Slot Machine Repair Guide for Beginners

Exploring the world of vintage gaming technology reveals a fascinating blend of mechanics and electronics. Restoring these classic devices can be an engaging process, bringing old memories back to life and ensuring that these timeless forms of entertainment remain functional. This section delves into the essential steps for reviving and maintaining these nostalgic units, focusing on reliable methods for a smooth restoration process.

Understanding the Basics of Restoration is crucial for anyone looking to breathe new life into these well-loved machines. From identifying typical issues to finding the right tools and techniques, this guide offers practical advice on keeping these devices operational. Each component, from electrical connections to mechanical parts, plays a vital role in the seamless function of these entertainment pieces.

Whether you are a novice or have previous experience with electronics, knowledge of repair techniques will enhance your ability to maintain and troubleshoot. Step-by-step instructions simplify the intricate process, making it accessible for enthusiasts of all skill levels. Dive into the specifics of rejuvenating these unique gaming devices, ensuring they continue to offer enjoyment for years to come.

Slot Machine Repair Manuals

Understanding the inner workings and common challenges of entertainment devices can empower users to address technical issues effectively. This section provides insights on maintenance and troubleshooting steps that ensure these devices function optimally over time, enhancing their durability and usability.

General Maintenance Tips

To keep these devices running smoothly, regular upkeep is essential. Preventative care can minimize the likelihood of issues, saving time and resources in the long term.

- Inspect the device periodically for any loose or worn-out parts.

- Ensure that the power sources and connections remain stable and secure.

- Clean internal components gently, removing dust and debris that may interfere with performance.

Troubleshooting Common Issues

When facing operational challenges, a few targeted steps can often restore proper functionality. This list addresses some frequent problems and simple ways to resolve them.

- Check for minor connection disruptions, as these can often cause malfunction.

- Reset the device to its initial settings, which can sometimes clear temporary errors.

- Replace outdated parts with compatible alternatives to ensure consistent operation.

These strategies offer practical ways to handle technical difficulties without needing professional assistance, helping enthusiasts maintain their devices effectively.

