Essential Guide to Repairing Your Singer Sewing Machine

Maintaining a complex device can sometimes feel overwhelming, especially when unexpected issues arise. Knowing how to address common problems not only enhances the longevity of the equipment but also ensures a smoother experience during use. This guide aims to equip users with essential knowledge to effectively manage and rectify minor malfunctions.

Every apparatus has its intricacies, and familiarizing oneself with these nuances is crucial. From thread jams to tension adjustments, each challenge presents an opportunity to learn more about the functionality and care of your equipment. By understanding the foundational elements, you can approach issues with confidence and skill.

Moreover, this resource emphasizes the importance of regular upkeep and informed troubleshooting. With a proactive approach, users can mitigate potential setbacks, enhancing both the efficiency and enjoyment of their creative endeavors. Embrace the journey of discovery and mastery in handling your machine, transforming challenges into valuable learning experiences.

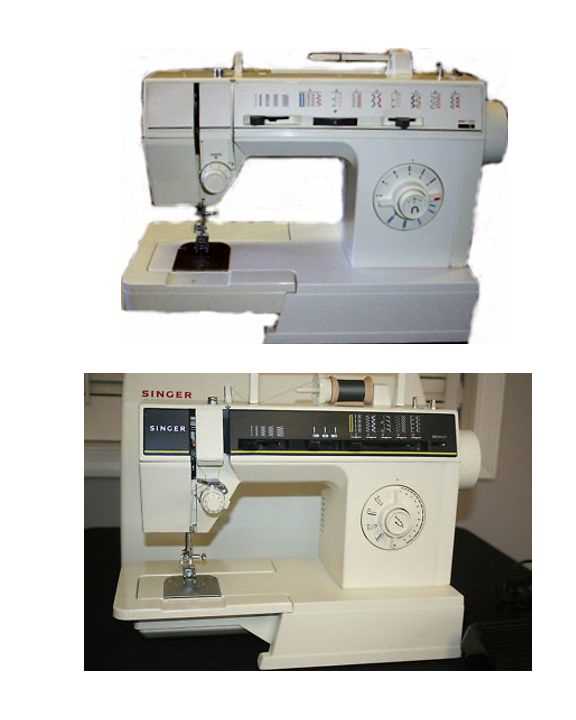

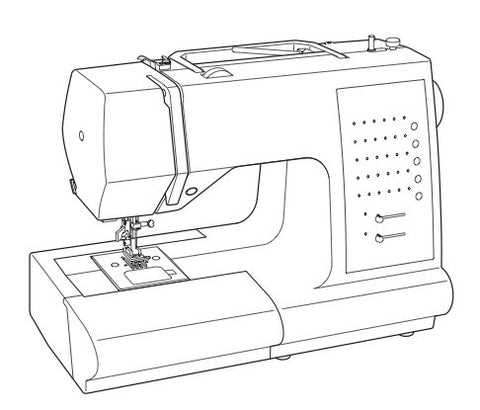

Singer Sewing Machine Overview

This section provides an insightful glimpse into the world of a renowned brand known for its exceptional craftsmanship in fabric manipulation devices. These innovative tools have been integral in both domestic and professional settings, enabling users to bring their creative visions to life.

Established in the 19th century, this esteemed name has consistently evolved, integrating technological advancements while retaining the essential features that enthusiasts and professionals adore. The machinery is celebrated for its reliability, precision, and user-friendly design.

Across various models, you will find a range of functionalities that cater to different skill levels and project types. From basic stitching to complex patterns, these machines are equipped to handle diverse materials, ensuring versatility in every task.

Moreover, the brand has cultivated a community of dedicated users who share tips, tricks, and techniques, fostering an environment of creativity and collaboration. Whether you are a beginner or a seasoned expert, there is a wealth of knowledge available to enhance your experience with these remarkable tools.

In summary, this iconic manufacturer has carved out a significant place in the fabric arts, blending tradition with modernity to meet the needs of a diverse audience.

Common Issues with Singer Models

When working with various stitching machines, users may encounter a range of challenges that can hinder performance. Recognizing these frequent problems can facilitate troubleshooting and enhance the overall experience. Below are some common concerns and their potential solutions.

Frequent Problems

- Thread Tension Issues: Inconsistent tension can lead to uneven stitches. Adjusting the tension dial may resolve this problem.

- Bobbin Problems: If the bobbin is not inserted correctly or is winding improperly, it can cause skipped stitches or thread jams.

- Needle Misalignment: A bent or dull needle can result in fabric damage. Regularly check and replace the needle as needed.

- Feed Issues: If the fabric isn’t moving smoothly, it may be due to dirty feed dogs or an incorrect presser foot pressure.

- Motor Malfunctions: Unusual noises or a lack of power may indicate motor issues. Regular maintenance can help prevent this.

