Comprehensive Guide to Sub Zero 550 Repair

Ensuring optimal functionality of high-end refrigeration systems is essential for preserving food quality and extending appliance lifespan. This section aims to provide essential insights into common challenges encountered with premium cooling units. Understanding the intricacies of these sophisticated devices can greatly enhance user experience and reliability.

Throughout this guide, users will find detailed instructions, helpful tips, and strategies to address various operational issues. Each aspect of these cooling solutions will be explored, offering clarity on potential problems and their resolutions. With the right knowledge and tools, maintaining peak performance becomes an achievable goal.

By following the outlined recommendations, individuals can gain confidence in managing their refrigeration units effectively. Whether it’s troubleshooting minor inconveniences or performing routine checks, this guide serves as a valuable resource for enhancing the longevity and efficiency of your appliance.

Understanding Sub Zero 550 Features

This section delves into the distinctive attributes of a premium refrigeration system designed for efficiency and functionality. The focus lies on the innovative aspects that elevate user experience and operational performance.

Advanced Temperature Control

One of the standout characteristics is the precise climate management technology, ensuring optimal preservation of perishable goods. This feature helps maintain consistent temperatures, adapting swiftly to changes in the environment.

Robust Construction and Design

The appliance is built with high-quality materials that enhance durability and aesthetic appeal. The elegant finish not only complements modern kitchen designs but also ensures longevity, making it a worthwhile investment for any culinary enthusiast.

In summary, this refrigeration system combines cutting-edge technology with elegant design, making it a leader in its category.

Common Issues and Troubleshooting Tips

This section addresses frequent complications encountered with high-performance refrigeration units and offers practical solutions for efficient resolution. Understanding these common challenges can significantly enhance the longevity and functionality of the appliance.

- Temperature Inconsistencies:

Inaccurate temperature settings can lead to improper cooling. Ensure that the thermostat is correctly calibrated and check for any obstructions around the airflow vents.

- Noisy Operation:

Unusual sounds may indicate loose components or debris in the fan. Inspect the internal elements and clean as necessary to eliminate excess noise.

- Frost Buildup:

Excessive frost can obstruct airflow and affect efficiency. Regularly check door seals for damage and defrost the unit if needed.

- Water Leakage:

Moisture accumulation may signal a blocked drainage system. Clear any obstructions from the drain hole and ensure proper alignment of the unit.

- Electrical Issues:

Frequent tripping of circuit breakers or failure to power on can suggest electrical malfunctions. Inspect the power cord and connections for any signs of wear or damage.

By addressing these common issues promptly, users can maintain optimal performance and extend the lifespan of their refrigeration unit.

Essential Tools for Repairing Appliances

When tackling the task of fixing household devices, having the right equipment is crucial. This collection of essential instruments not only enhances efficiency but also ensures safety and precision in various procedures. From basic hand tools to specialized gadgets, each plays a vital role in the restoration process.

Common Hand Tools

Basic hand tools form the foundation of any repair kit. These items are versatile and can be used in a wide array of situations, making them indispensable for anyone looking to address appliance issues.

| Tool | Function |

|---|---|

| Screwdriver Set | For fastening and loosening screws |

| Wrench | For gripping and turning nuts and bolts |

| Pliers | For gripping, twisting, and cutting |

| Utility Knife | For cutting various materials |

Specialized Equipment

In addition to basic tools, certain specialized devices can make complex tasks more manageable. These items are designed for specific purposes and can significantly improve the efficiency of repair work.

| Tool | Function |

|---|---|

| Multimeter | For measuring electrical voltage, current, and resistance |

| Heat Gun | For applying heat to soften materials |

| Diagnostic Tool | For analyzing performance issues |

Step-by-Step Repair Procedures

This section outlines a systematic approach to addressing common issues encountered with your appliance. Following these detailed instructions will help ensure that each task is executed effectively and safely.

-

Initial Assessment: Begin by evaluating the current condition of the unit.

- Check for any visible damage.

- Listen for unusual sounds during operation.

- Note any irregularities in performance.

-

Gather Necessary Tools: Collect all tools required for the process.

- Screwdrivers

- Wrenches

- Multimeter

- Replacement parts

-

Power Off the Unit: Ensure the appliance is disconnected from the power source before beginning any work.

