Comprehensive Guide to Stihl 028 AV Repair

Effective maintenance is essential for the longevity and optimal performance of any outdoor power tool. This section provides crucial insights into the upkeep and troubleshooting techniques necessary for ensuring that your equipment operates smoothly and efficiently.

Understanding the components and functionality of your device allows for more effective problem-solving when issues arise. By following the outlined procedures and guidelines, users can enhance the reliability of their machinery and minimize downtime caused by malfunctions.

Whether you are a seasoned operator or a newcomer to outdoor tools, this guide will equip you with the knowledge needed to tackle common challenges and perform necessary adjustments, ensuring that your equipment remains in peak condition.

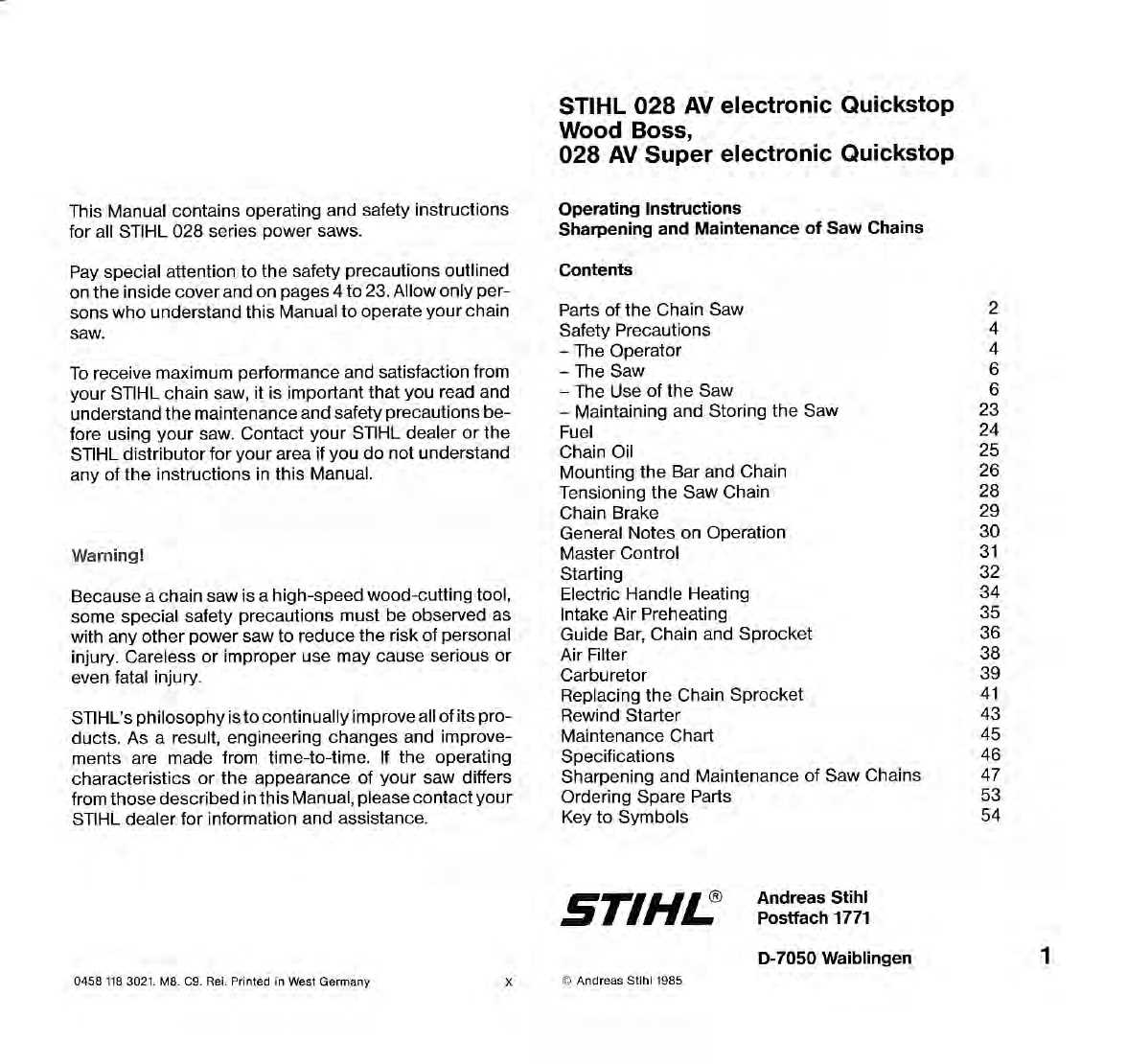

Overview of Stihl 028 AV

This section provides a comprehensive insight into a specific model of power equipment known for its reliability and efficiency. Designed for various outdoor tasks, this machine is favored by both professionals and enthusiasts. Its robust construction and user-friendly features make it an ideal choice for handling challenging projects.

