Comprehensive Guide to Repairing Stihl MS 310 Chainsaw

For enthusiasts and professionals alike, the proper upkeep of cutting equipment is crucial to ensuring optimal performance and longevity. This section delves into essential techniques and insights to assist users in maintaining their machinery effectively. With the right approach, you can extend the life of your tools and enhance their efficiency.

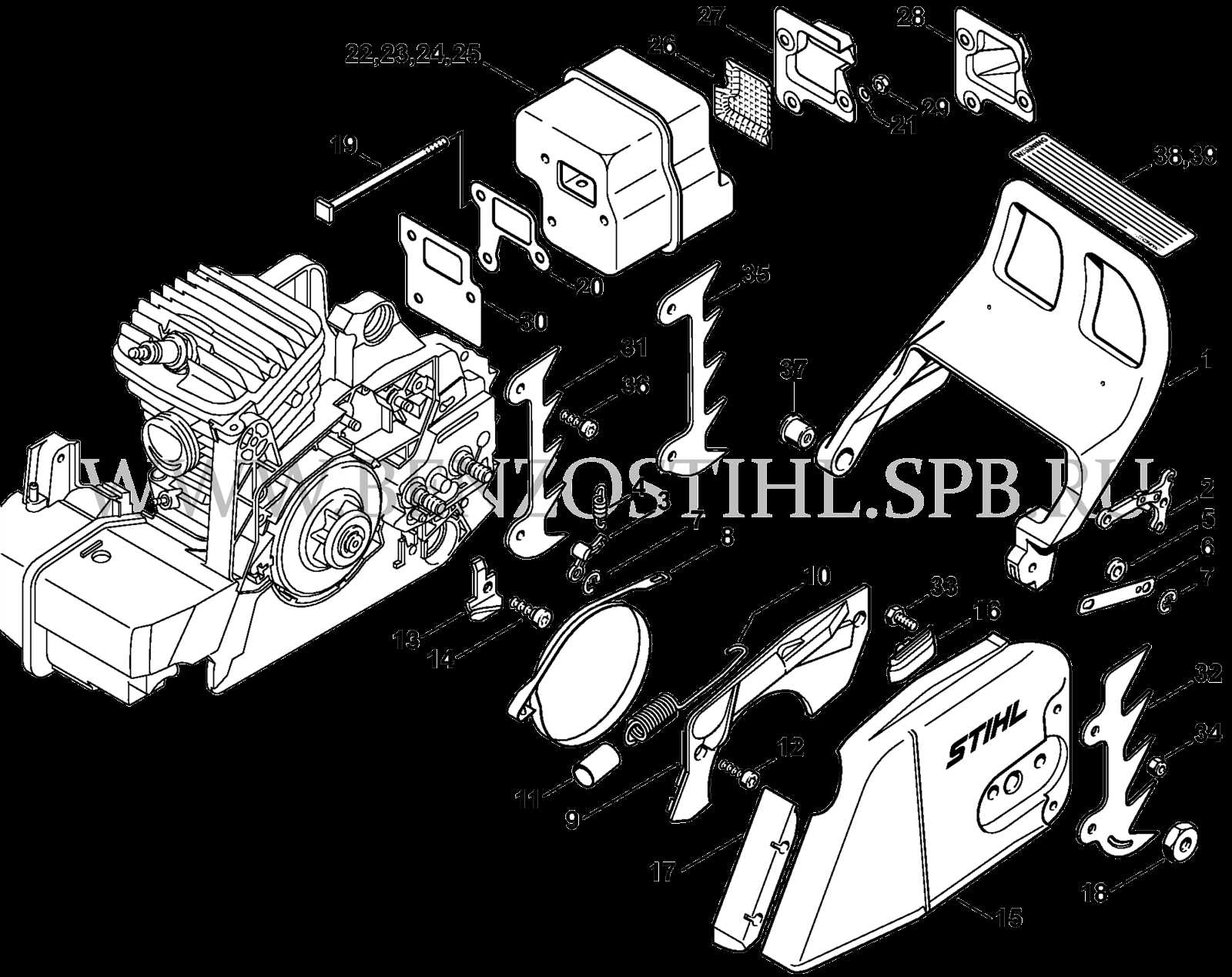

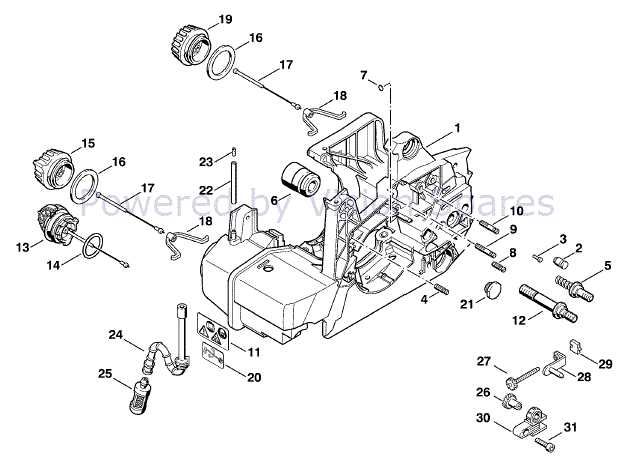

Understanding the intricacies of your chainsaw is key to troubleshooting common issues that may arise during operation. By familiarizing yourself with the components and mechanisms involved, you can swiftly identify potential problems and take corrective measures. This guide aims to empower users with the knowledge needed to tackle various challenges and keep their equipment in peak condition.

In addition to basic maintenance tips, this resource highlights specific strategies for addressing frequent malfunctions. Whether it’s addressing fuel system concerns, chain tension adjustments, or ignition issues, having a comprehensive understanding of these areas can save both time and money. By following the outlined procedures, users will find themselves equipped to handle most situations confidently.

Understanding Stihl MS 310 Features

The model in question is designed for a range of tasks, combining power and efficiency to meet the needs of both professionals and hobbyists. Its innovative features contribute to enhanced performance, making it a reliable choice for various cutting and trimming applications.

Powerful Engine: At the heart of this tool lies a robust engine that provides ample power for demanding jobs. This capability ensures quick and effective cutting, allowing users to complete tasks with minimal effort.

Lightweight Design: The design prioritizes ease of use, with a lightweight structure that minimizes fatigue during extended operation. This ergonomic feature is essential for users who require prolonged handling without compromising comfort.

Advanced Safety Mechanisms: Equipped with several safety features, the equipment promotes secure usage. These mechanisms are crucial for preventing accidents, offering peace of mind to users as they operate the device.

