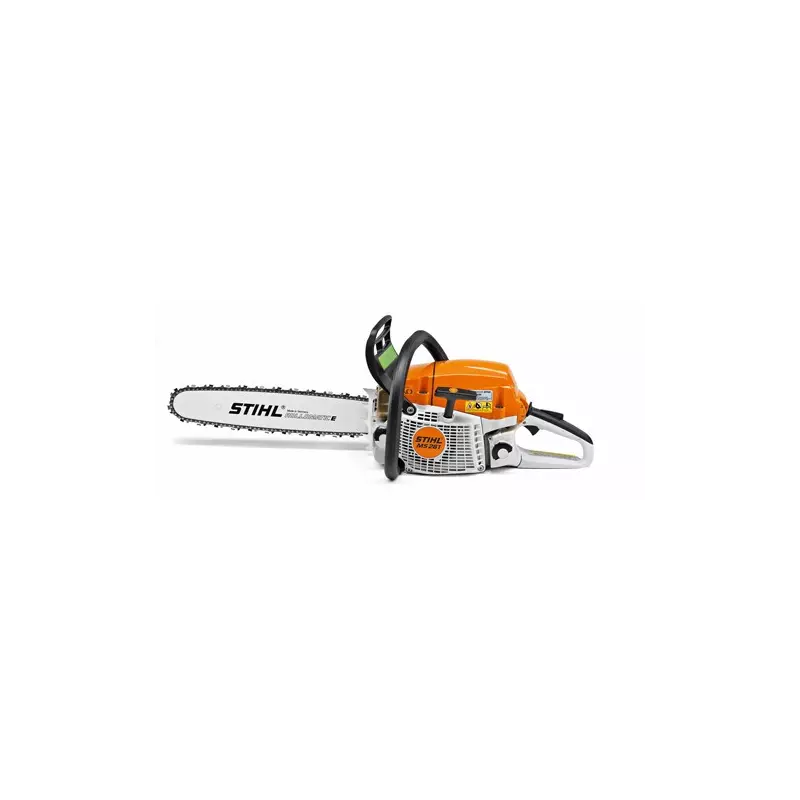

Comprehensive Guide for Stihl MS260 Repair

The effective upkeep of a power tool is essential for ensuring optimal performance and longevity. This section offers insights into the necessary steps and precautions involved in the maintenance of a specific cutting device. Understanding these guidelines can significantly enhance its reliability and functionality.

Regular servicing not only addresses potential issues but also fosters a better understanding of the equipment’s mechanics. By familiarizing oneself with the intricacies of operation and care, users can take proactive measures to prevent malfunctions and extend the lifespan of their tool.

In this guide, we will explore various aspects of the maintenance process, emphasizing key practices that promote safety and efficiency. Whether you are a seasoned user or a novice, following these recommendations will empower you to maintain your equipment with confidence.

Common Issues and Symptoms

When working with various types of power equipment, operators may encounter a range of problems that can affect performance. Identifying these common difficulties is essential for effective troubleshooting and maintenance. Understanding the signs and indicators associated with these issues can help in timely resolutions, ensuring smooth operation.

Performance Degradation

One of the most noticeable symptoms is a decline in efficiency. If the equipment struggles to perform tasks that were previously manageable, it may be an indication of underlying mechanical or operational issues. Regular inspections and attention to maintenance schedules can prevent this situation.

Unusual Noises

Unexpected sounds during operation often signal potential complications. Grinding, rattling, or excessive vibration may suggest loose components or wear and tear that requires immediate attention. Promptly addressing these noises can prevent further damage and prolong the lifespan of the machine.

Required Tools for Repairs

When undertaking maintenance tasks on outdoor machinery, having the right equipment is essential for ensuring effective and safe operation. A well-prepared toolkit can make the process smoother and more efficient, enabling users to address various issues with confidence.

Essential Hand Tools

Basic hand tools are crucial for most servicing activities. These include screwdrivers, wrenches, and pliers, which allow for adjustments and replacements of components. It’s advisable to have a variety of sizes to accommodate different fasteners.

Specialized Equipment

In addition to standard tools, certain specialized instruments may be necessary. This can include torque wrenches for precise tightening, as well as diagnostic tools to troubleshoot operational problems. Investing in quality equipment ensures durability and reliability during maintenance tasks.

