Comprehensive Guide to John Deere 110 Tractor Loader Backhoe Service and Repair

The effective upkeep of heavy machinery is essential for ensuring optimal performance and longevity. Understanding the intricacies of maintenance practices can significantly impact the efficiency of operations in various sectors, particularly in construction and agriculture. This resource delves into essential guidelines for preserving the functionality of specific models, equipping users with the knowledge needed for proper care.

Attention to detail in maintenance not only enhances productivity but also minimizes the risk of unexpected breakdowns. Users will discover various strategies and techniques tailored to the unique characteristics of this equipment. From routine checks to troubleshooting common issues, these insights aim to empower operators and technicians alike.

By engaging with comprehensive procedures, individuals can foster a deeper connection with their machinery. This engagement not only promotes safety but also encourages a culture of proactive maintenance practices. The information provided here serves as a valuable tool for anyone looking to maximize the performance and reliability of their construction assets.

Understanding the John Deere 110

This section explores the essential features and capabilities of a compact earthmoving machine designed for versatility and efficiency. It highlights how this equipment stands out in various applications, from construction sites to landscaping projects, by combining power with maneuverability.

Key Features

Equipped with a powerful engine, this machine ensures optimal performance even under heavy loads. Its ergonomic design facilitates ease of operation, allowing operators to navigate tight spaces effortlessly. Additionally, the hydraulic systems integrated into this equipment provide exceptional lifting and digging capabilities, making it suitable for a variety of tasks.

Maintenance Considerations

Regular upkeep is crucial to ensure the longevity and reliability of this machinery. Routine checks of fluid levels, filters, and mechanical components can prevent unexpected breakdowns. Understanding the operational requirements will not only enhance performance but also save costs associated with major repairs. Proper maintenance practices are essential for achieving peak functionality throughout its operational lifespan.

Key Features of the 110 Loader

This section highlights the essential characteristics that define the functionality and versatility of this equipment. Designed to meet the diverse needs of operators, it combines power with efficiency, making it suitable for a variety of tasks.

Robust Performance: The machinery is equipped with a powerful engine that ensures optimal performance, allowing users to tackle heavy-duty jobs with ease.

Enhanced Maneuverability: Its compact design facilitates movement in tight spaces, making it an ideal choice for urban environments and confined job sites.

Versatile Attachments: A wide range of compatible tools enhances its functionality, enabling operators to switch between tasks such as digging, lifting, and loading effortlessly.

Operator Comfort: The ergonomic cabin design includes adjustable seating and intuitive controls, providing a comfortable working environment for extended periods.

Durability: Built with high-quality materials, this machinery is designed to withstand harsh conditions, ensuring longevity and reduced maintenance needs.

Hydraulic Efficiency: An advanced hydraulic system allows for smooth operation and quick response times, increasing productivity on the job.

Overall, this equipment stands out in its category due to its combination of strength, versatility, and operator-friendly features, making it a reliable choice for various applications.

Importance of Regular Maintenance

Consistent upkeep is essential for ensuring optimal performance and longevity of machinery. By adhering to a routine maintenance schedule, operators can prevent potential issues, enhance efficiency, and reduce overall operational costs. Ignoring this critical aspect may lead to more significant problems down the line, resulting in increased downtime and expensive repairs.

Benefits of Regular Upkeep

- Increased Reliability: Regular checks help identify and resolve minor issues before they escalate.

- Enhanced Efficiency: Well-maintained equipment operates at peak performance, saving time and resources.

- Extended Lifespan: Routine care contributes to the durability of machinery, ensuring it serves longer.

- Cost Savings: Preventive measures reduce the likelihood of costly repairs and replacements.

Key Maintenance Tasks

- Regularly check and change fluids.

- Inspect and replace worn parts as needed.

- Clean components to prevent build-up of debris.

- Perform routine checks of safety systems.

In summary, prioritizing regular maintenance not only enhances performance but also safeguards your investment, ensuring that machinery operates smoothly and efficiently over time.

Common Issues with the 110 Model

The machine in question is widely used for various tasks, but like any piece of equipment, it can encounter several challenges. Understanding these common problems can help operators and technicians diagnose issues more effectively and ensure smoother operation.

