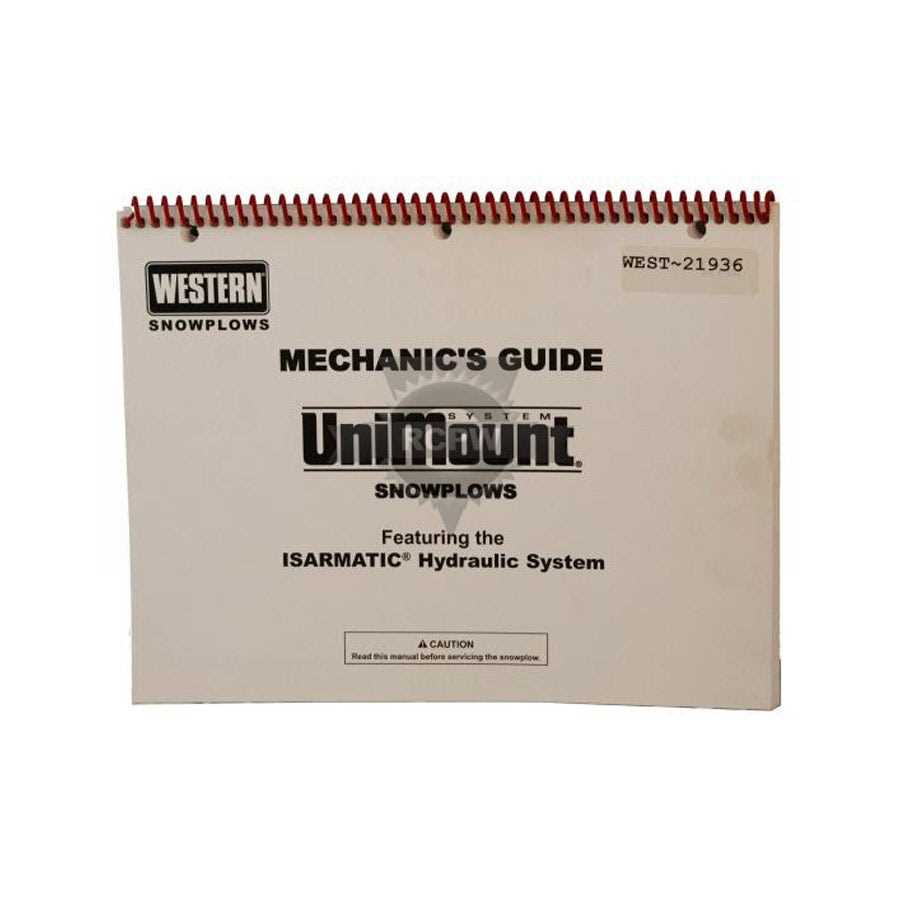

Guide to Repairing Western Unimount

Understanding the nuances of equipment upkeep is essential for ensuring optimal performance and longevity. This section provides an overview of best practices and essential procedures that can help maintain functionality and prevent unexpected failures.

By following systematic approaches to service and troubleshooting, users can address common issues effectively. Regular checks and proper handling techniques can significantly reduce the need for extensive interventions, thus enhancing the overall efficiency of the machinery.

Engaging with detailed instructions will empower operators to tackle minor adjustments independently. Familiarity with the operational aspects is vital for maximizing the potential of the apparatus while minimizing downtime.

