Service Repair Guide for John Deere XUV 825i Gator Utility Vehicle

This section offers a detailed overview for the upkeep and enhancement of your all-terrain companion. It serves as an essential resource for users seeking to optimize the functionality and longevity of their equipment. Through methodical guidance, it addresses common challenges and provides effective solutions tailored to various scenarios.

Whether you’re facing routine maintenance tasks or more complex issues, this guide is designed to assist you every step of the way. By following the outlined procedures, users can ensure that their machinery operates at peak performance, thus enhancing reliability and efficiency. A well-maintained machine not only extends its lifespan but also improves overall user satisfaction.

Equipping yourself with the right knowledge and techniques is crucial for any operator. This comprehensive approach not only empowers users but also fosters a deeper understanding of the inner workings of the equipment. By applying these insights, you can navigate potential obstacles with confidence, ensuring that your all-terrain companion remains in top condition.

John Deere XUV 825i Overview

This section provides a comprehensive examination of a popular all-terrain transport solution designed for both recreational and practical applications. The model combines performance with versatility, making it an ideal choice for various tasks and outdoor activities.

With its robust build and advanced features, this model ensures reliability and ease of use across different environments. It is engineered to handle challenging terrains while providing comfort and functionality for the operator and passengers alike.

| Feature | Description |

|---|---|

| Engine | Powerful and efficient engine offering superior torque. |

| Seating Capacity | Spacious design accommodating multiple occupants comfortably. |

| Payload Capacity | Impressive load capacity for transporting equipment and supplies. |

| Terrain Capability | Designed to excel in various off-road conditions. |

| Accessories | Compatible with a range of attachments for enhanced functionality. |

Key Features of the Utility Vehicle

This section highlights the essential characteristics that define this robust all-terrain machine, showcasing its versatility and capability in various applications.

| Feature | Description |

|---|---|

| Powerful Engine | Equipped with a high-performance engine that ensures efficient operation across diverse terrains. |

| Durable Design | Constructed with high-quality materials to withstand harsh conditions, providing longevity and reliability. |

| Ample Cargo Space | Features a spacious cargo area, ideal for transporting tools, equipment, and other essentials. |

| Advanced Suspension | Incorporates a sophisticated suspension system that enhances ride comfort and stability over uneven surfaces. |

| All-Wheel Drive | Provides enhanced traction and control, making it suitable for challenging terrains and weather conditions. |

Maintenance Guidelines for Optimal Performance

To ensure the longevity and efficiency of your equipment, regular upkeep is essential. Adhering to maintenance protocols not only enhances functionality but also minimizes the risk of unforeseen breakdowns. This section outlines key practices to maintain peak performance.

Regular Inspection

Consistent evaluations of various components are crucial. Follow these steps:

- Check fluid levels regularly, including oil and coolant.

- Inspect tires for wear and proper inflation.

- Examine belts and hoses for signs of damage or wear.

- Ensure that filters are clean and replace as necessary.

Scheduled Servicing

Establish a routine servicing schedule based on usage. Key activities include:

- Change the oil and replace the oil filter at specified intervals.

- Lubricate all moving parts to prevent friction and wear.

- Test the battery and clean terminals to avoid corrosion.

- Adjust brakes and steering systems to maintain control and safety.

Following these guidelines will help in maintaining optimal performance and ensuring reliable operation throughout the lifespan of your machinery.

Common Issues and Troubleshooting Tips

This section addresses frequent challenges encountered with all-terrain transporters and provides practical advice for resolving them. Understanding these common problems can help users maintain optimal performance and prolong the lifespan of their equipment.

| Issue | Description | Troubleshooting Steps |

|---|---|---|

| Engine Won’t Start | The engine fails to ignite or crank. | Check the battery charge, inspect ignition connections, and ensure fuel supply is adequate. |

| Overheating | Excessive temperature rise during operation. | Inspect coolant levels, check for leaks, and ensure the radiator is clean. |

| Poor Handling | Difficulties in steering or maneuvering. | Examine tire pressure, inspect suspension components, and align steering mechanisms. |

| Noisy Operation | Unusual sounds during use. | Investigate loose parts, check for worn bearings, and tighten any loose bolts. |

Essential Tools for Repairs

When undertaking maintenance tasks, having the right equipment is crucial for efficiency and effectiveness. Various instruments can significantly enhance the process, ensuring that every task is executed with precision. Below are some fundamental tools that should be part of any toolkit for such endeavors.