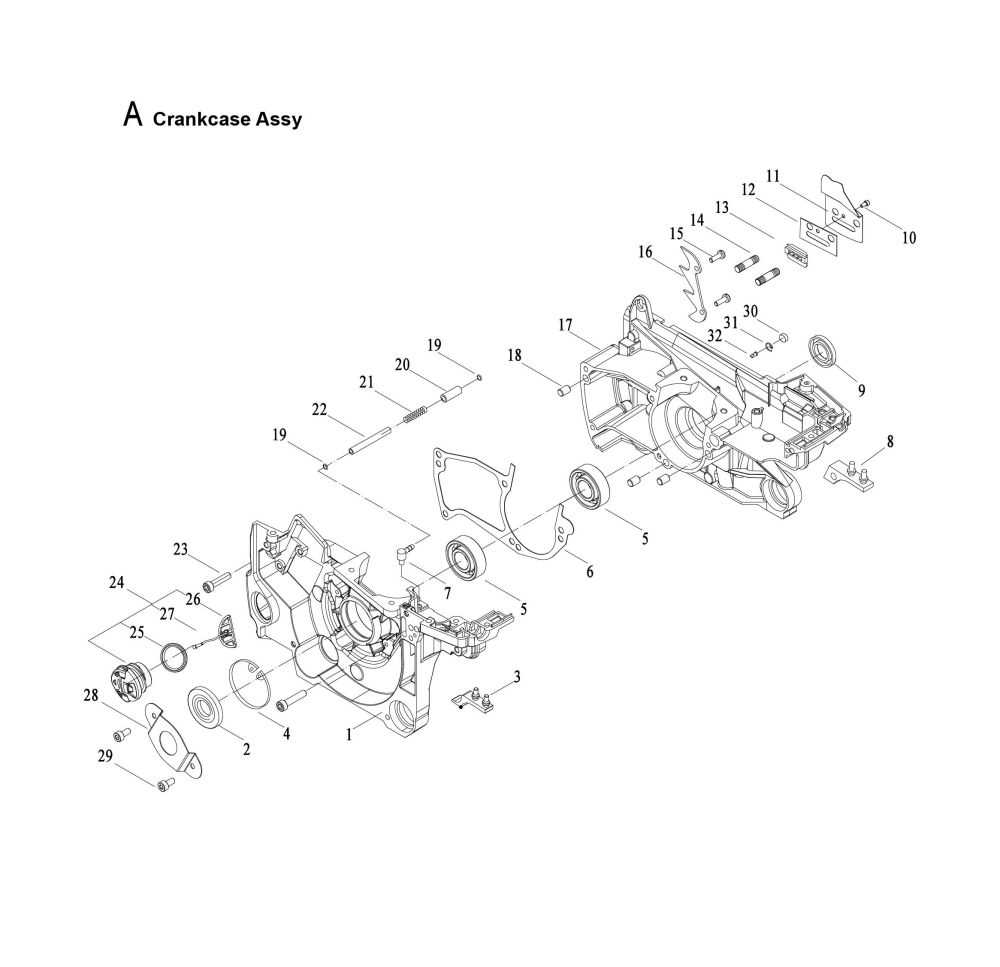

Disassembly Instructions

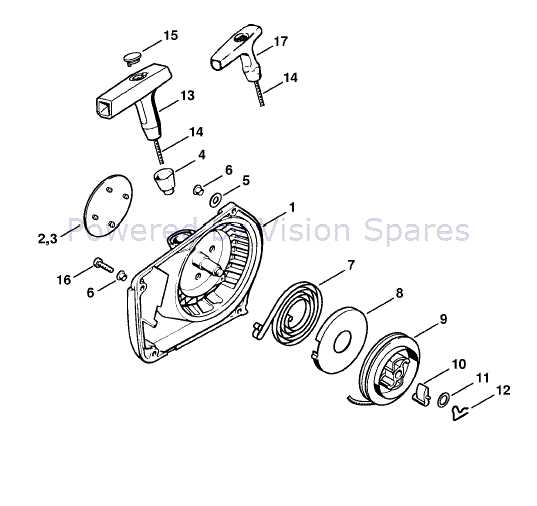

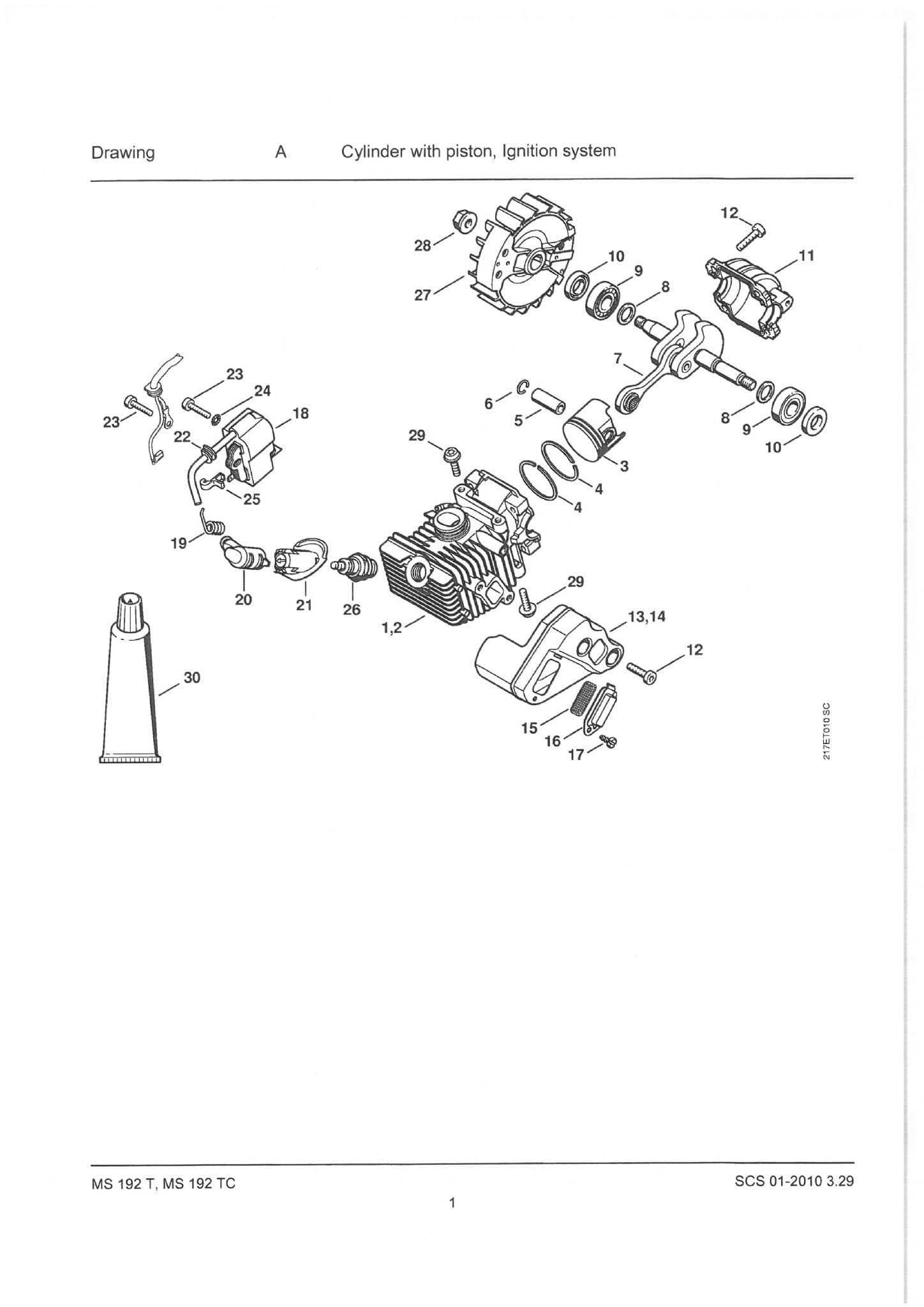

This section provides a comprehensive guide for taking apart the device to facilitate maintenance or troubleshooting. Proper disassembly is crucial for ensuring all components can be accessed and serviced effectively.

Preparation Steps

Before beginning the disassembly process, follow these steps:

- Ensure the equipment is powered off and disconnected from any power source.

- Gather all necessary tools, including screwdrivers, pliers, and a clean workspace.

- Refer to any diagrams or manuals that may assist in the identification of parts.