The equipment is engineered with innovative technology, ensuring optimal performance and ease of use. Its lightweight design enhances maneuverability, while the powerful engine allows for effective operation across different applications. Additionally, maintenance and care are simplified, making it accessible for users with varying levels of experience.

In summary, this model stands out in the market due to its combination of performance, durability, and user-centric design, catering to the needs of users who seek dependable machinery for their outdoor endeavors.

Key Features of the Chainsaw

This section highlights the essential characteristics of a popular cutting tool designed for efficient operation in various woodwork tasks. Understanding these features can greatly enhance the user experience and ensure optimal performance.

Power and Efficiency

The tool is equipped with a robust engine that delivers significant power output, making it capable of tackling demanding jobs with ease. Its design allows for efficient fuel consumption, ensuring that users can operate for extended periods without frequent refueling.

Safety Mechanisms

Safety is paramount when handling cutting equipment. This tool incorporates several advanced safety features, including a chain brake that quickly stops the chain in case of kickback and a throttle lock that prevents accidental activation. These mechanisms provide users with peace of mind during operation.

| Feature | Description |

|---|---|

| Engine Power | High output for demanding tasks |

| Fuel Efficiency | Extended operational time between refuels |

| Chain Brake | Immediate stop in kickback situations |

| Throttle Lock | Prevents unintentional activation |

Common Issues and Solutions

This section addresses frequently encountered problems with the equipment and offers practical solutions to enhance its performance and longevity.

Frequent Problems

- Difficulty starting the device.

- Inconsistent power output during operation.

- Excessive vibration while in use.

- Fuel leakage from the tank.

- Chain not moving smoothly.

Solutions

-

Difficulty starting the device:

Ensure the spark plug is clean and properly connected. Check the fuel mixture for the correct ratio and replace if necessary.

-

Inconsistent power output:

Inspect the air filter for dirt buildup and clean or replace it as needed. Verify that the fuel line is free from obstructions.

-

Excessive vibration:

Examine the chain tension and adjust it to the manufacturer’s specifications. Ensure that the guide bar is not worn or damaged.

-

Fuel leakage:

Inspect the fuel lines and tank for cracks or damage. Replace any faulty components to prevent leaks.

-

Chain movement issues:

Check the chain for wear and proper lubrication. Adjust tension as needed to ensure smooth operation.

Essential Tools for Repair

When it comes to maintaining and fixing outdoor power equipment, having the right instruments at your disposal is crucial. These tools not only facilitate the process but also ensure that tasks are completed efficiently and safely. A well-equipped toolkit can make a significant difference in the overall performance and longevity of your equipment.

Some fundamental items include a reliable wrench set, which allows for easy adjustment of various components. Additionally, screwdrivers with different heads are essential for accessing tight spaces and securing parts properly. A quality saw file can help sharpen blades effectively, while a sturdy workbench provides a stable surface for conducting repairs.

Moreover, safety gear, such as gloves and eye protection, should never be overlooked. These items help safeguard the user against potential hazards during maintenance tasks. By assembling a comprehensive collection of essential tools, you can enhance your ability to care for your machinery and extend its operational life.

Step-by-Step Maintenance Guide

Proper upkeep of your outdoor power equipment is essential for optimal performance and longevity. This section provides a systematic approach to ensure your device remains in top condition, helping you avoid common issues and enhance efficiency.

Essential Tools and Supplies

Before beginning the maintenance process, gather the necessary tools and supplies:

- Wrench set

- Screwdrivers (flat and Phillips)

- Cleaning cloths

- Chain oil

- Fuel mixture

- Protective gloves

Maintenance Steps

- Clean the Air Filter: Remove the air filter cover and take out the filter. Clean it with compressed air or replace it if necessary.

- Inspect the Spark Plug: Disconnect the spark plug wire and remove the plug. Check for wear and replace it if it appears damaged.

- Sharpen the Cutting Blade: Using a suitable sharpening tool, carefully sharpen the cutting edge to maintain efficiency.