Basic Hand Tools

Hand tools are indispensable in any maintenance situation. Items such as wrenches, pliers, and screwdrivers allow for the completion of most basic tasks. A comprehensive set of these instruments can facilitate quick adjustments and replacements, making them essential for routine work.

Diagnostic Equipment

To troubleshoot issues effectively, diagnostic tools are vital. Devices like multimeters and compression testers help identify underlying problems that may not be immediately visible. Utilizing such equipment can save time and ensure that repairs are based on accurate assessments.

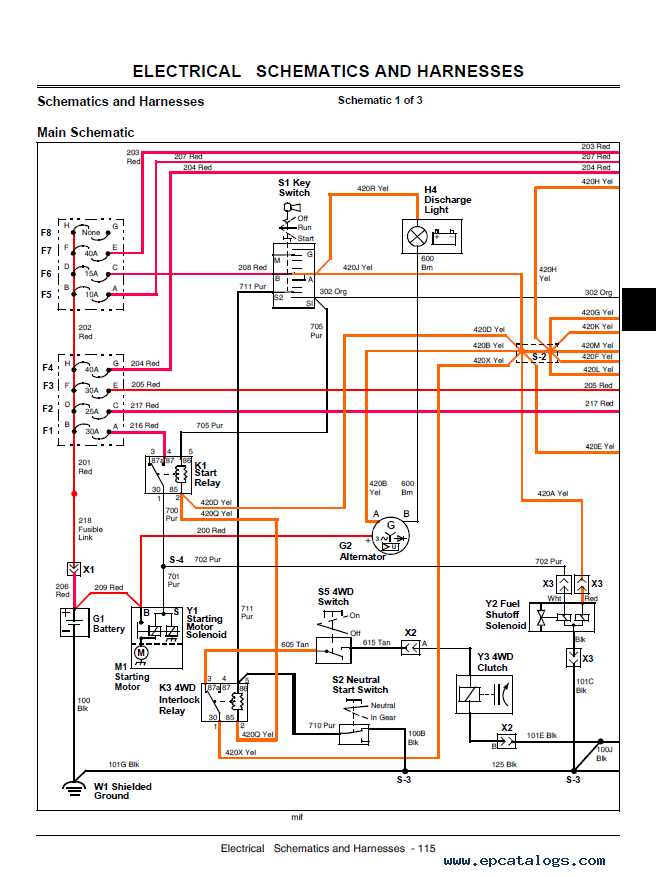

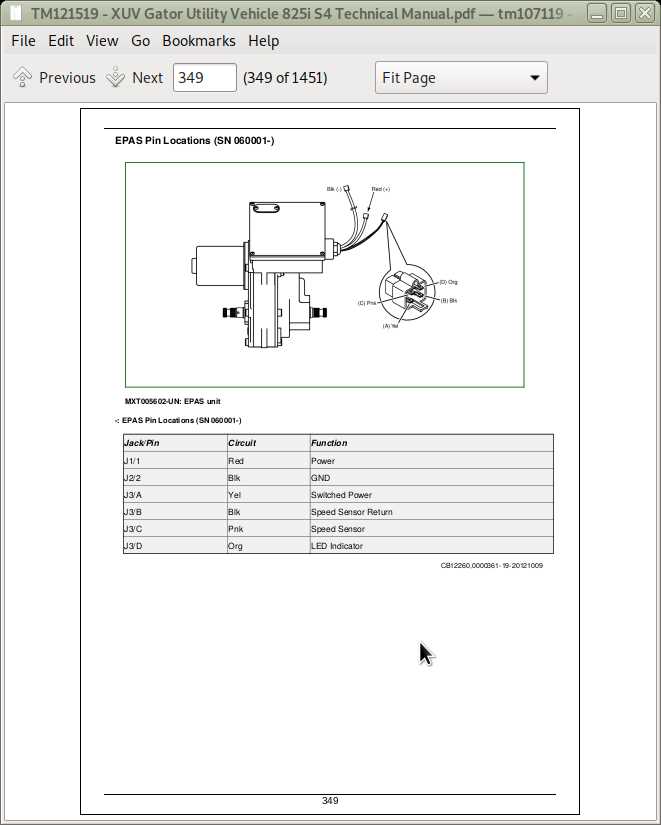