One prevalent issue involves hydraulic system failures. Operators may notice a decrease in lifting capability or slow response times, often linked to leaks or low fluid levels. Regular inspection of hoses and connections can prevent more significant problems.

Another concern is engine performance. Difficulties such as stalling or reduced power output can arise from fuel system blockages or air filter obstructions. Routine maintenance of fuel lines and filters is essential to keep the engine running optimally.

Electrical system malfunctions are also frequent, with symptoms including faulty lights or starting problems. Corroded connections or drained batteries are common culprits. Ensuring proper electrical maintenance can mitigate these risks.

Lastly, transmission issues may arise, leading to difficulty in shifting gears. This can stem from low transmission fluid or worn components. Regular checks and timely replacements of fluid can help maintain smooth gear transitions.

Tools Needed for Repairs

When maintaining and fixing heavy machinery, having the right tools is essential for achieving efficient and effective results. A well-equipped workspace not only streamlines the process but also ensures safety and accuracy. The following list highlights the necessary instruments and equipment required for a thorough overhaul of your machine.

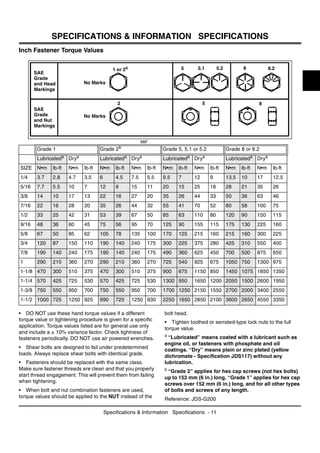

Basic hand tools are fundamental; wrenches, screwdrivers, pliers, and hammers form the backbone of any toolkit. Additionally, specialized tools such as torque wrenches and impact drivers can significantly enhance your ability to handle specific tasks with precision.

Power tools, including drills and saws, may be required for more extensive repairs. These devices can expedite tasks that would otherwise be time-consuming and labor-intensive. Safety gear, such as gloves, goggles, and protective clothing, is also critical to safeguard against potential hazards during the repair process.

Lastly, having diagnostic equipment on hand, such as multimeters and pressure gauges, allows for accurate troubleshooting and assessment of issues, ensuring that your machinery operates at peak performance.

