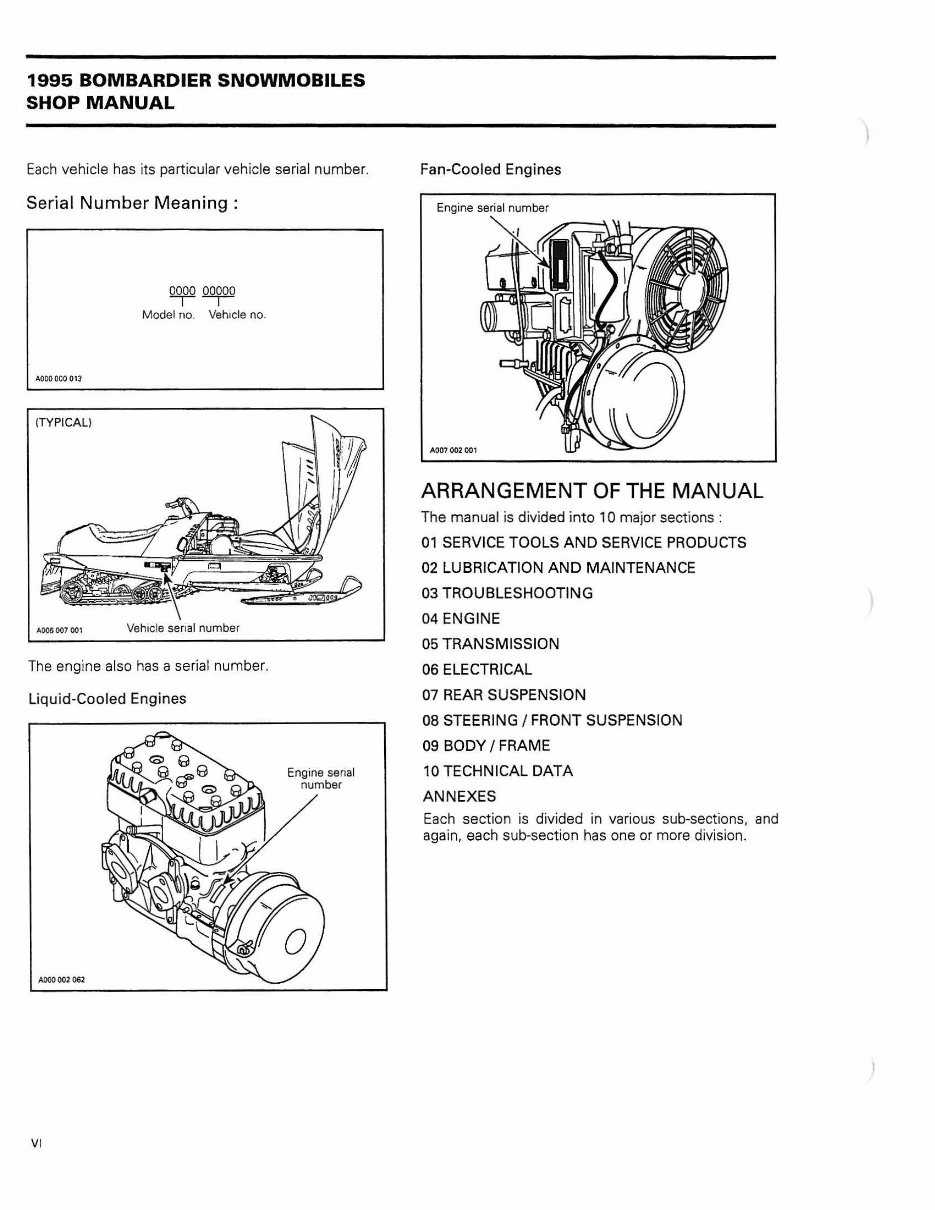

Comprehensive Guide to Ski-Doo Repair

Proper upkeep of your winter vehicle is essential for optimal performance and longevity. Understanding the various components and their functions allows you to ensure everything operates smoothly. Whether you’re a novice or an experienced enthusiast, having access to detailed instructions can enhance your knowledge and skills.

In this section, you will discover comprehensive information designed to assist you in maintaining your snow machine effectively. From troubleshooting common issues to performing routine tasks, this guide provides step-by-step directions that empower you to handle repairs with confidence. Investing time in learning about your vehicle will not only improve its efficiency but also contribute to your overall enjoyment on the trails.

Stay informed about the latest techniques and practices to keep your sled in peak condition. Regular maintenance can prevent unexpected breakdowns and ensure a safe and exhilarating ride every time you venture out into the snow. Embrace the journey of becoming familiar with your machine, and elevate your winter experiences.