Easy Maintenance: The straightforward maintenance process is a key advantage, allowing users to perform routine checks and repairs with ease. This aspect not only extends the lifespan of the tool but also enhances overall performance.

Versatile Applications: This machine excels in various applications, from cutting firewood to handling larger landscaping tasks. Its adaptability makes it a valuable addition to any toolkit, accommodating different user needs effectively.

Common Issues with Stihl MS 310

When it comes to outdoor power tools, users often encounter a range of challenges that can affect performance and efficiency. Understanding these common problems is essential for ensuring smooth operation and longevity of the equipment. This section highlights frequent issues that may arise, along with suggestions for troubleshooting and maintenance.

Engine Performance Problems

One of the most prevalent issues faced by users is engine performance. Symptoms such as stalling, rough idling, or difficulty starting may indicate various underlying causes. Fuel quality plays a crucial role; using stale or incorrect fuel can lead to significant issues. Additionally, clogged air filters and spark plug malfunctions can severely impact engine function, requiring regular checks and replacements to maintain optimal performance.

Chain and Bar Issues

Another common concern involves the cutting mechanism. Problems such as uneven cutting or the chain frequently coming off can frustrate users. These issues are often linked to improper tension settings or worn sprockets. Regular inspection and adjustment of the chain tension, along with keeping the bar lubricated, are critical for ensuring effective operation. Addressing these factors can significantly improve the efficiency and safety of the equipment.

Essential Tools for Repairing Chainsaws

Maintaining and fixing cutting equipment requires specific implements to ensure efficient and safe operation. Having the right tools not only simplifies the process but also enhances the longevity of the device. This section highlights the fundamental instruments that every user should possess for effective upkeep.

Wrenches are crucial for loosening and tightening various components. A good set ensures that you can handle different sizes and types of fasteners with ease.