Step-by-Step Service Procedures

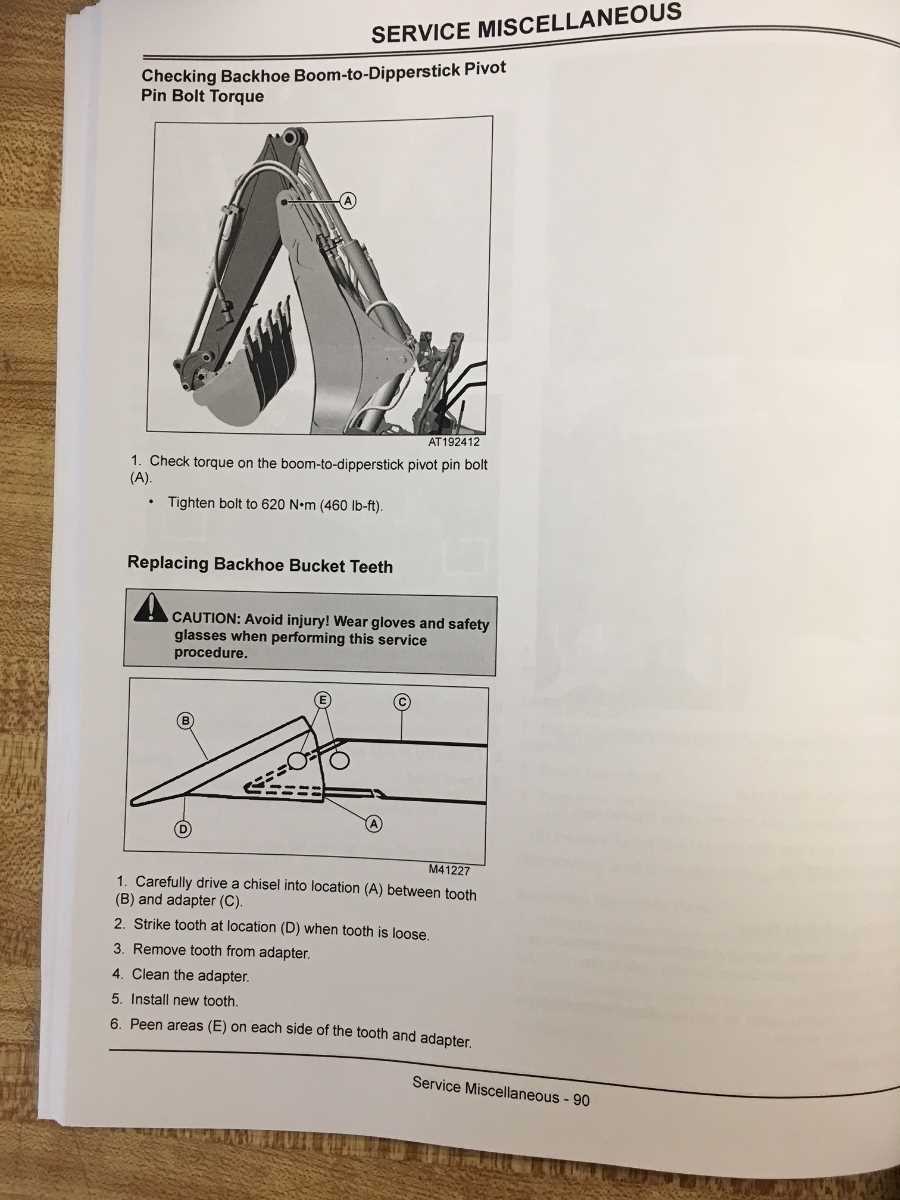

This section outlines the systematic approaches to maintaining and troubleshooting heavy machinery. Following these detailed steps ensures optimal performance and longevity of the equipment. Each procedure is designed to be straightforward, enabling operators and technicians to execute tasks efficiently.

Preparation for Maintenance

Before beginning any task, gather all necessary tools and materials. Ensure that the work area is clean and free of hazards. Safety gear should always be worn, including gloves, goggles, and appropriate footwear. Refer to the equipment specifications to confirm you have the correct parts and fluids needed for the job.

Executing the Procedure

Follow these sequential steps for effective maintenance:

- Inspect all components for signs of wear or damage.

- Clean the surfaces to remove debris and contaminants.

- Replace any faulty parts with new or refurbished items.

- Lubricate moving parts as specified in the guidelines.

- Test the functionality of the system to ensure proper operation.

Document each step taken, noting any anomalies encountered during the process. This record can be invaluable for future maintenance and diagnostics.

Electrical System Troubleshooting

Diagnosing issues within the electrical framework of heavy machinery can be a challenging task. Understanding the components involved, such as batteries, wiring, and control units, is essential for effective problem-solving. This section aims to guide you through common electrical faults and provide systematic approaches for resolution.

Identifying Common Issues

Several indicators can signal electrical malfunctions. Frequent problems include battery failure, faulty connections, and blown fuses. Signs such as dimming lights, sluggish starting, or erratic instrument readings may point to underlying issues. Begin by visually inspecting the battery terminals and connections for corrosion or looseness, which can disrupt power flow.

Troubleshooting Steps

To efficiently diagnose electrical problems, follow these structured steps:

- Check the Battery: Ensure the battery is fully charged and in good condition. A multimeter can help measure voltage and determine whether replacement is necessary.

- Inspect Wiring: Examine all wiring for signs of wear, fraying, or damage. Pay close attention to areas that may experience frequent movement.

- Test Fuses: Replace any blown fuses and ensure that the fuse ratings match the equipment’s requirements.

- Evaluate Ground Connections: A poor ground can lead to various issues. Make sure all ground points are clean and secure.

- Utilize Diagnostic Tools: Employ diagnostic equipment to pinpoint faults in the electronic control unit and other components.

By following these guidelines, operators can systematically address electrical challenges, ensuring their machinery remains functional and efficient.

Hydraulic System Maintenance Tips

Proper upkeep of the hydraulic mechanism is crucial for ensuring optimal performance and longevity of your equipment. Regular attention to this system can prevent costly breakdowns and enhance efficiency. Here are some essential guidelines to keep in mind.

