Toro Dingo Repair Manual Guide

In the realm of outdoor equipment, ensuring optimal performance and longevity is crucial for any operator. Understanding the intricacies of machinery not only enhances efficiency but also minimizes downtime. This guide serves as an essential resource for those seeking to delve into the nuances of maintaining their compact utility equipment.

Whether you’re facing minor hiccups or more significant issues, having a systematic approach to diagnostics and upkeep can make all the difference. This document is designed to empower users with knowledge, providing step-by-step instructions and valuable insights into effective troubleshooting techniques.

Equipping yourself with the right information is key to overcoming challenges that may arise during operation. With an emphasis on practical solutions and preventive care, this guide aims to facilitate a smoother experience in the field, allowing you to focus on the tasks at hand with confidence and ease.

Toro Dingo Overview

This section provides a comprehensive look at a versatile piece of equipment designed for various tasks in landscaping and construction. It highlights its capabilities, features, and benefits, making it an essential tool for professionals in the industry.

Key Features

- Compact design for easy maneuverability in tight spaces.

- Powerful engine options for enhanced performance.

- Multiple attachment compatibility for diverse applications.

- User-friendly controls for improved operational efficiency.

Applications

- Landscaping: Ideal for grading, digging, and moving materials.

- Construction: Efficient for site preparation and material handling.

- Utility work: Effective in trenching and utility line installation.

- Agricultural tasks: Useful for transporting soil and planting.

Common Issues and Troubleshooting

When operating compact earth-moving machinery, users may encounter a variety of challenges that can affect performance and efficiency. Understanding these common problems and how to address them is essential for maintaining optimal functionality and prolonging the lifespan of the equipment.

Below are some frequent issues along with potential solutions:

-

Engine Overheating:

- Check the coolant levels and refill if necessary.

- Inspect the radiator for blockages and clean as needed.

- Examine the thermostat to ensure it is functioning correctly.

-

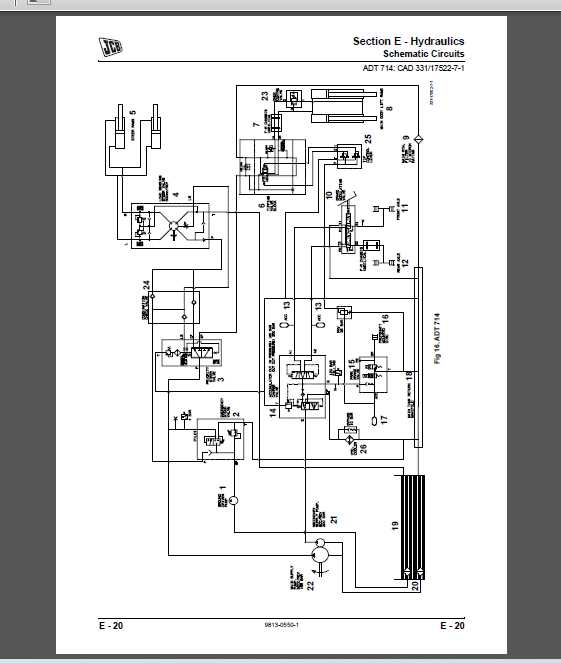

Hydraulic System Failures:

- Look for leaks in hoses and fittings.

- Ensure the hydraulic fluid is at the proper level.

- Test the hydraulic pump for any signs of wear or damage.

-

Starting Difficulties:

- Check the battery connections for corrosion or looseness.

- Test the battery charge and replace if low.

- Inspect the starter motor for proper function.

-

Unusual Noises:

- Listen for grinding or clanking sounds that may indicate mechanical issues.

- Check for loose components that might require tightening.

- Inspect belts and chains for wear or misalignment.

By addressing these common issues promptly, operators can enhance performance and minimize downtime. Regular maintenance checks are also recommended to prevent potential problems from arising.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting. This section outlines the fundamental implements that can facilitate various tasks, ensuring that you are well-prepared for any challenges that may arise during upkeep.

Basic Toolkit

- Wrenches: A set of adjustable and fixed wrenches to handle different sizes of nuts and bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers for versatile use.

- Pliers: Needle-nose and slip-joint pliers for gripping and manipulating objects.

- Socket Set: A collection of sockets for quick and efficient fastening.

Advanced Equipment

- Torque Wrench: Ensures fasteners are tightened to the manufacturer’s specifications.

- Multimeter: Useful for diagnosing electrical issues.

- Jack and Stands: Essential for lifting and securing equipment safely.

- Cleaning Supplies: Brushes, rags, and solvents for maintaining cleanliness and functionality.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues that may arise with your equipment. Following a structured process not only ensures efficiency but also enhances your understanding of the mechanics involved. With clear instructions, you will be able to diagnose problems and implement solutions effectively.

Step 1: Assess the Issue

Begin by observing the machine in operation. Listen for unusual sounds and note any performance irregularities. Documenting these details will help in pinpointing the problem more accurately.

Step 2: Gather Necessary Tools

Before starting, collect all essential tools and replacement parts. Having everything on hand streamlines the process and prevents unnecessary delays.