Screwdrivers, both flat and Phillips, are necessary for accessing internal parts. Selecting quality options helps prevent stripping screws and damaging the casing.

Chain tools are indispensable for adjusting or replacing the cutting chain. These specialized devices make it easy to maintain proper tension and alignment.

File sets are essential for sharpening the chain. Keeping the cutting edges sharp improves performance and reduces wear.

Protective gear, including gloves and goggles, ensures safety while working. Always prioritize personal safety to prevent accidents during maintenance tasks.

Equipping yourself with these vital tools will greatly enhance your ability to perform tasks effectively and maintain your equipment in top condition.

Step-by-Step Maintenance Guide

Regular upkeep of your outdoor power equipment is essential for optimal performance and longevity. This guide outlines the necessary steps to ensure your machine remains in top condition, minimizing the risk of malfunctions and enhancing its efficiency.

Essential Tasks

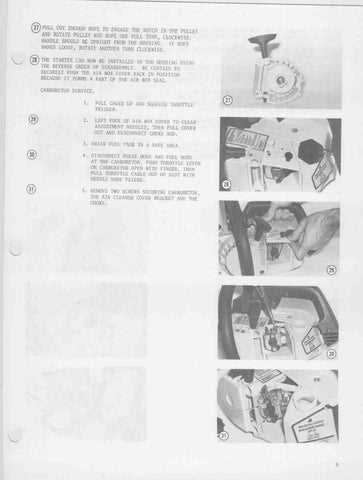

Start with the basics: clean the air filter regularly to prevent debris buildup, which can hinder airflow and performance. Check and replace the spark plug as needed, as a faulty plug can lead to starting issues and reduced power. Additionally, inspect the fuel system for leaks and ensure that you are using the correct fuel mixture to maintain engine health.

Advanced Care Techniques

For those comfortable with more intricate procedures, consider examining the ignition system and ignition coil for wear. Replacing worn components can significantly improve starting reliability. Don’t forget to sharpen the cutting blade periodically; a sharp blade enhances cutting efficiency and reduces strain on the engine. Always refer to specific guidelines for your equipment model to ensure proper technique.

In conclusion, following these maintenance steps will help prolong the life of your equipment and enhance its performance. Regular attention to detail can prevent minor issues from escalating into costly repairs.

How to Troubleshoot Engine Problems

When facing issues with a small engine, it’s crucial to identify the underlying causes effectively. Systematic troubleshooting can help in pinpointing the malfunction and restoring optimal performance. Understanding common symptoms and their potential sources is the first step towards resolution.

Here are some common symptoms along with possible causes and solutions:

| Symptom | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Insufficient fuel | Check fuel level and fill tank if necessary. |

| Engine runs rough | Clogged air filter | Clean or replace the air filter. |

| Overheating | Blocked cooling fins | Remove debris from cooling fins and ensure proper airflow. |

| Loss of power | Worn spark plug | Inspect and replace the spark plug if needed. |

| Excessive smoke | Oil in fuel mix | Adjust fuel mixture to proper ratio. |

By carefully examining these aspects, you can effectively troubleshoot engine issues and maintain the equipment in good working condition.

Replacing the Chain and Bar

Maintaining the cutting equipment is essential for optimal performance and safety. One crucial aspect of this maintenance involves the timely replacement of the chain and bar. Regularly inspecting these components can prevent damage and enhance the efficiency of your tool, ensuring it operates smoothly during use.

Before starting the replacement process, it is important to gather the necessary tools and materials. This preparation will facilitate a seamless operation, allowing you to complete the task efficiently and correctly.

| Tools Needed | Description |

|---|---|

| Wrench | For loosening and tightening nuts on the bar. |

| Screwdriver | To assist in removing any screws that may hold the bar in place. |

| Replacement Chain | A new chain that fits the specifications of your device. |

| Replacement Bar | A new bar that matches the requirements of your cutting equipment. |

Once you have gathered all the necessary tools, follow the steps below to successfully replace the chain and bar:

- Ensure the device is turned off and disconnected from any power source.

- Loosen the nuts that secure the bar using the wrench.

- Remove the old chain by sliding it off the bar.

- Take off the old bar from its position.

- Place the new bar in the same position as the old one.

- Fit the new chain onto the bar, ensuring it is properly aligned.

