Comprehensive Guide for JCB 3CX Backhoe Loader Maintenance and Repairs

Maintaining heavy machinery is crucial for ensuring optimal performance and longevity. Proper upkeep can prevent costly breakdowns and extend the life of your equipment. This section provides essential insights into the systematic care and troubleshooting techniques needed for complex machinery.

Understanding the inner workings of these powerful machines allows operators to identify potential issues early on. By familiarizing oneself with operational guidelines and maintenance procedures, users can effectively enhance functionality and minimize downtime. This guide emphasizes practical strategies and tips for efficient machine management.

From routine inspections to intricate adjustments, mastering the essential practices will empower operators to maintain high standards of performance. Utilizing the right tools and knowledge will ensure that equipment remains reliable and efficient, ready to tackle demanding tasks at any time.

Overview of JCB 3CX Features

This section provides a comprehensive insight into the notable characteristics of a well-regarded construction vehicle. Designed for versatility and efficiency, this machine is a popular choice in various excavation and earth-moving tasks.

Key Attributes

- Robust engine performance ensuring reliability and power

- Advanced hydraulic systems for enhanced lifting and digging capabilities

- Operator-friendly controls for intuitive handling

- Durable construction suitable for demanding work environments

Versatile Applications

- Ideal for construction and landscaping projects

- Efficient for utility installation and maintenance

- Effective in agricultural tasks and earth moving

- Useful in various other industrial applications

Essential Maintenance Practices for Operators

Regular upkeep of heavy machinery is crucial for ensuring optimal performance and longevity. Operators play a vital role in maintaining equipment, which directly impacts efficiency and safety on site. Implementing best practices not only enhances functionality but also minimizes the risk of unexpected breakdowns.

Routine Inspections

Conducting frequent checks is essential for identifying potential issues before they escalate. Operators should focus on the following areas:

- Fluid levels: Regularly check oil, coolant, and hydraulic fluid to ensure they are at appropriate levels.

- Filters: Inspect and replace air and fuel filters as needed to maintain engine performance.

- Tires and tracks: Examine for wear and damage to ensure safe mobility.

- Electrical systems: Test lights, signals, and battery connections for reliability.

Cleaning and Lubrication

Maintaining cleanliness and proper lubrication can significantly extend the life of the equipment. Operators should adhere to the following practices:

- Debris removal: Clear any dirt, mud, or debris from components after use to prevent wear and tear.

- Lubrication: Apply grease to moving parts and joints regularly to reduce friction and enhance performance.

- Washing: Periodically wash the machinery to prevent corrosion and maintain a professional appearance.

Common Repairs for Backhoe Loaders

Heavy machinery often requires attention to maintain optimal performance. Regular upkeep can help identify typical issues before they escalate, ensuring efficiency and longevity.

Among the frequent maintenance tasks, the following are essential:

| Repair Type | Description |

|---|---|

| Hydraulic System Maintenance | Checking fluid levels and inspecting hoses to prevent leaks and ensure proper operation. |

| Engine Troubleshooting | Examining belts, filters, and fluids to enhance performance and address starting issues. |

| Transmission Adjustments | Adjusting gears and fluid to facilitate smoother operation and response. |

| Electrical System Inspection | Testing batteries, connections, and wiring to avoid power failures. |

