Toro Mower Repair Guide for Efficient Maintenance

When it comes to keeping your outdoor tools in top condition, understanding their components and functionalities is essential. This section aims to provide valuable insights into troubleshooting and enhancing the performance of your grass-cutting machinery. A well-maintained device not only extends its lifespan but also ensures efficient operation throughout the mowing season.

Every gardener knows the importance of having reliable equipment at hand. Whether you are dealing with minor issues or preparing for seasonal upkeep, having a comprehensive resource can significantly ease the process. From routine checks to specific adjustments, familiarity with your device’s mechanisms will empower you to tackle challenges confidently.

In this guide, we will delve into various aspects of maintaining and optimizing your lawn care tools. By following practical tips and understanding key principles, you can ensure that your equipment remains efficient and ready for any task. With a proactive approach to maintenance, you can enjoy a lush, well-manicured yard season after season.

Toro Mower Overview

This section provides a comprehensive insight into a range of lawn care equipment designed for efficiency and performance. These machines are engineered to facilitate the upkeep of outdoor spaces, making the task of maintaining greenery easier and more effective. With various models and features available, users can find options that cater to their specific needs and preferences.

Key Features

The following table highlights essential characteristics of these gardening tools, illustrating their advantages and functionalities.

| Feature | Description |

|---|---|

| Engine Power | Robust engines provide reliable performance for various tasks. |

| Cutting Width | Different sizes available to suit diverse lawn sizes and conditions. |

| Adjustable Height | Allows customization for optimal grass length. |

| Durability | Built with high-quality materials to withstand tough conditions. |

| Ease of Use | Designed for user-friendly operation and maintenance. |

Conclusion

Understanding the various models and their capabilities is crucial for selecting the right equipment for lawn care. By considering the features and benefits outlined, users can make informed decisions that enhance their gardening experience.

Common Toro Mower Issues

When maintaining your lawn equipment, it’s essential to be aware of typical problems that can arise during operation. Identifying these issues early can help ensure optimal performance and prolong the life of your machine. This section explores some frequent challenges users may encounter, along with suggestions for resolution.

Engine Starting Difficulties

One prevalent concern is difficulty starting the engine. This issue can stem from various factors, including fuel problems, a discharged battery, or issues with the ignition system. Ensuring that fuel is fresh and that the battery is fully charged can often resolve the problem. Regularly checking spark plugs and air filters can also contribute to smoother starts.

Uneven Cutting Performance

Another common problem is uneven cutting, which can lead to an unsightly lawn. This may be caused by a dull blade, improper cutting height, or debris buildup under the deck. Sharpening or replacing the blade, adjusting the cutting height, and cleaning the underside of the deck can improve cutting quality and achieve a more uniform appearance.

Essential Tools for Repair

Having the right set of instruments is crucial for maintaining and fixing outdoor equipment. Proper tools not only make the job easier but also ensure that the work is done efficiently and safely. Below is a list of indispensable instruments that every technician should have on hand.

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, are essential for assembling and disassembling parts.

- Wrenches: Adjustable and fixed wrenches are necessary for loosening and tightening bolts and nuts.

- Socket Set: A comprehensive socket set allows for quick and easy access to fasteners in tight spaces.

- Pliers: Needle-nose and regular pliers are helpful for gripping and manipulating small components.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage.

- Multimeter: Used for electrical troubleshooting, a multimeter can measure voltage, current, and resistance.

- Fuel Container: A proper container is needed for safely storing and transporting fuel.

- Oil and Grease: Essential for lubrication, they help to keep moving parts functioning smoothly.

- Safety Gear: Always wear protective gloves and goggles to ensure personal safety during maintenance tasks.

Equipping yourself with these tools will not only enhance your efficiency but also prolong the lifespan of your equipment. A well-prepared technician is always ready to tackle any challenge that comes their way.

Step-by-Step Maintenance Guide

Proper upkeep of your lawn care equipment is essential for optimal performance and longevity. This guide outlines a systematic approach to ensure your device remains in excellent working condition, helping you maintain a pristine outdoor space.

Essential Tools and Supplies

Before starting the maintenance process, gather the necessary tools and materials. You will typically need:

- Wrenches for loosening and tightening bolts

- Oil for lubrication

- Replacement parts such as filters and blades

- Cleaning brushes to remove debris

Routine Maintenance Steps

Follow these steps to maintain your equipment effectively:

- Clean the exterior: Remove grass clippings and dirt to prevent rust and deterioration.

- Inspect the blades: Check for dullness or damage and replace them if necessary.