-

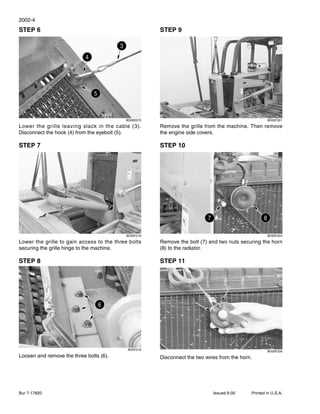

Disassembly: Carefully remove any panels or covers to access internal components.

- Follow a specific sequence to avoid damaging parts.

- Keep screws and small components organized.

-

Inspect Components: Examine each part for signs of wear or damage.

- Check seals and gaskets for leaks.

- Test electrical connections with a multimeter.

-

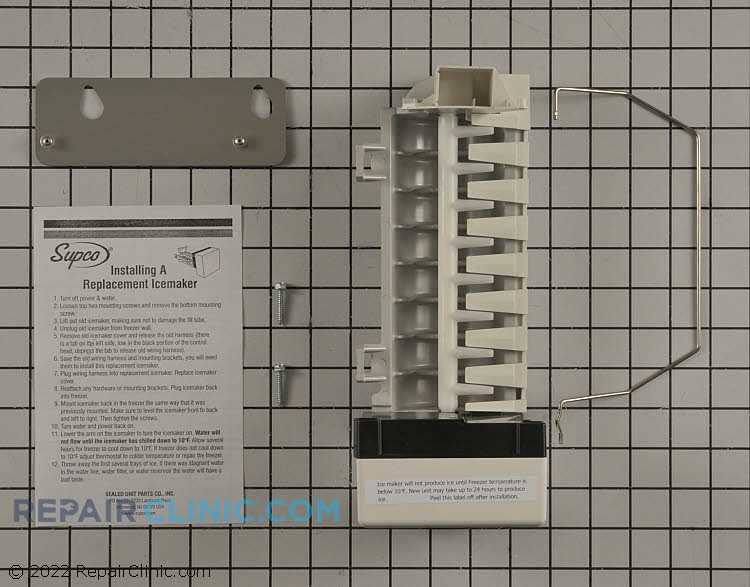

Replace Damaged Parts: Install new components where necessary.

- Ensure correct orientation and fitting.

- Tighten connections securely.

-

Reassemble the Unit: Replace panels and covers, ensuring everything is aligned properly.

-

Final Check: Perform a thorough inspection before powering on.

- Verify all tools are removed from the area.

- Ensure all components are securely in place.

-

Power On: Reconnect the appliance to the power source and monitor its operation.

By adhering to these procedures, you will enhance the likelihood of successful resolution of any issues encountered with your unit.

Safety Precautions During Repairs

Ensuring safety is paramount when undertaking maintenance tasks on refrigeration units. Proper precautions can significantly reduce the risk of accidents and injuries, promoting a secure working environment.

Before starting any work, it is crucial to disconnect the appliance from its power source. This action prevents electrical hazards and eliminates the possibility of accidental activation while conducting assessments or modifications.

Wearing appropriate personal protective equipment is essential. Use gloves to protect your hands from sharp edges and tools, and safety goggles to shield your eyes from debris or splashes that may occur during the process.

Ensuring proper ventilation in the workspace is also vital, particularly if working with chemicals or performing tasks that may release fumes. Adequate airflow minimizes the risk of inhalation and promotes a healthier environment.

Lastly, familiarize yourself with the unit’s components and tools. Understanding how each part functions and what tools are necessary for specific tasks can help prevent errors and enhance safety during the entire procedure.

Maintaining Your Sub Zero 550

Regular upkeep is essential for ensuring optimal performance and longevity of your refrigeration unit. By adhering to a few straightforward practices, you can keep your appliance running efficiently and prevent potential issues down the line.

Cleaning and Inspection

Routine cleaning is crucial. Ensure that the interior and exterior surfaces are wiped down to remove any spills or residues. Pay particular attention to the door seals; a clean and well-maintained seal enhances energy efficiency. Additionally, periodically check the condenser coils for dust buildup, as this can hinder performance.

Temperature Settings and Monitoring

Maintaining appropriate temperature settings is vital for food preservation. Regularly monitor the internal temperatures to ensure they remain within the recommended range. Adjustments may be necessary depending on the ambient conditions and load within the unit. Using a thermometer can provide accurate readings to help maintain optimal conditions.

Replacement Parts and Where to Find Them

Maintaining your appliance often requires sourcing specific components to ensure optimal functionality. Knowing where to look for these items can save time and effort.

Here are some reliable sources for obtaining essential parts:

- Manufacturer’s Website: Often the most trustworthy source, providing genuine items tailored for your unit.