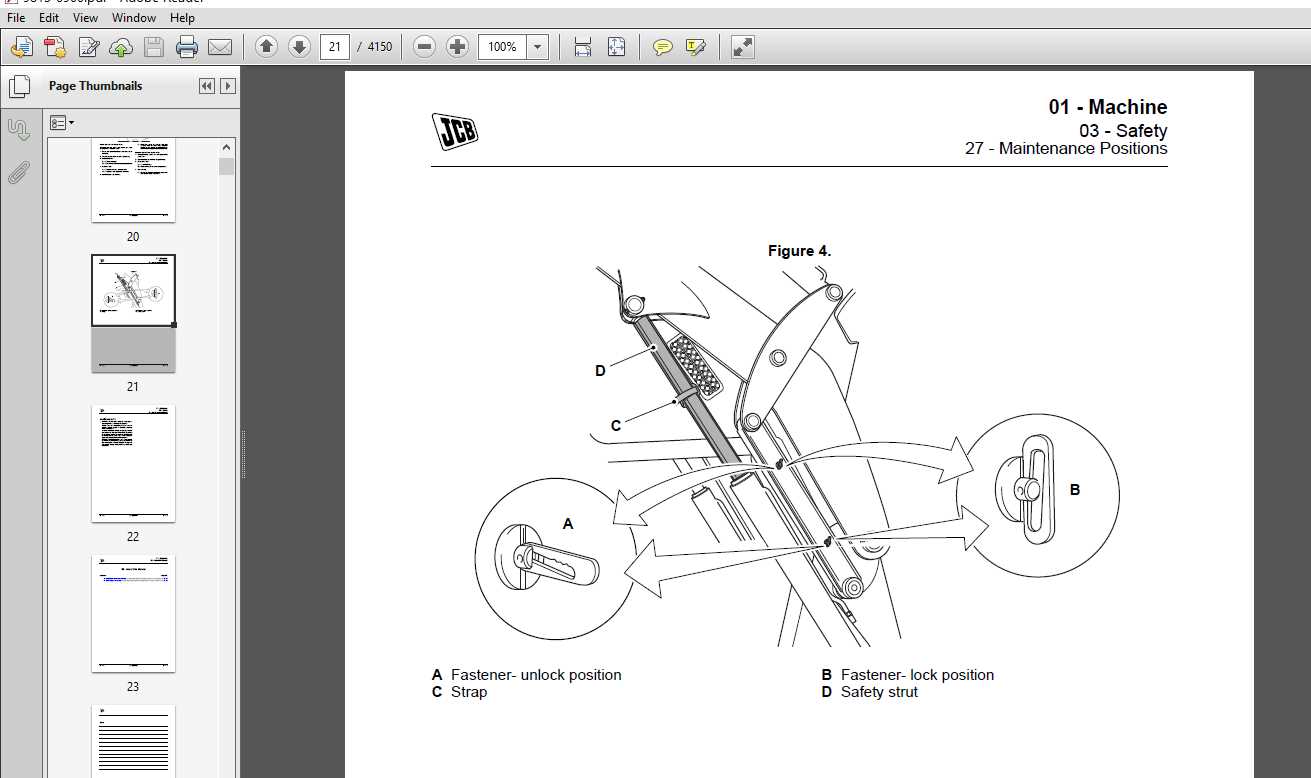

Safety Protocols During Service Tasks

Ensuring safety during maintenance activities is crucial for protecting both personnel and equipment. Implementing proper guidelines minimizes the risk of accidents and promotes a secure working environment. Awareness and adherence to safety measures foster an atmosphere where tasks can be completed efficiently and without incident.

Pre-Operation Guidelines

Before initiating any maintenance work, it is essential to conduct a thorough assessment of the work area. Clear any potential hazards and ensure adequate lighting is available. Additionally, the use of appropriate personal protective equipment (PPE) such as gloves, helmets, and eye protection is mandatory. Regular training on safety procedures enhances the preparedness of all team members.

During Operations

While performing tasks, continuous vigilance is key. Ensure that tools are in good condition and suitable for the job at hand. It is advisable to keep a first aid kit accessible and familiarize all personnel with its location. Emergency procedures should be well-known to the team, allowing for prompt action in case of an unforeseen incident. Regularly reviewing safety protocols can significantly improve overall compliance and awareness.