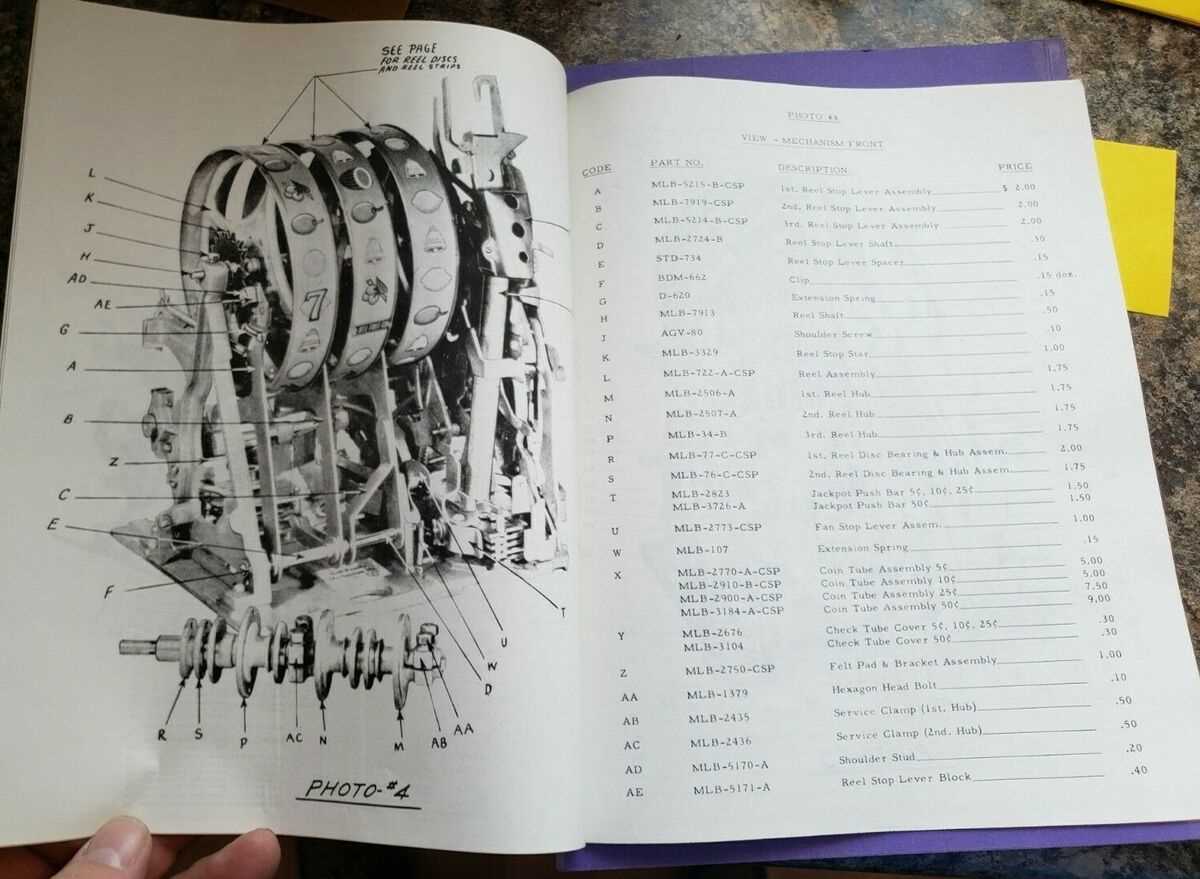

Understanding Slot Machine Mechanics

Understanding how these devices operate is essential for anyone looking to enhance their technical knowledge. The inner workings rely on a series of components and systems working in harmony to provide a seamless experience for the user. Each mechanism has a specific role, from energy supply to result generation, requiring a fundamental grasp of electronic and mechanical parts.

- Power Supply: The backbone of any device, providing the necessary energy for all internal systems to function efficiently.

- Reel Mechanism: A complex setup that includes motorized elements or virtual models, depending on the device’s design, influencing the rotation and stopping of the symbols.

- Randomization System: Often managed by a computerized algorithm, this ensures fair and unpredictable results for each play, adding to the device’s integrity.

- Control Board: The primary control center, directing each function from button responses to display information, crucial for operational stability.

- User Interface: Comprising buttons, screens, and lighting, this segment enhances player engagement while ensuring smooth interaction.

Grasping these essential systems provides a strong foundation in comprehending the core mechanics behind these entertainment devices, preparing one to approach technical complexities with confidence.

Common Issues in Slot Machines

Various mechanical and electronic devices used in entertainment can encounter challenges over time, impacting their functionality and performance. Understanding the frequent difficulties that arise in these systems can aid in maintaining smooth operation and prolonging their service life.

Jammed Components: One common issue involves the jamming of internal mechanisms. This can occur due to worn parts or debris obstructing movements, which disrupts the standard operation flow and may require careful inspection to pinpoint the exact cause.

Display Malfunctions: Electronic displays and lights occasionally fail to function correctly. Flickering or entirely unresponsive screens often indicate issues with power supplies, wiring connections, or control boards, requiring diagnostic testing to resolve effectively.

Unresponsive Controls: Control buttons and levers can sometimes become unresponsive, either due to mechanical wear or connection problems. Ensuring regular upkeep and checking for any loose parts can prevent more severe interruptions in usability.

Power Supply Issues: Power inconsistencies or failures are also frequent in these machines. Power supply units, connectors, and circuit components should be checked periodically to ensure stable and consistent functionality.

Diagnosing Power Supply Problems

Understanding issues related to power delivery can be crucial for maintaining the functionality of many types of equipment. Proper diagnostics allow for pinpointing where electrical issues may lie, whether within the wiring, connectors, or power sources themselves.