Disassembly Process

To successfully disassemble the unit, adhere to the following steps:

- Remove the outer casing by unscrewing the screws located on the sides.

- Carefully detach any wiring harnesses or connectors to avoid damage.

- Take out the internal components one by one, noting their positions for reassembly.

- Inspect each part for wear and tear during disassembly.

Following these guidelines will help ensure a smooth disassembly process and aid in the efficient repair or servicing of the unit.

Replacing the Fuel Filter

Maintaining optimal performance of a power tool requires periodic attention to its fuel system components. One crucial element in this system is the fuel filter, which ensures that impurities do not enter the engine. Replacing this component regularly helps to prevent operational issues and prolong the life of the equipment.

To carry out the replacement, follow these steps:

| Step | Description |

|---|---|

| 1 | Gather necessary tools and a new filter. |

| 2 | Disconnect the fuel line from the tank. |

| 3 | Remove the old filter from the line. |

| 4 | Install the new filter securely. |

| 5 | Reconnect the fuel line and ensure no leaks are present. |

Regular checks and replacements of the fuel filter can enhance the efficiency and reliability of your equipment, ensuring it operates smoothly over time.

Carburetor Cleaning Steps

Ensuring the optimal performance of an engine often requires attention to its fuel delivery system. Proper maintenance of this component is crucial for the efficient functioning of the machinery. This section outlines the essential procedures for cleaning the fuel mixing device, promoting better airflow and fuel flow.

Follow these steps to effectively clean the fuel mixing device:

| Step | Description |

|---|---|

| 1 | Remove the fuel mixing device from the engine, ensuring all connections are properly detached. |

| 2 | Disassemble the device, taking care to note the arrangement of parts for reassembly. |

| 3 | Use a specialized cleaner to remove any residues and deposits from the components. |

| 4 | Inspect all parts for wear or damage, replacing any that are not functioning properly. |

| 5 | Reassemble the device carefully, ensuring all parts are fitted correctly. |

| 6 | Reattach the cleaned fuel mixing device to the engine and check for any leaks before operation. |

Chain and Bar Maintenance

Proper upkeep of the cutting components is crucial for optimal performance and longevity. Regular attention to these parts not only enhances efficiency but also ensures safety during operation. Understanding the key practices involved in maintaining the chain and guide bar is essential for any operator.

Routine Inspection

Frequent examination of the chain and bar is vital. Look for signs of wear, such as stretching or damage. A well-maintained chain should fit snugly on the bar without excessive play. Inspect the bar for grooves or uneven wear, which can affect cutting performance.

Lubrication and Cleaning

Ensuring proper lubrication is essential to reduce friction and heat during use. Apply suitable oil regularly to keep the chain well-hydrated. Additionally, clean the bar and chain after each use to remove debris and resin buildup. A clean system functions more effectively and helps prevent premature wear.

Electrical System Troubleshooting

This section focuses on diagnosing issues related to the electrical components of the device. Proper assessment and resolution of electrical problems are crucial for optimal functionality and safety.

Common symptoms of electrical malfunctions may include:

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Device fails to start | Defective ignition system | Check and replace ignition components |

| Inefficient power delivery | Faulty wiring connections | Inspect and secure all connections |

| Inconsistent operation | Battery issues | Test battery and replace if necessary |

Addressing these issues promptly can restore performance and extend the lifespan of the equipment.

Lubrication Guidelines

Proper lubrication is essential for maintaining the performance and longevity of your equipment. Adequate oiling reduces friction, minimizes wear, and helps prevent overheating, ensuring that components operate smoothly. Following the right procedures will contribute significantly to the overall efficiency and reliability of the machinery.

It is advisable to use high-quality lubricants that are specifically formulated for the type of equipment in use. Regularly check and refill the lubrication system as needed, paying close attention to the manufacturer’s recommendations regarding oil types and intervals. Additionally, inspect the lubrication points periodically to ensure they are free of debris and functioning correctly.

When applying lubricant, use the appropriate method–whether it’s manual application or through an automated system. Ensure that excess oil is wiped away to avoid attracting dirt and grime, which can lead to complications over time. Maintaining clean and well-lubricated components will ultimately enhance the operational life of your machinery.

Safety Precautions During Repair

Ensuring safety during maintenance tasks is essential for both the individual performing the work and the equipment itself. Taking the right precautions can prevent accidents and injuries, as well as protect the functionality of the machinery.