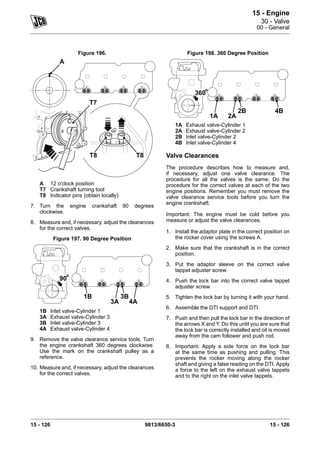

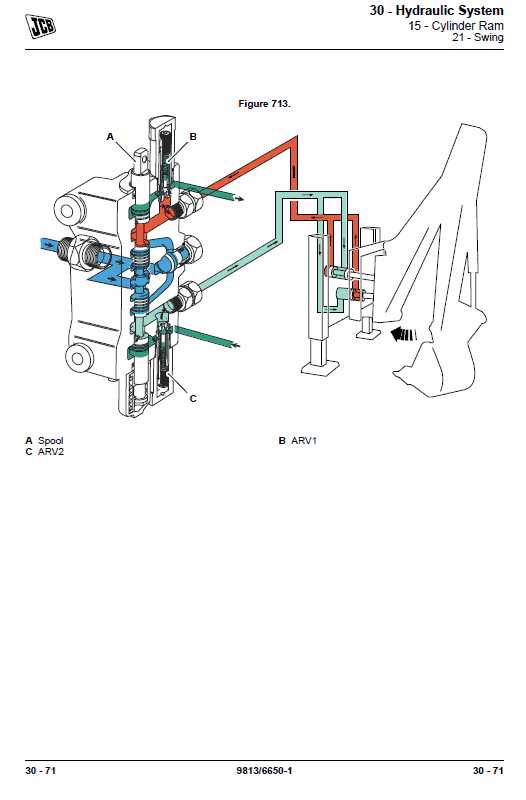

Understanding Hydraulic Systems in JCB

The hydraulic system plays a vital role in the functionality and efficiency of heavy machinery. This intricate network allows operators to manipulate various components with precision, enabling tasks such as lifting, digging, and transporting materials. A well-functioning hydraulic system is essential for maximizing performance and ensuring safety in operation.

Key Components of Hydraulic Systems

Hydraulic systems consist of several essential elements, each contributing to overall effectiveness:

- Pump: Converts mechanical energy into hydraulic energy, creating fluid flow.

- Actuator: Transforms hydraulic energy back into mechanical energy, performing physical work.

- Hydraulic fluid: Transmits power throughout the system and lubricates components.

- Valves: Control the direction and flow of hydraulic fluid, allowing for precise movements.

- Reservoir: Stores hydraulic fluid, ensuring a steady supply to the system.

Maintenance Considerations

To maintain optimal performance, regular checks and maintenance are crucial:

- Inspect hydraulic fluid levels and quality.

- Monitor for leaks in hoses and fittings.

- Ensure proper operation of pumps and valves.

- Clean or replace filters as needed to prevent contamination.

- Conduct pressure tests to verify system integrity.

Diagnostic Tools for Effective Troubleshooting

Utilizing the right diagnostic instruments is essential for identifying and resolving issues efficiently in heavy machinery. These tools not only facilitate a deeper understanding of mechanical and electronic systems but also enhance maintenance practices, ensuring optimal performance and longevity.

- Multimeter: A versatile device used for measuring voltage, current, and resistance, helping to pinpoint electrical faults.

- OBD-II Scanner: A tool that retrieves diagnostic trouble codes from the vehicle’s onboard computer, aiding in the identification of engine-related issues.

- Pressure Gauges: Instruments that measure hydraulic pressure, crucial for diagnosing problems in hydraulic systems.

- Thermal Imager: A device that visualizes temperature variations, useful for detecting overheating components.

- Vibration Analyzer: A tool that monitors vibration patterns, helping to identify mechanical imbalances and potential failures.

Each of these tools plays a significant role in the diagnostic process, allowing technicians to accurately assess conditions and implement timely interventions. By employing a combination of these instruments, operators can ensure their equipment runs smoothly and efficiently.