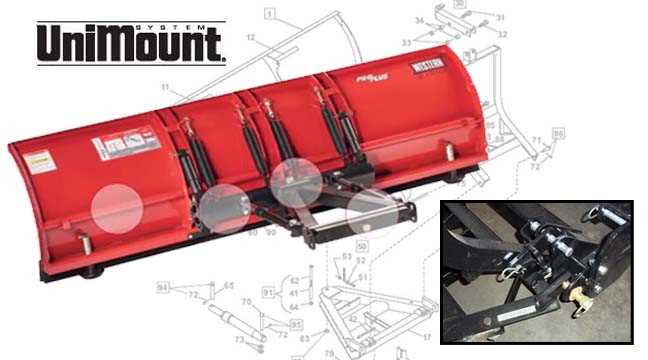

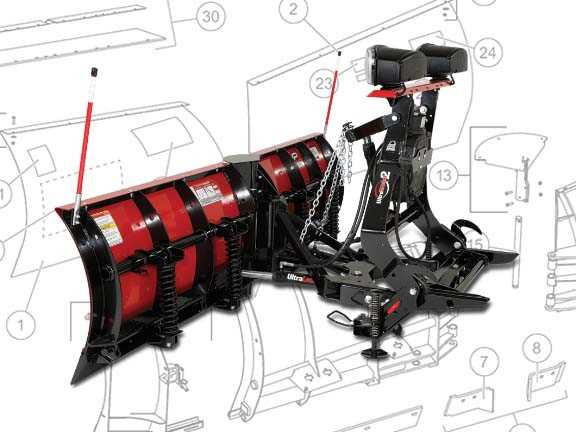

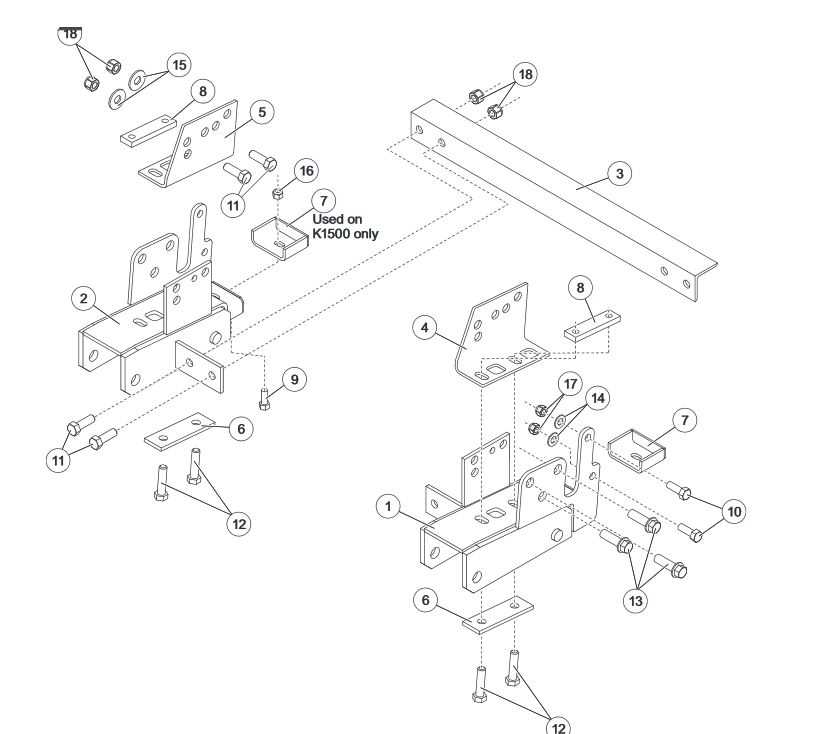

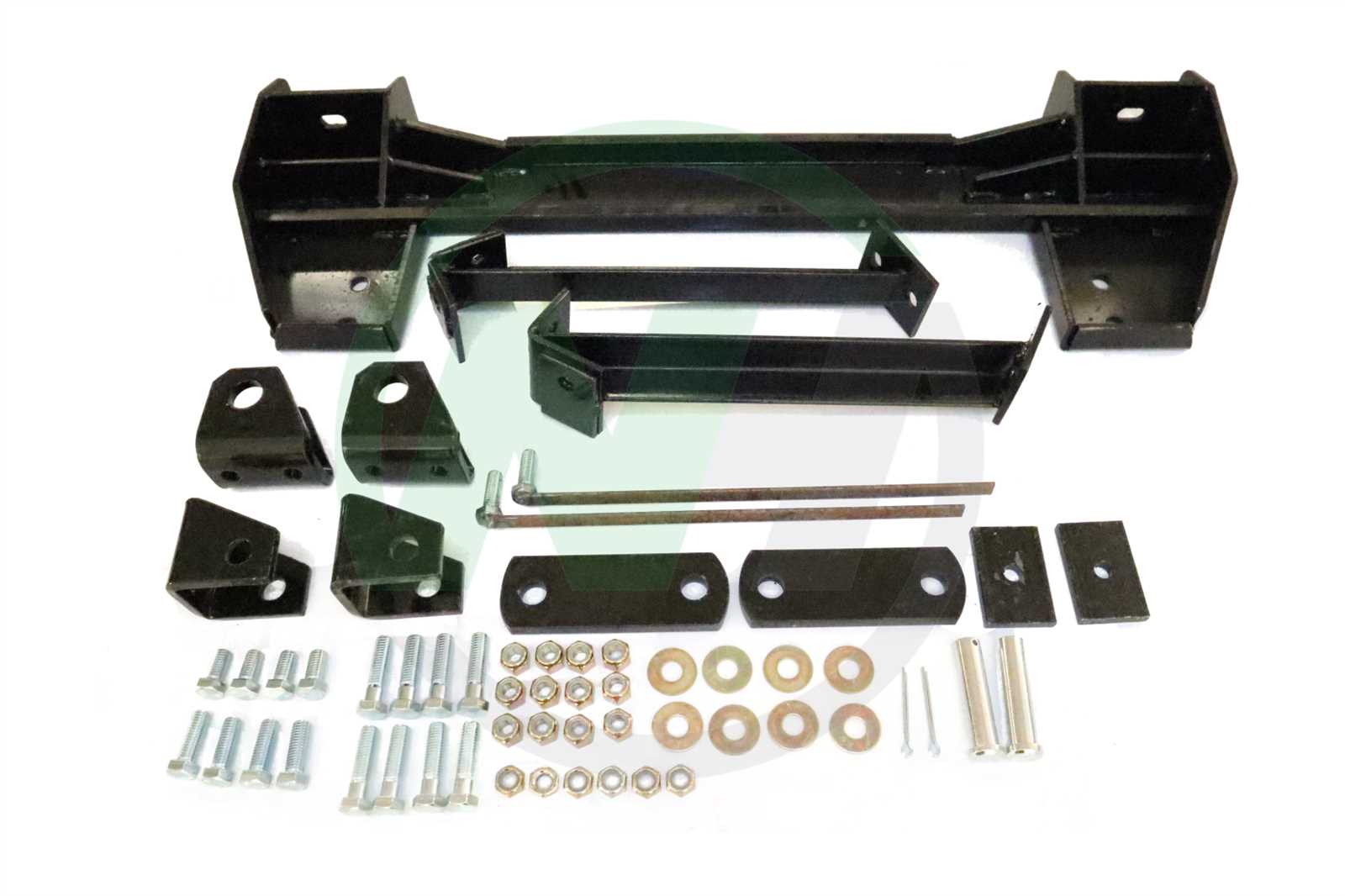

This section provides a comprehensive overview of a specific mounting system commonly used in various applications. The focus will be on understanding its components, functionality, and the best practices for maintenance to ensure optimal performance.

