Comprehensive Guide to Snapper Mower Repair

Effective upkeep of outdoor machinery is essential for optimal performance and longevity. This section offers insights into maintaining and addressing common issues that may arise with your equipment. Understanding the mechanisms involved can significantly enhance your user experience.

By delving into practical solutions and preventive measures, you can ensure that your device operates smoothly and efficiently. Equipped with the right knowledge, you can tackle challenges with confidence, leading to a more satisfying and productive experience.

Snapper Mower Repair Manual Outline

This section provides a comprehensive framework for understanding the guidelines and procedures related to maintaining and fixing a specific type of garden equipment. It aims to assist users in navigating the necessary steps to ensure optimal performance and longevity of the machinery.

1. Introduction

Overview of the equipment and its importance in gardening tasks.

2. Safety Precautions

Essential measures to ensure user safety while handling the equipment.

3. Tools Required

- List of necessary tools for various tasks.

4. Common Issues

- Identification of frequent problems and symptoms.

5. Maintenance Tips

Guidelines for regular upkeep to prevent malfunctions.

6. Troubleshooting

Steps to diagnose and resolve typical challenges encountered during use.

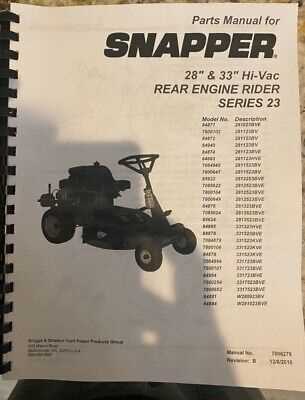

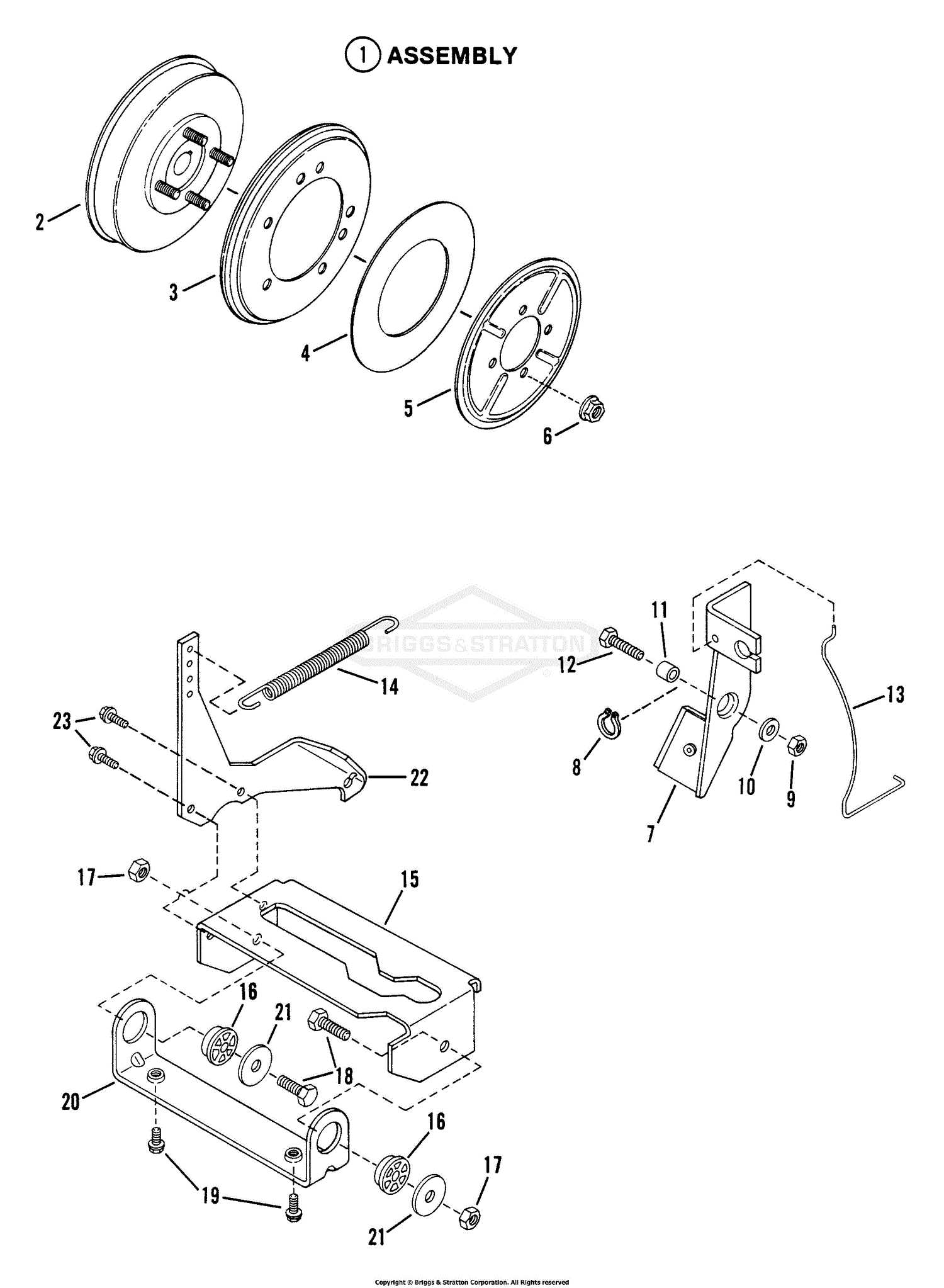

7. Parts Replacement

Information on how to effectively replace worn-out components.

8. Conclusion

Summary of best practices for care and maintenance of the equipment.

Essential Tools for Mower Maintenance

Maintaining outdoor equipment requires a set of fundamental instruments that ensure optimal performance and longevity. Proper tools help to simplify tasks and enhance efficiency, making the upkeep process more manageable. Here is a list of key instruments that every owner should consider for routine care and service.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | Essential for adjusting and securing various components. |

| Oil Can | To lubricate moving parts and ensure smooth operation. |

| Fuel Container | For safely storing and transferring fuel. |

| Cleaning Brush | To remove debris and grass clippings from critical areas. |

Understanding Common Mower Issues

Maintaining a lawn care device can present various challenges. Familiarizing yourself with typical complications can enhance your troubleshooting skills and ensure efficient operation. This section will explore prevalent concerns and their potential solutions.