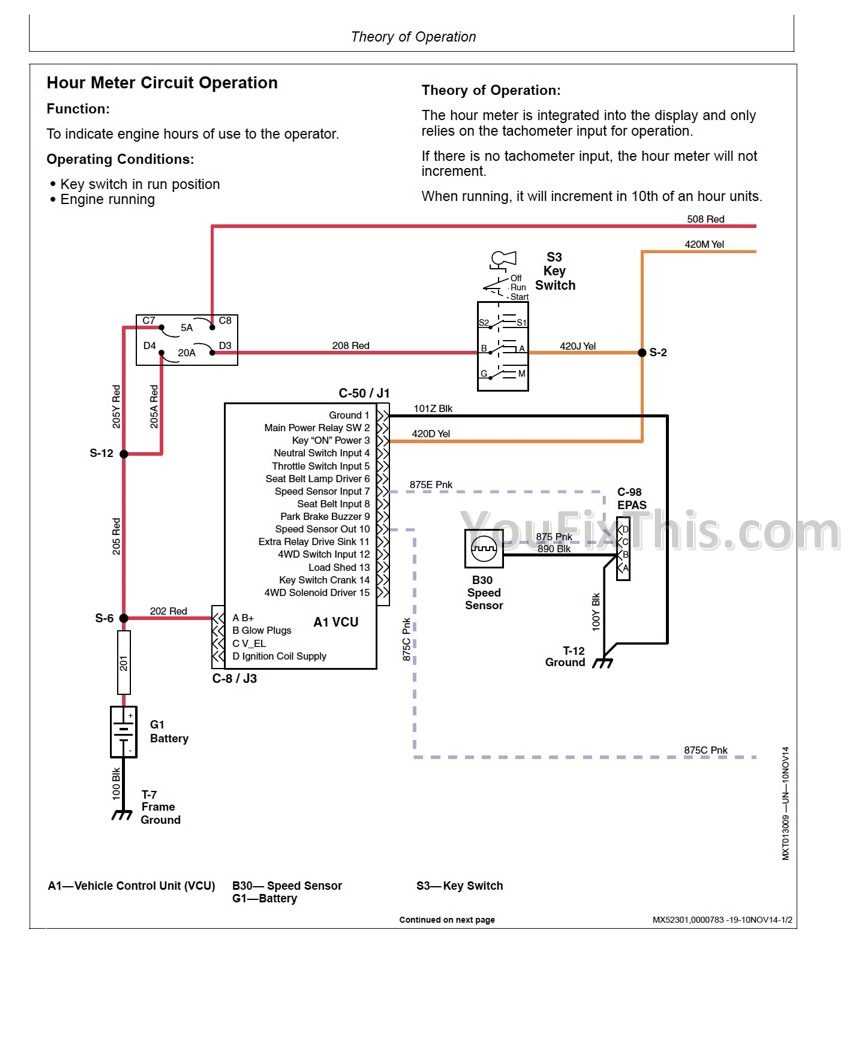

Understanding the Electrical System

The electrical system in off-road machines plays a crucial role in their overall functionality and performance. This section delves into the components and operations of the electrical framework, highlighting its importance in ensuring efficient operation and reliability.

Main Components

- Battery: Provides the necessary power to start the engine and operate electrical accessories.

- Alternator: Generates electricity to recharge the battery and power the vehicle’s electrical systems while in operation.

- Wiring Harness: Connects various electrical components, allowing for the transmission of electrical signals and power.

