Singer Quantum Stylist 9960 Comprehensive Repair Guide

In the world of textile creation, having a well-functioning sewing apparatus is essential for achieving professional results. This section aims to provide insightful guidance for enthusiasts looking to troubleshoot and maintain their beloved machines. Understanding the intricacies of these devices can significantly enhance their longevity and performance.

From simple adjustments to more complex procedures, knowing how to care for your equipment is vital. This guide will cover various aspects, including common issues, preventative measures, and techniques for restoring optimal functionality. Whether you are a novice or an experienced seamstress, the information presented here will empower you to handle your machine with confidence.

Equipped with the right knowledge, you can avoid the frustration of unexpected malfunctions. This resource will serve as a practical reference, offering step-by-step instructions and valuable tips to ensure your apparatus remains in peak condition. Embrace the art of sewing with the assurance that you have the tools needed to manage any challenge that may arise.

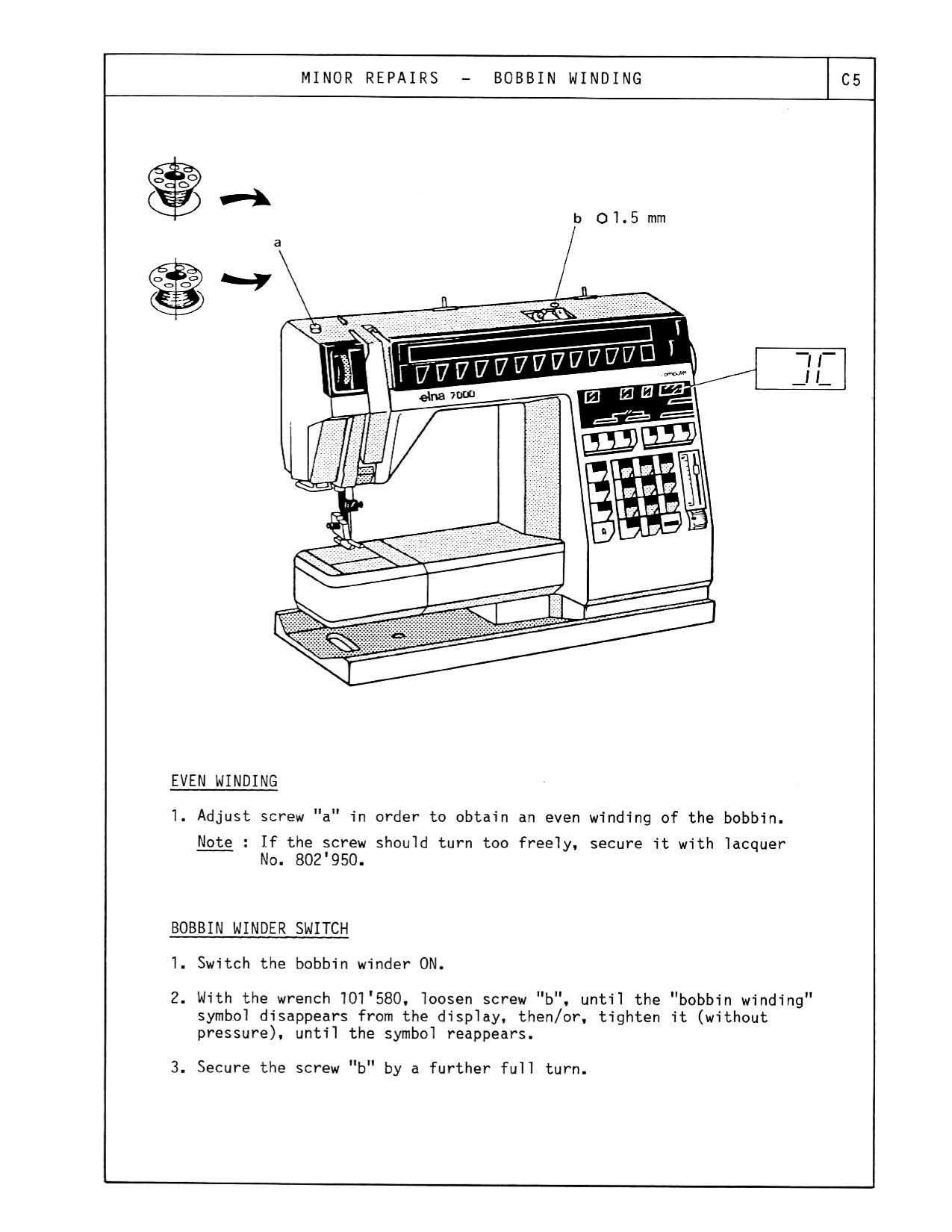

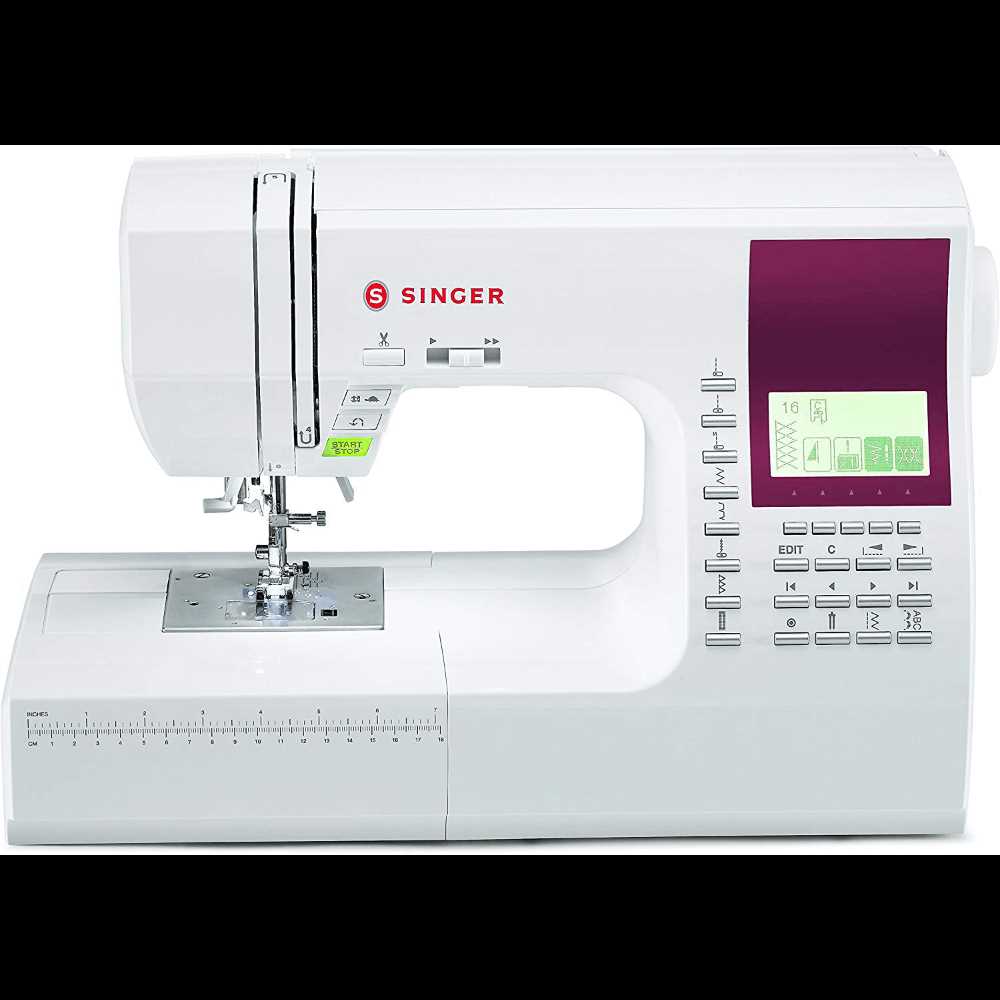

Overview of the Advanced Sewing Machine

This section provides a comprehensive look at a sophisticated sewing machine designed for both novice and experienced crafters. With a wide range of features and functions, it offers unparalleled versatility, enabling users to explore their creativity through various stitching options and customization capabilities.