- Authorized Dealers: Check with local retailers that specialize in home equipment; they frequently stock original replacements.

- Online Marketplaces: Websites like eBay or Amazon can offer a wide range of options, including new and refurbished components.

- Parts Distributors: Specialized companies that focus solely on selling replacement items for various appliances.

- Local Repair Shops: Sometimes, local technicians can provide or order the necessary parts for you.

When searching for components, be sure to verify compatibility with your specific model to avoid issues during installation.

Upgrading Components for Improved Performance

Enhancing system functionality often involves the strategic replacement of specific parts with superior alternatives. This process not only boosts overall efficiency but also extends the longevity of the equipment. Careful consideration of component selection is essential for achieving optimal results.

First and foremost, evaluating existing components can identify bottlenecks that hinder performance. By analyzing the specifications and operational capabilities, one can pinpoint areas needing enhancement. Upgrading critical elements such as the cooling system or power supply can lead to significant improvements.

Moreover, investing in advanced components ensures compatibility and maximizes performance gains. High-quality materials and technologies can dramatically improve reliability and efficiency. Regularly assessing and upgrading these elements will maintain a competitive edge in performance.

Understanding Electrical Schematics

Electrical diagrams are essential tools for comprehending the complex interconnections within electronic systems. They serve as visual representations that depict how various components interact, making it easier to troubleshoot and maintain the system. By interpreting these illustrations, users can identify paths for electrical flow, understand the function of each part, and recognize potential issues that may arise.

Familiarity with symbols and conventions used in these diagrams is crucial. Each symbol represents a specific component, such as resistors, capacitors, or switches, and understanding their meanings allows for more effective analysis. Additionally, recognizing how these elements are interconnected helps in tracing circuits and diagnosing faults.

By mastering the art of reading electrical schematics, individuals can enhance their problem-solving skills and improve their ability to work with complex electronic systems. This knowledge not only aids in repairs but also fosters a deeper understanding of how devices operate.

Cooling System: Repair and Maintenance

Proper care and upkeep of the cooling mechanism are vital for optimal performance and longevity. Regular inspections and timely interventions can prevent issues that may lead to significant malfunctions. Understanding the components and their functions helps ensure the system operates efficiently.

Common Issues and Solutions

Identifying typical problems, such as insufficient cooling or unusual noises, is essential. These symptoms often indicate a need for adjustments or part replacements. Regular checks on fluid levels and potential leaks can help catch these issues early. Additionally, cleaning components like the condenser and evaporator can enhance functionality and prolong the lifespan of the system.

Best Practices for Maintenance

To maintain efficiency, it is advisable to follow a routine maintenance schedule. This includes periodic inspections and ensuring that all components are in good condition. Utilizing high-quality refrigerants and following manufacturer guidelines can also contribute to better performance. By prioritizing these practices, you can keep the cooling system in excellent working order.

Managing Temperature Control Problems

Temperature regulation is crucial for the optimal functioning of cooling units. Issues in this area can lead to inefficiencies and spoilage of stored items. Identifying and resolving these problems promptly can ensure consistent performance and longevity of the equipment.

Common Issues and Symptoms

Several factors may contribute to temperature management challenges. Here are some common problems and their indicators:

| Problem | Symptoms |

|---|---|

| Insufficient Cooling | Items are warmer than expected; frost buildup may occur. |

| Excessive Frost Build-Up | Frequent need for defrosting; ice formation on surfaces. |

| Temperature Fluctuations | Inconsistent readings; frequent cycling on and off. |

Troubleshooting Steps

To address temperature control issues, follow these troubleshooting steps:

- Check the thermostat settings and calibration.

- Inspect door seals for damage and ensure they close properly.

- Examine the airflow and clear any obstructions.

- Verify that the condenser coils are clean and free of debris.

Cleaning and Preventive Maintenance Tips

Regular upkeep and sanitation of appliances not only enhance their performance but also prolong their lifespan. Implementing simple cleaning routines and preventive measures can help maintain optimal functionality and prevent common issues.

Essential Cleaning Procedures

- Wipe down surfaces with a mild detergent to remove stains and spills.

- Inspect and clean door seals to ensure they are free of debris, preventing air leaks.

- Remove and clean any removable shelves and bins with warm, soapy water.

- Use a vacuum cleaner or a brush to remove dust and dirt from the condenser coils.

Preventive Measures

- Check and replace filters regularly to maintain airflow and efficiency.

- Avoid overcrowding to ensure proper air circulation within the unit.

- Schedule professional maintenance at least once a year to address potential issues early.