Preventive Measures

- Keep the machine clean and free from lint buildup.

- Regularly check and replace the needle to ensure optimal performance.

- Adjust the tension settings based on the type of fabric being used.

- Consult the user guide for specific maintenance tips and techniques.

Essential Tools for Sewing Repair

When it comes to mending fabrics and ensuring longevity, having the right implements at your disposal is crucial. A well-equipped workspace can make all the difference in achieving a polished finish and tackling any challenge that arises during the process.

Scissors are a fundamental asset, essential for precise cutting of threads and materials. Investing in a quality pair will enhance efficiency and ensure clean edges. Additionally, a seam ripper is invaluable for removing unwanted stitches without damaging the surrounding fabric.

Needles come in various sizes and types, catering to different materials and tasks. Choosing the correct one can significantly impact the outcome of your work. Alongside needles, a selection of threads in multiple colors and weights is necessary to match and blend seamlessly with the fabric being used.

A measuring tape and ruler are indispensable for accuracy. They allow for precise measurements, ensuring that each piece fits perfectly together. Lastly, having a reliable iron is essential for smoothing out wrinkles and setting seams, giving your finished project a professional look.

Equipped with these fundamental tools, anyone can approach fabric-related tasks with confidence and creativity.

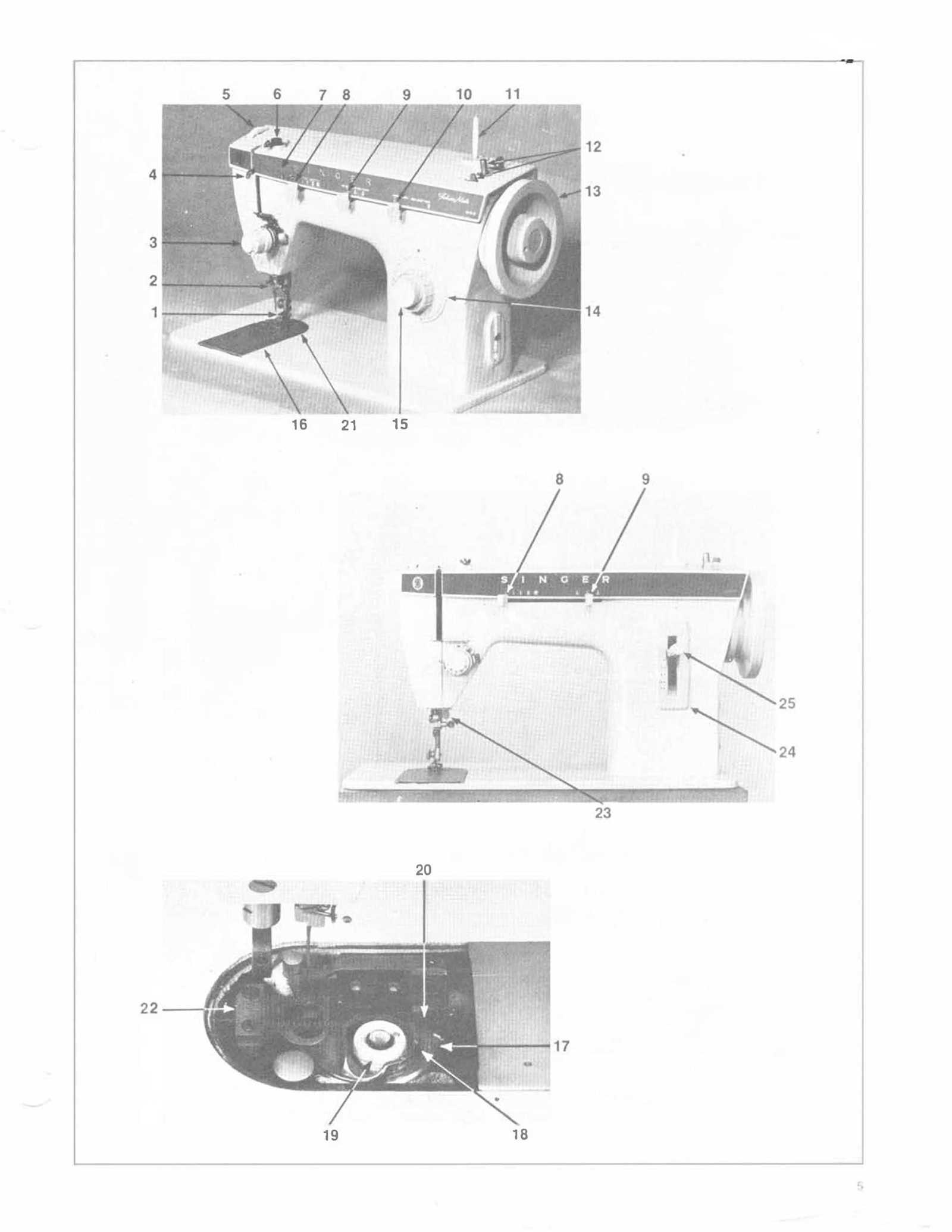

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues with your textile machine. By following these structured steps, you can efficiently diagnose problems and apply effective solutions, ensuring your device functions optimally.