Frequent Problems Encountered

- Starting Difficulties: Many users report issues when attempting to initiate the engine. This may stem from fuel quality, battery conditions, or electrical connections.

- Uneven Cutting: Inconsistent results can arise from dull blades or improper height settings. Regular checks can prevent these issues.

- Excessive Vibration: Unusual shaking may indicate loose components or imbalanced parts. Inspecting for wear and tear is essential.

Preventative Measures

- Regularly check and change the blades to maintain sharpness.

- Ensure that all parts are secured and properly aligned.

- Use high-quality fuel to minimize starting complications.

Being aware of these common issues and implementing preventative strategies can significantly enhance the longevity and performance of your equipment.

Step-by-Step Blade Replacement Guide

Replacing the cutting element is an essential task for maintaining optimal performance and achieving a neat finish in your outdoor work. This guide will walk you through the process to ensure safety and efficiency.

- Gather Required Tools:

- Wrench

- Protective gloves

- New cutting element

- Screwdriver

- Safety First:

Before starting, disconnect the power source to avoid any accidental activation.

- Access the Cutting Element:

Remove the protective cover to expose the cutting component. Refer to the specific design for instructions on how to do this.

- Remove the Old Cutting Element:

Using the wrench, unscrew the bolts that hold the cutting piece in place. Carefully detach it and set it aside.

- Install the New Cutting Element:

Position the new component correctly and secure it with the bolts. Ensure it is tightly fastened to avoid any issues during operation.

- Reattach the Protective Cover:

Once the new component is in place, reattach the protective cover, ensuring everything is secure.

- Reconnect Power:

Plug in the device or reconnect the power source to complete the process.

Regular maintenance and timely replacement of components will enhance the longevity and performance of your equipment.

Engine Troubleshooting Techniques

Understanding common issues with mechanical power sources is essential for optimal performance. By identifying symptoms early, one can enhance longevity and efficiency. This section explores effective methods for diagnosing and resolving typical problems encountered in these systems.