Key Features

The device boasts an impressive array of built-in stitches, making it suitable for a multitude of projects, from simple repairs to intricate designs. It includes user-friendly technology, such as an intuitive interface and a digital display, which enhances the sewing experience. Additionally, the ability to easily adjust stitch length and width provides further flexibility, catering to individual preferences.

Performance and Reliability

Noteworthy for its consistent performance, this model is engineered to handle different fabric types with ease. Its sturdy construction ensures longevity, while the efficient motor supports smooth operation, reducing the likelihood of disruptions during use. With proper maintenance, this machine can serve as a reliable partner for all your sewing endeavors.

Common Issues with the Singer 9960

When working with advanced sewing machines, users may encounter a variety of challenges that can hinder their creative projects. Understanding these frequent problems can help in troubleshooting and maintaining optimal performance. Below are some typical concerns faced by operators of this particular model.

Threading Complications

One of the most prevalent issues arises from improper threading. If the upper thread is not correctly threaded through the tension disks, it can lead to uneven stitching or thread breakage. Ensure that the thread path is followed accurately, and always check the bobbin placement, as incorrect loading can also contribute to these complications.

Stitch Quality Problems

Poor stitch quality can be a frustrating experience. This may manifest as skipped stitches or inconsistent tension. Various factors can cause this, including worn needles, unsuitable thread type, or even fabric thickness. Regularly changing needles and selecting the appropriate settings for different materials can significantly improve the overall stitching outcome.

In conclusion, familiarizing oneself with these common difficulties can enhance the sewing experience and prolong the lifespan of the machine. Regular maintenance and attention to detail are key to achieving excellent results.

Essential Tools for Repairs

When it comes to maintaining and fixing intricate machinery, having the right instruments at your disposal is crucial. The appropriate tools not only streamline the process but also enhance the quality of the work done. Understanding which implements are necessary can significantly reduce the time spent on troubleshooting and adjustments.

First and foremost, a quality screwdriver set is indispensable. Various sizes and types, such as flathead and Phillips, ensure that you can tackle a range of screws found in the device. Additionally, needle-nose pliers are perfect for reaching tight spaces, allowing for precise manipulation of small components.

Moreover, a reliable pair of scissors or thread snips can be handy for quick cuts, especially when dealing with fabric or thread. A good quality multimeter is also essential for diagnosing electrical issues, providing accurate readings of voltage and continuity.

Lastly, having a sturdy workbench with adequate lighting can greatly enhance your workspace, making it easier to focus on intricate details. With these fundamental tools in your arsenal, you’ll be well-equipped to handle various tasks with confidence and efficiency.

Step-by-Step Troubleshooting Guide

This guide is designed to assist users in identifying and resolving common issues that may arise during the operation of their sewing machine. By following systematic steps, you can effectively diagnose problems and restore functionality.

Common Issues

- Machine not powering on

- Thread bunching or tangling

- Needle breaking frequently

- Skipped stitches

- Uneven tension

Troubleshooting Steps

- Check Power Source:

- Ensure the machine is plugged in securely.

- Test the outlet with another device.

- Inspect Threading:

- Verify that the upper and lower threads are threaded correctly.

- Re-thread if necessary, following the threading diagram.

- Evaluate the Needle:

- Check for bends or damage on the needle.

- Replace the needle if it appears worn or broken.

- Adjust Tension:

- Test the upper and bobbin thread tension settings.

- Make minor adjustments and test on fabric.

- Clean the Machine:

- Remove lint and debris from the feed dogs and bobbin area.

- Use a small brush to reach tight spaces.

By following these steps, users can often resolve issues independently, ensuring smooth operation and enhancing the longevity of the sewing device.