- Identify the Problem:

Begin by observing the symptoms. Common issues may include:

- Unusual noises during operation

- Inconsistent stitching

- Frequent thread breakage

- Machine not powering on

- Gather Necessary Tools:

Before starting, collect the required tools such as:

- Screwdrivers (flathead and Phillips)

- Replacement parts (needles, belts, etc.)

- Cleaning supplies (brushes, oil)

- Power Off and Unplug:

Ensure your device is turned off and disconnected from the power source to guarantee safety while working on it.

- Inspect the Machine:

Carefully examine various components, looking for signs of wear or damage. Key areas to check include:

- Needle and presser foot

- Bobbin case

- Thread tension settings

- Perform Cleaning and Maintenance:

Regular maintenance is crucial. Clean lint and debris from:

- Feed dogs

- Underneath the needle plate

- Machine exterior

- Replace or Adjust Parts:

If you identify any defective parts, replace or adjust them as needed. Ensure all components are securely in place.

- Test Functionality:

After completing the above steps, reconnect the power and test your device. Observe its performance and make any necessary adjustments.

By adhering to this detailed guide, you can effectively address common issues and maintain your equipment in peak condition, prolonging its lifespan and enhancing your crafting experience.

Replacing the Sewing Machine Needle

Changing the needle in your fabric manipulation device is essential for maintaining optimal performance and ensuring high-quality results. A dull or damaged point can lead to uneven stitching and fabric snags, making this task an important part of routine upkeep.

Before you begin, ensure that the machine is turned off and unplugged for safety. Gather your new needle, appropriate for the fabric type you intend to work with. Typically, needles come in various sizes and types, so selecting the right one is crucial.

Step-by-step instructions:

- Locate the needle clamp, usually situated at the top of the device.

- Loosen the clamp by turning the screw counterclockwise with a screwdriver or your fingers.

- Gently pull the old needle downward and out of the clamp.

- Take the new needle and insert it into the clamp, ensuring that the flat side is facing the correct direction.

- Tighten the clamp securely by turning the screw clockwise.

Once the needle is replaced, re-thread the machine and test it on a scrap piece of fabric. This will help confirm that everything is functioning smoothly. Regularly replacing the needle will enhance your results and prolong the lifespan of your equipment.

Troubleshooting Tension Problems

Achieving the perfect balance in thread tension is crucial for producing high-quality stitches. When issues arise, it can lead to various complications in the final outcome. This section provides insights into identifying and resolving common tension-related challenges, ensuring a smooth and effective experience.

Common Symptoms of Tension Issues

Recognizing the signs of incorrect tension is the first step towards troubleshooting. Here are some prevalent indicators:

| Symptom | Possible Cause |

|---|---|

| Loopy stitches on the underside | Upper thread tension is too loose |

| Tight or puckered fabric | Upper thread tension is too tight |

| Thread breaking frequently | Thread tension may be set improperly or the thread is unsuitable |

| Skipped stitches | Incorrect tension or needle issues |

Adjusting Thread Tension

To address tension problems, adjustments can be made based on the identified symptoms. Follow these steps:

1. Check the Upper Thread: Ensure that the thread is threaded correctly through the tension discs and that there are no obstructions.

2. Adjust Tension Settings: If the upper thread tension is too tight or loose, make small adjustments to the tension dial, testing the results after each change.

3. Inspect the Bobbin Area: A misaligned bobbin or improper threading can also affect tension. Ensure the bobbin is correctly inserted and the thread is fed properly.

By systematically addressing these issues, achieving the ideal thread tension becomes manageable, leading to better stitching results.

Cleaning and Oiling Your Machine

Maintaining the functionality of your equipment is essential for achieving optimal performance and longevity. Regular upkeep, including cleaning and lubrication, ensures that all moving parts operate smoothly and prevents potential issues that could hinder your work.

Begin by gathering the necessary supplies: a soft cloth, a small brush, and quality oil suitable for your machine. Make sure to unplug the device before starting any maintenance tasks to ensure safety.

Follow these steps for an effective cleaning and oiling process:

| Step | Action |

|---|---|

| 1 | Remove any attachments and dust covers to access the internal components. |

| 2 | Use a soft cloth to wipe down the exterior surfaces, removing any dust and debris. |

| 3 | Utilize a small brush to clean out lint and particles from hard-to-reach areas. |

| 4 | Apply a few drops of oil to the designated points as indicated in the device’s instructions. |

| 5 | Reassemble any components and plug the unit back in, ready for use. |

By incorporating this routine into your maintenance schedule, you will enhance the efficiency and lifespan of your equipment, allowing you to focus on your creative endeavors without interruption.