Identifying Symptoms

Start by observing unusual sounds or vibrations, which may indicate underlying issues. Pay attention to irregular starts or stalling, as these can signal fuel delivery problems or ignition failures. Noticing changes in performance can also guide you toward the root cause.

Diagnostic Steps

Begin troubleshooting by checking essential components such as the fuel system, air intake, and electrical connections. Ensure that the fuel is fresh and clean, as contaminants can lead to poor performance. Inspecting spark plugs and filters can also reveal potential faults that need addressing. Using a systematic approach will lead to the ultimate resolution of the problem.

Cleaning the Carburetor Effectively

Regular maintenance of the fuel delivery component is crucial for optimal performance. A clean mechanism ensures smooth operation and enhances longevity. This section outlines essential steps for thorough cleaning.

Follow these steps to achieve effective results:

- Gather Necessary Tools:

- Screwdriver set

- Cleaning brush

- Fuel solvent

- Safety gloves

- Disconnect Power Source:

Ensure the device is turned off and disconnected from any power supply to prevent accidents.

- Remove the Component:

Carefully detach the assembly from the unit, taking note of how it connects for easier reinstallation.

- Clean Thoroughly:

Utilize a suitable solvent and brush to remove any residue. Pay special attention to small passages and jets.

- Inspect for Damage:

Check for any wear or cracks. Replace any damaged parts as needed.

- Reassemble and Test:

Reattach the component securely and test the system to ensure proper functionality.

By following these steps, you can maintain efficiency and ensure reliable operation of the equipment.

Battery Care and Replacement Tips

Proper maintenance of power sources is essential for ensuring optimal performance and longevity. Following a few simple guidelines can help extend the life of these components and prevent unexpected issues.

Here are some important practices for maintaining and replacing your power sources:

- Regular Inspection: Check connections and terminals for signs of corrosion or damage.

- Cleanliness: Keep the area around the power source clean to avoid dirt accumulation.

- Proper Charging: Use the recommended charger and avoid overcharging to prevent overheating.

- Storage Conditions: Store in a cool, dry place to protect from extreme temperatures.

- Replacement Signs: Monitor performance; replace the unit if it no longer holds a charge effectively.

When it’s time for a replacement, consider the following:

- Choose a compatible model that meets your device’s specifications.

- Follow safety precautions during removal and installation.

- Dispose of the old unit responsibly, adhering to local regulations for hazardous materials.

By following these guidelines, you can ensure reliable operation and extend the lifespan of your power source.

Regular Oil Change Procedure

Maintaining optimal performance of your equipment requires periodic updates to the lubricant. This process ensures the longevity and efficiency of the machine, preventing potential issues that may arise from neglected maintenance.

Follow these essential steps for an effective oil change:

- Gather Necessary Tools:

- Oil container

- Wrench

- Funnel

- New lubricant

- Cleaning cloth

- Prepare the Equipment:

Ensure the unit is on a stable surface and turned off. Allow it to cool if it has been recently used.

- Drain the Old Lubricant:

Locate the drainage plug. Position your container beneath it and remove the plug carefully, allowing the old oil to flow out completely.

- Replace the Filter:

If applicable, remove the old filter and replace it with a new one, ensuring a secure fit.

- Add New Lubricant:

Using a funnel, pour the fresh oil into the designated opening until it reaches the recommended level.

- Check for Leaks:

After reassembling, run the equipment for a few minutes and inspect for any leaks around the drainage area.

- Dispose of Old Oil:

Dispose of the used lubricant responsibly by taking it to a recycling center or a designated collection point.

Regularly changing the lubricant is crucial for maintaining performance and reliability. Adhering to this procedure will help ensure your equipment operates smoothly and efficiently.

Adjusting Mower Height Settings

Modifying the cutting level of your lawn care equipment is essential for achieving the desired appearance of your lawn. Proper adjustments can enhance the overall health of your grass, ensuring it remains vibrant and well-kept. Understanding the mechanisms involved in changing these settings will help you maintain an optimal environment for growth.

