Comprehensive Guide to Wheel Horse Repair Manual

Ensuring the longevity and efficiency of your machinery is essential for optimal performance. This section delves into the intricate details of upkeep and troubleshooting techniques that every operator should be familiar with. Whether you’re a seasoned expert or a novice, understanding the fundamentals of your device can significantly enhance its lifespan.

In this informative piece, you will discover various strategies for addressing common challenges that may arise during operation. By learning how to identify issues early and implementing effective solutions, you can prevent minor problems from escalating into major setbacks. Each step outlined here is designed to empower you, providing the confidence needed to tackle maintenance tasks with ease.

Additionally, we will cover important safety considerations that should always be at the forefront of your maintenance routine. Prioritizing safety not only protects you but also ensures the reliability of your machinery. With the right knowledge and tools, you can keep your equipment running smoothly and efficiently for years to come.

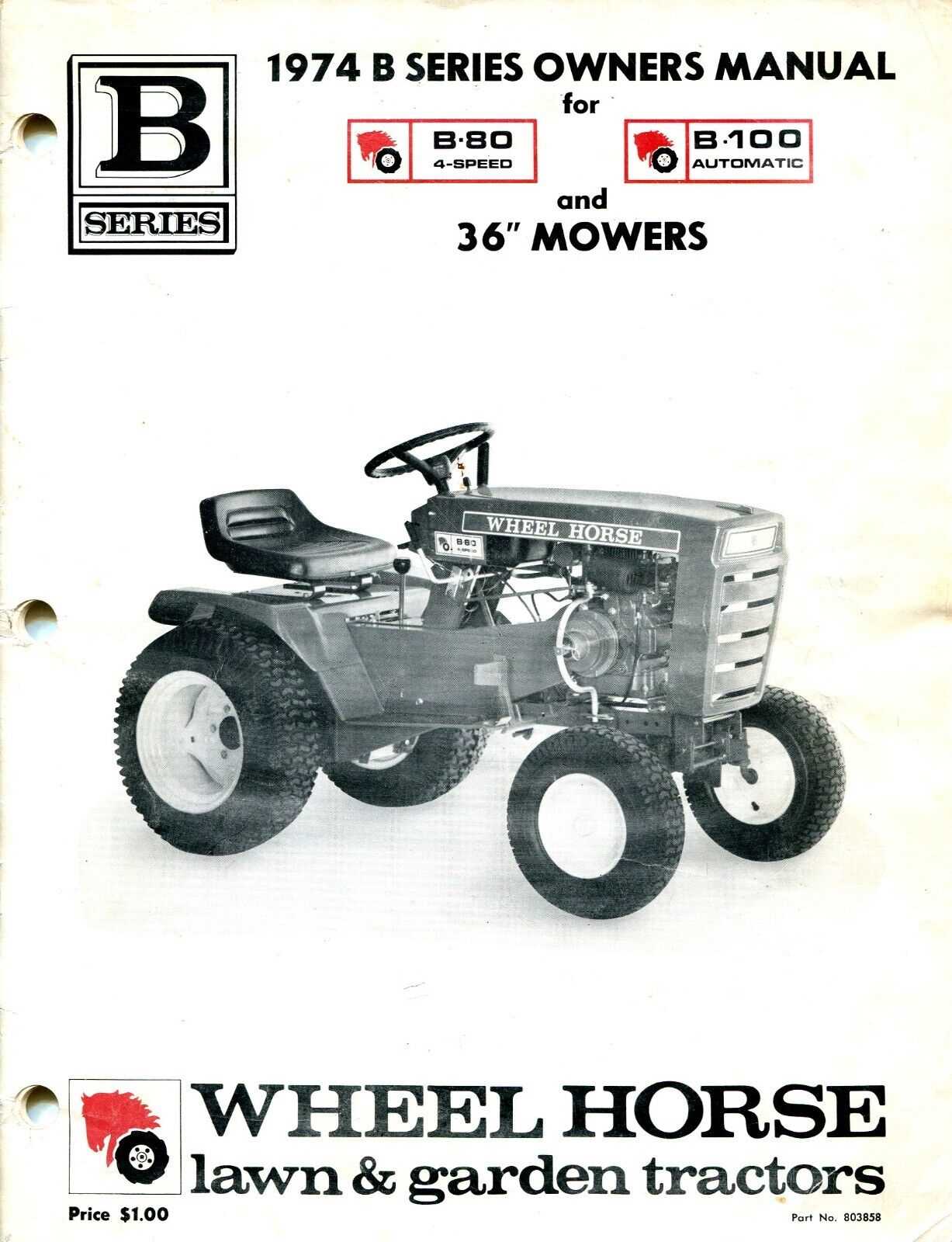

Understanding Wheel Horse Models

This section aims to provide insight into the various types of garden tractors, emphasizing their unique features and capabilities. Each model possesses distinct characteristics that cater to different landscaping needs and user preferences.