- Tighten the nuts to secure the bar and chain in place.

After completing these steps, double-check that everything is securely fastened before operating your tool again. Regular maintenance will prolong the life of your equipment and enhance your cutting experience.

Safety Precautions During Repairs

When undertaking maintenance tasks on power equipment, ensuring personal safety and the integrity of the machine is paramount. Adhering to specific safety measures not only protects the individual performing the work but also enhances the overall efficiency and longevity of the equipment.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and ear protection.

- Ensure the work area is clean and free from any obstacles that could cause tripping or falling.

- Disconnect the spark plug or power source before beginning any disassembly.

- Use the correct tools for each task to avoid injury or damage to the equipment.

- Keep a first aid kit nearby in case of emergencies.

Handling Hazardous Materials

- Read and understand all safety data sheets (SDS) for any lubricants, fuels, or chemicals used.

- Store hazardous substances in labeled containers away from direct sunlight and heat sources.

- Dispose of any waste materials in accordance with local regulations to prevent environmental harm.

Where to Find Replacement Parts

Finding quality components for your equipment is essential to ensure its longevity and optimal performance. Whether you’re looking for specific items or general accessories, there are several reliable sources where you can procure the necessary parts to keep your machinery running smoothly.

Authorized Dealers

One of the best places to start your search is through authorized dealers. These establishments provide genuine components that meet the manufacturer’s standards. Benefits include:

- Expert assistance from knowledgeable staff

- Access to the latest products and innovations

- Warranty coverage on purchased items

Online Retailers

The internet offers a wide range of online retailers specializing in parts for various types of equipment. Here are some tips for shopping online:

- Look for well-reviewed websites with a robust selection of parts.

- Check for customer feedback to gauge product quality.

- Verify the return policy before making a purchase.

By utilizing these resources, you can ensure that you find the appropriate components to maintain your machinery effectively.

Tips for Long-Term Chainsaw Care

Proper maintenance is essential for ensuring the longevity and efficiency of your cutting tool. By following a few key practices, you can keep your equipment in top shape and ready for any task. This section outlines effective strategies for ongoing care that can help extend the lifespan of your saw.

1. Regular Cleaning: After each use, take the time to clean your device thoroughly. Remove any debris, sawdust, or resin buildup from the bar, chain, and air filter. A clean machine operates more efficiently and reduces the risk of damage.

2. Chain Tension Adjustment: Maintaining the correct tension on the cutting chain is vital. A loose chain can derail, while one that is too tight can cause excessive wear on the bar and motor. Check and adjust the tension regularly to ensure optimal performance.

3. Lubrication: Regularly check and refill the oil reservoir for the chain and bar. Proper lubrication minimizes friction and heat, preventing premature wear. Always use the recommended type of oil for best results.

4. Sharpening the Chain: A sharp chain is crucial for efficient cutting. Regularly inspect the chain for dullness and sharpen it as needed. This not only improves cutting performance but also reduces strain on the engine.

5. Storage Practices: When storing your device, keep it in a dry, cool place. Avoid leaving it exposed to harsh weather conditions. Consider using a protective cover to shield it from dust and debris.

6. Periodic Inspections: Conduct regular inspections of your equipment for any signs of wear or damage. Check the fuel lines, spark plug, and other components to ensure everything is functioning properly. Early detection of issues can prevent costly repairs.

By incorporating these maintenance tips into your routine, you can enhance the performance and durability of your cutting tool, ensuring it remains a reliable companion for years to come.

Seeking Professional Repair Services

When faced with issues related to your outdoor equipment, seeking the expertise of a qualified technician can be a wise decision. Professional services not only ensure that your machinery is handled with care, but they also provide peace of mind that comes from knowing your tools are in capable hands.

Why Choose a Specialist?

Opting for a trained specialist brings numerous advantages. Their extensive knowledge and experience enable them to quickly diagnose problems and implement effective solutions. Additionally, they often have access to genuine parts, which enhances the longevity and performance of your equipment.

Identifying Reliable Services

It is essential to choose a reputable service provider. Look for customer reviews, recommendations from friends, and certifications that demonstrate their proficiency. A trustworthy technician will be transparent about their process and pricing, ensuring you feel confident in their work.