Singer 99k Repair Guide

Understanding the intricacies of vintage sewing equipment can significantly enhance your crafting experience. This section is dedicated to exploring essential techniques and tips for maintaining these cherished devices, ensuring they continue to operate smoothly for years to come.

Regular upkeep is crucial in preserving the functionality of these machines. By following systematic procedures, users can prevent common issues that may arise over time. This guide will provide insights into the essential aspects of care and troubleshooting, allowing enthusiasts to fully appreciate their sewing tools.

Moreover, knowing how to handle minor adjustments and fixes can lead to a more enjoyable sewing journey. Each machine has unique characteristics, and familiarizing yourself with these can transform your creative projects. Embrace the art of maintenance to keep your equipment in top condition, allowing your sewing adventures to thrive.

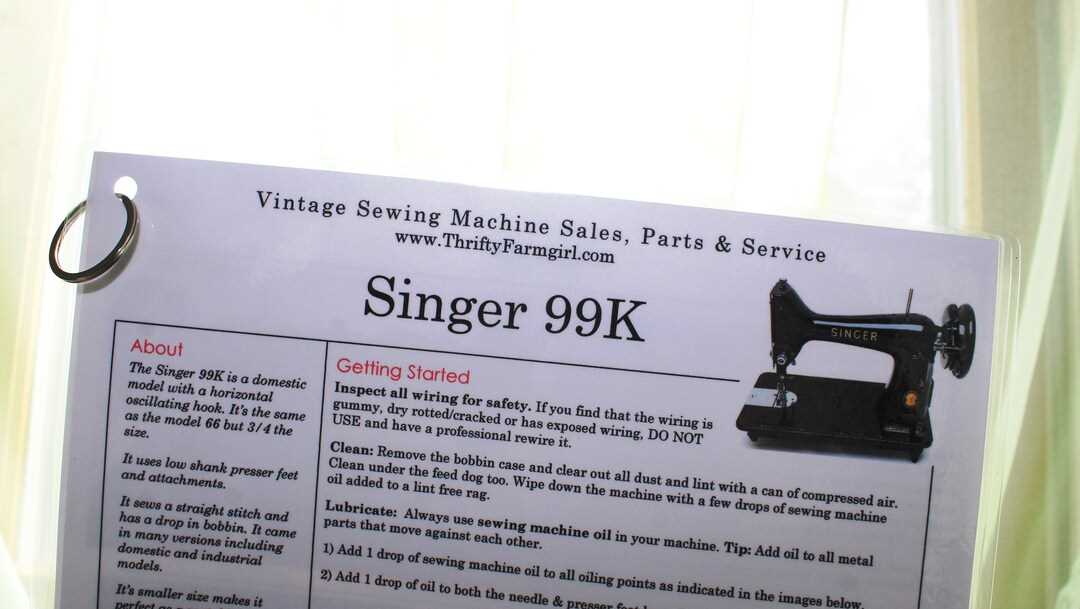

Overview and Features

This section provides a comprehensive insight into a classic sewing machine that has captivated enthusiasts and professionals alike. Known for its robust construction and user-friendly design, this model is celebrated for its reliability and performance in various sewing tasks.

Key Specifications

| Feature | Description |

|---|---|

| Build Quality | Sturdy metal frame ensuring durability and stability during operation. |

| Stitch Options | Offers a variety of stitch patterns suitable for different fabric types. |

| Ease of Use | Designed with intuitive controls, making it accessible for users of all skill levels. |

| Foot Pedal | Responsive foot control that allows for smooth and precise sewing. |

Performance Highlights

This machine excels in handling both lightweight and heavier materials, providing consistent results. Its ability to adapt to various sewing techniques makes it a versatile choice for any project, from simple repairs to intricate designs.

Common Issues with Singer 99k

This section highlights frequent challenges encountered with a specific sewing machine model. Understanding these problems can aid users in troubleshooting and maintaining optimal functionality.

| Issue | Description |

|---|---|

| Thread Bunching | This occurs when the thread fails to form a proper stitch, often due to incorrect threading or tension settings. |

| Skipped Stitches | Stitches may be missed if the needle is dull or improperly installed, or if the fabric is too thick. |

| Machine Jamming | Obstructions in the bobbin area or improper alignment can lead to frequent jamming during operation. |

| Uneven Stitching | Inconsistent stitch quality can arise from issues with the feed dogs or incorrect presser foot pressure. |

Essential Tools for Repair

Having the right equipment is crucial when it comes to maintaining and fixing sewing machines. This section outlines the basic items you will need to ensure a smooth and effective restoration process.

- Screwdrivers: A set of both flat and Phillips screwdrivers is necessary for removing screws and accessing various components.

- Wrenches: Adjustable wrenches are useful for loosening and tightening nuts and bolts.

- Needle Nose Pliers: These are essential for reaching tight spaces and handling small parts.

- Seam Ripper: A handy tool for removing stitches and unraveling seams.

- Lint Brush: Keeping the machine clean is vital; a lint brush helps remove debris and dust.