Models in this category are often classified based on several key factors:

- Engine Size: Ranging from small, efficient engines suitable for light tasks to more powerful options designed for heavy-duty operations.

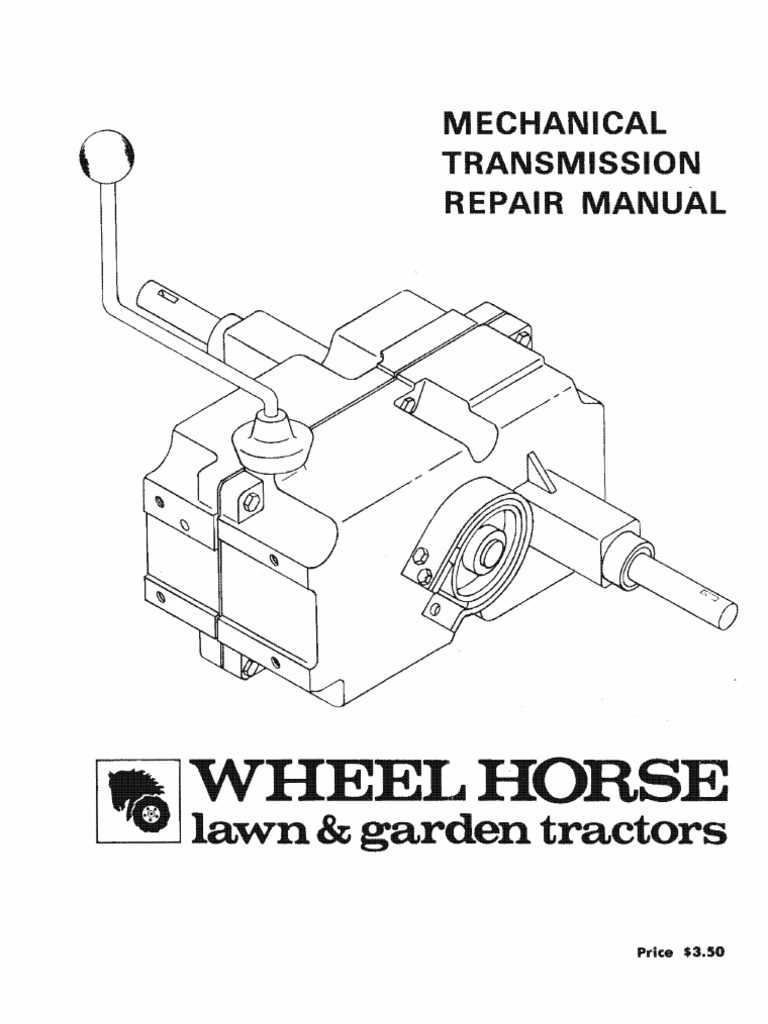

- Transmission Type: Options may include manual and automatic systems, affecting ease of use and performance.

- Design Features: Elements such as frame construction and wheel configuration can impact stability and maneuverability.

- Attachment Compatibility: Many models offer versatility through various attachments, enhancing functionality for different applications.

Understanding these classifications helps users select the right equipment based on their specific landscaping requirements and personal preferences.

Common Issues with Wheel Horse Tractors

Many users encounter various challenges while operating these versatile garden machines. Understanding the most frequent problems can help owners troubleshoot effectively and maintain optimal performance.

| Issue | Description | Possible Solutions |

|---|---|---|

| Starting Difficulties | Engine fails to turn over or starts inconsistently. | Check the battery, ignition system, and fuel supply. |

| Poor Performance | Loss of power or slow operation under load. | Inspect air filters, spark plugs, and fuel lines. |

| Transmission Issues | Problems with shifting gears or slipping. | Examine fluid levels, linkage, and wear on components. |

| Hydraulic Failures | Inadequate lifting power or slow response in attachments. | Check hydraulic fluid levels and inspect hoses for leaks. |

| Excessive Vibration | Unusual shaking or noise during operation. | Balance wheels, check for loose parts, and inspect the deck. |

Tools Needed for Repairs

When it comes to maintaining and fixing your equipment, having the right instruments at your disposal is crucial. These essential items not only facilitate the process but also ensure that the job is done efficiently and effectively. Being well-prepared with the appropriate tools can save time and prevent potential mishaps.

