Comprehensive Guide to Service and Repair Manuals

In the realm of machinery and equipment, ensuring optimal performance is paramount. A structured approach to understanding and addressing various issues can significantly enhance longevity and efficiency. This section aims to provide comprehensive insights into the best practices for maintaining operational integrity.

Knowledge of fundamental principles plays a crucial role in diagnosing complications effectively. Familiarity with the components and their functions empowers users to identify potential problems before they escalate. This proactive stance not only saves time but also minimizes costs associated with unexpected breakdowns.

Furthermore, systematic approaches to addressing common malfunctions foster a deeper understanding of the underlying mechanics. By equipping oneself with practical solutions and techniques, individuals can confidently tackle challenges, ensuring their equipment continues to perform at its best.

Understanding Service and Repair Manuals

This section delves into the essential resources that provide guidance for maintaining and fixing various types of equipment. Such documents are invaluable for users seeking to understand the intricacies of their machinery and ensure optimal performance. Knowledge from these resources empowers individuals to troubleshoot issues effectively and carry out necessary adjustments or replacements.

Importance of These Resources

- Facilitates problem identification

- Provides step-by-step procedures

- Increases user confidence in handling equipment

- Ensures safety during maintenance tasks

Key Components

- Specifications: Detailed information about the equipment’s features and requirements.

