Xantrex Inverter Repair Guide

Understanding the intricacies of electrical devices that transform one form of energy into another is crucial for ensuring their longevity and efficiency. These systems are integral in various applications, from residential to industrial setups, allowing users to harness power in versatile ways. This section provides insights into common issues, maintenance practices, and effective solutions to optimize performance.

As users engage with these essential components, they may encounter challenges that hinder functionality. By familiarizing oneself with typical malfunctions and learning how to address them, individuals can save time and resources. This guide aims to empower users with the knowledge needed to troubleshoot effectively and maintain these vital systems.

Through detailed explanations and practical tips, this resource serves as a valuable tool for anyone seeking to enhance their understanding of energy transformation devices. Whether you’re a novice or an experienced technician, the information provided here will aid in identifying problems and implementing corrective measures, ensuring seamless operation.

Xantrex Inverter Repair Manual Overview

This section provides a comprehensive overview of guidance documents designed to assist in the troubleshooting and restoration of power conversion devices. These resources aim to equip users with the necessary information to effectively address common issues and ensure optimal functionality.

Key aspects covered include:

- Understanding device components and their functions.

- Identifying frequent malfunctions and their causes.

- Step-by-step troubleshooting procedures.

- Maintenance tips to prolong lifespan and efficiency.

- Safety precautions during diagnostics and fixes.

Utilizing these resources can significantly enhance the knowledge and skills required for effective handling of power management systems, leading to improved performance and reliability.

Common Issues and Troubleshooting Tips

In the realm of power conversion systems, various challenges may arise that can hinder optimal performance. Identifying these typical problems and employing effective solutions can greatly enhance functionality and longevity.

Frequent Problems Encountered

One of the most prevalent issues involves unexpected shutdowns, often triggered by overheating or overload situations. Additionally, users may experience fluctuating output voltages, which can lead to inefficient power delivery and potential damage to connected devices. Furthermore, noise during operation can indicate internal faults or inadequate grounding.

Effective Solutions

To address sudden power losses, ensure proper ventilation around the device and avoid overloading the system by checking the connected load. For voltage inconsistencies, verifying the integrity of wiring and connections is essential. If unwanted noise persists, inspecting grounding connections and internal components can help identify the source of the issue.

Proactive maintenance and regular inspections are vital in preventing many common challenges, ensuring that the system operates smoothly and efficiently.