Essential Hand Tools

Basic hand tools are the foundation of any maintenance task. Items such as wrenches, pliers, and screwdrivers are indispensable. They enable you to tackle a variety of issues, from loosening tight components to making precise adjustments. Investing in a quality set of these tools can greatly enhance your capabilities.

Power Tools and Equipment

In addition to hand tools, power tools can significantly expedite the repair process. Drills, grinders, and impact wrenches are examples of equipment that can provide the extra power needed for more demanding tasks. Utilizing these tools can lead to a more thorough and timely completion of your projects.

Step-by-Step Repair Procedures

This section outlines a systematic approach to troubleshooting and fixing common issues that may arise with your machinery. By following these organized steps, you can ensure that you address problems effectively, minimizing downtime and maximizing performance.

Initial Assessment

Begin with a thorough examination of the equipment. Look for visible signs of wear, damage, or malfunction. Document any unusual sounds or behaviors that could indicate underlying issues. A keen observation will help in identifying the root cause of the problem.

Disassembly and Inspection

Once you have pinpointed the issue, carefully disassemble the components involved. Take notes or photographs to track the arrangement of parts for easier reassembly. Inspect each piece for damage, such as cracks, rust, or deformities. Pay special attention to moving parts that may require lubrication or replacement.

After completing the inspection, you can proceed with the necessary fixes, whether it involves replacing parts or making adjustments. Remember to reassemble everything methodically, ensuring each component is secured properly.

By adhering to these outlined procedures, you can effectively restore functionality and extend the lifespan of your equipment.

Maintenance Tips for Longevity

Ensuring the durability and efficient operation of your equipment requires consistent care and attention. By following a few essential practices, you can significantly extend its lifespan and maintain optimal performance.

Regular Inspection

- Check for wear and tear in components.

- Look for any signs of rust or corrosion.

- Examine belts and hoses for cracks or fraying.

Routine Cleaning

- Keep surfaces free from dirt and debris.

- Use appropriate cleaning solutions for specific materials.

- Inspect and clean air filters regularly to ensure proper airflow.

By implementing these simple maintenance strategies, you can ensure that your equipment remains in excellent condition for years to come.

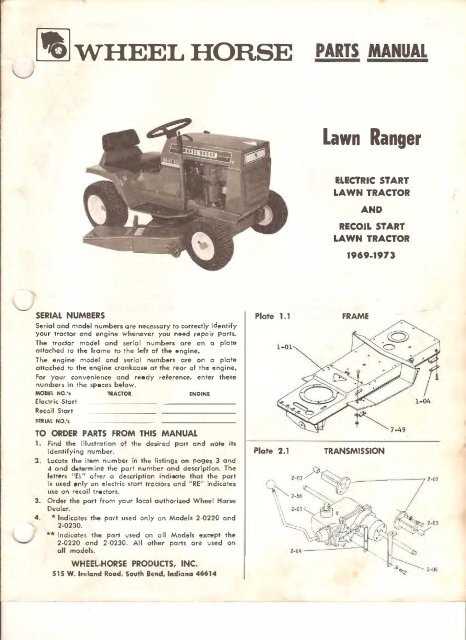

Identifying Replacement Parts

When it comes to maintaining equipment, recognizing the right components for substitution is crucial. Understanding the specifics of each part not only ensures optimal performance but also prolongs the lifespan of your machinery. This section aims to guide you through the process of identifying and sourcing the necessary elements for effective upkeep.

Assessing Component Compatibility

The first step in identifying suitable substitutes is to evaluate the compatibility of components. This includes checking dimensions, materials, and functionality. By cross-referencing existing parts with manufacturer specifications, you can determine which alternatives will seamlessly fit your machinery.

