Comprehensive Guide to Servicing and Repairing the Volvo L90F Wheel Loader

This section provides an extensive overview of essential procedures and protocols for maintaining and enhancing the functionality of construction equipment. Understanding these guidelines ensures optimal performance and longevity of your machinery, allowing operators to maximize productivity on job sites.

Effective upkeep involves a systematic approach to troubleshooting and resolving common issues, ensuring that every component functions harmoniously. Emphasizing routine checks and timely interventions can prevent minor problems from escalating into significant challenges.

Moreover, this guide is designed to equip operators with the knowledge needed to conduct various maintenance tasks. By following these recommendations, individuals can confidently address concerns and enhance the operational efficiency of their equipment, ultimately leading to a more successful and efficient work environment.

This section provides an overview of the essential characteristics and capabilities of a specific type of heavy machinery designed for construction and material handling tasks. Understanding these features is crucial for maximizing efficiency and ensuring optimal performance in various operational environments.

Key Characteristics

- Powerful Engine: Equipped with a robust power unit that ensures reliable performance and effective operation in demanding conditions.

- Advanced Hydraulics: Features a sophisticated hydraulic system that enhances lifting and digging capabilities, allowing for precision work.

- Operator Comfort: Designed with an ergonomic cab, providing an optimal working environment with user-friendly controls and visibility.

Operational Benefits

- High load capacity, enabling the handling of substantial material weights with ease.

- Versatile attachment compatibility, allowing for various tools to be used for different tasks.

- Durability and reliability, ensuring long service life and reduced downtime.

Common Issues with Wheel Loaders

In the realm of heavy machinery, certain challenges frequently arise that can hinder performance and efficiency. Understanding these prevalent complications is crucial for maintaining optimal functionality and longevity of the equipment. Various factors can contribute to these issues, from mechanical wear to environmental conditions.

Hydraulic System Failures

One of the most critical components in this type of machinery is the hydraulic system. Malfunctions in this area can manifest as poor lifting capacity or slow operation. Common reasons include leaks, damaged hoses, or insufficient fluid levels. Regular maintenance and timely inspections are essential to prevent significant downtime.

Engine Performance Problems

The power unit is vital for overall operation. Inconsistencies in engine performance may result from fuel quality, air filter blockages, or exhaust restrictions. Addressing these concerns promptly can ensure smoother operation and reduce the risk of extensive damage to the machinery.

Maintenance Schedule for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of any heavy machinery. A well-structured maintenance plan helps in identifying potential issues before they escalate, thereby maximizing performance and reducing downtime.

The following guidelines outline a recommended schedule for various maintenance tasks:

- Daily Inspections:

- Check fluid levels, including hydraulic and engine oil.

- Inspect for any visible leaks or damage.

- Examine tires for proper inflation and wear.

- Test safety features and controls.

- Weekly Maintenance:

- Clean air filters to ensure proper airflow.

- Inspect and clean external components, including lights and mirrors.

- Grease all moving parts to prevent wear.

- Monthly Checks:

- Change engine oil and replace oil filters as needed.

- Inspect hydraulic systems for signs of wear or damage.

- Evaluate the condition of belts and hoses for cracks or fraying.

- Annual Overhaul:

- Conduct a comprehensive inspection of the entire system.

- Replace any worn or damaged components.

- Calibrate systems for optimal performance.

Adhering to this schedule not only enhances operational efficiency but also prolongs the lifespan of the machinery. Proper maintenance is a vital investment for any operator seeking reliability and peak performance.

Step-by-Step Repair Procedures

This section outlines detailed instructions for addressing various issues that may arise in heavy machinery. By following these organized steps, operators can ensure efficient and effective maintenance, leading to enhanced performance and longevity of the equipment.

Initial Assessment

Before undertaking any corrective actions, it is crucial to perform a thorough evaluation. This will help identify the root cause of the malfunction. Follow these steps:

- Inspect the exterior for any visible damage.

- Check fluid levels and look for leaks.

- Listen for unusual sounds during operation.

- Examine the control panel for warning indicators.

Procedure for Component Replacement

When a specific component requires replacement, adhere to the following steps:

- Gather necessary tools and replacement parts.

- Ensure the equipment is powered down and secured.

- Remove the damaged component carefully, taking note of the connections.

- Install the new part, ensuring all connections are secure.

- Restore power and conduct a test run to verify functionality.

Essential Tools for Service Tasks

Performing maintenance and troubleshooting on heavy machinery requires a set of specialized instruments. These tools not only enhance efficiency but also ensure that all tasks are executed with precision and safety. Understanding which instruments are indispensable can streamline the process and help prevent unnecessary delays.

Basic Tools Required

- Wrenches: A variety of sizes for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips for assembling and disassembling components.

- Pliers: Useful for gripping, twisting, and cutting wires.

- Hammer: Essential for driving objects into place or removing them.

- Socket set: For dealing with different fastener types efficiently.

Advanced Equipment for Complex Tasks

- Diagnostic scanner: For identifying issues and reading error codes.

- Torque wrench: Ensures bolts are tightened to the manufacturer’s specifications.

- Oil filter wrench: Simplifies the process of changing filters.

- Lift equipment: Necessary for accessing elevated components safely.

- Fuel line disconnect tool: Facilitates the removal of fuel lines without damage.

Safety Precautions During Repairs

Ensuring a secure environment during maintenance tasks is essential for the safety of personnel and the efficiency of operations. Awareness of potential hazards and adherence to established protocols can significantly reduce the risk of accidents and injuries.

Personal Protective Equipment

Wearing appropriate personal protective gear is crucial. This includes helmets, gloves, and eye protection. Each piece of equipment serves as a barrier against physical injuries and chemical exposures, enhancing overall safety.