- Fuses: Protect the electrical system from overloads and short circuits by breaking the circuit when excessive current flows.

Importance of Maintenance

Regular inspection and upkeep of the electrical system are essential for preventing failures and ensuring the longevity of the machinery. Key practices include:

- Checking battery terminals for corrosion and ensuring a secure connection.

- Inspecting wiring for signs of wear or damage.

- Testing the alternator output to confirm it is functioning properly.

- Replacing fuses as needed to maintain circuit integrity.

Engine Specifications and Care

This section provides essential details regarding the performance and maintenance of the power unit, ensuring optimal functionality and longevity. Understanding the key characteristics and proper upkeep methods is crucial for enhancing the reliability and efficiency of the engine.

Key Specifications

- Type: Four-stroke, liquid-cooled engine

- Displacement: Approximately 812 cc

- Power Output: Up to 50 horsepower

- Fuel Type: Unleaded gasoline with a minimum octane rating

- Cooling System: Liquid cooling with an efficient radiator

Maintenance Guidelines

- Regularly check and change the engine oil to ensure smooth operation.

- Inspect air filters periodically and replace them as needed to maintain airflow.

- Monitor coolant levels and top off as necessary to prevent overheating.

- Examine the fuel system for any leaks or irregularities to ensure proper performance.

- Perform routine inspections of belts and hoses for signs of wear or damage.

By adhering to these specifications and maintenance practices, operators can significantly enhance the performance and lifespan of their engine, ensuring it operates efficiently in various conditions.

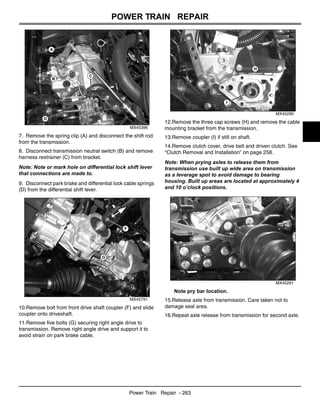

Transmission and Drive Train Insights

This section delves into the essential components of power transfer systems, focusing on how these systems optimize performance and efficiency. Understanding the intricacies of these elements can significantly enhance the operation and longevity of the machinery.

Key Components

- Transmission: The core element responsible for modulating engine power and controlling speed.

- Drive Shaft: A critical component that transmits torque from the engine to the wheels.

- Differential: A mechanism that allows wheels to rotate at different speeds, particularly during turns.

Maintenance Tips

- Regularly check fluid levels to ensure optimal operation.

- Inspect belts and hoses for wear and tear.

- Maintain clean filters to prevent debris from affecting performance.

By keeping these components in top condition, operators can ensure reliable performance and reduce the likelihood of operational disruptions.

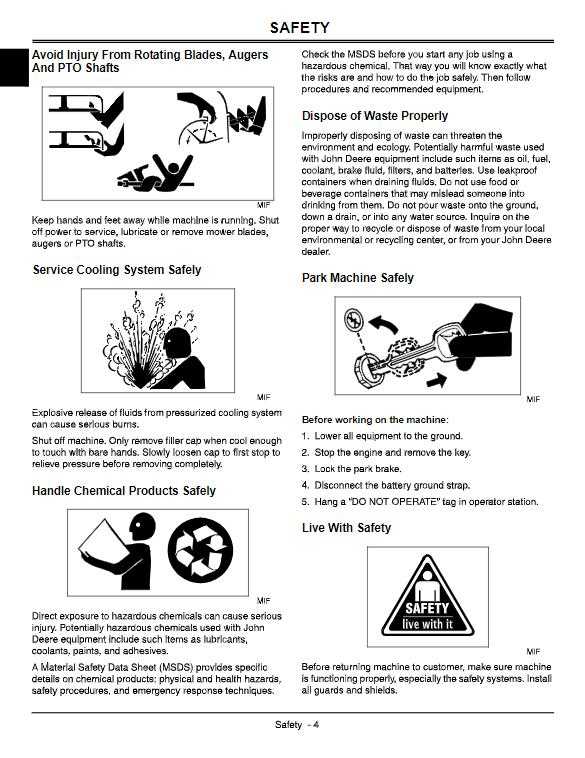

Safety Precautions During Service

Ensuring safety while maintaining machinery is crucial to prevent accidents and injuries. Adhering to proper guidelines can significantly mitigate risks associated with maintenance tasks.