In various models of snowmobiles, users often encounter similar challenges that can impact performance and safety. Understanding these frequent problems can help owners address them effectively and maintain optimal functionality.

| Issue | Description | Possible Solutions |

|---|---|---|

| Starting Problems | Difficulty in ignition due to battery issues or fuel delivery problems. | Check battery voltage and connections; inspect fuel lines for blockages. |

| Overheating | Engine temperature rising excessively, which may lead to severe damage. | Ensure coolant levels are adequate and inspect the cooling system for leaks. |

| Vibration | Excessive shaking while in motion, which can be unsettling and indicate mechanical issues. | Examine track alignment and suspension components for wear and tear. |

| Handling Difficulties | Poor maneuverability can result from worn skis or improper adjustment. | Inspect ski condition and adjust alignment as necessary for better control. |

Tools Needed for Effective Repairs

Having the right equipment is essential for conducting successful maintenance tasks. Whether addressing minor adjustments or extensive overhauls, specific instruments can significantly streamline the process, ensuring that each job is completed efficiently and accurately.

Essential Instruments

- Wrenches: A variety of sizes, including adjustable and socket types, are crucial for loosening and tightening bolts.

- Screwdrivers: A set that includes both flathead and Phillips head options will help tackle different types of screws.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Pliers: Needle-nose and slip-joint pliers can be invaluable for gripping and manipulating components.

- Jack Stands: Providing stability while working underneath, these are vital for safety during any undercarriage work.

Additional Helpful Tools

- Multimeter: Essential for diagnosing electrical issues, this tool can help measure voltage, current, and resistance.

- Inspection Camera: A useful gadget for visualizing hard-to-reach areas, aiding in troubleshooting.

- Cleaning Supplies: Brushes, rags, and solvents are necessary for maintaining cleanliness and ensuring parts are free from debris.

- Work Gloves: Protecting your hands while providing a better grip on tools and components enhances overall safety.

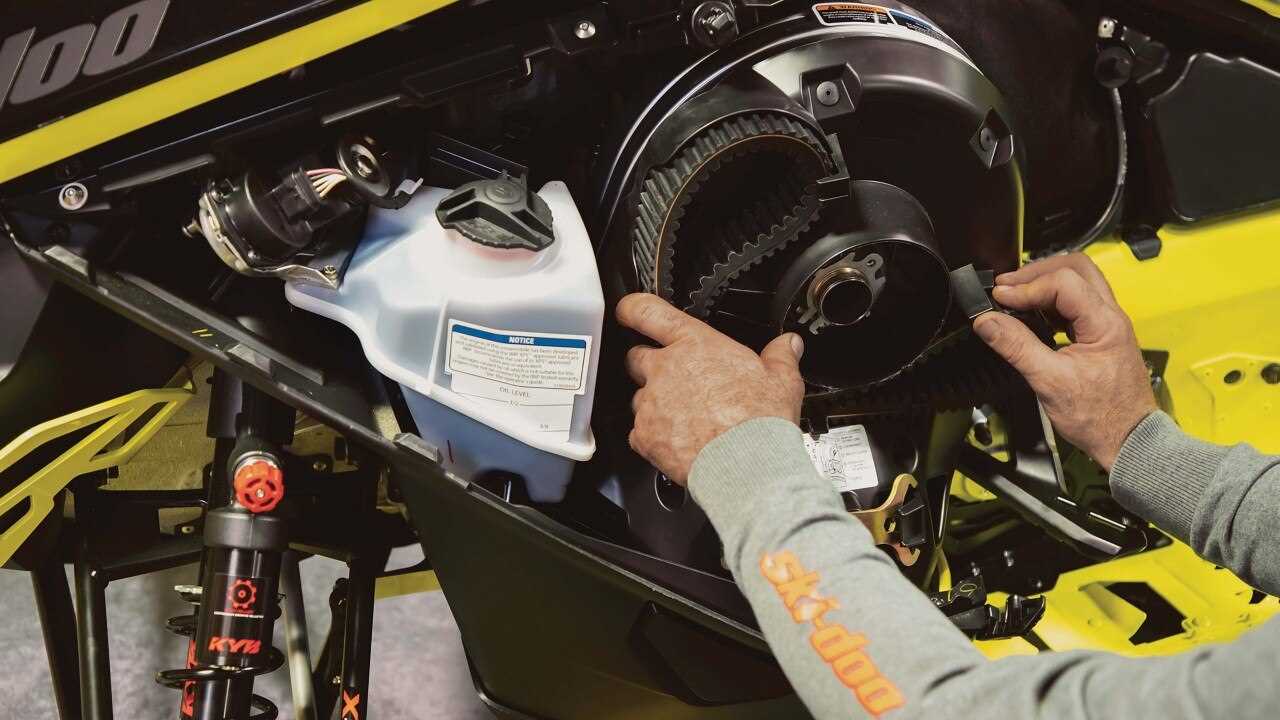

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your snow vehicle. By following a structured routine, you can identify potential issues early and keep your machine running smoothly throughout the season.