Adjusting Stitch Length and Width

Modifying the length and width of stitches is essential for achieving desired results in various fabric projects. This adjustment allows for greater versatility in creating different patterns and finishes, catering to diverse material types and design requirements. Understanding how to manipulate these settings can enhance both functionality and aesthetics in your work.

Importance of Stitch Adjustments

Altering stitch dimensions affects not only the appearance but also the strength and flexibility of seams. Shorter stitches typically provide stronger seams, while longer ones can create a more decorative effect. Similarly, the width can determine the look of the stitch, influencing whether it appears subtle or bold in the final piece.

How to Adjust Settings

Most machines feature dials or digital displays to facilitate easy modifications. Here’s a simple guide to making adjustments:

| Adjustment Type | Recommended Use |

|---|---|

| Stitch Length | For standard seams, set between 2.5mm to 3mm. For basting, increase to 4mm or more. |

| Stitch Width | For straight stitches, keep at 0mm. For zigzag, adjust between 2mm to 5mm based on desired effect. |

By mastering these adjustments, you can significantly elevate the quality of your fabric creations and adapt your work to meet specific needs efficiently.

Fixing Motor and Electrical Issues

When it comes to troubleshooting mechanical devices, understanding the intricacies of motor and electrical components is essential. This section aims to provide insights into common problems and solutions that can restore functionality to your equipment. By identifying symptoms and applying systematic approaches, you can effectively address these challenges.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Motor Not Starting | No response when activated | Check power supply, replace fuse, or inspect wiring connections |

| Intermittent Operation | Stops and starts unexpectedly | Examine control switch, clean contacts, or check for loose connections |

| Overheating | Device feels hot to the touch | Ensure proper ventilation, lubricate moving parts, or reduce load |

| Unusual Noises | Grinding or buzzing sounds | Inspect for debris, check bearings, or replace worn components |

By methodically diagnosing these common electrical and motor issues, you can enhance the longevity and performance of your machinery. Regular maintenance and prompt attention to symptoms are key to preventing further complications.

Updating and Upgrading Parts

Maintaining optimal performance in your crafting machine often involves enhancing its components. By focusing on modernizing and replacing specific parts, you can significantly improve efficiency and prolong the lifespan of your device. This process not only revitalizes functionality but also ensures that your equipment remains compatible with current standards.

Identifying Parts for Replacement

Start by evaluating the functionality of various components. Look for signs of wear or decreased performance, such as unusual noises or inconsistent results. Key areas to consider include the motor, needles, and belts. Prioritizing these elements will allow you to make informed decisions about which parts to upgrade.

Selecting High-Quality Alternatives

When it comes to replacements, choose high-quality alternatives that promise durability and reliability. Research options from reputable manufacturers to ensure compatibility with your equipment. Upgrading to advanced materials can yield better performance, helping your machine reach its ultimate potential.

Finding Replacement Accessories

Locating suitable components for your machine can greatly enhance its performance and longevity. Whether you need to replace worn-out parts or upgrade your tools, understanding where to find quality accessories is essential.

Here are some reliable sources for obtaining the necessary items:

- Manufacturer’s Website: Always check the official site for original components. They often provide detailed information about compatible items.

- Local Retail Stores: Visit craft shops or specialized stores in your area. Staff members can offer guidance on the best choices for your equipment.

- Online Marketplaces: Websites like eBay or Amazon frequently have a vast selection of parts, both new and used. Be sure to read reviews before purchasing.

- Third-Party Suppliers: Many companies specialize in aftermarket components. Research their reputation to ensure quality.

- Community Forums: Engage with fellow enthusiasts online. They can provide recommendations on where to find specific parts or share their own experiences.

When searching for accessories, keep in mind the following tips:

- Compatibility: Always confirm that the part matches your machine’s specifications.

- Quality: Opt for well-reviewed items to avoid issues with performance.

- Pricing: Compare prices across different platforms to ensure you get the best deal.

- Return Policies: Check the return options in case the part does not fit or meet your expectations.

With these strategies in mind, you’ll be well-equipped to find the components you need to keep your machine operating smoothly.

Resources for Singer Support

When seeking assistance with your stitching equipment, numerous valuable resources are available to enhance your experience. Whether you need troubleshooting advice or parts replacement, tapping into the right channels can make a significant difference in your crafting journey.

Online Forums and Communities

Engaging with fellow enthusiasts through dedicated online platforms can provide quick answers and shared experiences. These communities often feature discussions, tips, and even videos that delve into various topics, offering the ultimate support for users at all skill levels.

Official Customer Service

For specific inquiries, reaching out to the official customer support team can yield reliable information. They are equipped to assist with technical issues, parts availability, and warranty matters, ensuring you receive the guidance you need.