Equipped with these fundamental tools, you will be well-prepared to tackle various maintenance tasks and keep your sewing machine in optimal condition.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing and resolving common issues encountered with your sewing machine. By following a systematic process, users can effectively identify the root causes of problems and implement appropriate solutions.

Begin by examining the device for any visible signs of wear or damage. Ensure that all components are properly assembled and that there are no obstructions in the threading path. Check the needle for bends or breaks, as this can significantly impact performance.

If the machine fails to stitch correctly, inspect the tension settings. Adjusting these can often resolve issues related to loose or tight stitches. Additionally, ensure that the bobbin is correctly placed and that the thread is wound evenly.

In cases where the motor does not engage, verify that the power supply is connected and functioning. A blown fuse or a faulty foot pedal may also contribute to this issue. Testing these components can help isolate the problem.

Finally, regular maintenance, including cleaning and oiling, can prevent many common malfunctions. Implementing these practices will extend the longevity of your sewing machine and improve its overall performance.

Replacing the Needle and Thread

Changing the needle and thread in your sewing device is essential for maintaining optimal performance and ensuring quality stitching. A fresh needle can enhance the precision of your work, while the right type of thread is crucial for achieving the desired results.

To begin the process, make sure to turn off the machine for safety. Remove any existing thread from the spool and the tension mechanism. Next, take out the current needle by loosening the needle clamp screw. Carefully slide the needle out and replace it with a new one, ensuring it is inserted correctly and securely fastened.

After replacing the needle, it’s time to re-thread the machine. Start by placing your chosen spool on the spindle, then guide the thread through the designated tension discs and around any necessary guides. Finally, thread it through the needle’s eye from front to back, adjusting the tension as needed to suit your project.

Regularly checking and replacing these components not only improves the quality of your sewing but also extends the life of your equipment.

Maintenance Tips for Longevity

Proper care and attention are essential for ensuring the extended lifespan of your sewing machine. By following a few key practices, you can enhance its performance and reliability over time.

Regular Cleaning: Dust and lint can accumulate within the machine, leading to potential issues. Make it a habit to clean the components frequently, especially around the feed dogs and bobbin area. Use a soft brush or a lint roller to gently remove debris.

Lubrication: Keeping moving parts well-lubricated is crucial for smooth operation. Refer to the manufacturer’s recommendations for suitable oils and application points. A well-oiled machine runs quieter and with less friction.

Proper Storage: When not in use, store your machine in a dust-free environment. Consider using a protective cover to prevent dust buildup and exposure to moisture, which can cause rusting and damage.

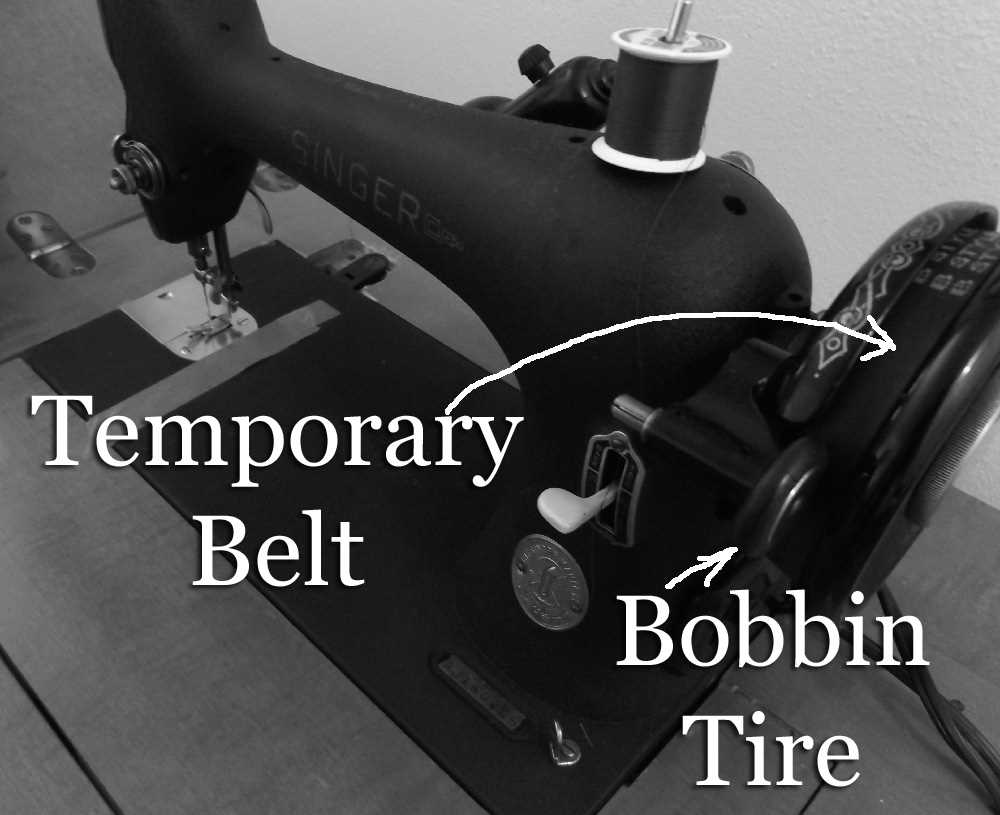

Regular Inspections: Check the condition of belts and cords periodically. Replacing worn parts promptly can prevent further damage and costly repairs. Ensure that all connections are secure before operating the machine.