Maintenance Tips for Longevity

To ensure your sewing machine remains in optimal condition for years to come, regular upkeep is essential. Proper care not only enhances performance but also extends the life of your device. By following a few simple practices, you can maintain functionality and avoid unnecessary repairs.

First, keep the machine clean by removing dust and lint after each use. Use a soft brush or a vacuum attachment designed for delicate areas. Regularly check and clean the feed dogs, as accumulated debris can hinder their movement.

Next, regularly oil the moving parts as recommended by the manufacturer. This lubrication reduces friction and prevents wear, contributing to smoother operation. Be sure to use the appropriate type of oil and avoid over-lubricating, as excess can attract dirt.

Additionally, ensure that the needle is changed frequently. A dull or bent needle can cause stitching issues and strain the machine’s motor. Choose the correct needle type for the fabric being used to prevent damage.

Store the machine in a dust-free environment and consider using a cover when it is not in use. Protecting your equipment from environmental factors like humidity and temperature fluctuations can significantly impact its longevity.

Lastly, refer to the user guide for specific maintenance recommendations and adhere to any service schedules. Professional servicing can help identify potential issues before they escalate, ensuring your sewing companion remains reliable for all your projects.

How to Replace the Needle

Changing the sewing needle is a crucial maintenance task that ensures your machine operates smoothly and produces high-quality stitches. A dull or damaged needle can lead to poor performance, fabric snags, and even damage to your projects. This guide will provide clear steps to successfully replace the needle, enhancing your sewing experience.

Tools You Will Need

Before starting, gather the following items:

| Item | Description |

|---|---|

| New Needle | Select the appropriate needle type for your fabric. |

| Screwdriver | A small screwdriver to loosen the needle clamp. |

| Pair of Tweezers | Useful for handling small parts and the needle. |

Step-by-Step Replacement Process

Follow these simple steps to replace the needle:

- Ensure the machine is turned off and unplugged for safety.

- Loosen the needle clamp screw using the screwdriver.

- Carefully remove the old needle by pulling it straight out.

- Take the new needle and insert it into the clamp, ensuring it is facing the correct direction.

- Tighten the clamp screw securely to hold the needle in place.

- Finally, check that the needle is properly aligned and re-plug the machine.

Regularly replacing the needle will improve your sewing quality and extend the life of your equipment.

Understanding the Stitch Selector

The stitch selector is a vital component that allows users to choose from a variety of sewing patterns, enabling creative expression and enhancing the functionality of the sewing machine. By providing a straightforward interface for selecting different stitches, it empowers sewists to tailor their projects to specific needs and preferences.

Each stitch represents a unique design or function, from basic straight stitches to intricate decorative patterns. The selector typically features a dial or a digital interface that displays the available options, making it easy to navigate through choices. Understanding how to effectively utilize this feature can significantly impact the quality and appearance of the finished product.

When using the stitch selector, it is essential to consider the type of fabric and the intended outcome of the sewing project. Certain stitches are better suited for specific materials, while others can enhance durability or aesthetic appeal. Familiarizing oneself with the characteristics of each stitch can lead to more successful and satisfying sewing experiences.

In addition to choosing stitches, the selector may also influence settings such as tension and stitch length, which can vary depending on the selected pattern. Proper adjustments ensure optimal performance, allowing for smooth operation and high-quality results. Mastering the use of the stitch selector is a key skill for any sewing enthusiast, paving the way for endless creative possibilities.

Fixing Tension Problems

Achieving the right level of tension in your stitching is essential for high-quality sewing results. Incorrect tension can lead to a variety of issues, including uneven stitches, thread breakage, and fabric puckering. This section provides insights into diagnosing and correcting these common tension-related challenges.