- Check Fuel Lines: Inspect the fuel lines for cracks or leaks. Replace any damaged sections.

- Lubricate Moving Parts: Apply appropriate lubricant to all moving components to ensure smooth operation.

- Test Functionality: After completing the maintenance tasks, reassemble any removed parts and test the equipment to ensure it operates correctly.

Following these maintenance steps regularly will help prolong the life of your device and ensure it operates at its best.

Engine Troubleshooting Techniques

Effective diagnostics are crucial for maintaining optimal performance of any machinery. Understanding common issues and their resolutions can significantly enhance the longevity and efficiency of the engine. This section outlines various techniques to identify and address typical engine-related problems.

- Check for Fuel Quality: Ensure that the fuel used is fresh and free from impurities. Old or contaminated fuel can lead to poor engine performance.

- Inspect Air Filters: Clogged or dirty air filters restrict airflow, affecting combustion efficiency. Regular cleaning or replacement is recommended.

- Examine Spark Plug Condition: Worn or fouled spark plugs can cause ignition problems. Inspect for signs of wear and replace as necessary.

- Monitor Engine Temperature: Overheating can indicate various issues, such as low coolant levels or malfunctioning thermostats. Keeping an eye on temperature readings is essential.

- Check Exhaust Emissions: Unusual emissions can signal incomplete combustion or other underlying problems. Identifying these early can prevent further damage.

By employing these techniques, operators can diagnose issues more effectively, ensuring that the machinery runs smoothly and efficiently. Regular maintenance and attention to detail are key in preventing minor issues from escalating into significant problems.

Understanding the Fuel System

The fuel system plays a crucial role in the overall performance and efficiency of outdoor power equipment. It is responsible for delivering the right mixture of fuel and air to the engine, ensuring optimal combustion and power output. A well-functioning fuel system is essential for reliable operation and longevity of the machine.

Components of the Fuel System

The primary components of the fuel system include the fuel tank, fuel lines, filter, and carburetor. Each part has a specific function that contributes to the effective delivery of fuel to the engine.

| Component | Function |

|---|---|

| Fuel Tank | Holds the fuel required for operation. |

| Fuel Lines | Transport fuel from the tank to the engine. |

| Filter | Cleans the fuel before it enters the engine. |

| Carburetor | Mixes fuel with air for combustion. |

Troubleshooting Common Issues

Understanding potential issues within the fuel system can help in maintaining the equipment’s performance. Common problems include fuel leaks, clogs in the filter, and issues with the carburetor adjustment. Regular checks and maintenance can prevent these issues from affecting functionality.

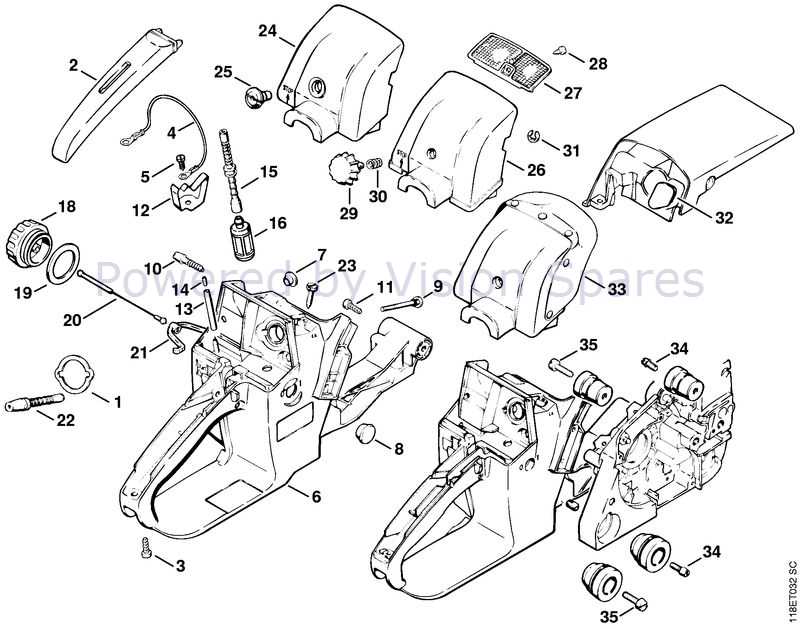

Chain and Bar Adjustments

Proper alignment and tensioning of the cutting mechanism are essential for optimal performance and safety. Adjustments to the chain and guide bar can significantly enhance the efficiency of your tool, ensuring smooth operation and preventing unnecessary wear.