Before delving into specific solutions, it’s essential to verify key power components for stability and consistency. Voltage readings, cable integrity, and connector status are important checks in ensuring reliable performance. This table outlines common symptoms and potential causes to guide initial assessments.

| Symptom | Possible Cause | Suggested Check |

|---|---|---|

| No Power Response | Disconnected power source or faulty switch | Ensure cables are secure and test switches for continuity |

| Frequent Power Cycling | Overloaded circuit or overheating issue | Monitor load levels and inspect cooling systems |

| Flickering Operation | Loose connectors or fluctuating voltage | Tighten connectors and check for voltage consistency |

| Low Power Output | Damaged transformer or aging power supply | Test voltage output and inspect transformer condition |

Following these initial checks, if issues persist, consider inspecting more complex elements such as internal regulators or filtering circuits. Understanding how these components interact can provide further insights into resolving power inconsistencies effectively.

Fixing Coin Mechanism Malfunctions

Understanding and addressing issues with the coin acceptance system is essential for keeping coin-operated equipment functioning smoothly. Coin mechanisms can sometimes fail to recognize, accept, or properly sort currency, leading to operational interruptions. Below, we’ll cover typical issues and their solutions to ensure reliability in the coin handling process.

- Cleaning the Mechanism: Dust and debris can interfere with the accurate detection of coins. Regularly clean all accessible parts using compressed air or a soft brush to remove buildup without damaging components.

- Checking for Jammed Coins: A coin stuck within the mechanism can prevent further acceptance. Inspect the coin pathway carefully, removing any obstructions or bent coins with a gentle tool.

- Aligning Sensors: Sensors that detect coin size and metal composition may shift over time, causing acceptance errors. Ensure all sensors are properly aligned and test them after adjustments.

- Inspecting Spring Tension: Springs that guide coins may lose tension or wear out, impacting coin movement. Replace worn springs or adjust tension to maintain smooth operation.

- Begin with a visual inspection of the coin path.

- Use appropriate cleaning tools for removing dirt and debris.

- Carefully realign any mispositioned sensors.

- Test with multiple coin types to ensure accurate sorting.

By following these steps, you can address common issues in the coin mechanism, enhancing reliability and reducing downtime. Regular maintenance will help ensure that the coin handling system remains in optimal working order.

Maintaining Slot Machine Displays

Ensuring the functionality and clarity of visual interfaces is crucial for optimal performance in gaming devices. Regular attention to these displays can significantly enhance user experience and prevent issues that may arise from neglect. This section outlines effective strategies for upkeep, emphasizing best practices for preserving display quality and longevity.

Regular Cleaning Techniques

Consistent maintenance is key to avoiding buildup that can obscure images. Use a soft, lint-free cloth to gently wipe the surface, avoiding harsh chemicals that could damage the screen. For more stubborn stains, a mild solution of water and isopropyl alcohol can be effective. Make sure to power off the unit before cleaning to prevent any accidental damage.

Monitoring for Issues

It’s essential to routinely check for signs of wear or malfunction, such as flickering or discoloration. Early detection of these problems can prevent more significant disruptions in functionality. If anomalies are noticed, consulting technical specifications or seeking professional assistance may be necessary to address the concerns effectively.

Repairing Slot Machine Sound Systems

Ensuring optimal audio performance in gaming devices is crucial for an engaging user experience. Sound systems in these entertainment units can sometimes face issues, leading to diminished audio quality or complete failure. This section outlines effective strategies for diagnosing and resolving common audio problems.

Key components to focus on include:

- Speakers: Inspect for damage or disconnections.

- Amplifiers: Check for proper functionality and power supply issues.

- Wiring: Look for frayed or broken connections that may affect sound output.

- Control Boards: Ensure that settings are correctly configured for optimal sound.

When troubleshooting, consider the following steps:

- Begin with a visual inspection of all components.

- Test each speaker individually to isolate faults.

- Use a multimeter to check for electrical continuity in wiring.

- Review the control settings to confirm they match the desired output levels.

Implementing these techniques will help restore the audio systems to their full potential, enhancing the overall experience for users.