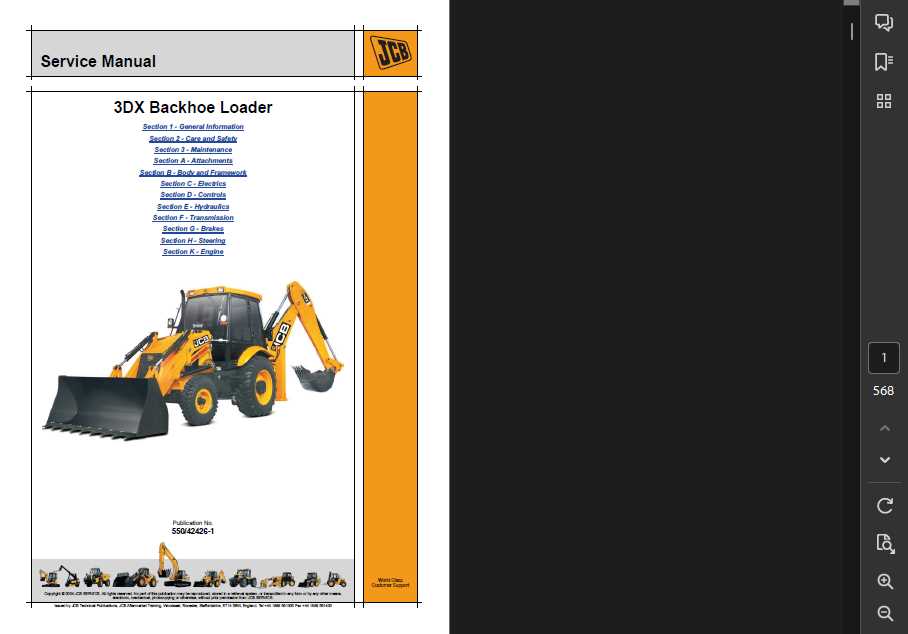

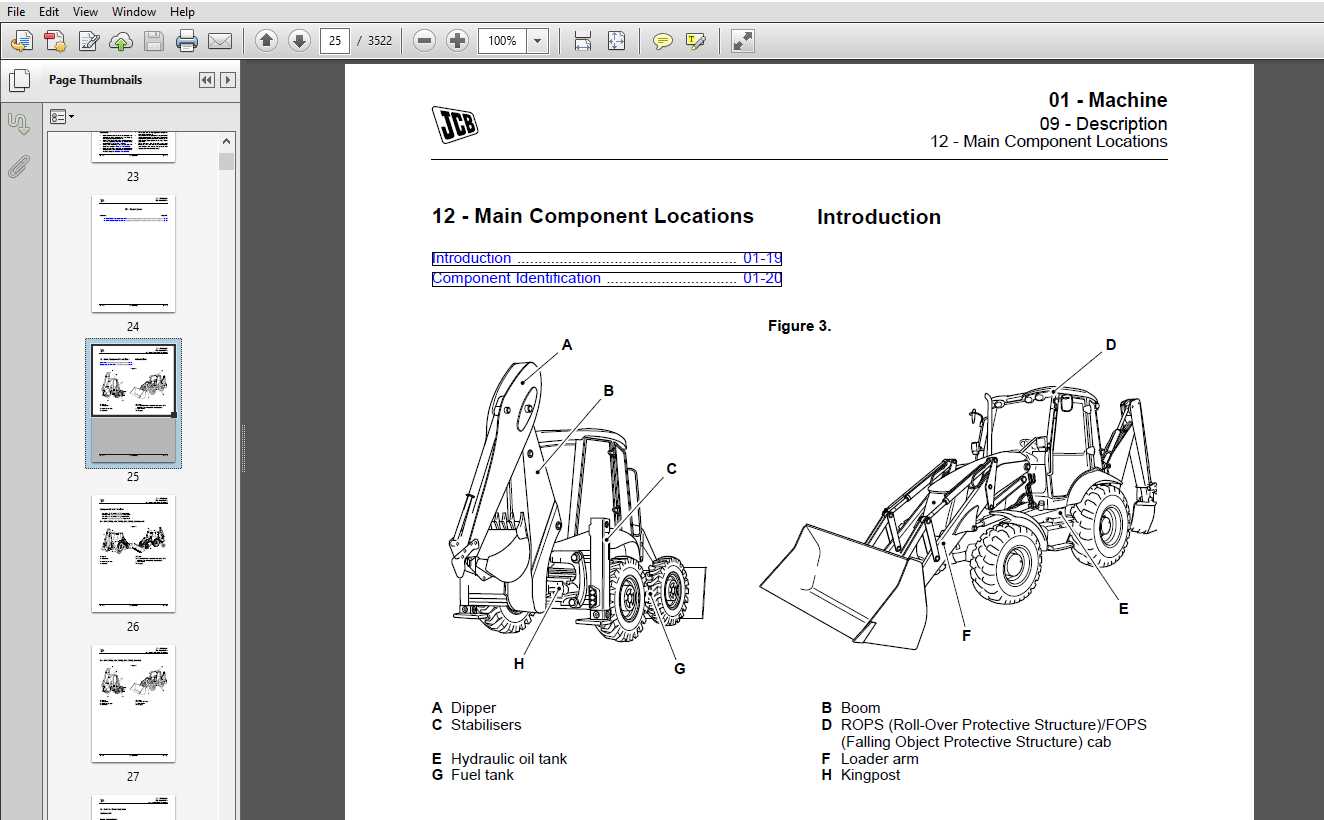

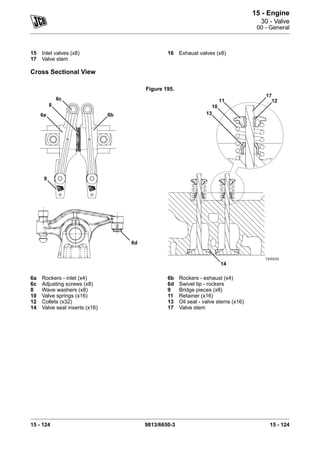

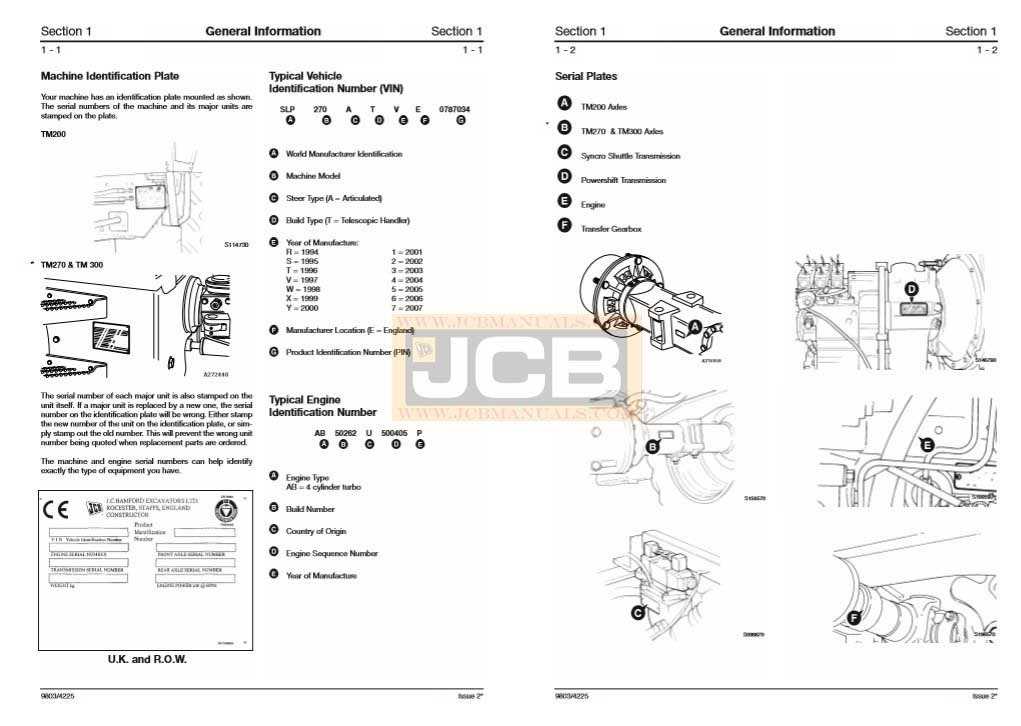

Parts Identification and Replacement Guide

This section aims to assist operators and technicians in recognizing various components of the machinery and understanding the process of their substitution. A thorough knowledge of each element’s function and characteristics is essential for maintaining optimal performance.