Chain Tensioning

To maintain effective cutting, it is crucial to regularly check and adjust the tension of the chain. A correctly tensioned chain should allow for slight movement when pulled, but should not sag excessively. Over-tightening can lead to damage, while a loose chain may disengage during use.

Guide Bar Alignment

Ensuring the guide bar is correctly aligned is vital for proper chain movement. Misalignment can cause uneven wear on both the chain and bar, leading to premature failure. Regular inspections and adjustments help maintain alignment, contributing to the longevity of your equipment.

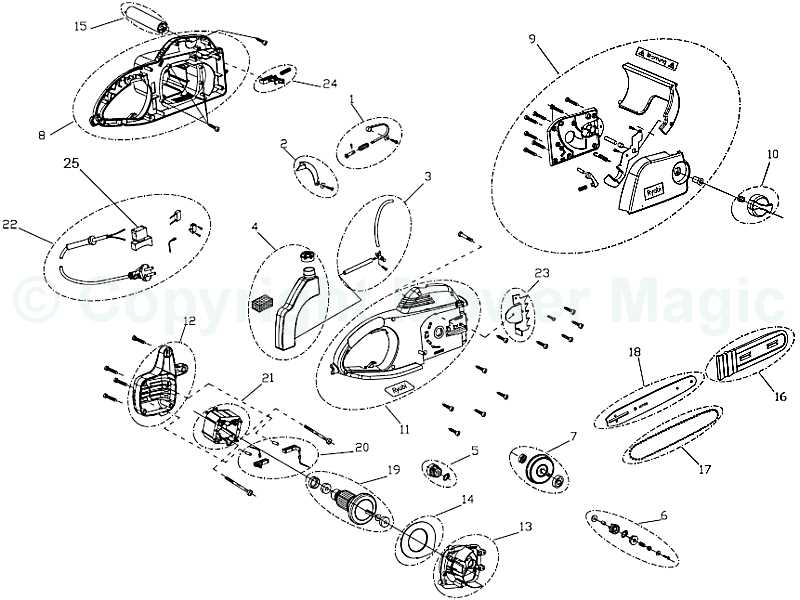

Electrical Components and Repair

This section focuses on the essential electrical parts that contribute to the overall functionality of the equipment. Understanding these components is crucial for effective maintenance and troubleshooting, ensuring the device operates efficiently and reliably.

Key Electrical Elements

The primary electrical elements include the ignition system, wiring harness, and various sensors. Each component plays a significant role in initiating the power cycle and regulating the machine’s performance. Proper inspection and timely replacement of faulty parts can prevent operational failures.

Troubleshooting Techniques

Identifying issues within the electrical system often involves systematic testing of each component. Begin by checking connections for signs of wear or damage. Utilize a multimeter to measure voltage levels and verify continuity. This methodical approach will aid in pinpointing the source of any malfunction.

Cleaning and Storage Tips

Maintaining your equipment in optimal condition is essential for its longevity and performance. Regular cleaning and proper storage practices can prevent damage and ensure that your tool remains reliable for years to come.

Cleaning Procedures

- After each use, remove any debris or dirt that may have accumulated on the exterior.

- Use a soft brush to clean the air filter and ensure proper airflow.

- Inspect and clean the cutting components carefully to avoid wear and tear.

- Wipe down any metal surfaces with a cloth to remove moisture and prevent rust.

Storage Recommendations

- Store the tool in a dry, cool place to prevent humidity-related damage.

- Keep it out of direct sunlight to avoid degradation of materials.

- Use a protective cover to shield it from dust and contaminants.

- Ensure that any fuel is drained before long-term storage to prevent residue buildup.

Safety Precautions for Users

Ensuring safety during operation is crucial for all users of outdoor power equipment. Adhering to specific guidelines not only protects the operator but also enhances overall performance and longevity of the equipment.

- Always wear appropriate personal protective gear, including safety glasses, gloves, and sturdy footwear.

- Before starting, inspect the equipment for any damages or wear. Address any issues immediately.

- Keep the work area clear of obstacles and bystanders to prevent accidents.

- Be aware of your surroundings, including overhead hazards and nearby individuals or pets.

- Maintain a firm grip on the equipment at all times and use both hands when operating.

Following these precautions will help create a safer working environment and reduce the risk of injuries.