- Change the oil: Regularly replace the oil to ensure smooth operation.

- Check the air filter: Clean or replace the filter to maintain optimal airflow.

- Examine the spark plug: Ensure it is clean and functioning properly for reliable starts.

Adhering to this maintenance guide will help you keep your equipment running smoothly, ultimately saving you time and enhancing the efficiency of your lawn care tasks.

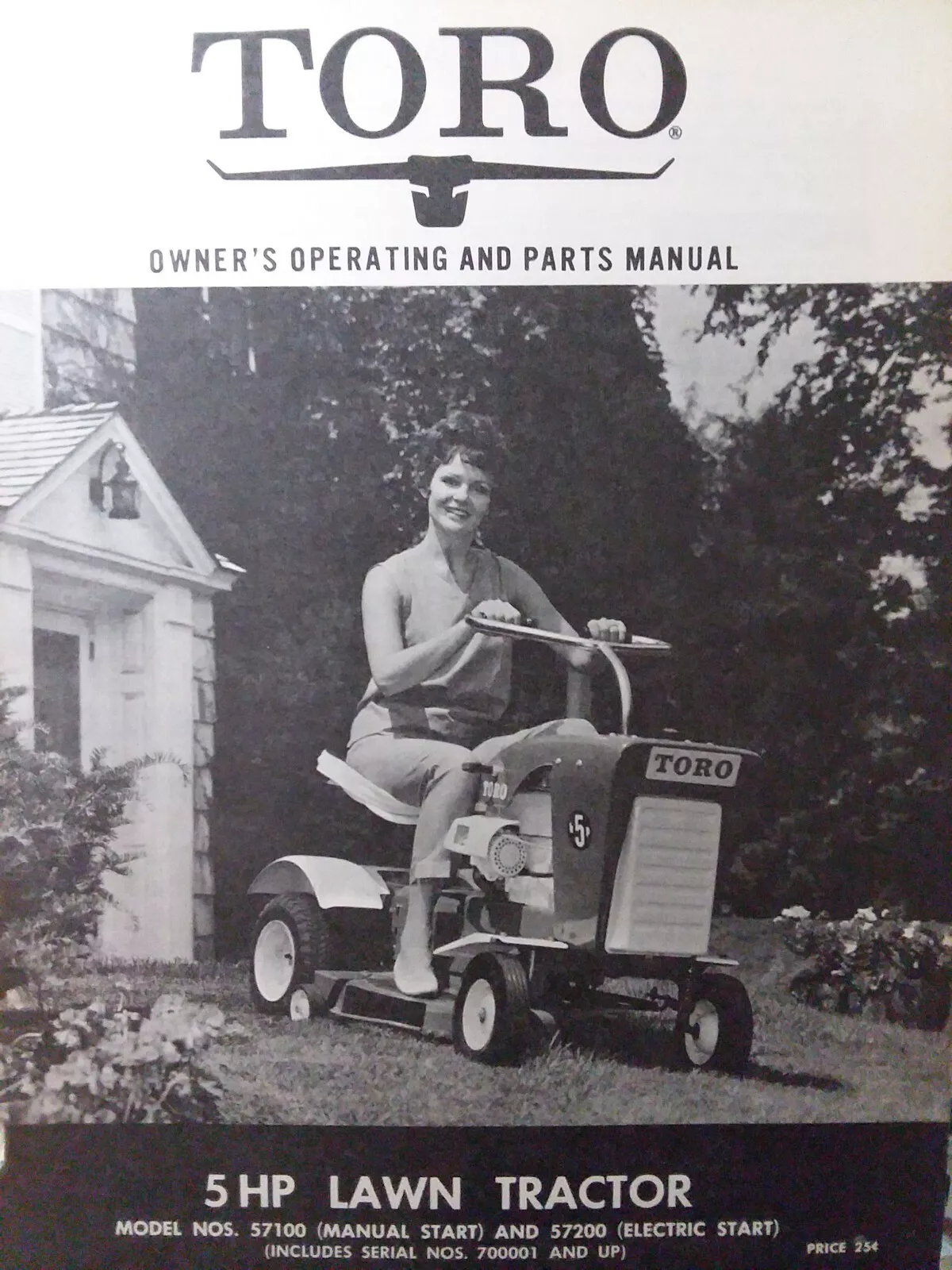

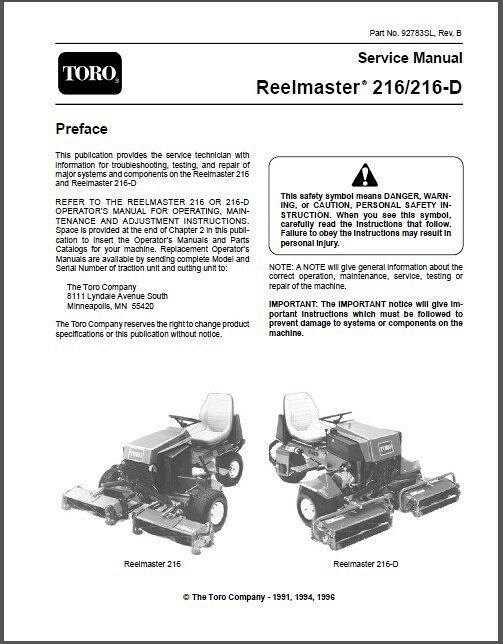

Understanding the User Manual

A user guide serves as an essential resource for anyone seeking to operate and maintain their equipment effectively. It provides detailed instructions, safety information, and troubleshooting tips, ensuring users can maximize the performance and longevity of their device.

Within the guide, users will find sections dedicated to setup procedures, operational guidelines, and routine maintenance tasks. Familiarizing oneself with these areas is crucial for achieving optimal functionality and preventing common issues.

Additionally, the manual often includes diagrams and illustrations that enhance comprehension, allowing users to visualize complex processes. Understanding these visual aids can significantly ease the learning curve for new users.

Furthermore, a well-structured guide contains a glossary of terms and an index, making it easier to locate specific information quickly. This feature is particularly useful for troubleshooting and addressing any concerns that may arise during usage.

Ultimately, taking the time to thoroughly read and understand the user guide not only promotes safe and effective operation but also empowers users to confidently address potential challenges that may occur over time.

Replacing Blades: A How-To

Maintaining sharp cutting implements is essential for optimal performance and a clean finish on your lawn. Over time, these components can wear down or become damaged, necessitating their replacement to ensure efficient operation. This guide will walk you through the steps to effectively swap out the old cutting edges for new ones, enhancing your equipment’s functionality.

Before starting, gather the necessary tools, including a socket wrench, safety gloves, and eye protection. Always ensure the machine is powered off and disconnected from any electrical source to prevent accidental starts. Place the equipment on a stable surface and secure it to avoid any movement during the process.

Begin by removing the protective cover, if applicable, to access the cutting mechanism. Locate the fastening bolts that secure the blades in place. Using your socket wrench, carefully unscrew these bolts, taking note of their orientation for reinstallation. Once the bolts are removed, gently lift off the old blades and inspect the spindle for any debris that may need cleaning.