Troubleshooting Electrical Connections

Understanding the intricacies of electrical linkages is vital for maintaining optimal functionality. This section delves into common issues encountered with electrical connections, offering practical guidance for effective diagnosis and resolution.

Identifying Common Issues

Electrical connectivity problems can manifest in various forms. Common signs include inconsistent performance, failure to power on, or unexpected shutdowns. Recognizing these symptoms is the first step toward a successful troubleshooting process.

Diagnostic Steps

To effectively troubleshoot, follow these steps:

| Step | Action | Notes |

|---|---|---|

| 1 | Inspect Connections | Check all wires and connectors for damage or looseness. |

| 2 | Test Voltage | Use a multimeter to ensure voltage is present at key junctions. |

| 3 | Examine Grounding | Ensure proper grounding to prevent short circuits. |

| 4 | Replace Faulty Components | Identify and replace any damaged or defective parts. |

Replacing Slot Machine Circuit Boards

Replacing electronic components is a crucial task to ensure optimal functionality and longevity. In this section, we will explore the essential steps and considerations involved in replacing the circuit boards within gaming devices. Proper handling and understanding of the components are key to successful replacements.

Tools and Materials Needed

- Screwdriver set

- Anti-static wrist strap

- Replacement circuit board

- Multimeter

- Cleaning solution

Steps for Replacement

- Ensure the device is powered off and unplugged.

- Wear an anti-static wrist strap to prevent static discharge.

- Remove the casing using the screwdriver.

- Identify the faulty circuit board that needs replacement.

- Carefully disconnect all connectors and cables from the board.

- Remove the faulty board and replace it with the new one.

- Reconnect all connectors and ensure a secure fit.

- Clean the area around the new board before reassembling the casing.

- Test the device to verify proper operation.

Essential Tools for Slot Repairs

When it comes to maintaining and fixing gaming devices, having the right equipment is crucial. A well-equipped toolkit not only facilitates efficient troubleshooting but also enhances the overall effectiveness of the servicing process. This section outlines the necessary implements that are fundamental for ensuring these devices operate smoothly and reliably.

Basic Hand Tools

Every technician should start with a set of basic hand tools. These include screwdrivers, wrenches, and pliers. These items are essential for opening cabinets, securing components, and making precise adjustments. The variety in sizes and types ensures that technicians can handle various tasks with ease.

Diagnostic Equipment

In addition to hand tools, diagnostic instruments play a vital role in the maintenance of these devices. Multimeters and oscilloscopes help in diagnosing electrical issues, while specialized software can analyze performance data. Having access to these tools allows for quick identification of problems, streamlining the repair process.

Safety Tips for Slot Technicians

Ensuring a secure work environment is crucial for professionals handling gaming devices. Adhering to safety guidelines not only protects individuals but also enhances the efficiency of their tasks. By prioritizing safety, technicians can prevent accidents and maintain a high standard of service.

1. Personal Protective Equipment (PPE): Always wear appropriate protective gear, including gloves and safety glasses, to minimize exposure to harmful components. This equipment is essential for shielding against potential hazards.

2. Electrical Safety: Before starting any work, ensure that the device is unplugged or properly disconnected from the power source. This precaution helps prevent electrical shocks and other related injuries.

3. Proper Handling Techniques: Utilize correct lifting and carrying techniques to avoid physical strain. This is especially important when moving heavy components or equipment.

4. Fire Safety: Be aware of fire hazards in the workspace. Keep flammable materials away from heat sources and ensure that fire extinguishers are easily accessible and in working order.

5. Hazardous Materials: Familiarize yourself with any hazardous substances present in the components you work with. Always follow the manufacturer’s guidelines for safe handling and disposal of these materials.

6. Workspace Organization: Maintain a clean and organized work area to reduce the risk of accidents. Clutter can lead to trips and falls, so keep tools and materials stored properly when not in use.

By implementing these safety practices, technicians can significantly reduce risks and create a safer working atmosphere, ultimately contributing to a more efficient operation.