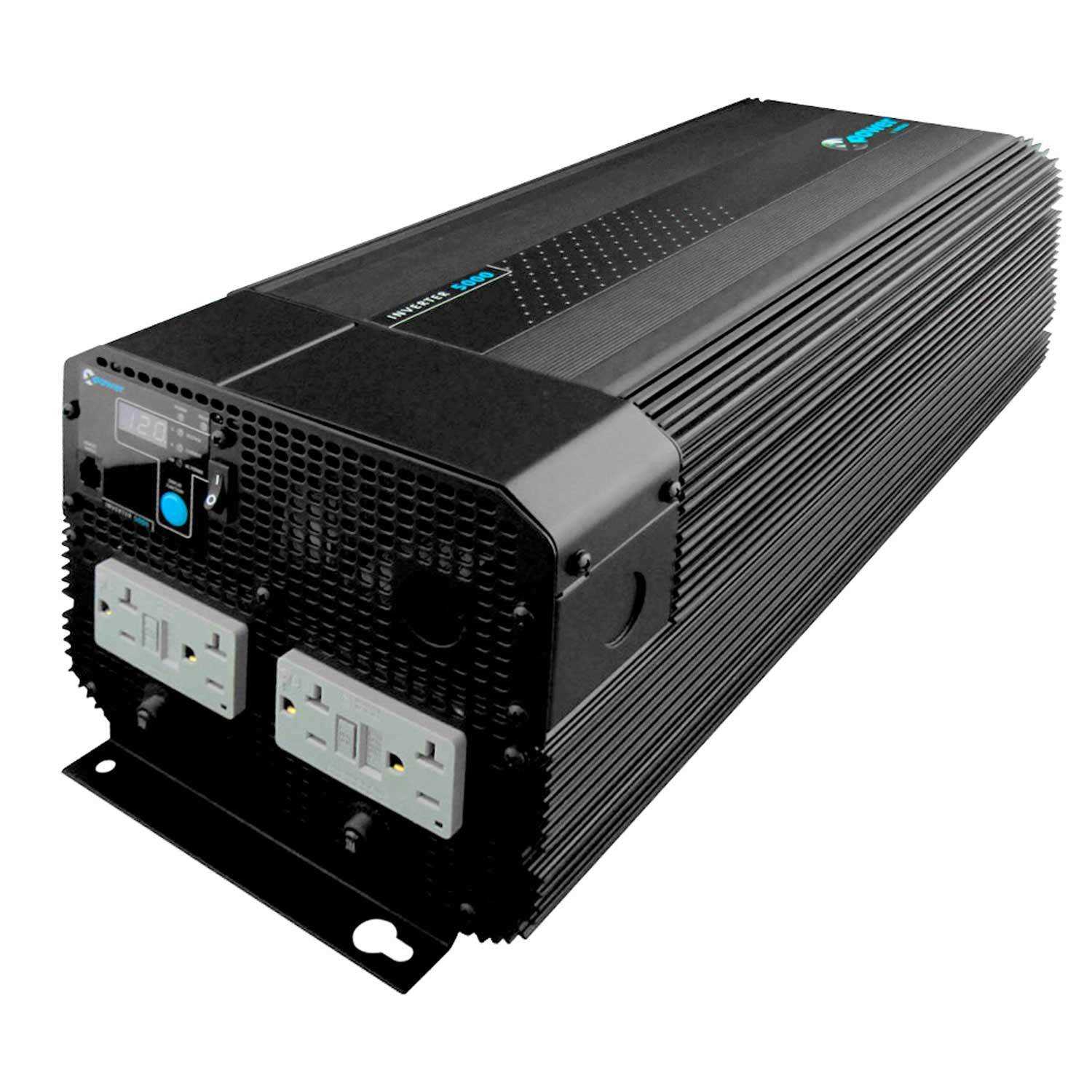

Understanding Xantrex Inverter Components

Grasping the essential elements of power conversion devices is crucial for effective troubleshooting and maintenance. Each component plays a significant role in the overall functionality, impacting performance and reliability. A thorough comprehension of these parts allows users to address issues efficiently and enhance the longevity of the system.

| Component | Description |

|---|---|

| Transformer | Transforms voltage levels to ensure compatibility with various electrical systems. |

| Capacitor | Stores electrical energy and helps in stabilizing voltage fluctuations. |

| Cooling Fan | Maintains optimal operating temperatures by dissipating heat generated during operation. |

| Control Circuit | Monitors and regulates the device’s operations, ensuring safe and efficient performance. |

| Output Socket | Facilitates the connection of electrical devices, providing the necessary power supply. |

Step-by-Step Repair Procedures

This section outlines a comprehensive approach to troubleshooting and restoring functionality to malfunctioning power conversion devices. Following these detailed steps will help identify and address common issues effectively.

-

Preparation: Gather the necessary tools and safety equipment before beginning the process.

- Screwdriver set

- Multimeter

- Insulation gloves

- Work surface

-

Initial Inspection: Examine the device for any visible signs of damage or wear.

- Look for burnt components

- Check for loose connections

- Inspect for corrosion or debris

-

Electrical Testing: Use a multimeter to test the internal circuits and components.

- Measure voltage levels at various points

- Check for continuity in critical connections

- Identify any components that may be out of specification

-

Component Replacement: If faulty components are found, carefully replace them with compatible parts.

- Desolder defective parts

- Install new components following manufacturer specifications

- Ensure proper orientation and secure connections

-

Reassembly: Once all necessary replacements have been made, reassemble the unit carefully.

- Ensure all screws and fasteners are tightened

- Reattach covers and panels securely

-

Final Testing: Conduct a thorough operational test to verify functionality.

- Monitor performance under load conditions

- Check for any unusual noises or overheating

- Confirm that all indicators and outputs operate as expected

Following these systematic procedures can significantly increase the chances of restoring performance and ensuring long-term reliability of the unit.

Safety Precautions During Repair

When undertaking maintenance on electronic devices, it is essential to prioritize safety to prevent accidents and ensure a successful outcome. Adhering to established guidelines not only protects the technician but also extends the longevity of the equipment being worked on.

General Guidelines

Before beginning any work, familiarize yourself with the specific equipment and its components. Ensure that the power source is disconnected to prevent electrical shock. Using insulated tools and wearing appropriate personal protective equipment, such as gloves and goggles, can significantly reduce risks during the procedure.

Environment Considerations

Create a clean and organized workspace to minimize hazards. Remove any unnecessary items that could obstruct movement or cause accidents. Good ventilation is crucial, especially when working with components that may emit fumes or dust. Keeping the area well-lit will help identify potential issues quickly and enhance overall safety.