1. Regular Inspections: Begin by conducting visual checks of all key components. Look for any signs of wear, loose parts, or leaks that could affect performance. Pay close attention to the track, skis, and engine area.

2. Fluid Levels: Check and maintain appropriate levels of essential fluids such as oil, coolant, and fuel. Keeping these fluids at their recommended levels is crucial for efficient operation and to prevent overheating.

3. Filter Cleaning: Ensure that the air and fuel filters are clean and free from debris. Clogged filters can restrict airflow and fuel supply, leading to reduced efficiency. Replace them if necessary.

4. Battery Maintenance: Inspect the battery terminals for corrosion and ensure a secure connection. Regularly check the charge level and consider using a trickle charger during off-season storage.

5. Seasonal Preparation: Before the first outing of the season, run a thorough check on all systems. This includes testing brakes, steering, and lights to ensure everything is functioning correctly. Proper preparation enhances safety and enjoyment.

6. Storage Practices: When the season ends, clean your machine thoroughly and store it in a dry place. Use protective covers and consider adding fuel stabilizers to prevent degradation during storage.

By adhering to this maintenance routine, you will enhance the performance and reliability of your vehicle, ensuring many enjoyable rides ahead.

Engine Troubleshooting Techniques

Diagnosing issues in an engine requires a systematic approach to identify and resolve problems effectively. This section outlines essential methods to analyze engine performance, ensuring that potential faults are addressed promptly.

Common Symptoms and Their Implications

Recognizing typical signs of engine malfunction is crucial. Unusual noises may indicate mechanical wear, while decreased power output often suggests fuel or ignition system problems. Keeping a close watch on these symptoms can help pinpoint the underlying cause.

Diagnostic Tools and Methods

Utilizing the right diagnostic tools enhances the troubleshooting process. OBD-II scanners can reveal error codes related to engine management, guiding repairs. Additionally, performing a compression test assesses the health of the engine’s internal components, providing valuable insight into its condition.

Electrical System Diagnosis Tips

Understanding the functionality and intricacies of electrical systems is essential for effective troubleshooting. Whether facing intermittent failures or complete outages, a systematic approach can help identify underlying issues and restore functionality.

Common Issues to Look For

Begin by examining the battery connections, ensuring they are clean and tight. Corrosion can lead to poor conductivity, resulting in power loss. Additionally, inspect wiring harnesses for signs of wear or damage, as frayed wires can disrupt the flow of electricity.

Utilizing Diagnostic Tools

Employing appropriate diagnostic tools is crucial in pinpointing problems. A multimeter can measure voltage, current, and resistance, allowing for a thorough assessment of components. Additionally, using a wiring diagram can help trace circuits and identify potential faults.

Handling Fuel System Problems

Issues related to the fuel mechanism can lead to various performance challenges in your vehicle. Recognizing and addressing these problems promptly is essential for ensuring optimal operation. Understanding common symptoms and solutions will help you maintain efficiency and reliability.

Common Symptoms

- Difficulty starting the engine

- Unusual engine noises

- Stalling or sputtering during operation

- Decreased fuel efficiency

- Fuel leaks or strong fuel odors

Troubleshooting Steps

- Check fuel levels and ensure the tank is adequately filled.

- Inspect the fuel lines for any signs of wear, damage, or leaks.

- Examine the fuel filter for blockages and replace it if necessary.

- Test the fuel pump to confirm it is functioning correctly.

- Evaluate the fuel injectors for clogs or malfunction.

By systematically following these steps, you can effectively identify and resolve issues within the fuel system, enhancing your vehicle’s performance and longevity.

Track and Suspension Adjustments

Proper alignment and configuration of the undercarriage are essential for optimal performance and handling. Adjustments to the track and suspension systems can significantly enhance stability and ride quality. Understanding how to fine-tune these components allows for a smoother experience on various terrains.