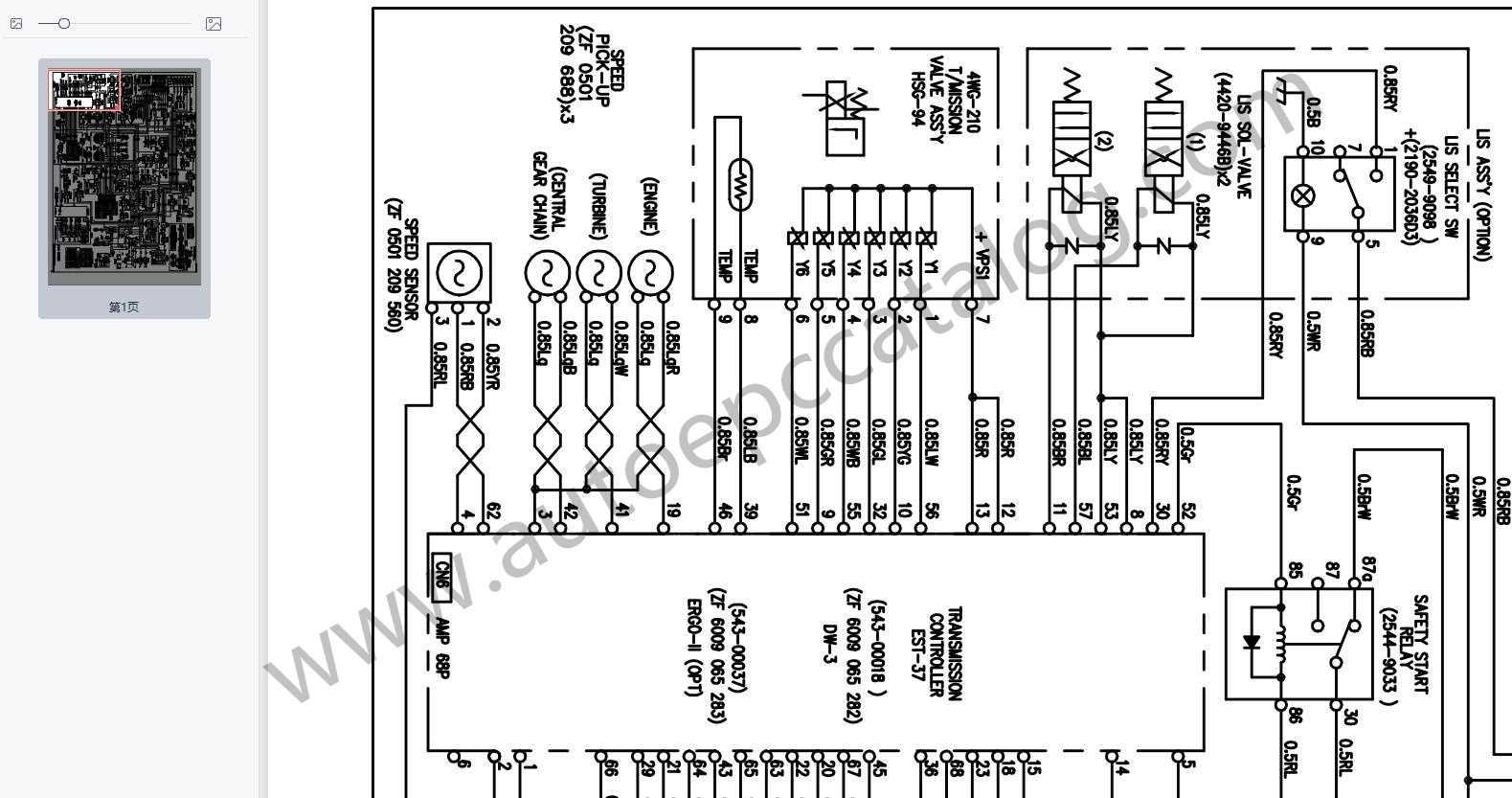

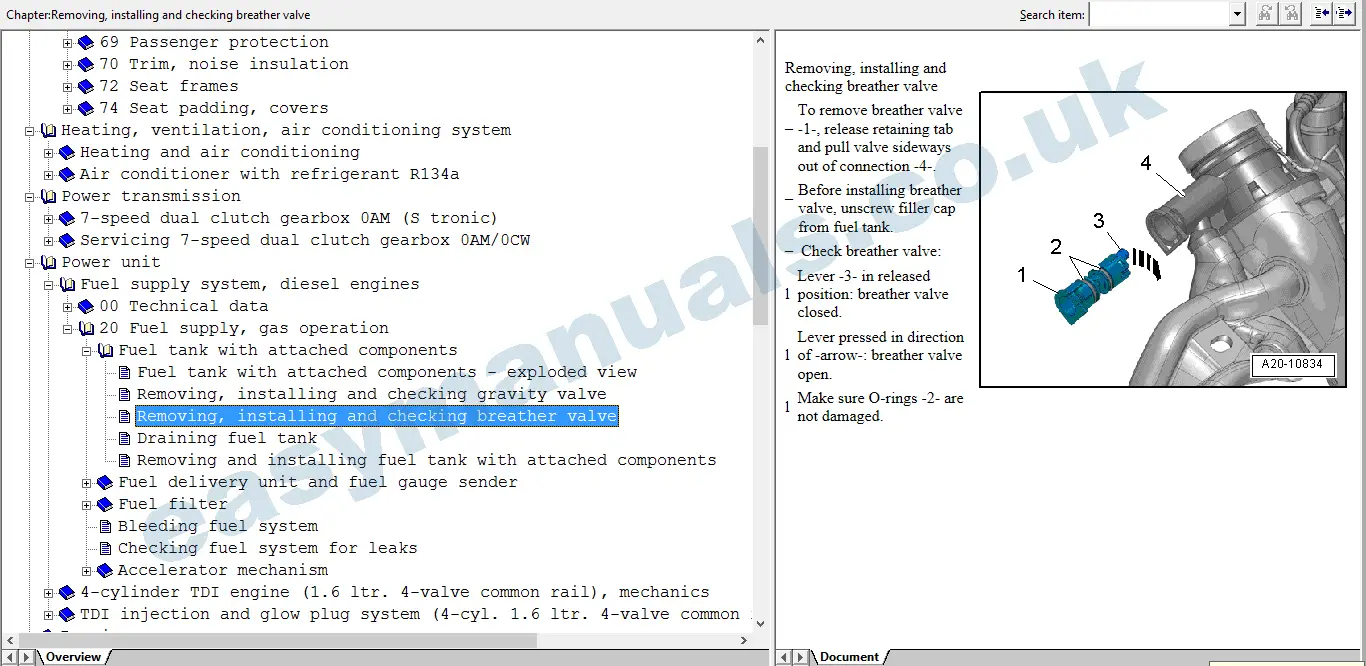

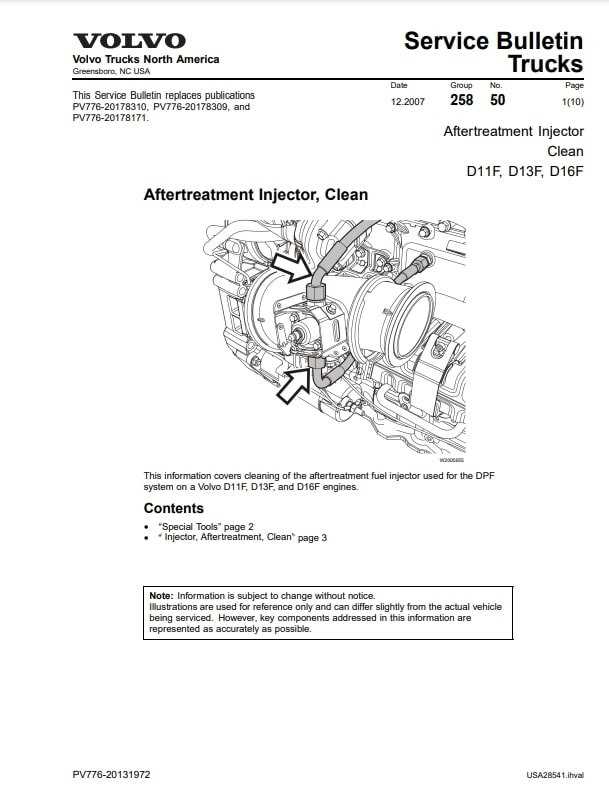

- Diagrams: Visual aids that help in understanding assembly and disassembly processes.

- Troubleshooting guides: Lists of common problems and their solutions.

- Maintenance schedules: Recommended timelines for regular upkeep to enhance longevity.

Importance of Detailed Documentation

Comprehensive records play a crucial role in ensuring efficiency and clarity in various processes. They serve as a foundational element that supports both individuals and teams in executing tasks effectively. Well-structured information not only streamlines workflows but also enhances understanding and fosters consistency in performance.

Benefits of Thorough Documentation

- Clarity: Detailed records eliminate ambiguity, making it easier for individuals to grasp complex procedures.

- Consistency: Consistent documentation helps maintain uniformity in actions, reducing errors and improving outcomes.

- Efficiency: Access to clear guidelines enables quicker decision-making and minimizes the time spent on troubleshooting.

- Training Resource: Comprehensive documentation serves as an invaluable tool for onboarding new personnel, facilitating smoother transitions.

Long-term Advantages

- Knowledge Preservation: Detailed records ensure that valuable insights and experiences are not lost over time.

- Accountability: Clear documentation establishes responsibility, enabling better tracking of actions and outcomes.

- Improvement Opportunities: Analyzing well-maintained records can highlight areas for enhancement, driving continuous progress.

Types of Service Manuals Available

Understanding the various categories of technical documentation can significantly enhance the effectiveness of maintenance tasks. Each type serves distinct purposes, catering to different needs and levels of expertise. Below are the main classifications found in the realm of technical guides.