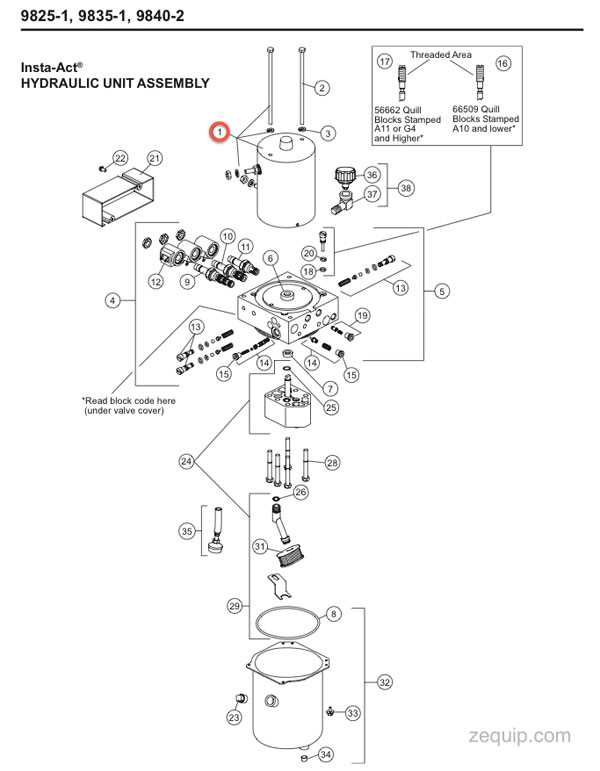

Components of the System

The system consists of several key elements that work together to provide stability and efficiency. Each component plays a vital role in the overall function, making it essential to comprehend how they interact.

Maintenance Tips

Regular upkeep is crucial to prevent issues and enhance longevity. Implementing straightforward maintenance practices can significantly improve the functionality and reliability of the system.

| Component | Function | Maintenance Frequency |

|---|---|---|

| Mounting Bracket | Supports and stabilizes | Every 6 months |

| Adjustment Mechanism | Allows for alignment | Every 3 months |

| Fasteners | Secures components together | Monthly |

Common Issues and Solutions

This section addresses frequent challenges encountered with the equipment and provides effective solutions to resolve them. Understanding these issues can enhance the overall performance and longevity of the system.

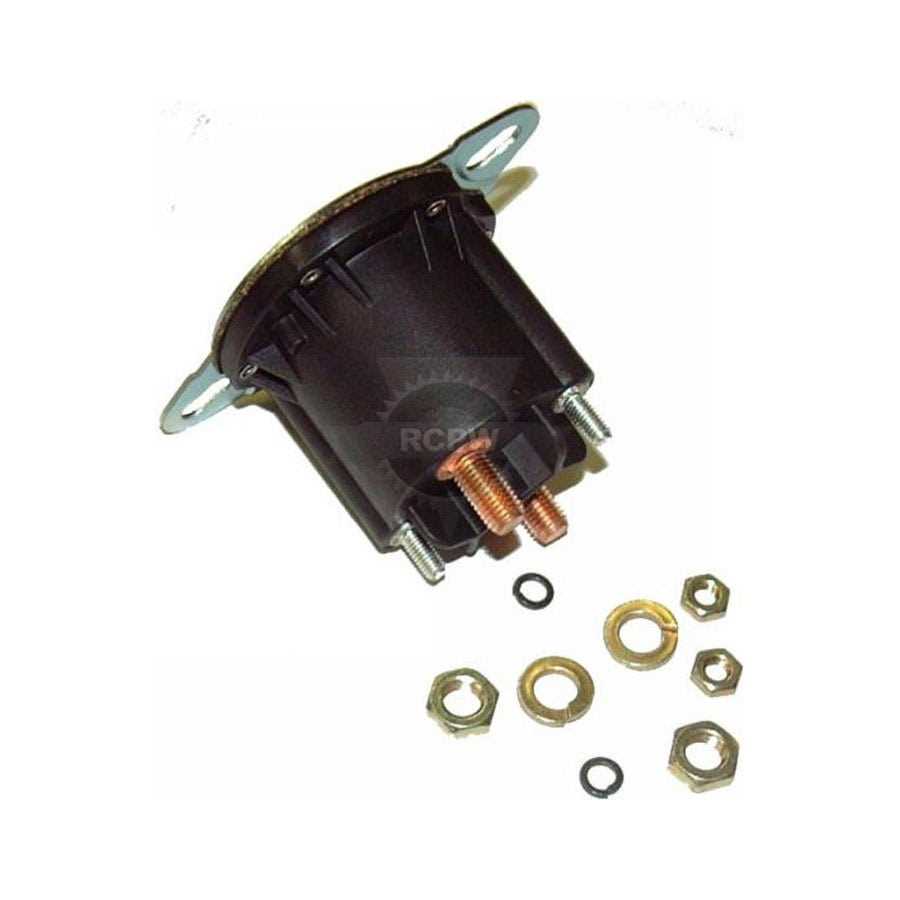

- Electrical Failures:

- Check all connections for corrosion or damage.