Step 3: Disconnect Power

Ensure the equipment is completely powered down. Disconnecting from the power source is crucial for your safety as you begin the disassembly.

Step 4: Disassemble the Unit

Carefully remove any covers or panels to access internal components. Keep track of screws and parts as you go to facilitate reassembly later.

Step 5: Inspect Components

Thoroughly examine each part for signs of wear or damage. Look for cracks, corrosion, or other indicators that a component may need to be replaced.

Step 6: Implement Solutions

Based on your inspection, proceed with necessary adjustments or replacements. Follow the manufacturer’s guidelines to ensure proper installation of new parts.

Step 7: Reassemble and Test

Once repairs are complete, reattach any covers or panels securely. Reconnect the power source and perform a test run to verify that the issue has been resolved.

Step 8: Regular Maintenance

After successful troubleshooting, establish a routine maintenance schedule to keep the machine in optimal condition. Regular checks can prevent future issues and extend the lifespan of the equipment.

Preventive Maintenance Tips

Regular upkeep of your equipment is essential for optimal performance and longevity. Implementing a proactive approach can significantly reduce the likelihood of unexpected breakdowns and costly repairs. Here are some fundamental strategies to ensure your machinery remains in excellent working condition.

Daily Checks

Conducting brief inspections on a daily basis can help identify minor issues before they escalate. Focus on the following components:

| Component | Check for |

|---|---|

| Fluid Levels | Ensure oil, fuel, and hydraulic fluids are at appropriate levels. |

| Belts and Hoses | Look for wear, cracks, or leaks that may compromise performance. |

| Filters | Inspect air and fuel filters for cleanliness and replace if necessary. |

| Tires | Check for proper inflation and any signs of damage. |

Scheduled Maintenance

In addition to daily inspections, establishing a routine maintenance schedule is crucial. This should include:

- Regular lubrication of moving parts to minimize friction.

- Periodic replacement of worn-out components as per manufacturer recommendations.

- Thorough cleaning to prevent dirt accumulation that can lead to mechanical issues.

By following these preventive measures, you can enhance the reliability of your equipment and extend its lifespan significantly.

Parts Replacement Procedures

This section provides essential guidelines for swapping out components effectively and safely. Understanding the correct methods ensures optimal performance and longevity of your equipment. Following systematic procedures will help in minimizing downtime and avoiding potential damage during the process.