- Owner’s Guides: Designed for general users, these provide basic information on operation and upkeep.

- Technical Handbooks: Targeted at professionals, these contain detailed instructions and specifications for intricate processes.

- Diagnostic Resources: Focused on troubleshooting, these tools help identify and resolve specific issues efficiently.

- Parts Catalogs: Comprehensive lists of components, essential for ordering replacements and understanding assembly.

- Installation Documents: Step-by-step instructions for setting up equipment or systems, ensuring proper installation procedures.

Each type plays a crucial role in facilitating effective maintenance and support, helping users navigate the complexities of their equipment.

How to Interpret Repair Guidelines

Understanding maintenance instructions is crucial for effective troubleshooting and restoring functionality. By grasping the principles behind these recommendations, individuals can make informed decisions and carry out tasks more efficiently.

When approaching these directives, consider the following aspects:

- Clarity of Language: Ensure that the terms used are understood. If technical jargon appears confusing, look for definitions or explanations.

- Step-by-Step Instructions: Follow the sequence laid out. Each phase often builds upon the previous one, ensuring a logical flow.

- Visual Aids: Diagrams and illustrations can enhance comprehension. Pay attention to any accompanying images that clarify complex steps.

Additionally, keep in mind these tips to enhance your interpretation:

- Cross-Reference: If unclear, check multiple sources for similar guidance. Variations can provide better insights.

- Note Common Tools: Identify essential tools listed within the guidelines, as using the correct equipment is vital for success.

- Document Your Process: Take notes during your work. Recording observations can help in future undertakings.