Work Area Management

Maintaining a tidy workspace is vital. Keep tools organized and ensure that the area is free from unnecessary obstacles. Adequate lighting and ventilation should also be provided to promote visibility and reduce the accumulation of hazardous fumes.

Understanding Electrical Systems

The functionality of modern machinery relies heavily on intricate electrical frameworks. These systems are responsible for powering various components, ensuring efficient operation, and providing necessary feedback for maintenance and troubleshooting. A solid grasp of these systems is essential for anyone involved in the upkeep of such equipment.

Electrical systems encompass a range of elements, including wiring, connectors, and control units. Each part plays a critical role in the overall performance and reliability of the machine. Understanding the flow of electricity and how different components interact can greatly enhance one’s ability to diagnose issues and implement effective solutions.

Safety is paramount when working with electrical systems. Proper protocols must be followed to prevent accidents and ensure the longevity of the machinery. Familiarity with circuit diagrams and troubleshooting techniques is vital for effective maintenance and can aid in avoiding potential hazards.

In summary, a comprehensive understanding of electrical systems is crucial for the proper functioning of machinery. This knowledge not only facilitates effective maintenance practices but also enhances operational efficiency, ultimately leading to improved performance and reduced downtime.

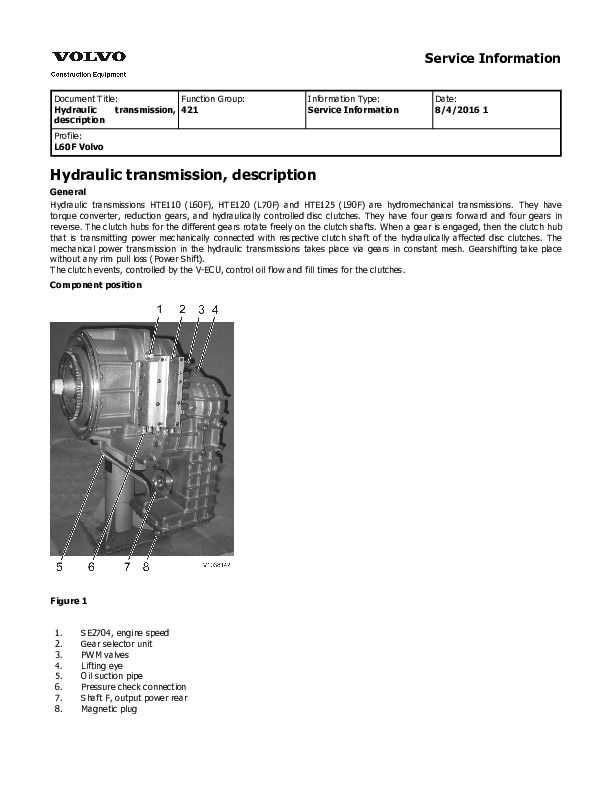

Hydraulic System Troubleshooting Guide

This section provides an overview of methods to identify and resolve common issues encountered within hydraulic systems. Proper diagnostics are essential for maintaining optimal functionality and ensuring longevity. By following systematic troubleshooting procedures, operators can efficiently address performance problems and reduce downtime.

Common Issues and Symptoms

Understanding the typical problems that arise in hydraulic mechanisms is crucial. Below is a table highlighting some prevalent issues, their potential causes, and suggested remedies:

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Inadequate Pressure | Leaks, worn pumps, or clogged filters | Inspect and repair leaks, replace or service pumps, and clean filters |

| Unresponsive Controls | Low fluid levels or air in the system | Check and refill fluid levels, bleed air from the system |

| Overheating | Blocked cooling lines or low fluid levels | Clear obstructions in cooling lines and ensure adequate fluid |

| Noise or Vibration | Loose components or cavitation | Tighten connections and assess for cavitation issues |

Diagnostic Procedures

Implementing structured diagnostic procedures can facilitate effective troubleshooting. Begin by checking fluid levels and inspecting for leaks. Use pressure gauges to evaluate system pressure and identify discrepancies. Additionally, monitoring the temperature of hydraulic fluid can reveal potential overheating issues. Regular maintenance checks are also vital to preemptively address problems before they escalate.

Parts Replacement and Sourcing

Effective maintenance and timely component replacement are crucial for the longevity and optimal performance of any machinery. Identifying the right parts and sourcing them from reliable suppliers can significantly enhance the efficiency of operations. This section delves into strategies for procuring necessary components and ensuring their proper installation.

Finding Quality Components

When seeking replacement components, it is essential to prioritize quality over cost. Utilizing parts from reputable manufacturers or authorized distributors guarantees compatibility and durability. Always check for certifications or warranties that validate the integrity of the components.

Reliable Sourcing Channels

Establishing relationships with trusted suppliers can streamline the procurement process. Explore online platforms, local dealerships, and specialized parts retailers to locate the necessary items. Additionally, participating in forums or community groups can provide valuable insights into sourcing options and recommendations from fellow operators.

Best Practices for Routine Checks

Conducting regular evaluations of machinery is essential for maintaining optimal performance and preventing unexpected breakdowns. Establishing a systematic approach to inspections can enhance efficiency and prolong the lifespan of equipment. This section outlines key strategies for executing effective routine checks.

1. Establish a Maintenance Schedule

Creating a detailed timetable for assessments ensures that no aspect of the machinery is overlooked. This schedule should include daily, weekly, and monthly tasks, allowing for thorough monitoring of essential components. Consistency is crucial in this process to identify potential issues before they escalate.

2. Focus on Critical Components

Prioritize the examination of vital parts, including hydraulic systems, electrical connections, and fluid levels. Regularly checking these elements can prevent operational failures. Utilize checklists to ensure all critical areas are covered during each inspection, and address any anomalies promptly.