1. Regular Fluid Checks: Monitor the hydraulic fluid levels consistently. Low fluid can lead to inadequate pressure and affect the entire system’s operation. Ensure the fluid is clean and at the appropriate level for optimal functioning.

2. Inspect for Leaks: Routinely examine hoses, fittings, and cylinders for any signs of leaks. Early detection can prevent significant damage and maintain system integrity. Address any leaks immediately to avoid fluid loss.

3. Change Filters: Dirty filters can impede fluid flow and cause system strain. Replace filters at recommended intervals to maintain clean fluid circulation and protect components from contamination.

4. Check Hoses and Connections: Look for wear and tear on hoses, ensuring there are no cracks or abrasions. Tighten any loose connections to prevent potential issues. Regular inspections help identify problems before they escalate.

5. Monitor Operating Temperature: Overheating can damage hydraulic components. Keep an eye on temperature gauges and ensure cooling systems are functioning correctly. Regular maintenance of cooling elements can prevent overheating.

6. System Purging: Periodically purge the hydraulic system to remove air pockets that can affect performance. This process helps maintain consistent pressure and enhances responsiveness.

7. Consult the Manual: Always refer to the specific guidelines provided in the equipment documentation for detailed maintenance procedures and recommendations. Following manufacturer instructions can significantly improve system reliability.

By adhering to these maintenance practices, you can ensure your hydraulic system remains efficient and functional, contributing to the overall performance of your machinery.

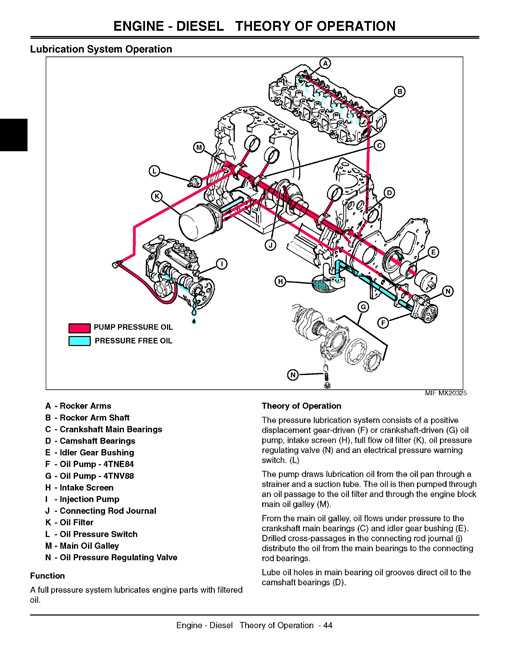

Engine Diagnostics and Repairs

Effective assessment and resolution of engine issues are crucial for optimal performance and longevity of heavy machinery. Understanding the signs of malfunction, employing appropriate diagnostic tools, and executing precise interventions can significantly enhance functionality. This section delves into essential techniques and methodologies for troubleshooting and addressing engine-related problems.

Identifying Symptoms is the first step in diagnosing engine troubles. Common indicators include unusual noises, decreased power output, and increased emissions. Observing these signs allows operators to pinpoint potential issues before they escalate into severe failures.

Utilizing Diagnostic Tools can streamline the troubleshooting process. Instruments such as multimeters, pressure gauges, and onboard diagnostic systems provide valuable data that aid in identifying faults. Regularly updating these tools ensures accurate readings and effective troubleshooting.

Common Repairs often involve components like filters, belts, and fuel injectors. Addressing these parts promptly can prevent more significant complications down the line. Regular maintenance checks are essential to catch wear and tear early, ensuring that all systems function smoothly.

Best Practices include maintaining a clean workspace and following safety protocols during any diagnostic or repair process. Keeping detailed records of previous issues and repairs can also provide insights into recurring problems and help in formulating preventive measures.

In summary, a systematic approach to engine diagnostics and corrective actions not only improves machinery performance but also extends its operational lifespan. By remaining vigilant and proactive, operators can ensure their equipment remains reliable and efficient.

Replacing Worn Out Components

Maintaining the functionality of heavy machinery requires regular attention to its parts. As components experience wear and tear over time, replacing them is essential to ensure optimal performance and safety. This section outlines the steps involved in identifying and replacing these critical elements.