Utilizing Resources for Identification

Several resources can aid in the identification process. Catalogs, online databases, and community forums are valuable tools for discovering the right components. Additionally, consulting with experts or experienced users can provide insights that are not readily available in manuals or guides.

Safety Precautions During Repairs

Ensuring a safe environment is paramount when undertaking maintenance tasks. Following certain guidelines not only protects the individual performing the work but also preserves the integrity of the equipment being serviced. Understanding and implementing these measures can significantly reduce the risk of accidents and injuries.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes gloves to prevent cuts and abrasions, goggles to shield the eyes from debris, and steel-toed boots to protect the feet from heavy objects. Additionally, using ear protection when working with loud machinery can help avoid long-term hearing damage.

Workspace Organization

Maintaining a tidy and organized workspace is critical. Clutter can lead to slips, trips, and falls. Ensure that all tools are stored properly and that hazardous materials are clearly labeled and secured. Implementing a routine check for potential hazards can create a safer environment and enhance overall efficiency during maintenance activities.

Lubrication and Fluid Management

Effective maintenance of machinery relies heavily on proper lubrication and fluid management. These processes are crucial for ensuring the longevity and optimal performance of equipment. Regular attention to lubricants and fluids minimizes wear and tear, reduces the risk of overheating, and enhances overall efficiency.

Importance of Regular Lubrication

Consistent lubrication is vital in preventing friction between moving parts. By applying the right type and amount of lubricant, you create a protective barrier that helps to decrease wear and tear. Additionally, regular checks and replenishments of lubricants ensure that the machinery operates smoothly, ultimately extending its service life.

Fluid Types and Maintenance Tips

Different types of machinery require specific fluids for optimal operation. It is essential to understand the distinctions between hydraulic fluids, engine oils, and other lubricants. Regularly monitoring fluid levels and maintaining cleanliness are key practices. Schedule periodic inspections and replace fluids as recommended by the manufacturer to avoid contamination and degradation.

Troubleshooting Electrical Problems

Addressing issues related to electrical systems can be challenging, yet understanding the common signs and symptoms can significantly simplify the diagnostic process. Identifying the root cause of malfunctioning components requires a systematic approach, allowing for effective resolution and restoration of functionality.

Start by examining the power source. Ensure that connections are secure and that there is no visible damage to cables or connectors. A multimeter can be a valuable tool for measuring voltage levels, helping to pinpoint whether the issue lies within the power supply or downstream components.

Next, assess the circuit for any signs of short circuits or blown fuses. These problems often manifest through unexpected shut-downs or failures to operate. Inspecting the wiring for frayed or exposed areas can help identify potential hazards that may disrupt performance.

If the electrical system features switches or relays, test their operation individually. A faulty switch can prevent power from reaching the intended components, causing a range of operational issues. By isolating each part, one can determine whether they are functioning as expected.

Finally, don’t overlook the importance of grounding. An inadequate ground can lead to erratic behavior or intermittent faults. Ensuring proper grounding throughout the system can help stabilize performance and enhance overall safety.

Restoration Techniques for Vintage Models

Revitalizing classic machinery requires a thoughtful approach to preserve its character while ensuring functionality. Understanding the unique challenges associated with vintage equipment is crucial for enthusiasts and restorers alike. This section outlines effective methods and considerations for restoring cherished models, focusing on both aesthetic appeal and mechanical reliability.

One of the first steps in the restoration process is assessing the condition of the unit. This evaluation will help in planning the required tasks and determining the necessary resources. Key aspects to consider include:

| Aspect | Description |

|---|---|

| Structural Integrity | Check for any signs of damage, rust, or wear that could compromise the unit’s stability. |

| Mechanical Functionality | Test all moving parts to identify any issues with performance or responsiveness. |

| Aesthetic Condition | Evaluate the finish and appearance, noting areas that require repainting or refinishing. |

Once the assessment is complete, the restoration process can begin. Key techniques include:

- Disassembly: Carefully take apart the components to access internal mechanisms.

- Cleaning: Use appropriate solvents and methods to remove grime and corrosion from surfaces.

- Repairs: Address any structural or mechanical issues using suitable materials and techniques.

- Repainting: Apply a high-quality finish to restore the original appearance while protecting against future wear.

Lastly, after completing the restoration, it is essential to perform thorough testing to ensure that the equipment operates as intended. Regular maintenance and careful storage can help preserve the restoration for years to come.