Importance of Alignment

Maintaining correct alignment is crucial for effective power transfer and minimizing wear on components. Misalignment can lead to uneven track wear and reduced handling capabilities. Regular inspections and adjustments can help ensure that all elements are functioning harmoniously.

Adjustment Procedures

Follow these guidelines to make necessary adjustments:

| Step | Description |

|---|---|

| 1 | Inspect the track tension and adjust as needed to ensure optimal contact with the drive system. |

| 2 | Check suspension settings and modify preload to achieve desired ride height and comfort. |

| 3 | Evaluate alignment of the track and suspension components; adjust as necessary to ensure proper tracking. |

| 4 | Test ride to assess performance and make additional adjustments if required. |

Body and Chassis Repair Methods

This section outlines various techniques for addressing issues related to the framework and outer structure of the vehicle. Proper maintenance and handling of these components are crucial for ensuring optimal performance and safety.

Common Techniques

- Visual Inspection: Regularly check for signs of damage, corrosion, or wear.

- Welding: Utilize appropriate welding methods for joining or repairing metal parts.

- Painting: Apply protective coatings to prevent rust and enhance appearance.

Safety Considerations

- Always wear appropriate safety gear during maintenance tasks.

- Ensure a well-ventilated workspace when using chemicals or paints.

- Follow manufacturer guidelines for specific procedures and materials.

Winter Preparation and Safety Tips

As the colder months approach, ensuring readiness for outdoor activities becomes crucial. Proper preparation not only enhances enjoyment but also prioritizes safety in potentially challenging conditions.

Here are some essential tips to consider:

- Gear Inspection: Regularly check all equipment for functionality, ensuring that everything is in optimal condition.

- Clothing Layering: Dress in layers to regulate body temperature effectively. Choose moisture-wicking materials as a base layer.

- Stay Hydrated: Even in cold weather, hydration is vital. Keep water accessible to maintain energy levels.

Prior to heading out, familiarize yourself with the terrain and weather forecasts. Awareness of conditions can significantly impact safety.

Remember to keep a few emergency items on hand:

- First-aid kit

- Flashlight with extra batteries

- Emergency food supplies

- Map and compass

By following these guidelines, participants can enjoy their time outdoors while minimizing risks associated with winter activities.

Upgrades and Performance Enhancements

Enhancing the capabilities of your snow vehicle can significantly elevate your riding experience. By implementing various modifications, you can achieve improved speed, handling, and overall efficiency. This section explores several popular upgrades that enthusiasts consider to maximize performance.

Engine Modifications

One of the most impactful areas for enhancement is the engine. Upgrading components such as the exhaust system can lead to better airflow, resulting in increased horsepower. Additionally, tuning the engine’s mapping ensures optimal fuel efficiency while boosting power output. Aftermarket parts often provide superior performance compared to stock options, making them a wise investment for serious riders.

Suspension Improvements

Another vital aspect is the suspension system. Upgrading shocks and springs can dramatically improve handling and comfort on challenging terrains. A well-tuned suspension allows for better stability, making it easier to navigate through various snow conditions. Quality suspension components can transform the ride, providing a smoother and more controlled experience.

Where to Find Replacement Parts

Locating suitable components for your vehicle is essential for maintaining its performance and longevity. Whether you need a specific item or looking to stock up on essentials, there are several reliable sources available.

Here are some options to consider when searching for quality parts:

| Source | Description |

|---|---|

| Authorized Dealers | These establishments offer original components, ensuring compatibility and quality for your model. |

| Online Retailers | Websites provide a wide range of parts at competitive prices, often with user reviews to help with your choices. |

| Local Shops | Local businesses may carry a selection of parts and can often order specific items for you. |

| Salvage Yards | Used parts can be found at lower prices, but make sure to check the condition and compatibility. |

| Manufacturer’s Website | The official site may have a dedicated section for parts and accessories, along with detailed information. |

Frequently Asked Repair Questions

This section addresses common inquiries related to the maintenance and troubleshooting of snowmobiles. Understanding the typical concerns can help enthusiasts effectively manage their machines and enhance their performance.

Common Issues and Solutions

Many users experience challenges such as starting difficulties or engine stalling. These problems often stem from issues like fuel supply or electrical components. Regular checks of the fuel lines and battery connections can help prevent such occurrences. If the vehicle fails to start, inspecting the ignition system may also yield solutions.

Maintenance Tips

Routine upkeep is crucial for optimal functioning. Recommended practices include changing the oil, checking the spark plugs, and ensuring that the track tension is appropriate. Adhering to these guidelines not only prolongs the life of the machine but also improves overall performance during use.