- Ensure that the power source is stable and functional.

- Mechanical Malfunctions:

- Inspect for any loose components that may need tightening.

- Lubricate moving parts to prevent friction-related issues.

- Performance Degradation:

- Regularly clean filters and other components to ensure optimal airflow.

- Monitor usage patterns and adjust settings as necessary.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and servicing tasks. Proper tools ensure that the process is efficient and the results are reliable. Below are some of the key instruments necessary for handling various maintenance activities.

- Wrenches: Adjustable and socket wrenches are vital for loosening or tightening bolts.

- Screwdrivers: Both flat-head and Phillips screwdrivers are essential for working with different types of screws.

- Plier Set: A variety of pliers, including needle-nose and cutting pliers, are useful for gripping and cutting wires.

- Torque Wrench: This tool is important for applying a specific torque to bolts, ensuring proper fastening.

- Diagnostic Tools: Multimeters and pressure gauges help in assessing electrical systems and fluid levels.

Utilizing these essential tools can greatly enhance the quality of work and extend the lifespan of the equipment. It is advisable to invest in high-quality instruments to ensure durability and efficiency in all tasks.

Step-by-Step Repair Process

This section outlines a systematic approach to address issues commonly encountered with the equipment. Following these guidelines will help ensure effective resolution and restore functionality efficiently.

1. Initial Assessment: Begin by evaluating the condition of the device. Identify any visible damages or irregularities that may require attention.

2. Gather Tools: Assemble the necessary tools and replacement parts needed for the task. This may include wrenches, screwdrivers, and any specific components pertinent to the job.

3. Disassembly: Carefully take apart the unit, ensuring that each component is removed in the correct order. Document the process or take photographs to aid in reassembly.

4. Inspection: Examine each part for wear, corrosion, or any signs of malfunction. Pay close attention to critical areas that might affect overall performance.

5. Replacement: Replace any damaged or worn-out parts with new ones. Ensure that the components are compatible and properly fitted to avoid future complications.

6. Reassembly: Follow the documentation from the disassembly phase to put the unit back together. Ensure that all screws and fasteners are securely tightened.

7. Testing: Once reassembled, conduct a thorough test to confirm that the device operates as intended. Monitor for any unusual sounds or behaviors that may indicate further issues.

8. Final Review: After successful testing, perform a final check to ensure everything is in place. Clean the area and properly dispose of any waste materials.

Maintenance Tips for Longevity

Proper care and attention can significantly extend the lifespan of your equipment. By implementing regular maintenance practices, you can ensure optimal performance and prevent unexpected breakdowns.

Here are some essential maintenance tips to follow:

| Tip | Description |

|---|---|

| Regular Inspections | Conduct thorough inspections periodically to identify wear and tear. Check for loose parts and ensure everything is securely fastened. |

| Cleaning | Keep the equipment clean by removing dirt and debris. Regular cleaning prevents buildup that can lead to malfunction. |

| Lubrication | Apply appropriate lubricants to moving parts to reduce friction and prevent premature wear. |

| Storage | When not in use, store the equipment in a dry and protected environment to avoid damage from elements. |

Parts Replacement Guide

This section provides essential information on how to effectively substitute components within the system. Properly replacing parts ensures optimal functionality and prolongs the lifespan of your equipment.

Common Components to Replace

- Blades: Ensure they are sharp and free of damage for effective performance.

- Electrical connections: Check for wear and tear, replacing any faulty wires or connectors.

- Hydraulic hoses: Inspect for leaks and replace if any signs of deterioration are found.

- Mounting brackets: Ensure they are secure and free from rust or corrosion.

Replacement Procedure

- Identify the part that needs replacement.

- Gather necessary tools and new components.

- Follow the manufacturer’s guidelines for removal and installation.

- Test the system after replacement to ensure proper functionality.

Safety Precautions During Repairs

When undertaking maintenance on machinery, prioritizing safety is crucial to ensure a secure working environment. Adhering to established guidelines helps prevent accidents and protects both the individual and the equipment.