Take your new cutting edges and align them with the spindle. Ensure that they are positioned correctly according to the manufacturer’s guidelines. Once aligned, insert and hand-tighten the bolts to secure the blades. After all blades are in place, use the socket wrench to tighten the bolts firmly, but avoid over-tightening, as this may damage the components.

Finally, reattach any covers that were removed and perform a visual inspection to ensure everything is in order. Once satisfied, reconnect the power source, and you are ready to enjoy the benefits of well-maintained cutting tools.

Engine Troubleshooting Tips

Addressing issues with your machine’s power source can often enhance performance and extend its lifespan. Understanding common problems and their solutions is essential for effective maintenance.

Start by checking the fuel system. Ensure there’s enough fuel and that it is fresh. Stale or contaminated fuel can lead to starting difficulties.

Inspect the air filter. A clogged filter restricts airflow, leading to poor combustion and power loss. Replace or clean it regularly to maintain optimal performance.

Examine the spark plug for wear and carbon buildup. A faulty plug can cause misfiring or starting issues. Regular replacement can improve ignition reliability.

Review the ignition system. Loose or damaged wiring can lead to intermittent performance problems. Ensuring all connections are secure is crucial.

Lastly, monitor the overall engine temperature. Overheating can indicate problems with the cooling system or oil levels, necessitating prompt attention to avoid further damage.

Electrical System Checks

Ensuring the reliability of the electrical components is crucial for optimal performance. Regular assessments can help identify potential issues before they lead to more significant problems. This section outlines essential steps to evaluate the electrical system effectively.

Initial Inspection

Begin by visually examining the wiring and connections. Look for signs of wear, corrosion, or damage. A thorough inspection includes:

- Checking battery terminals for tightness and cleanliness.

- Inspecting wiring harnesses for fraying or breaks.

- Ensuring all connectors are secure and free from rust.

Testing Electrical Components

Once the initial inspection is complete, proceed to test individual electrical components to confirm their functionality. Key components to test include:

- Battery: Use a multimeter to check voltage; it should read around 12.6 volts when fully charged.