Proper Attire: Always wear suitable clothing that does not have loose ends, which could get caught in moving parts. Additionally, protective gear such as gloves, goggles, and ear protection should be utilized to safeguard against potential hazards.

Workspace Organization: Maintain a clean and organized workspace to minimize the risk of accidents. Ensure that tools are easily accessible and that there are no obstacles that could lead to slips or falls.

Tool Inspection: Before starting any maintenance, inspect all tools for damage or wear. Using faulty equipment can lead to severe injuries and complications during the servicing process.

Electrical Safety: If working with electrical components, make sure to disconnect the power source to avoid electric shocks. Be aware of the potential hazards associated with high-voltage systems.

Follow Guidelines: Always refer to the specific guidelines and recommendations provided by the manufacturer. Adhering to established procedures is crucial for ensuring safe and effective maintenance.

By following these safety measures, individuals can significantly reduce the risk of accidents while conducting essential maintenance on their equipment.

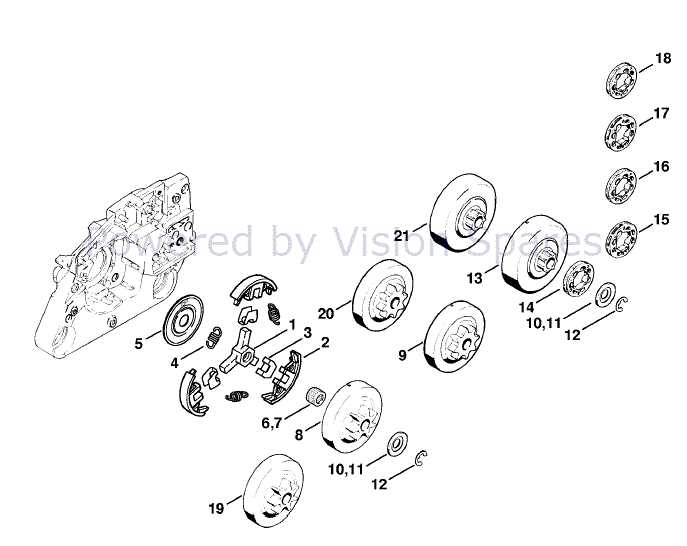

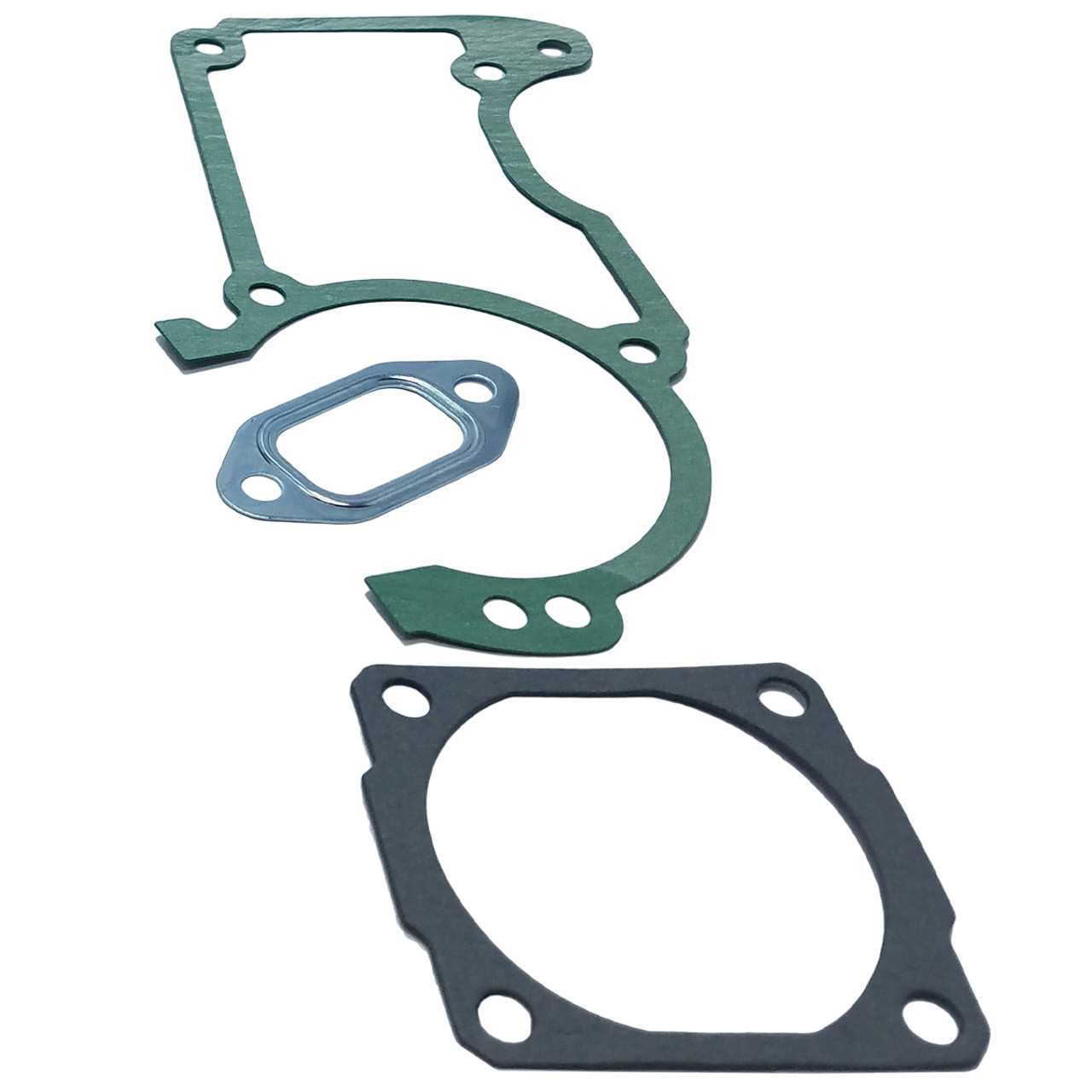

Parts Replacement and Sourcing

Maintaining and ensuring the longevity of equipment often requires timely component exchanges. Identifying appropriate replacements and sourcing them effectively is essential for optimal performance and reliability.

Identifying Necessary Components

Understanding which parts require attention is crucial. Regular inspections can help identify worn or damaged elements. Key components that often need replacement include:

- Chains and bars

- Filters and spark plugs

- Fuel lines and gaskets

Sourcing Quality Parts

When sourcing replacements, it is important to prioritize quality. Here are some recommended avenues:

- Authorized dealers for original components

- Reputable online retailers with good reviews

- Local repair shops that offer genuine parts

Using high-quality replacements will ensure the longevity and efficiency of your equipment, enhancing its overall performance.

Reassembly Process Explained