By implementing these practices, you will not only improve the functionality of your device but also prolong its lifespan, allowing you to enjoy many creative projects for years to come.

Cleaning the Sewing Machine Interior

Maintaining the cleanliness of the machine’s inner components is essential for ensuring optimal performance and longevity. Dust and lint can accumulate over time, potentially affecting the sewing quality and causing mechanical issues. Regular cleaning helps to prevent these problems and keeps the machine running smoothly.

Tools and Supplies Needed

Gather the necessary tools for the task, including a soft brush, a lint-free cloth, and a small vacuum attachment. These items will assist in effectively removing debris from hard-to-reach areas.

Cleaning Process

Begin by unplugging the machine for safety. Carefully remove any detachable parts, such as the needle plate and bobbin case. Use the soft brush to gently sweep away lint from the interior, focusing on corners and crevices. Wipe surfaces with a lint-free cloth to eliminate any remaining dust. Finally, reassemble all components securely before plugging the machine back in and testing its functionality.

Adjusting Tension Settings Effectively

Properly managing the tension of threads is crucial for achieving optimal stitch quality. When adjustments are made correctly, it ensures that the fabric is fed evenly and the stitches are secure, preventing issues such as puckering or loose seams.

To effectively adjust the tension settings, follow these steps:

| Step | Action | Outcome |

|---|---|---|

| 1 | Identify the upper thread tension dial and the bobbin case tension. | Understanding both components helps in pinpointing where adjustments are needed. |

| 2 | Test the stitch on a scrap piece of fabric. | Observe how the threads interact to assess whether the tension is too tight or too loose. |

| 3 | Make small adjustments to the upper thread tension first. | This allows for fine-tuning without drastic changes that could complicate the process. |

| 4 | Re-test the stitch and repeat adjustments as necessary. | Continuously testing will lead to achieving the desired tension balance. |

Regular checks and adjustments of tension settings can significantly enhance the overall sewing experience, ensuring that projects are completed with professional results.

How to Lubricate Moving Parts

Proper maintenance of mechanical devices is essential for their smooth operation and longevity. One critical aspect of this maintenance involves applying the right lubricant to the moving components, which helps minimize friction and wear. This guide outlines the steps for effectively applying lubrication to ensure optimal performance.

Choosing the Right Lubricant

Selecting an appropriate lubricant is crucial. Different materials and applications require specific types of lubricants, such as oil or grease. Always refer to the manufacturer’s recommendations to find the most suitable product for your device’s moving parts.

Applying Lubricant Correctly

Identifying Electrical Problems

Recognizing issues within the electrical system of your device is crucial for effective troubleshooting. Many problems may stem from faulty connections, damaged components, or power supply irregularities, which can lead to operational failures.

Begin by inspecting the power source to ensure it is functioning properly. Check for any signs of wear or damage in the cables and connectors. A loose connection can often disrupt the power flow, leading to inconsistent performance.

Next, examine the internal wiring for any visible signs of deterioration or fraying. This can indicate a need for replacement or repair to restore proper functionality. Additionally, utilizing a multimeter can help measure voltage levels, allowing for a more precise diagnosis of electrical irregularities.

Lastly, pay attention to any unusual sounds or smells that may arise during operation, as these can signal underlying electrical issues that require immediate attention. Regular maintenance and early detection are key to prolonging the life of your equipment.

Upgrading Components for Better Performance

Enhancing the efficiency of your sewing machine can significantly improve your overall crafting experience. By focusing on specific parts, you can elevate the functionality and durability of the device, ensuring smoother operation and better results. This section discusses various upgrades that can be applied to achieve optimal performance.

Consider replacing the standard needle with a high-quality option that suits your fabric type. Upgrading to specialized needles can help reduce skipping and breakage, allowing for more precise stitching. Additionally, examining the presser foot and swapping it for a more versatile version can enhance fabric handling and adaptability for different projects.

Another crucial area to focus on is the motor. If your current motor struggles under heavy use, upgrading to a more robust model can provide the necessary power for challenging tasks. This improvement not only enhances speed but also prolongs the life of your machine.

Finally, ensuring that all moving parts are well-lubricated and free from debris is essential. Regular maintenance combined with upgraded components will ensure your machine operates at its peak, making every project more enjoyable and efficient.

Resources for Further Assistance

For those seeking additional guidance and support in the maintenance and troubleshooting of their sewing machines, various resources are available. These can enhance understanding and provide expert insights into effectively managing common issues and enhancing performance.

| Resource Type | Description | Link |

|---|---|---|

| Online Forums | Community-driven platforms where users share experiences and solutions. | Visit Forum |

| Video Tutorials | Step-by-step visual guides available on platforms like YouTube. | Watch Tutorials |

| Books | Comprehensive guides on sewing machine care and techniques. | Browse Books |

| Local Workshops | Hands-on sessions with experts to learn more about machine upkeep. | Find Workshops |