Identifying Worn Components

Before undertaking replacements, it’s crucial to recognize which parts have deteriorated. Common signs of wear include:

- Unusual noises during operation

- Decreased efficiency or power

- Visible damage such as cracks or corrosion

- Fluid leaks around joints or seals

Conducting a thorough inspection regularly can help pinpoint issues before they escalate.

Replacement Process

Once worn parts have been identified, follow these steps for a successful replacement:

- Gather the necessary tools and new components.

- Power down the equipment and ensure it is secure.

- Carefully remove the damaged parts, taking note of their configuration.

- Install the new components, ensuring a proper fit and alignment.

- Test the machinery to confirm functionality before returning it to service.

By addressing worn-out parts promptly, operators can prolong the lifespan of their machinery and maintain peak operational efficiency.

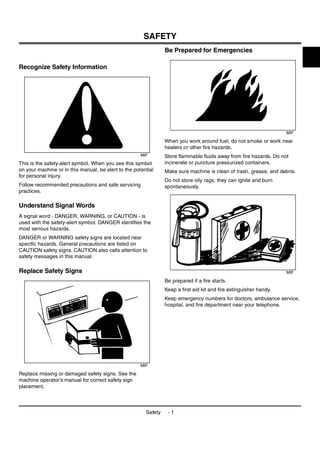

Safety Precautions During Service

Ensuring a secure working environment is crucial when performing maintenance on heavy machinery. Adhering to safety guidelines not only protects the operator but also minimizes risks associated with equipment malfunction or personal injury. By following proper protocols, one can create a safe atmosphere that fosters efficiency and reduces the likelihood of accidents.

Personal Protective Equipment (PPE) should be worn at all times. This includes helmets, gloves, eye protection, and steel-toed boots. Each of these items plays a vital role in safeguarding against potential hazards encountered during maintenance tasks.

Before beginning any task, it is essential to conduct a thorough inspection of the equipment. Check for any visible signs of wear or damage, ensuring that all safety features are operational. If any issues are detected, address them promptly to avoid further complications.

Additionally, always ensure the equipment is properly secured and immobilized before performing any maintenance activities. This includes engaging safety locks and stabilizers, which help prevent unintended movement. It is also advisable to work in well-ventilated areas, especially when dealing with fluids or chemicals that may emit harmful fumes.

Finally, familiarize yourself with the equipment’s operational guidelines and safety features. Knowing how to properly operate and troubleshoot can significantly reduce the risk of accidents. Always maintain communication with other personnel present to ensure a coordinated and safe work environment.

Finding Genuine Replacement Parts

When it comes to maintaining heavy machinery, sourcing authentic components is essential for optimal performance and longevity. Using original parts ensures compatibility and reliability, which are critical for efficient operation. Identifying where to find these genuine pieces can greatly impact the upkeep of your equipment.

Benefits of Using Authentic Components

Choosing certified parts offers several advantages. First, they are designed to meet the exact specifications of the equipment, which enhances durability. Additionally, authentic components often come with warranties, providing peace of mind. Cost savings can also be realized in the long run, as high-quality parts typically require less frequent replacement.

Where to Locate Genuine Parts

One of the best places to begin your search is through authorized dealers. These suppliers have direct access to manufacturers and can provide a range of options. Online marketplaces that specialize in heavy machinery components are also valuable resources. Always verify the credibility of the seller to ensure you are purchasing genuine items. Networking with other professionals in the field can lead to recommendations for reliable sources as well.