The reassembly of a power tool requires careful attention to detail and a systematic approach. Understanding the sequence of steps is essential to ensure optimal functionality and longevity of the device.

Begin by gathering all components and tools needed for the task. A clean workspace will help in organizing parts and preventing any loss during the process.

Steps for Reassembly

- Start with the base unit, ensuring all previous connections are intact.

- Reattach the motor assembly, aligning it with the corresponding mounts.

- Secure any fasteners tightly to avoid vibrations during operation.

- Reconnect any electrical wiring, making sure to follow the original routing.

- Reinstall covers and casings, ensuring a snug fit to protect internal components.

Final Checks

Once the reassembly is complete, conduct a thorough inspection:

- Verify that all screws and bolts are properly tightened.

- Check the alignment of moving parts to prevent any obstruction.

- Test the electrical connections for stability and security.

After completing these steps, your device should be ready for operational testing, ensuring all functions perform as intended.

Post-Repair Testing Techniques

After addressing mechanical issues, it’s crucial to evaluate the functionality and performance of the device. This phase ensures that all adjustments and replacements have been executed correctly, confirming optimal operation before returning the unit to service.

Functional Checks

Start with basic functionality tests. Assess the starting mechanism and idle performance, ensuring smooth operation without irregular sounds. Monitor the unit under various load conditions to verify its responsiveness and power output.

Safety Assessments

Conduct a thorough safety evaluation to identify potential hazards. Check all safety features and ensure they are operational. Perform tests that simulate typical usage scenarios, paying close attention to any unusual vibrations or overheating, which could indicate underlying issues.

Final Documentation: It’s advisable to document all testing results and observations for future reference. This record can help identify trends over time and facilitate timely maintenance.