- Ignition System: Inspect spark plugs for wear and carbon buildup; replace if necessary.

- Fuses: Check all fuses to ensure none are blown; replace any that are faulty.

By conducting these checks regularly, you can maintain the efficiency and reliability of the system, preventing unexpected breakdowns and ensuring a smooth operation.

Cleaning and Care Procedures

Maintaining equipment in optimal condition is essential for ensuring longevity and performance. Regular cleaning and care routines not only enhance the efficiency of the tools but also contribute to safety during operation. Proper upkeep helps in identifying potential issues before they escalate, thereby saving time and resources.

Following a systematic approach to maintenance can prevent the accumulation of dirt and debris, which can impair functionality. Below are recommended steps and guidelines for effective cleaning and care.

| Task | Frequency | Procedure |

|---|---|---|

| Clean exterior surfaces | After each use | Wipe down with a damp cloth to remove dust and grass clippings. |

| Inspect blades | Monthly | Check for wear and damage; sharpen or replace as needed. |

| Check air filter | Every 25 hours | Remove and clean the filter; replace if excessively dirty. |

| Examine fuel system | Seasonally | Inspect for leaks and ensure fuel is fresh to prevent clogging. |

| Inspect wheels and belts | Every 50 hours | Check for wear; lubricate or replace as necessary. |

By adhering to these care procedures, operators can ensure their equipment remains reliable and efficient, ready to tackle any task at hand. Regular attention to these details will ultimately lead to a more enjoyable and productive experience.

Winterizing Your Toro Mower

Preparing your lawn equipment for the colder months is essential for ensuring its longevity and performance. Proper maintenance before storage can prevent damage and reduce the risk of costly repairs when spring arrives. This process involves several key steps to protect your machine from harsh winter conditions.

Start by cleaning the exterior thoroughly to remove any grass clippings, dirt, and debris. A clean surface helps prevent rust and corrosion. Afterward, inspect the blades for sharpness; if necessary, sharpen or replace them to ensure optimal cutting efficiency when the season changes.

Next, drain the fuel tank to avoid deterioration over the winter. Fuel can go stale and cause issues during the next use. If you prefer not to drain it completely, consider adding a fuel stabilizer to maintain its quality. Run the engine for a few minutes after adding the stabilizer to ensure it reaches the carburetor.

Additionally, check the oil level and replace it if it appears dirty. Fresh oil helps to lubricate the engine parts and prevents internal damage. Replace the air filter if it’s clogged, as clean air intake is crucial for engine performance.

Finally, store your equipment in a dry, sheltered location to protect it from the elements. Covering it with a breathable tarp can also provide extra protection against dust and moisture. Following these steps will ensure your machine is well-prepared to spring back to life when the warmer months return.

When to Seek Professional Help

Understanding when to consult an expert can be crucial in maintaining equipment effectively. Some issues may seem manageable, but others require specialized knowledge and tools to ensure proper functioning and safety.

Consider the following scenarios where professional assistance is advisable:

- Complex Mechanical Issues: If you encounter unusual sounds, vibrations, or a complete breakdown, it may indicate a deeper mechanical failure.

- Electrical Problems: Issues involving wiring, batteries, or electronic components often require expert diagnostics to avoid safety hazards.

- Frequent Recurrence: If a problem persists despite your efforts to resolve it, professional evaluation can help identify underlying causes.

- Safety Concerns: If you are uncertain about safety protocols or feel uncomfortable handling repairs, it’s wise to contact a technician.

- Lack of Tools or Knowledge: Specialized repairs may require specific tools or expertise that you may not possess.

Seeking help from professionals not only ensures that issues are resolved correctly but also extends the lifespan of your equipment.

Resources for Further Assistance

When tackling maintenance and troubleshooting tasks, having access to reliable sources of information can significantly enhance your experience. Whether you are looking for expert advice, detailed guides, or community support, a variety of resources are available to help you navigate common challenges and ensure optimal performance of your equipment.

Online Communities

Engaging with online forums and social media groups can provide valuable insights from fellow enthusiasts. Many platforms host discussions where users share their experiences, tips, and solutions to specific issues. Participating in these communities allows for direct interaction with knowledgeable individuals who may have faced similar situations.

Professional Support Services

If you require expert assistance, consider reaching out to specialized service providers. Many professionals offer consultation and repair services, ensuring that any problems are addressed with precision. Additionally, some manufacturers provide customer support hotlines and chat options for immediate help, making it easier to resolve any concerns quickly.