By focusing on these elements, individuals can effectively navigate complex directives and achieve successful outcomes in their projects.

Common Tools Required for Repairs

When addressing mechanical issues, having the right instruments is essential for achieving effective results. These essential items facilitate tasks, ensuring that everything from minor adjustments to significant fixes can be completed with precision and efficiency.

A variety of hand tools are typically utilized, including wrenches, screwdrivers, and pliers, which allow for both fastening and loosening components. Additionally, power tools such as drills and grinders are invaluable for more demanding tasks, enhancing productivity and reducing manual effort.

Measuring instruments also play a crucial role, helping to ensure accuracy in every step. Items like tape measures and calipers aid in confirming dimensions, while levels assist in maintaining proper alignment.

Safety gear cannot be overlooked; gloves, goggles, and ear protection are vital for safeguarding oneself while working on various projects. With the appropriate set of tools and equipment, tackling issues becomes a more manageable and efficient endeavor.

Steps for Effective Troubleshooting

Identifying and resolving issues requires a systematic approach to ensure accuracy and efficiency. By following a structured process, one can effectively diagnose problems and implement appropriate solutions. Here are key steps to guide you through the troubleshooting journey.

- Gather Information:

Start by collecting relevant details about the issue. This includes:

- Symptoms experienced

- Any error messages

- Context of the occurrence

- Frequency and conditions under which the issue arises

- Analyze the Problem:

Examine the information collected to identify patterns or potential causes. Consider:

- Recent changes to the system

- Environmental factors that could affect functionality

- Develop a Hypothesis:

Based on your analysis, formulate a possible explanation for the issue. This will guide your next steps.

- Test Your Hypothesis:

Implement a solution based on your hypothesis. This might involve:

- Adjusting settings

- Replacing components

- Updating software

- Evaluate Results:

After testing, assess whether the problem persists. If resolved, document the process for future reference. If not, revisit your analysis and adjust your approach.

- Document Findings:

Record all steps taken, findings, and solutions implemented. This documentation can assist in addressing similar issues in the future.

Safety Precautions During Maintenance

Ensuring a safe environment while conducting maintenance tasks is paramount. Awareness of potential hazards and adherence to protective measures can significantly reduce risks associated with these activities. Implementing best practices not only safeguards individuals but also enhances the overall efficiency of the work being performed.

Here are essential precautions to consider:

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and helmets.

- Keep the workspace clean and organized to minimize trip hazards.

- Ensure proper ventilation in enclosed areas to avoid inhalation of harmful fumes.

- Disconnect power sources before starting any task to prevent electrical accidents.

In addition to these precautions, it’s vital to:

- Stay informed about the specific risks related to the equipment being handled.

- Utilize tools and machinery according to manufacturer guidelines.

- Have a first aid kit readily available in case of emergencies.

- Communicate clearly with team members to maintain awareness of each other’s activities.

By following these guidelines, individuals can significantly mitigate dangers and promote a safer working atmosphere during maintenance operations.

Routine Checks for Optimal Performance

Maintaining peak functionality requires regular evaluations and assessments of various components. These essential procedures help identify potential issues before they escalate, ensuring smooth operation and longevity of the equipment.

1. Fluid Levels: Regularly inspect all fluid levels, including oil, coolant, and brake fluids. Ensuring these are within the recommended range prevents overheating and mechanical failure.

2. Filters: Check and replace air and fuel filters as necessary. Clogged filters can impede performance and reduce efficiency, leading to increased wear and tear.

3. Tire Condition: Monitor tire pressure and tread depth. Properly inflated and maintained tires enhance handling, safety, and fuel efficiency.

4. Belts and Hoses: Inspect belts and hoses for signs of wear, cracks, or leaks. Regular checks can prevent unexpected breakdowns and ensure reliable operation.

5. Battery Health: Examine battery connections and clean any corrosion. A healthy battery is crucial for reliable starts and overall electrical performance.

By implementing these consistent checks, users can enhance the overall effectiveness and reliability of their equipment, ultimately leading to a more satisfying experience.

Identifying Common Faults and Solutions

Recognizing typical issues that may arise with equipment is essential for effective troubleshooting. By understanding these challenges, users can take proactive measures to restore functionality and extend the lifespan of their devices. This section outlines prevalent problems and their corresponding remedies, enabling individuals to address malfunctions with confidence.