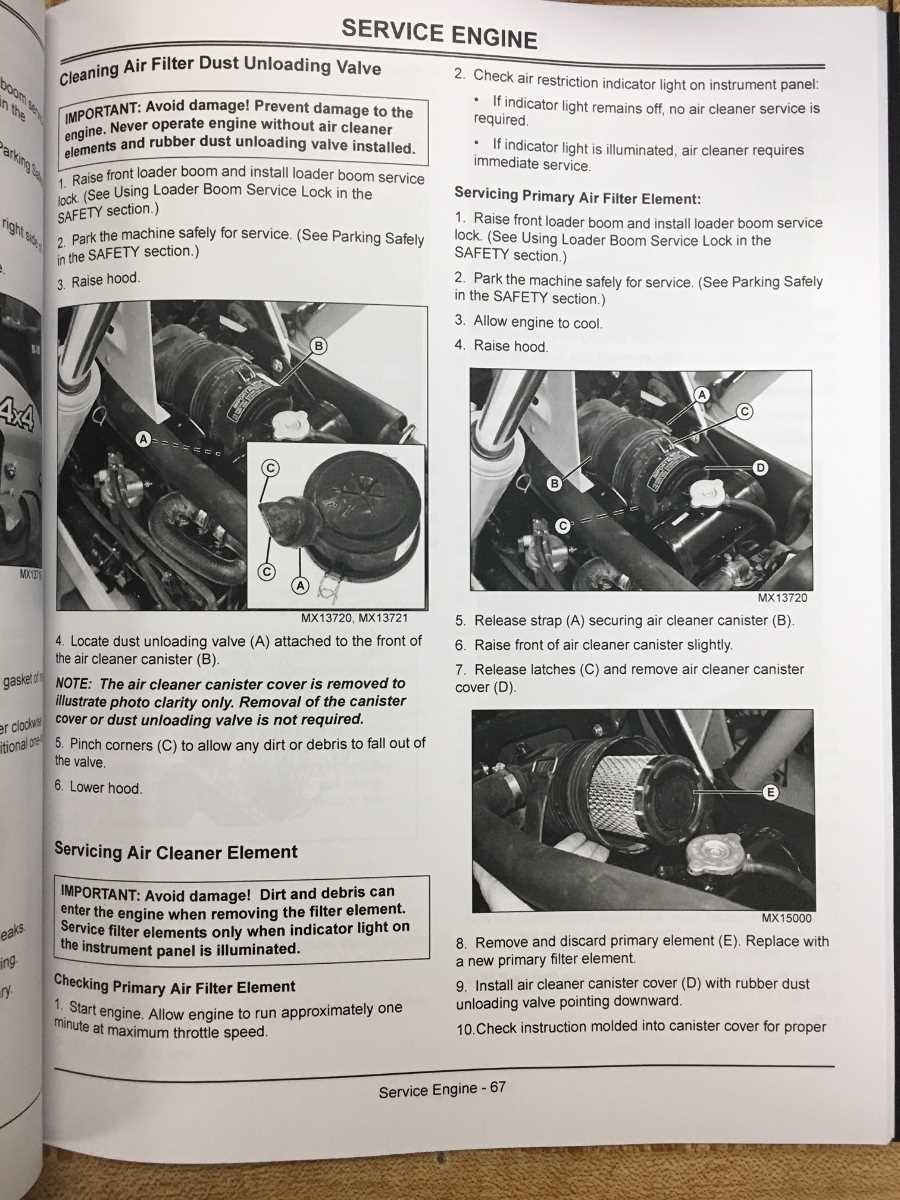

Tips for Optimal Performance

Achieving peak efficiency in your equipment requires regular attention and a proactive approach to maintenance. By implementing specific strategies, you can enhance functionality, extend lifespan, and reduce downtime. Here are essential tips to ensure your machinery operates at its best.

Regular Inspections: Conduct frequent checks on all key components. Look for signs of wear, leaks, or other issues that could impact performance. Early detection can save time and money.

Fluid Management: Ensure that all fluids, including engine oil and hydraulic fluids, are at appropriate levels and replaced as recommended. Clean fluids contribute significantly to operational efficiency and longevity.

Proper Lubrication: Regularly lubricate moving parts to minimize friction and prevent excessive wear. Follow the manufacturer’s guidelines for specific lubrication points.

Correct Tire Pressure: Maintain the correct tire pressure to improve traction and fuel efficiency. Under-inflated or over-inflated tires can lead to uneven wear and reduced performance.

Utilize Quality Parts: When replacing components, opt for high-quality parts. Inferior replacements can lead to performance issues and may not last as long.

Training and Familiarization: Ensure that operators are well-trained and familiar with the equipment. Knowledgeable operation can prevent misuse and enhance overall performance.

By adhering to these recommendations, you can ensure your equipment remains reliable and efficient, ultimately leading to better productivity and reduced operational costs.