Identifying Components

Familiarity with the machinery’s parts allows for effective troubleshooting. Essential elements include hydraulic systems, electrical connections, and structural frames. Each part plays a crucial role in the overall functionality, making accurate identification vital.

Replacement Procedures

When it comes to replacing components, following the correct procedures is critical to ensure safety and efficiency. Begin by consulting the appropriate resources that outline the specifications and requirements for each part. Ensure to use quality replacements that meet or exceed the original standards.

Maintenance Tips

Regular inspections and timely replacements can prevent major failures. Keep a log of the parts that have been replaced, along with their performance data. This practice not only helps in tracking the machinery’s history but also aids in future maintenance planning.

Fuel Efficiency Tips for Backhoe Loaders

Maximizing fuel economy is essential for operating heavy machinery effectively. By adopting specific practices, operators can enhance performance while reducing fuel consumption. Below are some strategies to achieve better efficiency.

- Regular Maintenance: Ensure that the equipment is well-maintained. Regular checks on filters, fluids, and components can prevent unnecessary fuel use.

- Optimal Operation Techniques: Train operators on efficient handling techniques. Smooth movements and gradual acceleration can significantly reduce fuel expenditure.

- Proper Load Management: Avoid overloading the machine. Carrying excessive weight not only strains the engine but also leads to higher fuel consumption.

- Idle Reduction: Minimize idle time by turning off the engine during breaks or when not in use. This simple action can lead to considerable fuel savings.

- Utilize Advanced Technology: Consider investing in modern machinery equipped with fuel-saving technologies. These innovations can help optimize fuel usage and enhance overall efficiency.

By implementing these tips, operators can not only extend the lifespan of their equipment but also contribute to cost savings and environmental sustainability.

Recommended Lubricants and Fluids

Proper maintenance of machinery relies heavily on the use of suitable lubricants and fluids. Selecting the right products not only enhances performance but also extends the lifespan of the equipment. This section highlights essential substances that contribute to optimal functionality.

Hydraulic Fluids

Hydraulic fluids are critical for the efficient operation of hydraulic systems. It is advisable to choose fluids that offer excellent lubricating properties and temperature stability. Ensure compatibility with system components to prevent wear and ensure reliable performance.

Engine Oils

Engine oils play a vital role in protecting internal components from friction and wear. It is important to select high-quality oils that meet or exceed industry standards. Regularly checking oil levels and changing the oil as recommended will significantly improve engine health.

Customer Feedback and Service Insights

This section focuses on the experiences and perspectives of users regarding the machinery and its operational effectiveness. Understanding customer sentiments provides valuable insights into performance, durability, and overall satisfaction, which are crucial for enhancing future models and services.

Understanding User Perspectives

Feedback from operators reveals key aspects of functionality and reliability. Many appreciate the ease of use and the machine’s capability to handle various tasks efficiently. Positive remarks often highlight the robustness and efficiency during operation, contributing to high productivity levels.

Identifying Areas for Improvement

While there are many commendations, some users have pointed out challenges they face. Common issues include maintenance accessibility and the need for clearer guidelines to troubleshoot minor problems. Addressing these concerns can significantly enhance user experience and reduce downtime.

Upgrades to Enhance Loader Performance

Improving the functionality of construction machinery can significantly boost productivity and efficiency. Implementing strategic enhancements can lead to better operation, increased durability, and optimized fuel consumption. Below are some key upgrades to consider for elevating performance.

Engine Enhancements

- Upgrading to a high-efficiency air filter can improve airflow and enhance combustion.

- Installing a performance chip can optimize engine parameters, resulting in increased horsepower.

- Utilizing synthetic engine oil may reduce friction, leading to smoother operation and longer service intervals.

Hydraulic System Improvements

- Incorporating a hydraulic fluid cooler can prevent overheating, ensuring consistent power delivery.

- Upgrading hoses and fittings to high-pressure variants can enhance fluid flow and minimize leaks.

- Implementing a more advanced control system can improve response times and operational precision.