings with different fabric samples. Adjust both upper and lower thread tensions incrementally, observing how these adjustments affect stitch evenness and fabric appearance.

Inspecting Needle and Feed Mechanism

A sharp needle and a well-aligned feed mechanism are essential for consistent stitching. Over time, needles may become dull or bent, affecting the stitch quality. Regularly inspect the needle and replace it if necessary. Additionally, check the feed mechanism alignment to ensure smooth fabric movement and accurate stitch placement.

| Component | Common Issue | Suggested Solution | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Upper Thread Tension | Loose stitches | Increase tension slightly | ||||||||||||||||

Lower Th

Replacing Damaged PartsWhen it comes to maintaining equipment, ensuring that all components are functioning correctly is essential. Over time, certain elements may become worn or damaged, affecting the overall performance. Addressing these issues promptly can prevent further complications and extend the life of the device. Identifying damaged components involves careful inspection. Look for signs of wear, such as cracks, breaks, or excessive wear on the surfaces. Once identified, it is crucial to source high-quality replacements that meet the specifications of the original parts. Utilizing parts that match the original design ensures compatibility and optimal performance. The replacement process typically begins with disassembling the device to access the affected area. This may require specific tools to safely remove the damaged parts without causing additional harm. Once the old component is removed, install the new piece by following the manufacturer’s guidelines, ensuring it is securely in place. After replacing the damaged parts, reassemble the equipment carefully. It is advisable to conduct a thorough test to confirm that the new components are functioning properly and that the overall performance meets expectations. Regular maintenance checks can help prevent future issues and ensure smooth operation. Adjusting Thread TensionProper thread tension is essential for achieving high-quality stitching in sewing machines. It influences how the fabric layers interact during the stitching process and can significantly affect the overall appearance of the final product. Ensuring that the tension is set correctly allows for consistent results and prevents issues such as puckering or thread breakage. Understanding Tension MechanismThe tension mechanism regulates how tightly the thread is pulled as it passes through the machine. This mechanism can be affected by several factors, including the type of fabric being used and the thickness of the thread. Adjustments may be necessary depending on the material and project requirements. Steps to Adjust TensionTo achieve the desired tension, follow these steps:

Fixing Feed Dog Problems

Issues with the mechanism that advances the fabric can significantly impact sewing performance. Understanding the underlying causes of these problems can help in effectively addressing them and ensuring smooth operation. Here are common reasons for feed dog issues:

To resolve these issues, follow these steps:

Regular maintenance and timely intervention can help prevent these problems, ensuring a smooth sewing experience. Maintaining Bobbin Functionality

Proper care and attention to the bobbin mechanism are essential for ensuring smooth operation of your sewing device. Maintaining the functionality of the bobbin will prevent issues such as thread tangling and inconsistent stitching, leading to better overall performance. Regular InspectionConducting regular checks on the bobbin system can help identify potential problems early. Here are some steps to follow:

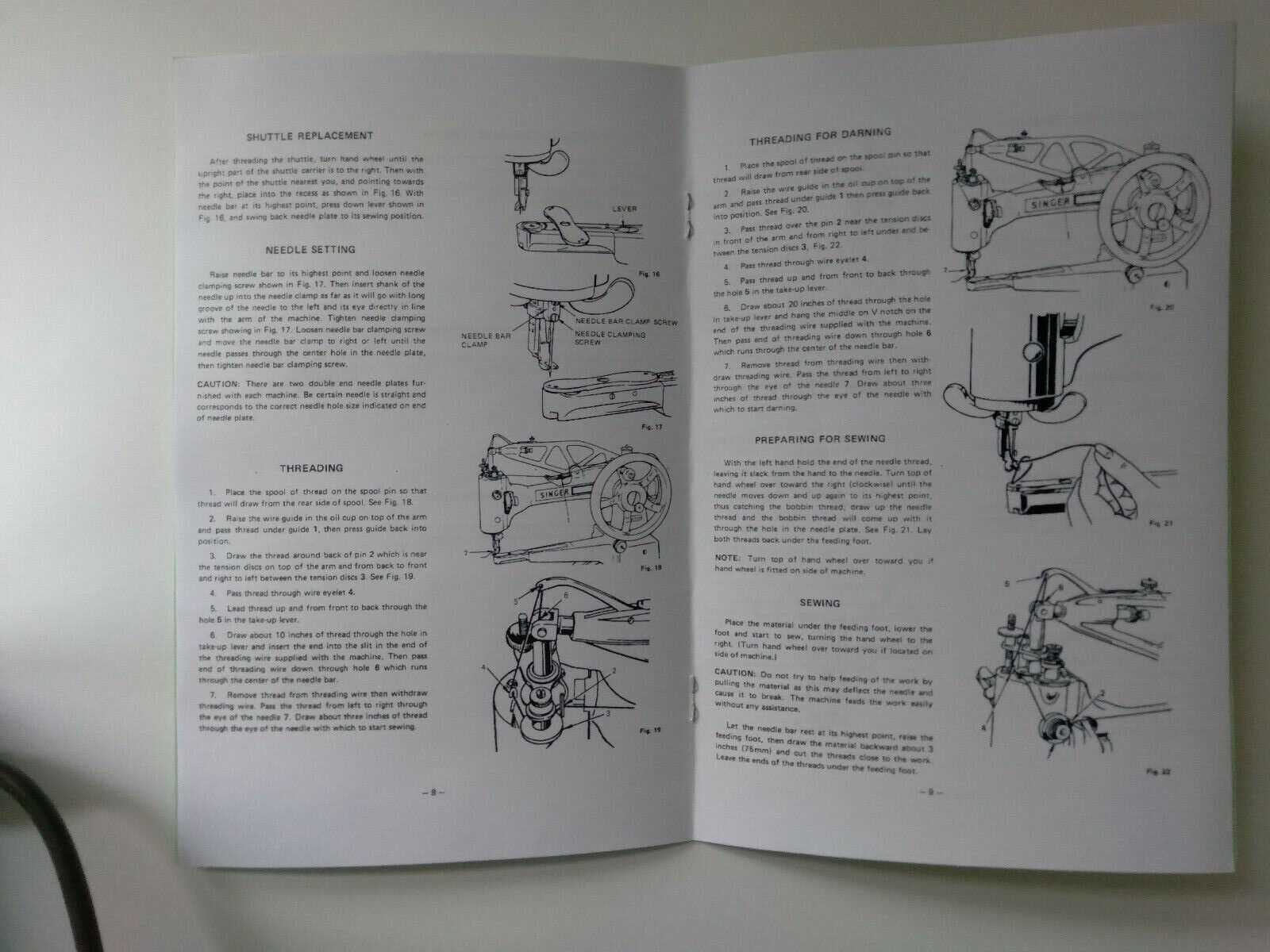

Threading Techniques

Correct threading of the bobbin is crucial for optimal function. Follow these guidelines:

Needle Replacement TechniquesReplacing the needle is an essential maintenance task that ensures optimal performance of your sewing device. A sharp and correctly positioned needle can greatly impact the quality of your stitching and the overall efficiency of your work. Understanding the proper techniques for replacing the needle is crucial for both novice and experienced users. To begin, always make sure to turn off the power of your machine before starting the replacement process. This ensures safety while handling the needle and other components. Next, identify the type of needle required for your specific projects, as there are various sizes and types designed for different fabrics and stitching techniques. Once you have selected the appropriate needle, remove the old one by loosening the needle clamp screw. Gently slide the needle out of its holder, ensuring you do not damage any surrounding parts. Insert the new needle with the flat side facing the appropriate direction, usually towards the back of the machine. Tighten the clamp screw securely to hold the needle in place. Finally, it’s advisable to perform a test stitch on a scrap piece of fabric to ensure that the needle is properly installed and functioning correctly. Regularly checking and replacing the needle as needed will help maintain the performance and longevity of your sewing device. Ensuring Proper Belt Alignment

Achieving optimal performance in machinery often hinges on the precise alignment of components. Proper belt positioning is crucial for maintaining efficiency and prolonging the lifespan of mechanical systems. Misalignment can lead to wear and tear, resulting in decreased functionality. To ensure correct alignment, consider the following steps:

Regular maintenance and attention to detail in these areas will help prevent problems and maintain the efficiency of the system. Troubleshooting Timing IssuesProper synchronization of components is essential for optimal functionality in sewing machines. When timing problems occur, they can lead to inconsistent stitching, skipped stitches, or thread jams. Identifying and resolving these issues promptly can restore machine performance and improve sewing outcomes. Here are some common signs of timing issues:

To address timing problems, follow these troubleshooting steps:

If issues persist, consider consulting a professional for further evaluation. Regular maintenance can also help prevent future timing complications. Preserving the Machine’s DurabilityMaintaining the longevity of a sewing device is essential for optimal performance and reliability. Proper care not only enhances its functionality but also extends the lifespan of its components. By implementing a few simple practices, users can ensure their equipment remains in excellent condition for years to come. Regular Maintenance Practices

Storing the Device Properly

|