General Guidelines

Before commencing any work, it’s essential to familiarize yourself with the equipment’s operational features. Always wear appropriate personal protective equipment, such as gloves, goggles, and helmets. Maintain a clean and organized workspace to minimize hazards.

Emergency Procedures

In case of an emergency, knowing the location of first aid kits and emergency shut-off switches is vital. Regularly conduct safety drills to prepare for unexpected situations.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Use gloves, goggles, and helmets to protect against injuries. |

| Work Area Organization | Keep tools and materials organized to prevent trips and falls. |

| Emergency Preparedness | Know the locations of first aid supplies and emergency switches. |

Upgrading Components for Better Efficiency

Enhancing various parts of machinery can lead to significant improvements in overall performance and productivity. By focusing on the replacement or enhancement of specific elements, operators can optimize functionality and reduce operational costs. This approach not only extends the lifespan of equipment but also ensures that it meets evolving demands.

One key area to consider is the powertrain. Upgrading components such as the transmission or differential can improve torque delivery and acceleration, allowing for more efficient operation across diverse terrains. Additionally, investing in high-quality filters and lubricants can enhance engine performance and reduce wear over time.

Another vital aspect is the suspension system. Upgrading to heavy-duty springs or shock absorbers can provide better stability and handling, particularly when navigating uneven surfaces. This results in a smoother ride and reduces fatigue for operators during prolonged use.

Finally, consider the electrical system. Incorporating advanced battery technology and efficient wiring can enhance energy management, leading to improved reliability and reduced downtime. By prioritizing these upgrades, operators can achieve a more efficient and reliable performance from their machinery.

Winterization Techniques for Longevity

Proper seasonal preparation is essential for ensuring the durability and efficient performance of your outdoor machinery. Implementing effective strategies during the colder months can significantly enhance the lifespan of your equipment, allowing for reliable operation when needed.

Fluid Management: Begin by thoroughly draining and replacing all fluids. This includes the engine oil, coolant, and fuel. Using winter-grade fluids can prevent issues related to freezing and viscosity changes. Ensure the fuel tank is full to minimize condensation.

Battery Care: A well-maintained battery is crucial for reliable starts in low temperatures. Disconnect the battery and store it in a warmer environment if possible. Regularly check the charge level and clean the terminals to prevent corrosion.

Cleaning and Protection: Clean the exterior of the machinery to remove dirt, grime, and debris that could lead to rust. Applying a protective coating or wax can also shield surfaces from harsh winter conditions.

Inspection of Components: Conduct a thorough inspection of all essential parts, including belts, hoses, and tires. Look for signs of wear or damage, and replace any components that could compromise performance during use.

Storage Considerations: If possible, store your machinery in a sheltered area to protect it from the elements. Using a breathable cover can help guard against moisture buildup while allowing airflow.

Where to Find Replacement Parts

When it comes to maintaining your outdoor machinery, locating suitable components is crucial for ensuring optimal performance and longevity. Various sources offer an array of options for acquiring necessary items that fit your specific needs.

Authorized Dealers are often the best starting point. They provide authentic parts that meet manufacturer standards, ensuring compatibility and reliability. Additionally, these dealers usually have knowledgeable staff who can assist with any questions you may have regarding your equipment.

Another viable option is online retailers. Numerous websites specialize in aftermarket components, often at competitive prices. Be sure to verify the seller’s reputation and read customer reviews to ensure quality before making a purchase.

Local auto parts stores can also be a great resource. Many of these establishments stock a variety of parts and accessories that may suit your requirements. It’s advisable to call ahead to confirm availability or to ask if they can order specific items for you.

Finally, consider joining enthusiast forums or online communities. These platforms not only provide advice and recommendations but often feature classified sections where members buy and sell parts. Engaging with fellow enthusiasts can lead to valuable insights and connections.