Common Symptoms of Tension Issues

| Symptom | Possible Cause | Solution |

|---|---|---|

| Uneven Stitches | Incorrect upper or lower tension | Adjust tension settings gradually and test on scrap fabric. |

| Thread Breakage | Too tight upper tension | Loosen upper tension slightly and re-test. |

| Fabric Puckering | Lower tension too loose | Tighten lower tension to smooth out the fabric. |

| Looping Threads | Upper tension too loose | Increase upper tension until loops are eliminated. |

Steps to Adjust Tension

To effectively manage tension, start by referencing the manufacturer’s guidelines for recommended settings. Adjust one tension dial at a time and always test on similar fabric before proceeding with your main project. Regular maintenance, such as cleaning and oiling the machine, can also help prevent tension problems.

Cleaning the Bobbin Area

Maintaining the cleanliness of the bobbin compartment is crucial for the optimal performance of your sewing machine. This area, often overlooked, can accumulate dust, lint, and thread remnants, which can lead to stitching issues and machine malfunctions. Regular cleaning not only enhances functionality but also extends the lifespan of your equipment.

Steps for Effective Cleaning

Begin by removing the needle plate and bobbin case. Use a small brush or a soft cloth to gently remove any debris. Pay special attention to the corners and crevices, where particles tend to gather. Afterward, inspect the bobbin case for any wear or damage. Reassemble the parts carefully to ensure everything fits snugly without obstruction.

Preventive Measures

To minimize future buildup, consider using a lint brush regularly after each sewing session. Additionally, keeping your sewing area tidy and using quality threads can significantly reduce lint production. Implementing these habits will help maintain the bobbin area in excellent condition, ensuring smooth sewing experiences.

Updating Firmware for Performance

Keeping your device’s software up to date is crucial for optimal functionality and improved user experience. Updating the internal programming can enhance features, fix bugs, and provide better overall performance. This process ensures that your machine operates smoothly and efficiently, allowing for more enjoyable usage.

Benefits of Firmware Updates

Regular updates offer numerous advantages, including enhanced stability, new functionalities, and increased security. By incorporating the latest improvements, users can take full advantage of the machine’s capabilities.

Steps to Update Firmware

Follow these straightforward steps to ensure your device is running the latest software:

| Step | Action |

|---|---|

| 1 | Check the current firmware version. |

| 2 | Visit the manufacturer’s website for updates. |

| 3 | Download the latest firmware file. |

| 4 | Connect your device to the computer. |

| 5 | Transfer the firmware file to your device. |

| 6 | Follow the on-screen instructions to complete the update. |

By regularly updating the software, users can significantly enhance the performance and longevity of their equipment, making it a vital part of maintenance.

Resources for Spare Parts

Finding the right components for your sewing machine can significantly enhance its performance and longevity. Whether you need a new needle, bobbin case, or any other essential element, a variety of resources are available to ensure you get high-quality parts. This section will guide you through various options for sourcing these items effectively.

Online Retailers

Numerous online platforms specialize in selling machine parts. Websites dedicated to sewing supplies often have extensive inventories, making it easy to find the specific items you require. Be sure to check customer reviews and ratings to ensure the reliability of the retailer.

Local Sewing Shops

Visiting nearby sewing or craft stores can provide the opportunity to obtain parts directly. Local shops often offer knowledgeable staff who can assist in identifying the correct components for your model. Additionally, they may provide insights on maintenance and troubleshooting, adding value to your visit.

When to Seek Professional Help

Understanding when to consult an expert can save time and prevent further complications. While many issues can be tackled with basic troubleshooting, certain situations require specialized knowledge to ensure effective resolution and maintain the longevity of the equipment.

Here are some indicators that it may be time to reach out to a professional:

| Indicator | Reason |

|---|---|

| Unusual Noises | Strange sounds can signify underlying mechanical issues that need attention. |

| Frequent Jamming | Repeated blockages suggest a deeper issue that may not be solvable with basic fixes. |

| Electrical Problems | Any electrical malfunction can pose safety risks and should be handled by a qualified technician. |

| Persistent Error Messages | Consistent notifications indicate a need for a more thorough diagnostic check. |

| Loss of Functionality | If essential features are not working, expert intervention may be required. |