Testing and Diagnostic Tools Required

To effectively assess the functionality of your power conversion system, having the right tools is essential. These instruments not only facilitate accurate measurements but also help identify potential issues, ensuring reliable performance.

Here are some key tools you will need:

- Multimeter: Essential for measuring voltage, current, and resistance, allowing you to troubleshoot electrical problems efficiently.

- Oscilloscope: Useful for observing the waveforms and characteristics of electrical signals, which can reveal abnormalities.

- Clamp Meter: Ideal for measuring current without needing to disconnect wires, making it safe and convenient.

- Load Tester: Helps simulate actual usage conditions to evaluate performance under load.

- Thermal Camera: Useful for identifying overheating components that may indicate underlying issues.

By utilizing these tools, you can systematically diagnose problems, enhancing the reliability of your system and prolonging its lifespan.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of power conversion devices involves consistent care and attention. Regular upkeep not only enhances efficiency but also extends the overall lifespan of the equipment.

1. Regular Cleaning: Dust and debris can accumulate and affect performance. It is essential to keep the exterior clean and free of obstructions. Use a soft cloth and a mild cleaning solution to wipe down surfaces.

2. Check Connections: Loose or corroded connections can lead to inefficiencies and potential failures. Periodically inspect all terminals and cables, ensuring they are tight and free from corrosion.

3. Monitor Temperature: Excessive heat can shorten the life of any electrical device. Ensure that the unit is placed in a well-ventilated area, away from direct sunlight and heat sources. Consider using a cooling fan if necessary.

4. Regular Testing: Performing routine checks on functionality can help identify issues before they escalate. Utilize diagnostic tools to assess performance and address any irregularities promptly.

5. Follow Manufacturer Guidelines: Adhering to the manufacturer’s recommendations for maintenance and usage is crucial. This includes recommended service intervals and operational limits to ensure optimal performance.

By implementing these maintenance practices, users can significantly enhance the durability and reliability of their power systems, leading to a more efficient and hassle-free experience.

Replacement Parts and Their Sources

When maintaining or restoring electronic power devices, identifying the necessary components for replacement is crucial. Understanding where to find quality parts can significantly influence the efficiency and longevity of the equipment. This section explores various sources for acquiring essential components to ensure optimal performance.

Authorized Distributors

One of the most reliable sources for obtaining replacement components is through authorized distributors. These vendors often stock genuine parts that meet the manufacturer’s specifications. Checking with local dealers or their online platforms can provide access to a range of compatible components suitable for various models.

Aftermarket Suppliers

Aftermarket suppliers also offer a viable alternative for replacement parts. These providers frequently feature a wider selection and competitive pricing. However, it’s essential to verify the compatibility and quality of these components before making a purchase. Reading customer reviews and product specifications can help ensure that the parts will meet your needs effectively.

Customer Support and Resources

Accessing reliable assistance and comprehensive resources is essential for users looking to enhance their experience with power conversion devices. This section outlines various avenues for obtaining help and information, ensuring that customers can navigate issues effectively.

Support is available through multiple channels, including online platforms and direct communication. Users are encouraged to explore FAQs, forums, and troubleshooting guides, which can provide immediate answers to common inquiries. Additionally, reaching out to customer service representatives can offer personalized assistance tailored to specific concerns.

| Resource Type | Description | Access Method |

|---|---|---|

| Online FAQs | A collection of frequently asked questions addressing common issues and solutions. | Website |

| User Forums | A platform for users to share experiences, tips, and solutions. | Online Community |

| Customer Service | Direct assistance from trained representatives for personalized support. | Phone/Email |

| Instructional Videos | Visual guides demonstrating setup and troubleshooting processes. | Video Platform |

Utilizing these resources can significantly enhance problem-solving capabilities and ensure a smooth experience with power management technologies.

Frequently Asked Questions About Repairs

This section aims to address common inquiries related to fixing energy conversion devices. Understanding the typical concerns can help users navigate the process more efficiently.

- What are the most common issues that arise?

- Power failure during operation

- Unusual noises coming from the unit

- Overheating during use

- How can I determine if my unit needs servicing?

- Check for warning indicators on the display

- Monitor performance inconsistencies

- Listen for abnormal sounds while functioning

- What tools do I need for basic troubleshooting?

- Multimeter for electrical testing

- Screwdriver set for access

- Cleaning supplies for maintenance

- Are there any safety precautions to consider?

- Always disconnect from power sources before inspection

- Use insulated tools to prevent electric shock

- Wear protective gear while handling components

- When should I consult a professional?

- If you encounter complex issues beyond basic troubleshooting

- When warranty coverage is applicable

- If you lack the necessary tools or expertise