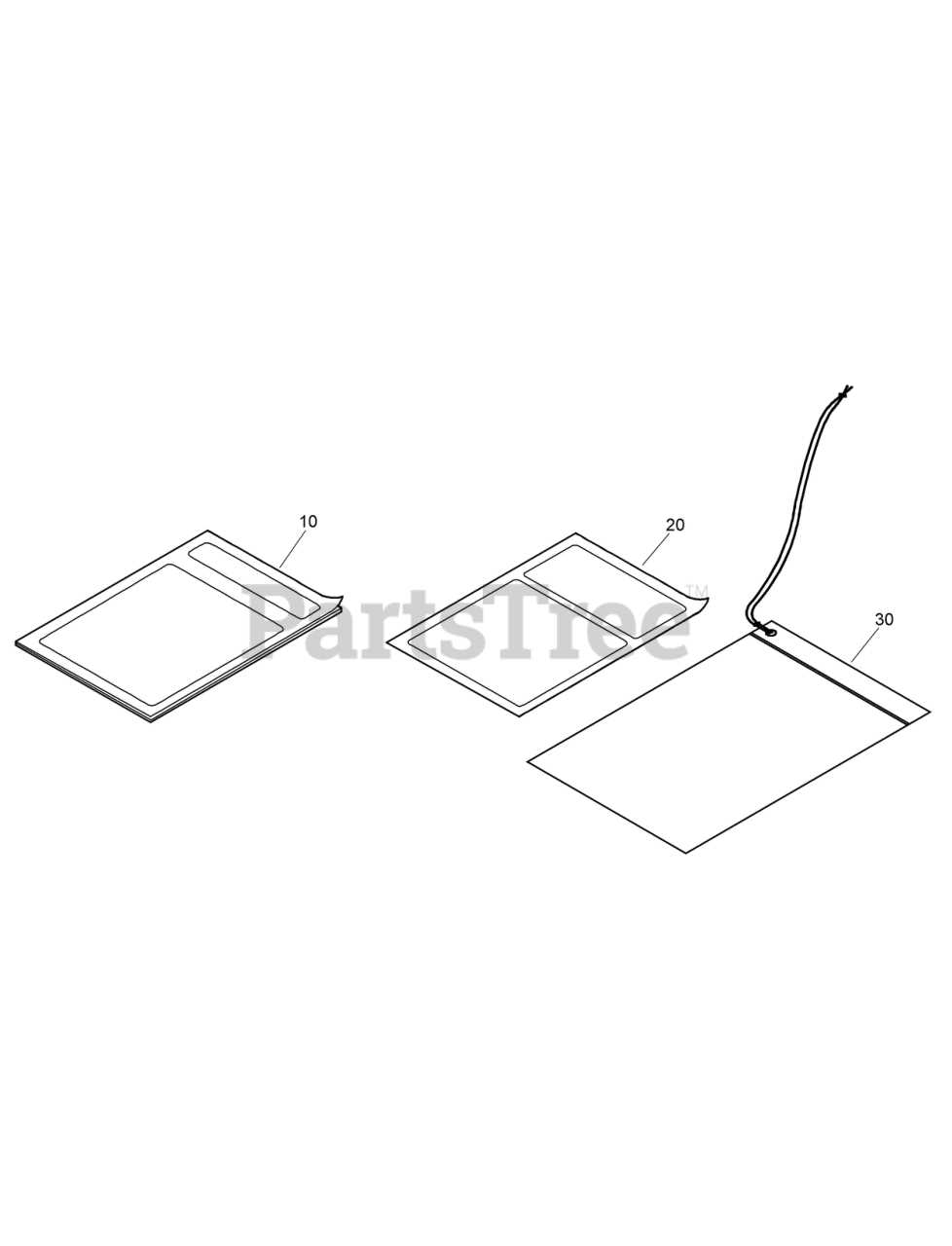

Identifying the Components

Before beginning the exchange, it is crucial to accurately identify the parts that require attention. Refer to the specifications to determine the appropriate replacements. Utilizing a detailed inventory will streamline the process, ensuring that all necessary items are on hand prior to starting.

Step-by-Step Replacement Instructions

Begin by gathering all required tools and safety gear. Next, power down the machine to prevent any accidental operation. Carefully remove the old component, taking note of any attached fasteners or connections. Ensure you document the configuration for reference during installation. Once the old part is out, install the new component by reversing the removal steps, ensuring all connections are secure and correctly aligned. Finally, conduct a thorough inspection before re-energizing the equipment to verify that everything is in place.

Understanding Dingo Components

Gaining insight into the various elements of compact utility machines is crucial for efficient operation and maintenance. Each component plays a significant role in ensuring optimal performance and durability. This section will explore the primary parts, their functions, and how they interact within the overall system.

- Engine: The heart of the machine, responsible for providing the necessary power for operation.

- Transmission: Facilitates the transfer of power from the engine to the wheels, affecting speed and torque.

- Hydraulic System: Enables lifting, tilting, and other movements through pressurized fluid, crucial for attachments.

- Chassis: The framework that supports all other components and provides stability during operation.

- Controls: The interface that allows the operator to manipulate various functions of the machine effectively.

Understanding how these components work together is essential for anyone looking to maximize the utility and longevity of their equipment. Regular inspection and knowledge of each part can prevent potential issues and enhance overall efficiency.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial for both personal protection and the longevity of equipment. Proper precautions help prevent accidents and injuries, fostering a secure working environment. It is essential to adhere to guidelines that minimize risks while performing any kind of servicing or adjustment.

Always wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and sturdy footwear to safeguard against potential hazards. Depending on the task, additional gear such as hearing protection or respiratory masks may also be necessary.

Before starting any work, ensure the machinery is turned off and disconnected from power sources. This reduces the risk of unintended activation, which can lead to serious injuries. Furthermore, allow any moving parts to come to a complete stop before proceeding.

Keep the workspace organized and free from clutter. A clean area minimizes tripping hazards and allows for better focus. Additionally, having tools and materials readily available helps streamline the process while reducing distractions.

Familiarize yourself with the equipment before undertaking any task. Understanding its components and functions is essential for identifying potential risks and addressing them effectively. Always refer to the provided instructions for specific guidance.

In case of an emergency, be prepared to act quickly. Know the location of first aid kits and emergency exits. Having a plan in place can make a significant difference in critical situations.

By prioritizing safety and following these guidelines, individuals can significantly reduce risks and ensure a more efficient and secure working experience.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and troubleshooting for compact machinery. Here, users can find valuable insights and solutions to enhance their understanding and ensure optimal performance of their equipment.

What should I do if my machine won’t start?

If your equipment fails to start, check the power supply and ensure that all safety features are disengaged. Inspect the ignition system and battery connections for any signs of wear or damage. If the issue persists, consult the troubleshooting guide for more specific steps.

How often should I perform maintenance?

Where to Find Replacement Parts

When it comes to maintaining and servicing your equipment, sourcing quality components is essential for ensuring longevity and optimal performance. Various avenues exist for locating the necessary items, catering to different preferences and needs.

Online Retailers

One of the most convenient methods is through online vendors. Websites specializing in machinery parts often offer a vast selection, competitive pricing, and customer reviews to help you make informed decisions. Always verify the authenticity of the seller and check return policies before purchasing.

Local Dealers and Shops

Another reliable option is to visit local distributors or repair shops. These establishments typically carry a range of components and can provide expert advice. Additionally, supporting local businesses can enhance community ties and may lead to personalized service.

Remember to compare prices and availability across different sources to ensure you get the best deal for your replacement items.