General Guidelines

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and helmets.

- Ensure the workspace is clean and free of hazards to minimize risks.

- Maintain proper ventilation in enclosed areas to avoid inhaling harmful fumes.

- Be aware of your surroundings and ensure that others are at a safe distance.

Equipment Handling

- Before starting, disconnect power sources to prevent accidental activation.

- Use tools correctly and only for their intended purpose.

- Inspect all equipment for damage or wear prior to use.

- Follow the manufacturer’s guidelines for any specific safety measures.

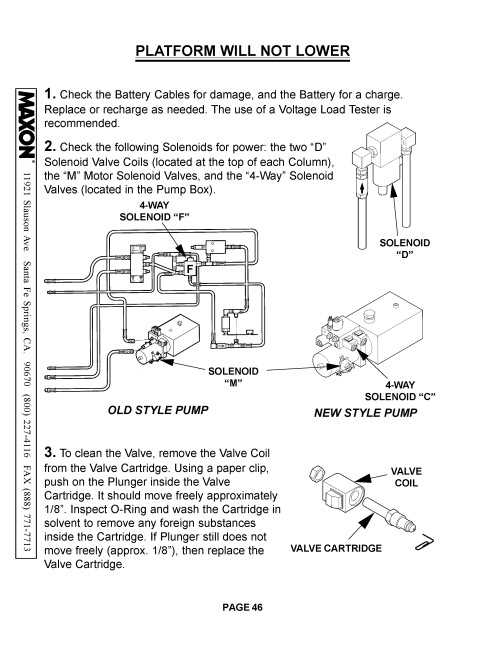

Troubleshooting Electrical Problems

Electrical issues can significantly impact the performance of your equipment. Identifying and resolving these challenges promptly is crucial for ensuring functionality and safety. This section provides guidance on common electrical malfunctions and their potential solutions.

Check Power Supply

Begin by verifying the power source. Ensure that all connections are secure and that the circuit is operational. A blown fuse or tripped circuit breaker can often be the culprit behind a lack of power.

Inspect Wiring and Connections

Examine the wiring for any visible damage or corrosion. Loose or frayed wires can lead to intermittent issues. Make sure all connectors are tight and free of debris to promote a stable electrical flow.

Test Electrical Components

If the power supply and wiring appear intact, test individual components such as switches, relays, and sensors. Utilize a multimeter to check for continuity and ensure that each part functions as intended.

Consult Technical Resources

If problems persist despite thorough troubleshooting, refer to technical documentation or seek assistance from qualified professionals. Accurate information and expert guidance can help pinpoint and resolve complex issues effectively.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and troubleshooting for the equipment in question. Here, users can find answers to prevalent concerns that may arise during usage, ensuring a smoother experience.

Common Issues and Solutions

Many users encounter similar challenges, and understanding these can help in resolving them effectively. Below are some frequent problems and their corresponding solutions.

| Issue | Solution |

|---|---|

| Difficulty in operation | Check for any loose connections and ensure all components are securely attached. |

| Inconsistent performance | Inspect for blockages and clean any dirt or debris that may affect functionality. |

| Strange noises | Look for any foreign objects or wear in parts that may cause unusual sounds. |

Maintenance Tips

Regular upkeep can prolong the lifespan of your equipment. Here are some essential maintenance tips:

- Perform routine checks on all connections.

- Keep the unit clean and free from debris.

- Follow the manufacturer’s guidelines for lubrication and servicing.

Resources for Further Assistance

When seeking additional support for maintenance or troubleshooting, various resources can be invaluable. These tools can provide insights, guidance, and community knowledge to enhance your understanding and skills.

Consider exploring online forums where enthusiasts and experts share their experiences. These platforms often contain a wealth of shared information, tips, and solutions to common issues.

Additionally, manufacturer websites may offer downloadable resources, including instructional videos and troubleshooting guides, ensuring you have access to the latest information.

Lastly, local workshops or service centers can provide hands-on assistance, allowing for a more personalized approach to learning and problem-solving.