No Power: One of the most frequent issues encountered is the complete lack of power. This could stem from a faulty outlet, a blown fuse, or an internal power supply malfunction. To resolve this, first check the outlet with another device. If the outlet is functioning, inspect the device’s power cord for damage and replace any blown fuses as needed.

Overheating: Excessive heat can lead to performance degradation or failure. Common causes include blocked vents, dust accumulation, or a malfunctioning fan. To remedy overheating, ensure that air vents are unobstructed and clean any dust buildup. If overheating persists, consider replacing the fan or seeking professional assistance.

Intermittent Functionality: When a device operates inconsistently, it can be frustrating. This may result from loose connections, outdated software, or hardware conflicts. Start by checking all connections to ensure they are secure. Updating the software and running diagnostics can also help identify and fix the issue.

Strange Noises: Unusual sounds often indicate internal problems. Grinding, clicking, or buzzing noises can point to worn-out components or debris inside the device. To address this, carefully inspect the interior for any foreign objects and replace any damaged parts as necessary.

By familiarizing oneself with these common faults, users can enhance their troubleshooting skills and maintain their equipment effectively.

How to Order Replacement Parts

Acquiring new components can be essential for maintaining the functionality of your equipment. This guide outlines key steps to ensure a smooth ordering process.

- Identify the Required Part:

- Refer to the original specifications or documentation.

- Check for part numbers on existing components.

- Consult online resources or forums for advice.

- Choose a Reliable Supplier:

- Look for authorized dealers or reputable online stores.

- Read customer reviews to gauge reliability.

- Consider local shops for immediate availability.

- Place Your Order:

- Provide accurate part details to avoid mistakes.

- Double-check quantities and pricing.

- Confirm shipping options and delivery times.

- Track Your Order:

- Utilize tracking numbers to monitor shipment.

- Contact the supplier if there are delays.

- Prepare for installation upon arrival.

Following these steps can streamline the process of obtaining necessary parts, ensuring your equipment remains in optimal condition.

Utilizing Online Resources for Assistance

In today’s digital age, a wealth of information is readily available at our fingertips, making it easier than ever to find help for various tasks. The internet offers a plethora of platforms where individuals can seek guidance, troubleshoot issues, and enhance their understanding of complex processes. Leveraging these resources can lead to more efficient solutions and a deeper knowledge of specific subjects.

Numerous forums and community-driven websites allow users to share experiences and tips, fostering collaboration among enthusiasts and experts alike. Video tutorials on popular platforms provide visual aids that can simplify even the most complicated tasks, while written guides and articles break down procedures into manageable steps. Utilizing these tools can significantly reduce the time and effort needed to resolve challenges.

Additionally, online databases and knowledge bases often contain detailed information that can address specific questions or concerns. Engaging with these resources not only aids in problem-solving but also encourages continuous learning. By actively participating in discussions and seeking advice, individuals can enhance their skills and build a network of like-minded individuals.

In summary, taking advantage of the vast array of online resources can transform the way individuals approach challenges, making them more manageable and less daunting. Whether through interactive platforms, visual content, or community support, the internet serves as an invaluable ally in the pursuit of knowledge and resolution.

Benefits of Professional vs. DIY Repairs

When it comes to addressing issues with equipment or systems, individuals often face a choice between seeking expert assistance or attempting the task themselves. Each approach carries its own set of advantages and drawbacks, influencing the decision-making process based on various factors such as complexity, cost, and time. Understanding these benefits can help in making a more informed choice.

| Aspect | Professional Assistance | DIY Approach |

|---|---|---|

| Expertise | Highly trained and knowledgeable in specialized fields. | Limited by personal skills and experience. |

| Tools | Access to advanced equipment and tools. | May lack necessary tools, leading to additional costs. |

| Time | Typically faster due to experience. | Can be time-consuming, especially for complex tasks. |

| Guarantee | Often provides warranties on work performed. | No guarantee of success, potential for repeated efforts. |

| Cost | Higher initial expense but may save money in the long run. | Lower upfront costs, but risk of additional expenses from mistakes. |

Ultimately, the choice between enlisting a professional or taking on a task personally hinges on individual circumstances, the nature of the problem, and personal preferences. Weighing these aspects carefully can lead to a more satisfactory outcome.