To effectively alter the height of your equipment, follow these straightforward steps:

| Step | Action |

|---|---|

| 1 | Locate the height adjustment lever or mechanism on your device. |

| 2 | Determine your preferred grass height by referring to local guidelines or personal preference. |

| 3 | Adjust the lever to raise or lower the cutting component accordingly. |

| 4 | Secure all adjustments to prevent unintended changes during operation. |

| 5 | Test the new settings by making a few passes over the lawn to ensure satisfaction. |

Regularly checking and modifying these settings will contribute significantly to the aesthetic and health of your yard, creating a lush and inviting space.

Identifying Electrical Problems

Understanding electrical issues is essential for maintaining functionality in your equipment. Recognizing signs of malfunction can prevent further damage and enhance overall performance. Common symptoms include inconsistent operation, failure to start, and unexpected shutdowns.

Common Indicators

Pay attention to unusual sounds, such as clicking or buzzing, as they may signal underlying electrical faults. Additionally, check for visible damage to wires or connectors, which can lead to poor connectivity. If the equipment shows erratic behavior, it may indicate a need for thorough examination.

Troubleshooting Steps

Begin troubleshooting by ensuring the power source is reliable. Test connections for secure fittings, and inspect fuses or circuit breakers for any signs of issues. If problems persist, consider utilizing diagnostic tools to further analyze the electrical system.

How to Sharpen Mower Blades

Maintaining the cutting edges of your grass trimming equipment is essential for optimal performance. Properly honed blades ensure clean cuts, promoting healthier growth and a well-groomed appearance. This section will guide you through the steps necessary to achieve sharp edges effectively.

Gathering Necessary Tools

Before starting, collect the essential tools. You will need a wrench, a sharpening tool or file, and safety gloves. Ensuring you have the right equipment at hand will facilitate a smooth sharpening process.

Sharpening Process

Begin by disconnecting the power source for safety. Next, remove the blades carefully, taking note of their orientation. Using your sharpening tool, work along the edge at a consistent angle, making sure to maintain the original bevel. After achieving the desired sharpness, clean any debris before reattaching the blades. Always remember to check the tightness before powering the unit back on.

Proper Tire Maintenance and Care

Ensuring optimal performance of outdoor equipment involves regular attention to tire upkeep. Proper maintenance enhances efficiency and prolongs the lifespan of the equipment. This section highlights essential practices for keeping tires in excellent condition.

Regularly checking tire pressure is crucial. Underinflated or overinflated tires can lead to uneven wear and decreased traction. Use a reliable gauge to monitor pressure levels and adjust them as necessary. Consult the manufacturer’s guidelines for recommended pressure specifications.

| Maintenance Task | Frequency |

|---|---|

| Check tire pressure | Every month |

| Inspect for damage | Before each use |

| Clean tires | As needed |

| Rotate tires | Every season |

Additionally, visual inspections should be part of regular care. Look for signs of wear, cracks, or punctures. Addressing issues promptly can prevent further damage and ensure safe operation.

Finally, cleaning tires helps maintain grip and prevent buildup of debris. Use mild soap and water for routine cleaning, and avoid harsh chemicals that can damage the rubber. By following these maintenance tips, the longevity and performance of outdoor equipment can be significantly improved.

Winterizing Your Mower for Storage

Preparing your cutting equipment for the colder months is essential to ensure optimal performance when the season changes. Proper care and maintenance during this period can help extend the lifespan of your machine and reduce the risk of future issues.

Follow these steps to effectively prepare your equipment for storage:

| Task | Description | Frequency |

|---|---|---|

| Clean the Exterior | Remove any grass, dirt, or debris from the surface. | Before storage |

| Drain Fuel | Empty the fuel tank to prevent degradation and gum formation. | Before storage |

| Change Oil | Replace old oil with fresh oil to ensure engine health. | End of season |

| Check Blades | Inspect and sharpen blades for efficient cutting next season. | Before storage |

| Store Properly | Keep in a dry, sheltered location to avoid weather damage. | During winter |

By following these guidelines, you can ensure that your cutting equipment is well-prepared to face the off-season, allowing for a smooth transition when it’s time to use it again.